Taper-controllable laser micropore machining light beam scanning device and control method thereof

A technology of micro-hole processing and beam scanning, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of non-adjustable reverse taper hole taper, high installation accuracy requirements, large energy loss, etc., and achieve cost reduction , high precision, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

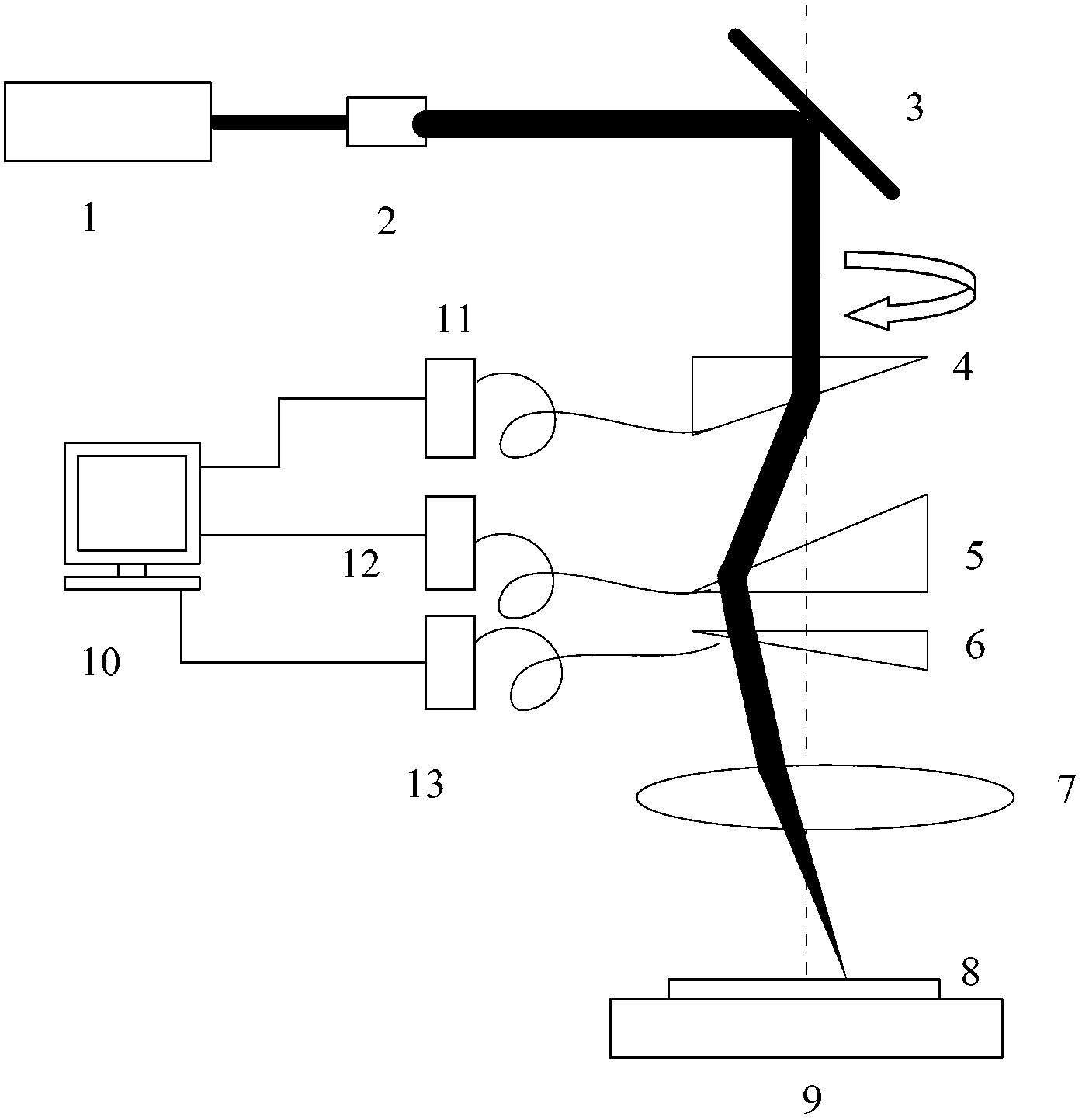

[0030] Such as figure 1 The experimental device shown is composed of a laser 1, a beam expander 2, a 45° reflector 3, a first large wedge angle wedge 4, a second large wedge angle wedge 5, a small wedge angle wedge 6, a focusing mirror 7, It consists of a sample to be processed 8, a clamping platform 9 and a computer 10 for controlling the movement of the optical wedge. When working, the three optical wedges are driven to rotate by the drive motors 12 and 13, and the laser beam punches holes on the surface of the sample 8 to be processed.

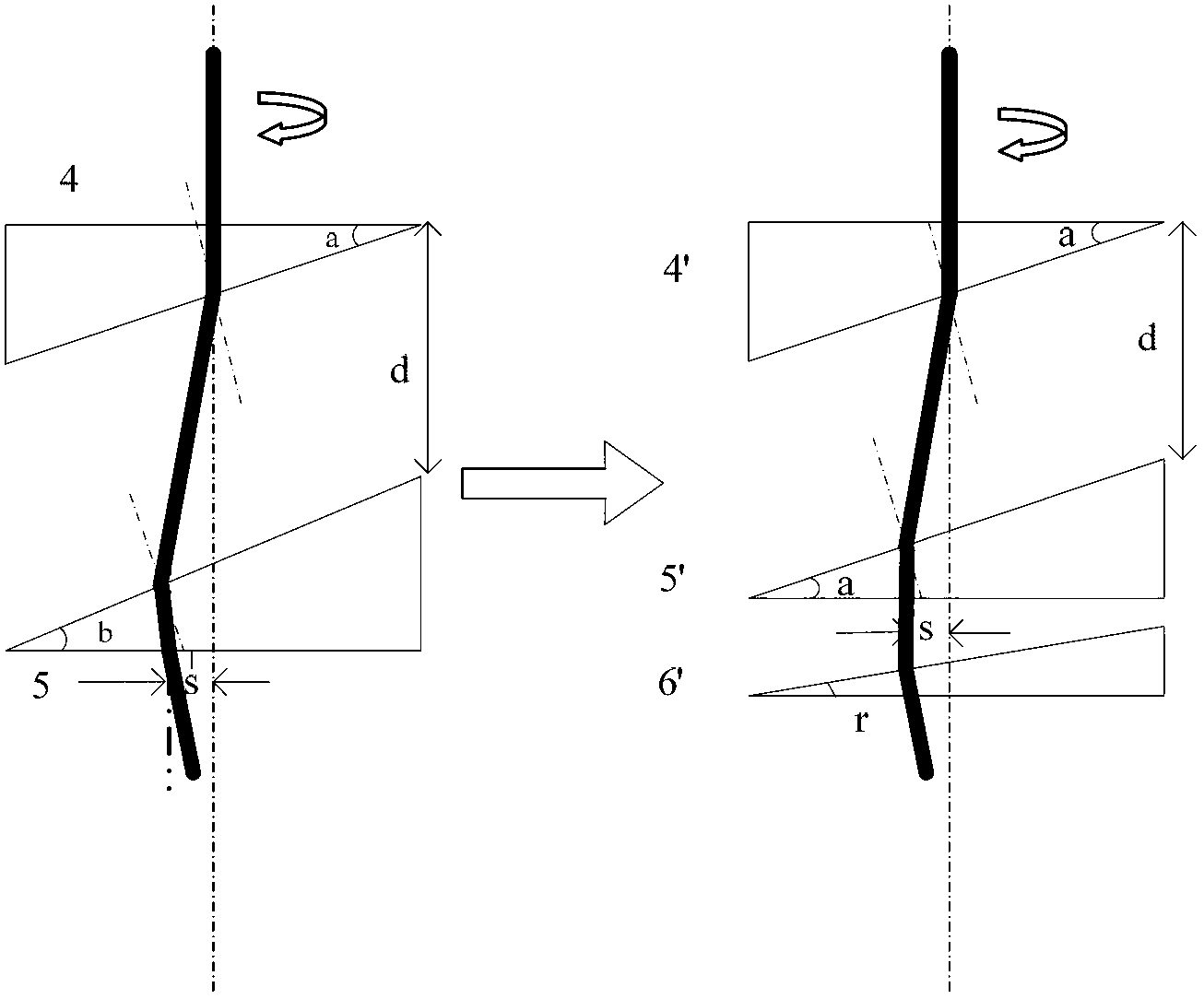

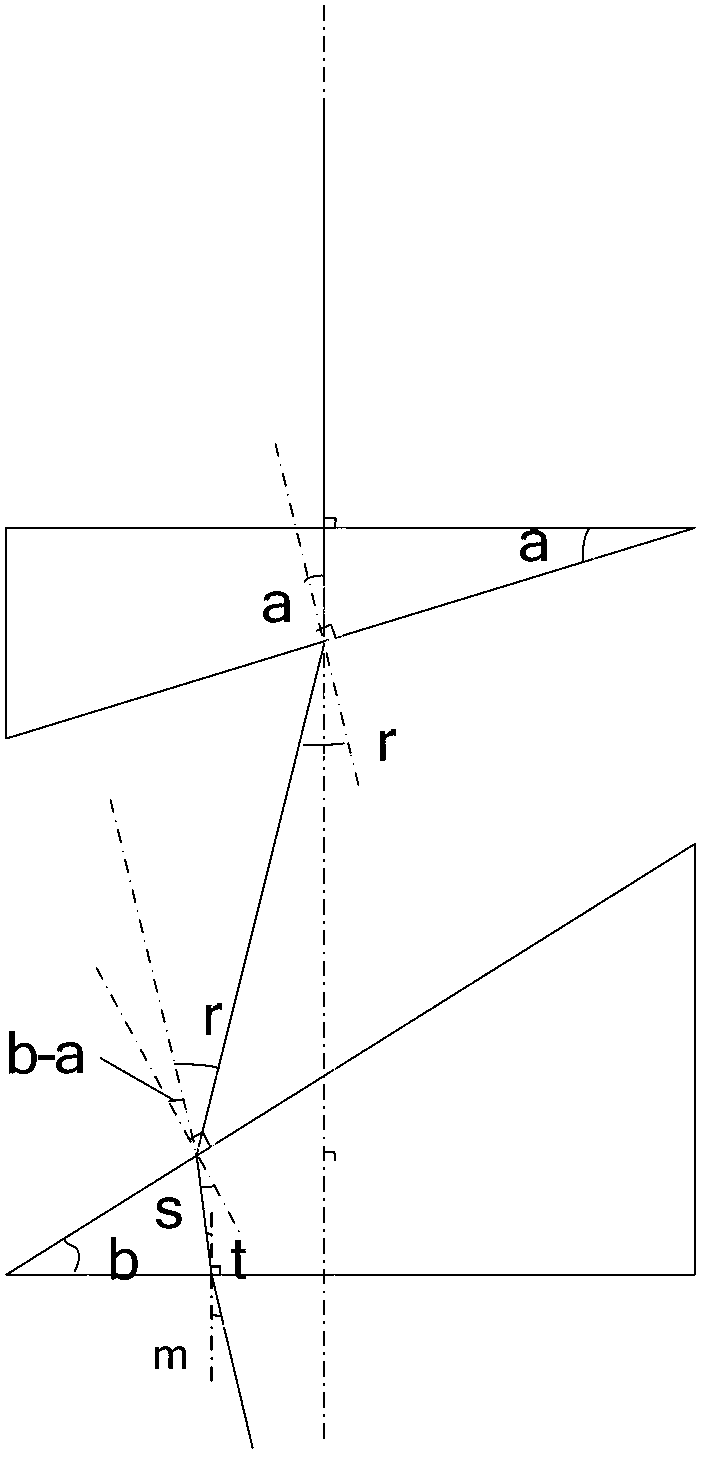

[0031] The laser beam is collimated by the beam expander, and the collimated light is then vertically incident on the non-parallel optical wedge group formed by the first large wedge angle 4 and the second large wedge angle 5 through the 45° reflector 3, and the non-parallel light The wedge group can produce a certain inclination and translation to the beam, which is equivalent to a pair of parallel optical wedge groups 4', 5' and a small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com