Equipment and method for single-cylinder type selective laser melting and milling composite processing

A laser selective melting and compound processing technology, applied in the field of 3D printing of metal parts, can solve the problems that it is difficult to produce high-precision metal parts that meet the requirements, restrict the application and development of SLM technology, and cannot meet the actual requirements, so as to save the follow-up Effects of surface treatment, shortening of powder spreading stroke, and reduction of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

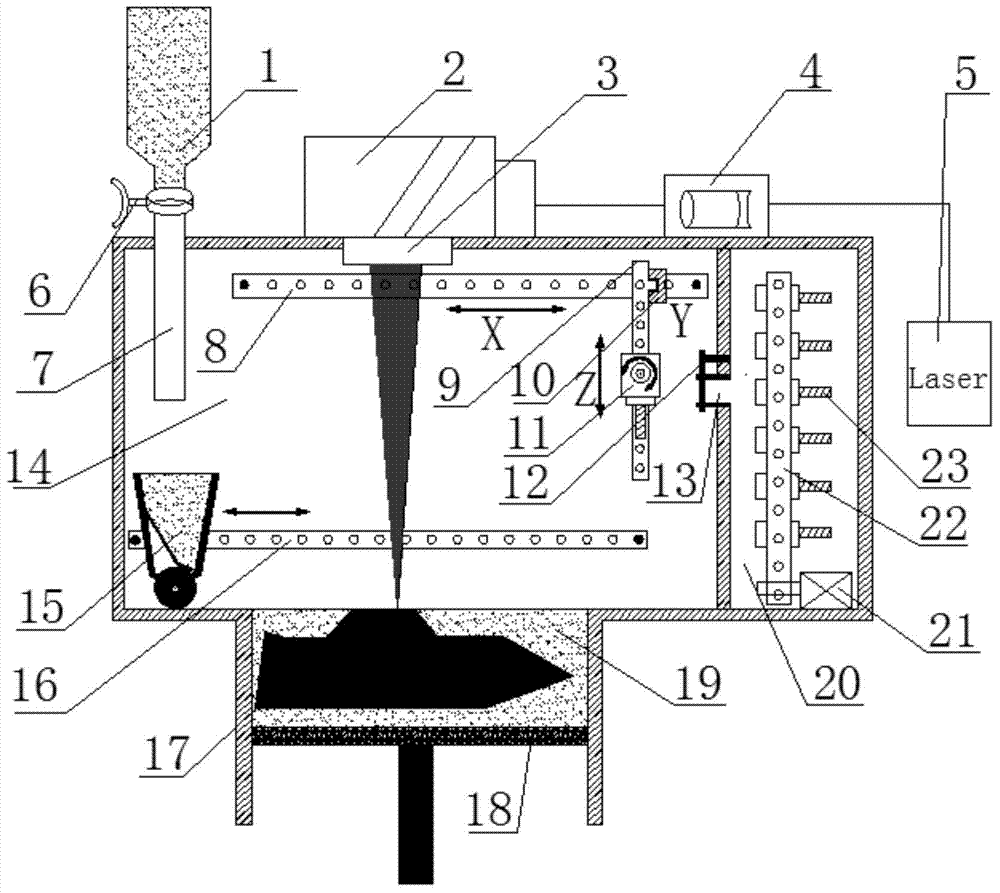

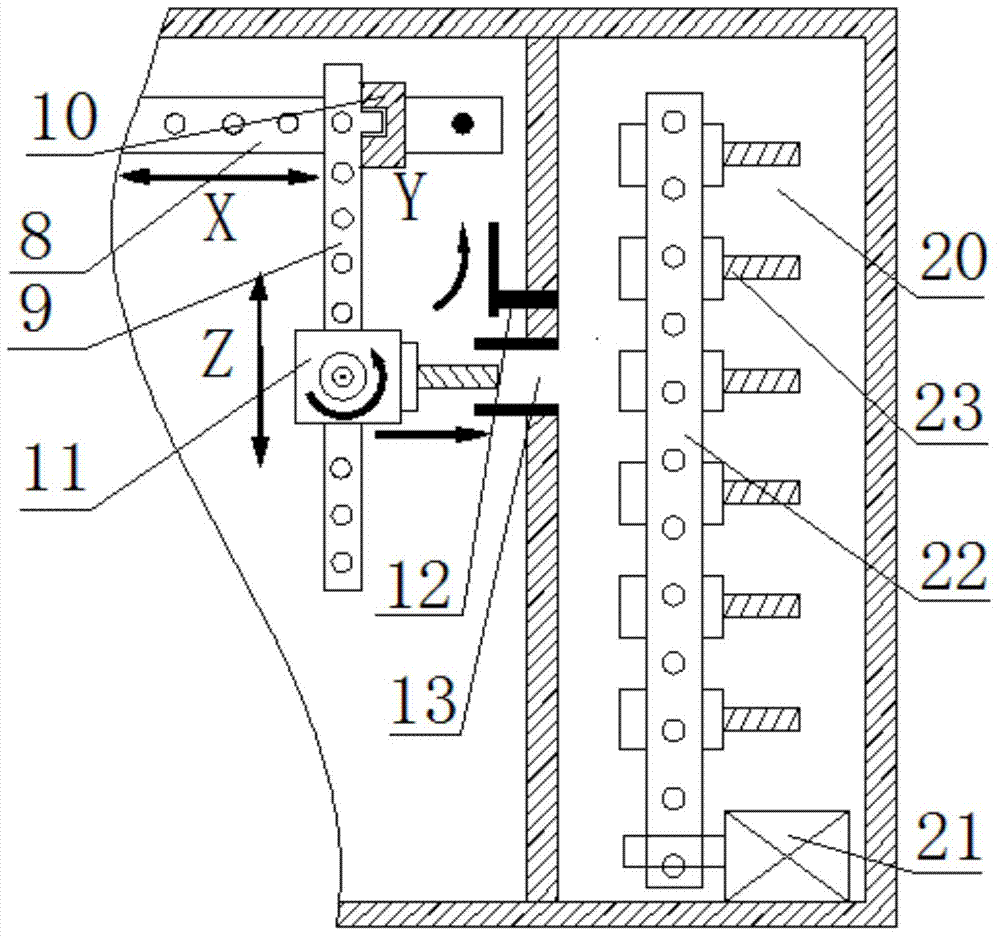

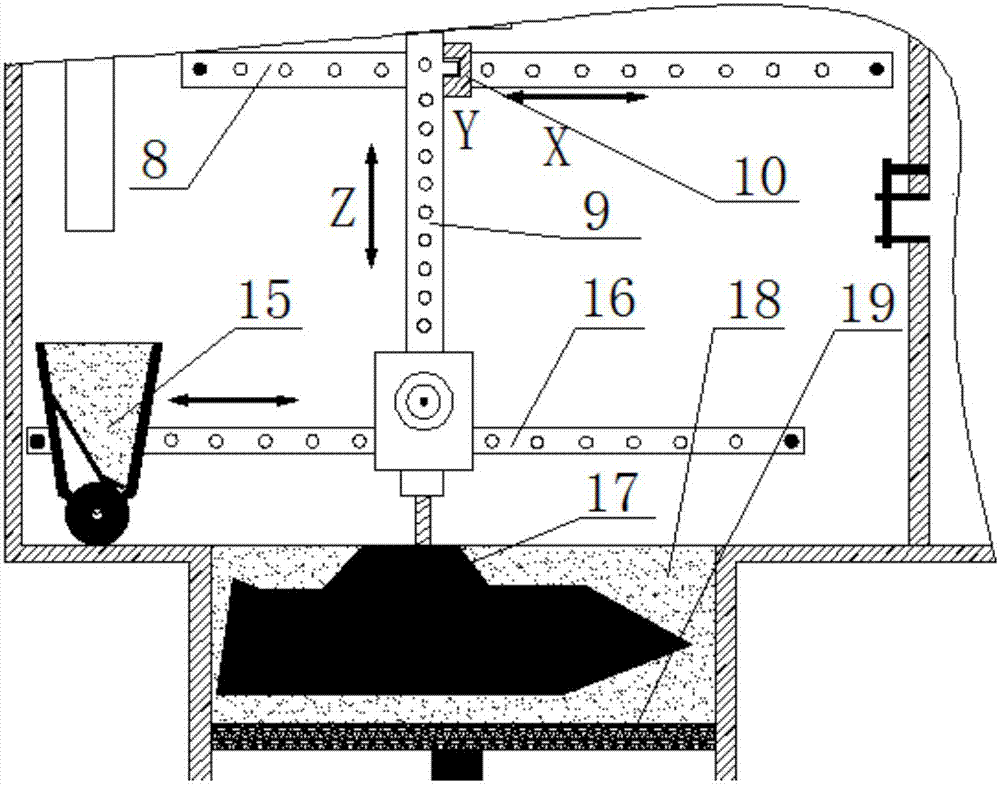

[0039] Such as Figure 1-3 shown. The single-cylinder type laser selective melting and milling compound processing equipment of the present invention includes a laser selective melting forming device and a vertical milling machine device, a central control system, and a laser selective melting forming device includes an optical system, a powder spreading system, a forming chamber 14 and a forming cylinder 18. The laser selective melting forming device and the vertical milling machine share the same central control system.

[0040] The vertical milling machine device is located in the molding chamber 14, and the vertical milling machine device also includes a chain tool magazine 20, and the chain tool magazine 20 is located on the right side outside the molding chamber;

[0041]The optical system includes a laser 5, a collimating beam expander 4, an optical lens 3, and a scanning galvanometer 2 sequentially connected by an optical path;

[0042] The laser 5 is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com