Picopulse optical fiber laser

A fiber laser, picosecond pulse technology, applied in the laser field, can solve the problem of low repetition frequency of picosecond light pulse, and achieve the effect of high repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

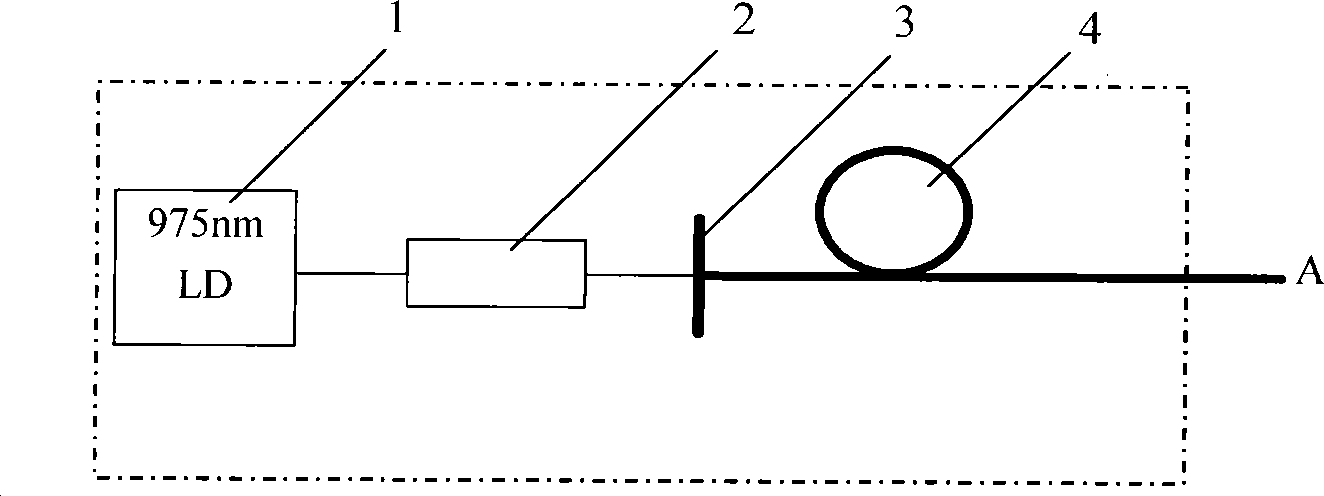

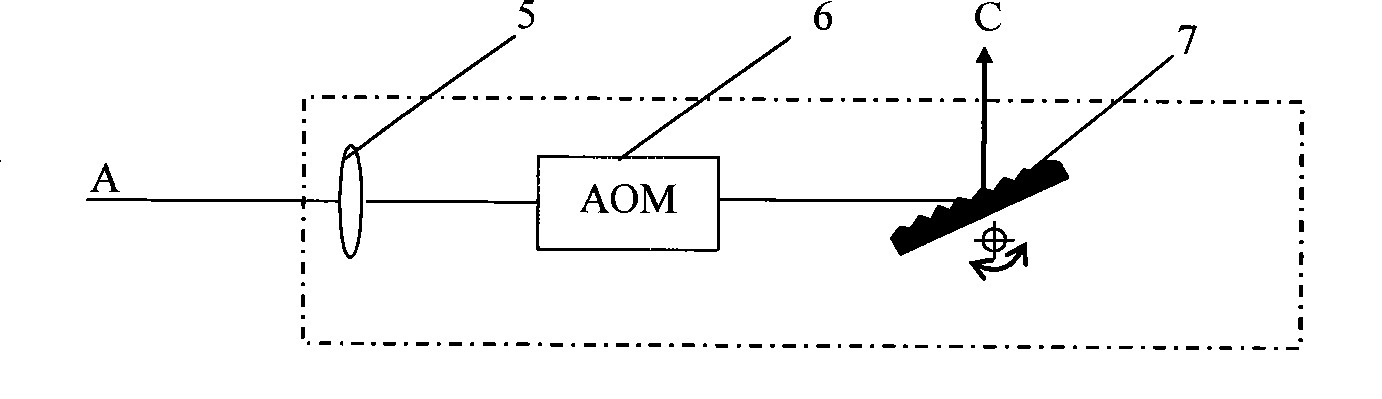

[0013] A preferred embodiment of the picosecond pulsed fiber laser of the present invention includes a main resonant cavity and an external cavity feedback part.

[0014] Among them, the external cavity feedback part includes AOM (acousto-optic modulator), AOM adopts Raman-Nath (Raman-Ness) diffraction, in the generated diffracted light, zero-order light output, any order of high-level light is fed back to in the main resonator. The laser output from the main resonator can be vertically incident on the crystal surface of the AOM after being collimated by the collimating lens. The high-level light can be any level of 2-level light, 3-laser to 5-level light, or higher-level diffracted light. The modulation frequency of the AOM may be greater than or equal to 40MHz.

[0015] Such as figure 1 As shown, the main resonant cavity may include a dichroic mirror 3 and an ytterbium-doped double-clad fiber 4 .

[0016] In a specific embodiment, the main resonator may include a semicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com