Gain narrowing controlled all-fiber laser amplifier for high-power picosecond pulses

A technology of laser amplifiers and power amplifiers, which is applied to lasers, laser devices, laser components, etc., can solve the problems of difficult and stable control of fiber laser mode locking, low average power of seed lasers, and increased system complexity, etc., so as to achieve easy optimization control , the effect of suppressing modulation instability and improving light-to-light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be further described in detail through embodiments in conjunction with the accompanying drawings to facilitate a better understanding of the present invention:

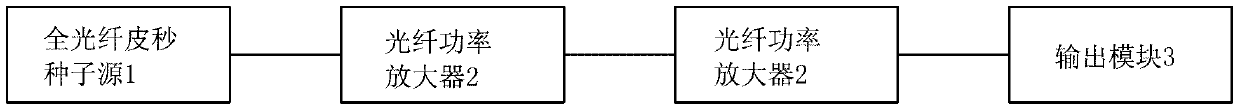

[0032] Such as figure 1 , The present invention introduces an all-fiber high-power picosecond pulse laser amplifier controlled by gain narrowing, including an all-fiber picosecond seed source 1, and one fiber power amplifier 2 or more is connected to the output end of the all-fiber picosecond seed source 1. A cascaded optical fiber power amplifier, and an output module 3 is connected to the output end of the optical fiber power amplifier 2.

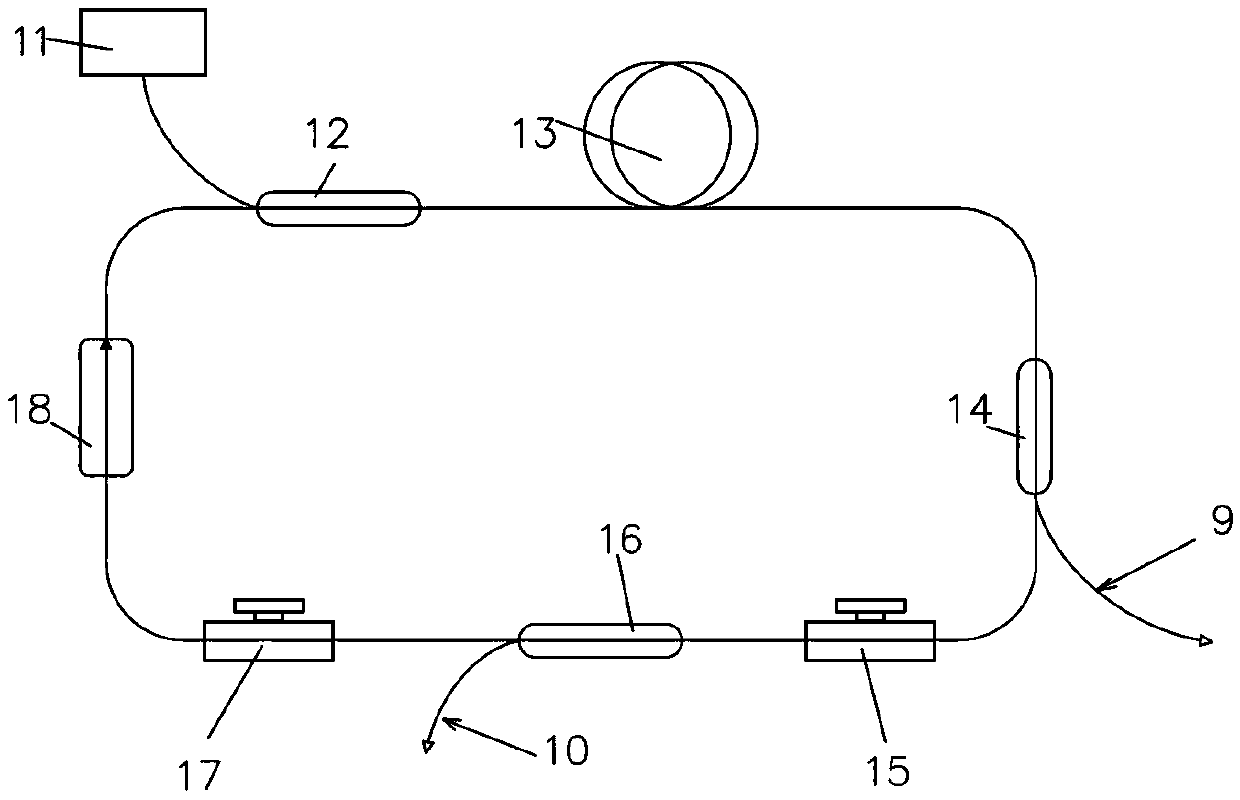

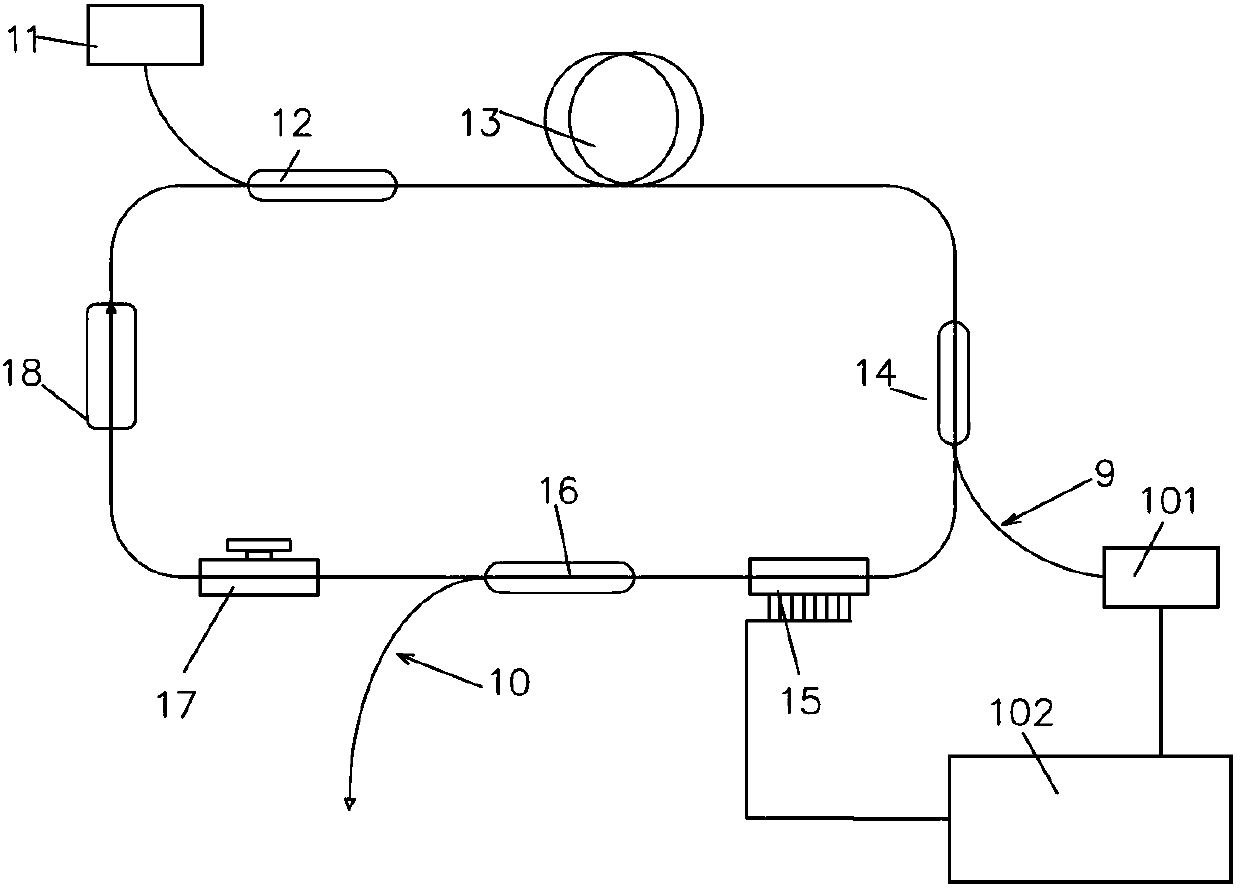

[0033] The all-fiber picosecond seed source 1 is a mode-locked laser with an all-fiber ring cavity structure. The cavity has a pump laser, a wavelength division multiplexer, a gain fiber, an output coupler, a polarization controller, a polarization-independent isolator, and a polarization Beam splitter. Adjust the polarization contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com