Self-lubricating anti-attrition composite structure surface manufacturing method based on laser texturing

A composite structure, self-lubricating technology, applied in the direction of lubricating composition, laser welding equipment, manufacturing tools, etc., can solve problems such as lubrication performance limitations, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing the surface of a self-lubricating antifriction composite structure based on laser texture, comprising the following steps:

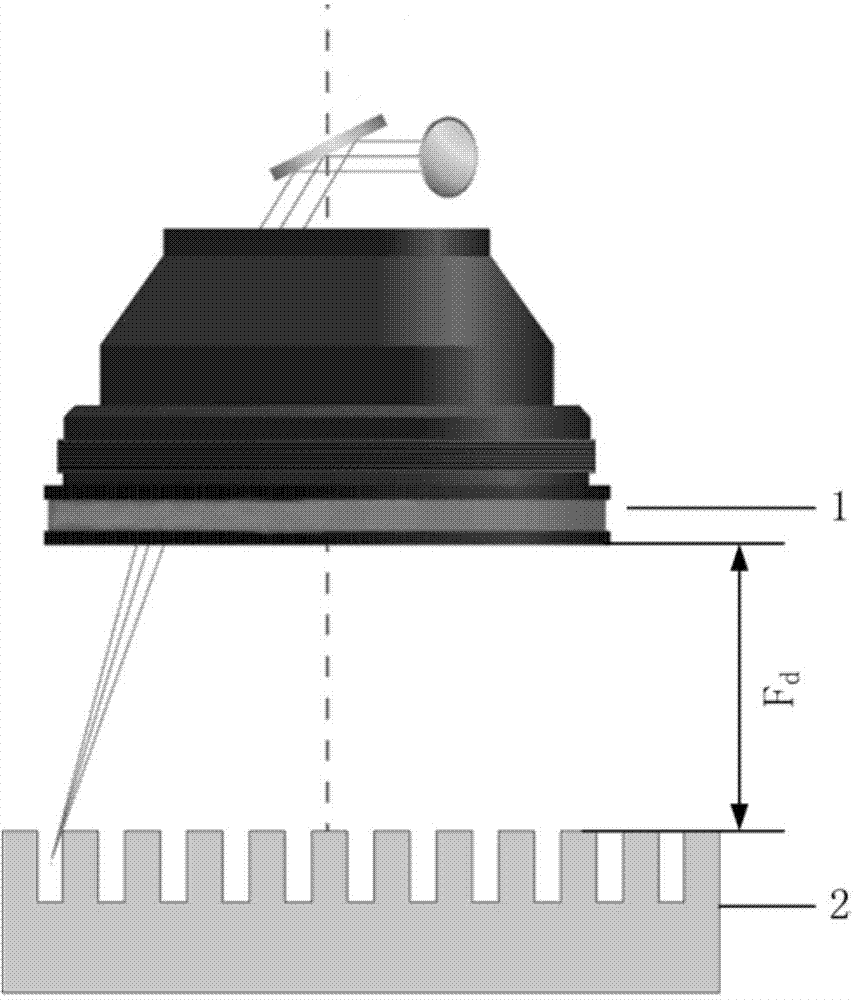

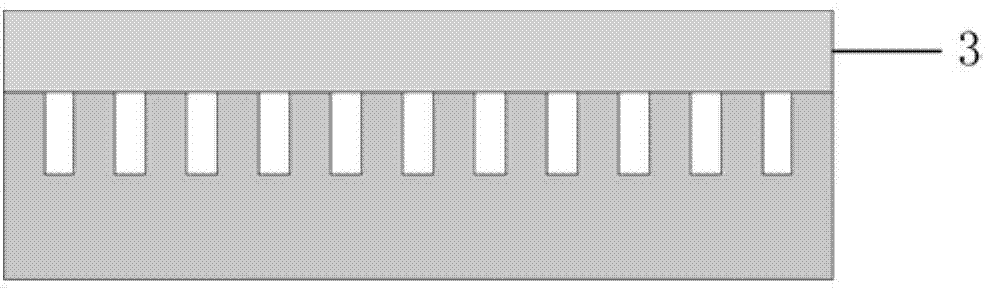

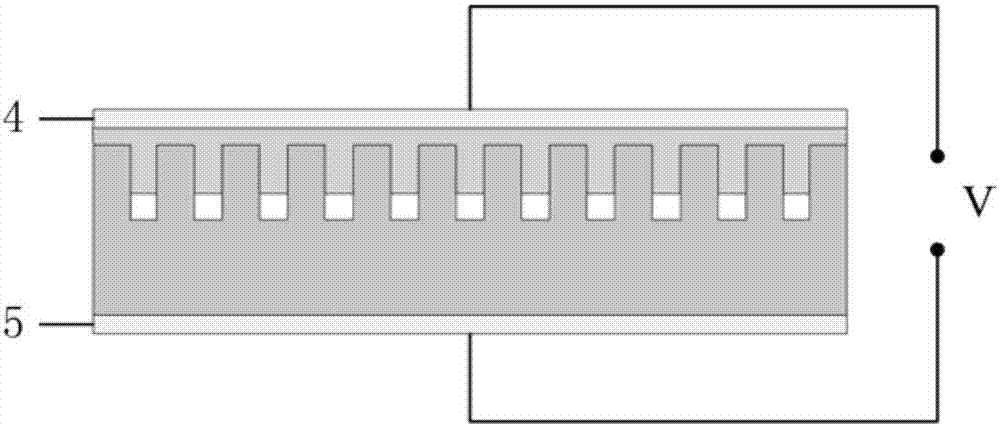

[0025] 1) Preparation of laser textured surface structure: refer to figure 1 , using Nd:VAN picosecond pulsed laser to pass through the laser scanning galvanometer processing system 1, to perform texturing treatment on the surface 2 of the material participating in the friction, that is, to ablate or induce an artificial surface structure with micron or nanometer scale, In the surface texturing process, the basic parameters of the picosecond pulse laser are: the laser wavelength λ is 1064nm or 532nm, the pulse frequency f is 1-100KHz, and the pulse width τ is 10ps; the basic parameters of the laser scanning galvanometer processing system 1 are: Laser working distance Fd, laser radiation pulse number N, laser scanning speed S; change parameters to realize micro-nano structured surface: use 1064nm wavelength laser, select 1KHz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com