System and method for preparing micro-pore array through femtosecond laser direct writing

A micro-hole array, femtosecond laser technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of complex experimental conditions, low processing efficiency, difficult to change, etc., to achieve good processing effect, high processing efficiency, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

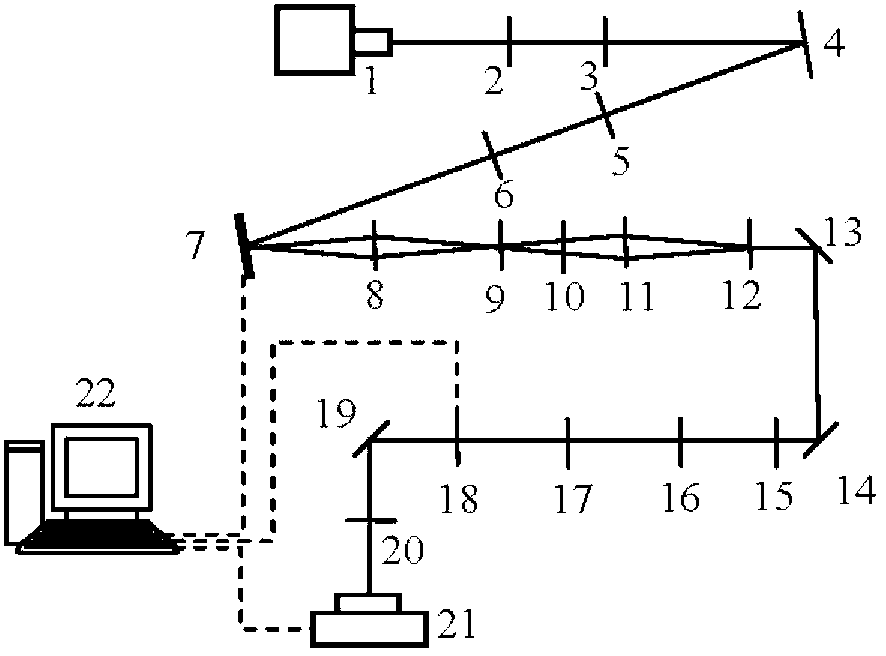

[0058] Example 1: Femtosecond laser direct writing system for preparing microwell arrays

[0059] Such as figure 1 As shown, the femtosecond laser direct writing system for preparing microwell arrays provided by the present invention includes a femtosecond vector light field generation system, a spatial filter component, a computer and a three-dimensional mobile platform; the femtosecond vector light field generation system consists of a reflective phase-only Composed of a spatial light modulator, a 4f system and a Rochi grating; the spatial filter component consists of a fourth achromatic convex lens (15), a second spatial filter (16) on the spectral plane, and a fifth achromatic convex lens (17);

[0060] On the output linear optical path of the femtosecond laser (1), a half-wave plate (2), a Glan laser prism (3) and a first high reflection mirror (4) are arranged in sequence, passing through the first high reflection mirror (4) ) on the first reflection optical path in tur...

Embodiment 2

[0061] Example 2, Femtosecond laser direct writing method for preparing microhole arrays

[0062] After the laser beam emitted by the femtosecond vector light field generation system is focused by a single lens, the light intensity distribution at the focal point will be determined by the light field amplitude and its local field distribution. The following will specifically analyze the wavefront shaping of a single linearly polarized laser beam to generate multiple parallel laser beams with different positions and local field distributions, and analyze the relationship between the field distribution at the focal point and the processing effect.

[0063] According to the Fourier transform of thin lenses, see Joseph W.Goodman, Introduction to Fourier Optics, Electronic Industry Press, Beijing, 2011. The geometric center of the generated parallel beams is the origin of the coordinates, and in the lens On the front focal plane (r, θ), for the wavelength λ and the topological numb...

example 1

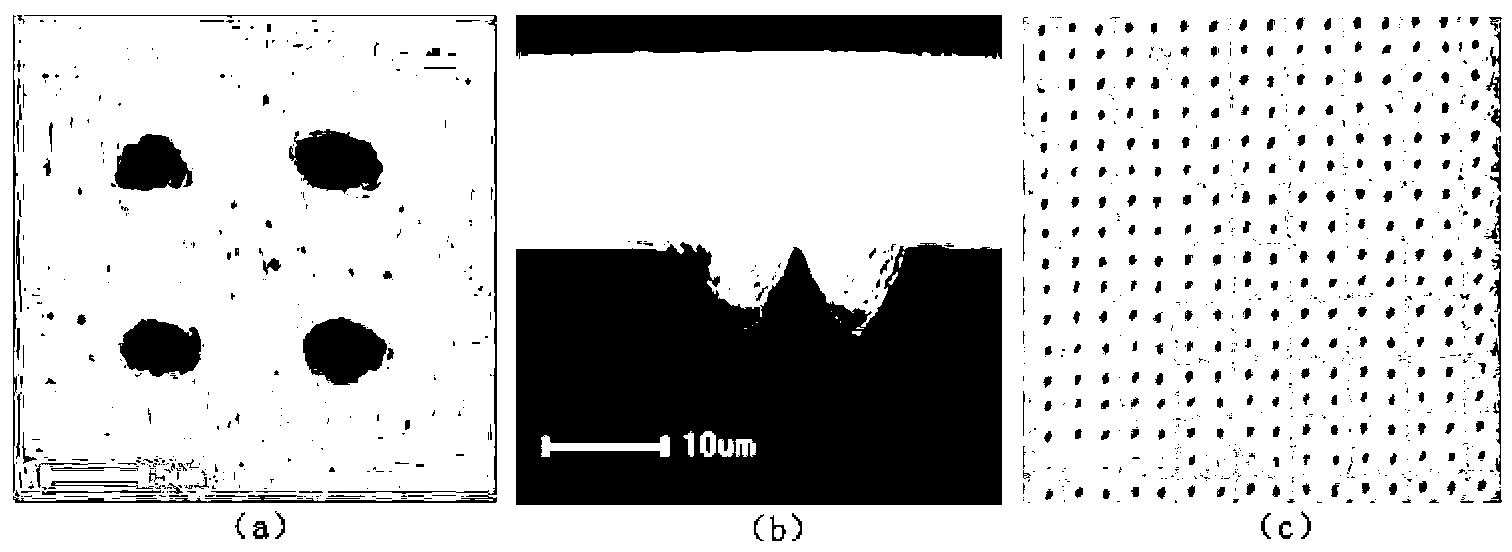

[0068] The following describes in detail the specific implementation steps of preparing the microhole array on the polished single crystal silicon surface placed on the three-dimensional mobile platform by combining the processing system of the present invention with femtosecond laser direct writing to prepare the microhole array.

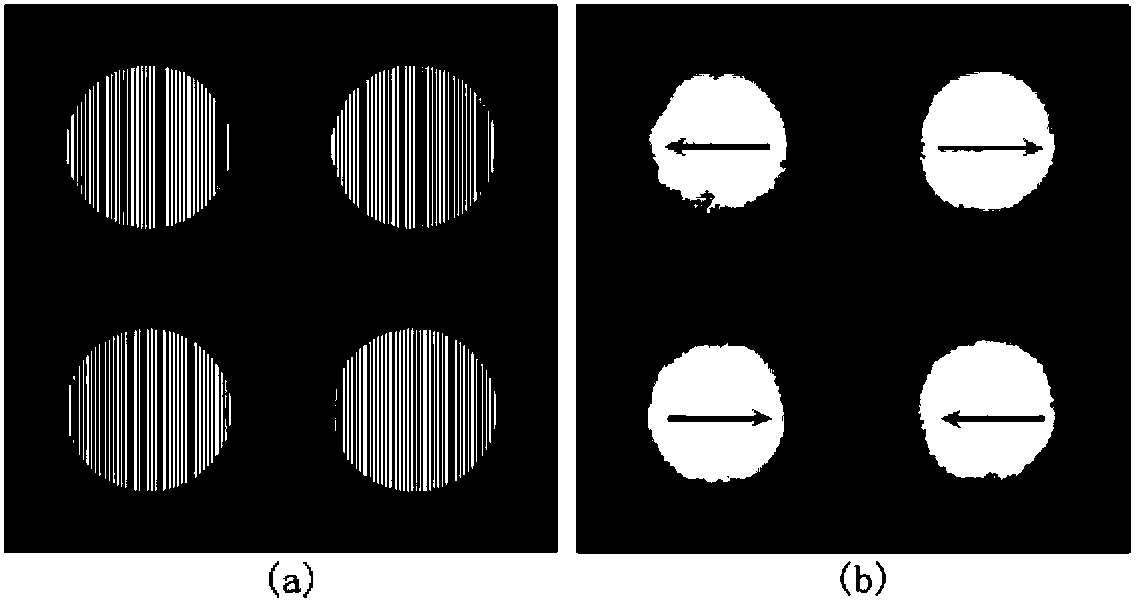

[0069] refer to figure 1 , using a computer to generate a holographic phase plate, there is no holographic grating in the central area of the phase plate, but four centrally symmetrical light-through circular holes are generated in the four quadrants of the coordinate axis, and the center positions of the light-through holes are: (156,1.56), (-1.56, 1.56), (-1.56, -1.56) and (1.56, -1.56). The topological number of each aperture holographic phase plate is 0. If the initial phase of each aperture is the same, there is only one extremely strong point on the focal plane. In this embodiment, the initial phases of the first and third quadrants are 0,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Slit width | aaaaa | aaaaa |

| Grating period | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com