Super-diffraction imaging device for improving resolution based on phase shifting principle and manufacturing method thereof

An imaging device and super-diffraction technology, applied in the field of nano-processing, can solve the problem that super-resolution imaging lithography is difficult to achieve lithography resolution of 40nm and below, and achieve the goal of improving light energy utilization, offsetting energy loss, and increasing focal depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But the following examples are only limited to explain the present invention, and the protection scope of the present invention should include the entire content of the claims, and those skilled in the art can realize the entire contents of the claims of the present invention through the following examples.

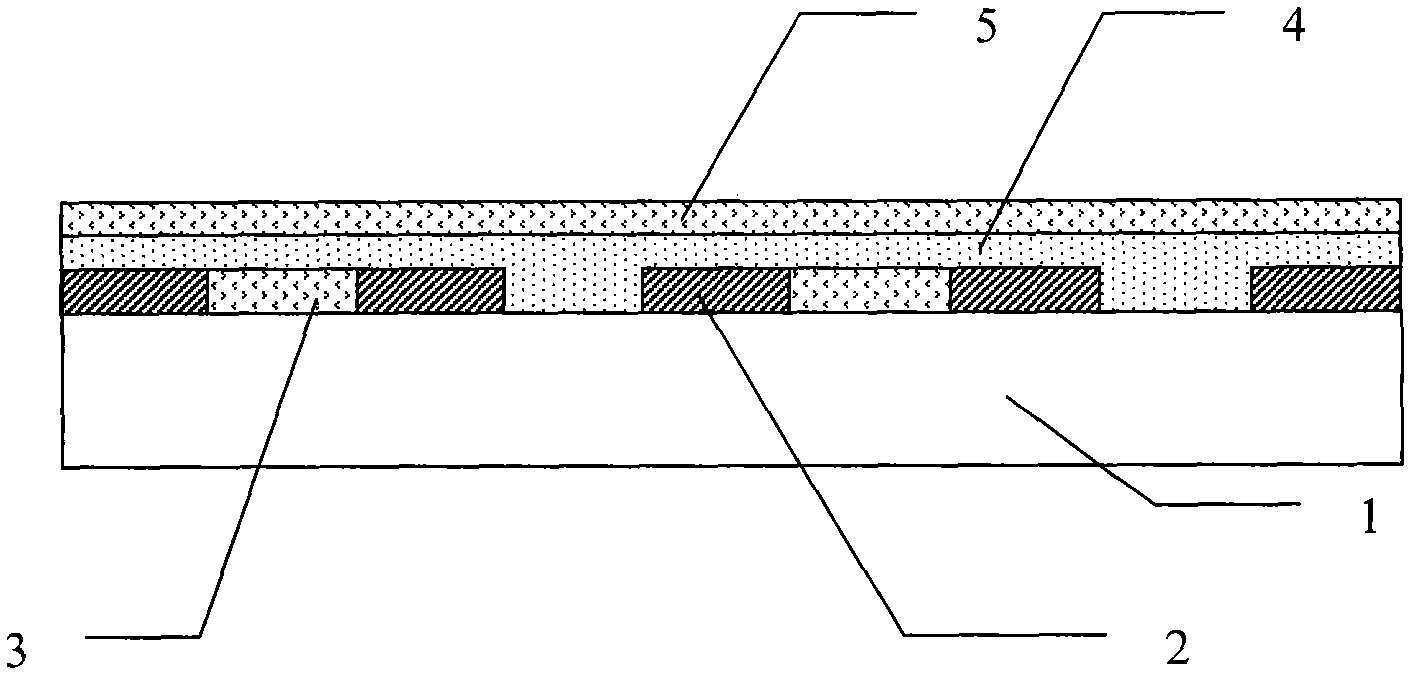

[0033] Embodiment 1 of the present invention is to make a phase-shift mask with a period of 40nm and a line width of 20nm, and the exposure wavelength is 365nm. The mask includes a transparent quartz substrate, a chromium film pattern, and PMMA and metallic silver.

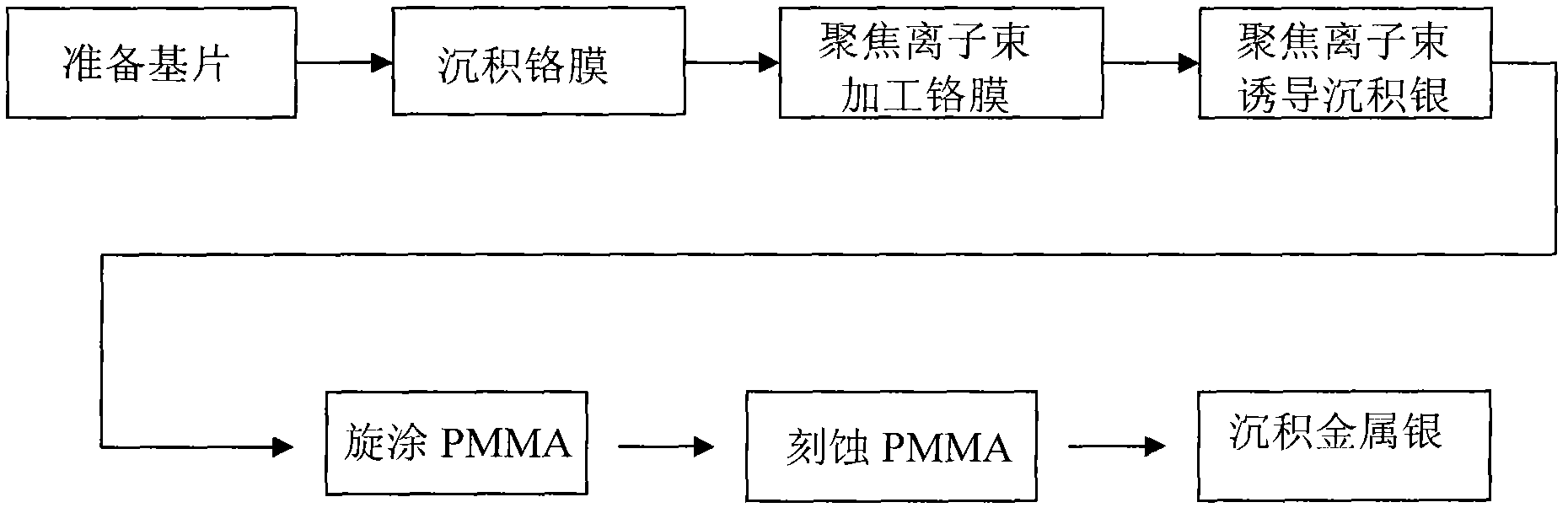

[0034] The mask fabrication steps are as follows figure 2 Shown:

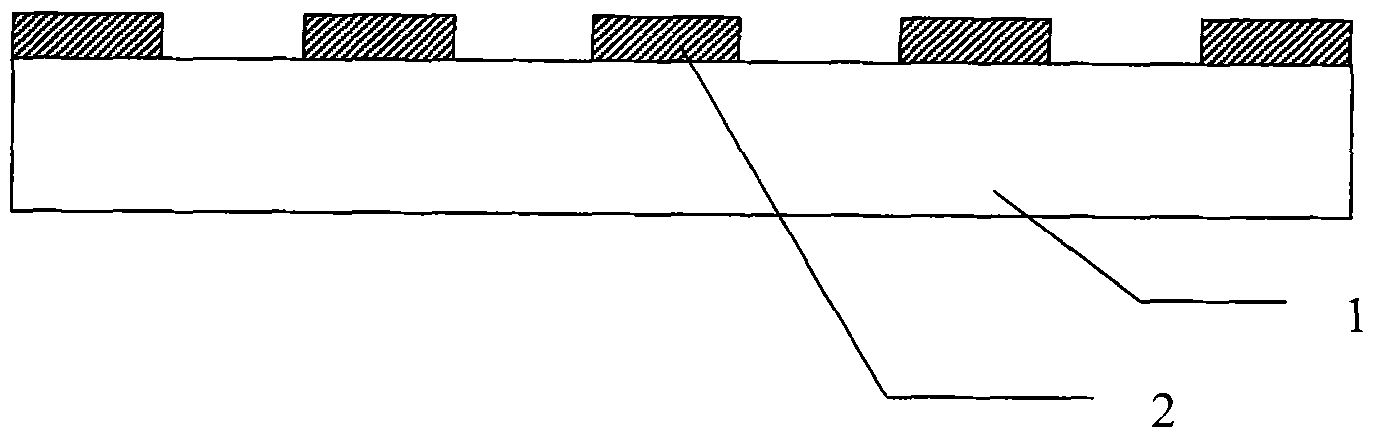

[0035] (1) select quartz to make ultraviolet light transparent substrate;

[0036] (2) Utilize magnetron sputtering to process the chromium film that thickness is 50nm on one side of ultraviolet light trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com