Method for preparing nano strip V2O5

A V2O5, ribbon-shaped technology, which is applied in the field of simple low-temperature hydrothermal reaction to prepare nano-ribbon vanadium pentoxide, can solve the complex problems of the template method, and achieve the effects of good repeatability, huge application potential, and short experimental cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) The surfactant Pluronic P123 was dissolved in secondary deionized water to obtain a solution 1 with a concentration of 0.01M;

[0027] (2) Add NH to solution 1 obtained in step (1) 4 VO 3 powder, stirred until the solution was dissolved and turned light yellow, and a solution 2 with a concentration of 14.2mM was obtained;

[0028] (3) Add 4ml of reducing agent isopropanol to 36ml of solution 2 obtained in step (2), stir for 10min, then transfer to a polytetrafluoroethylene-lined reactor, keep at 160°C for 24h, cool to room temperature, and filter with suction , washed 6 times with water and ethanol, and dried at 60 °C to obtain dark green NH 4 V 4 o 10 precipitation;

[0029] (4) Change the dark green NH 4 V 4 o 10 Precipitate in air atmosphere and heat at 400°C for 2 hours to obtain orange V 2 o 5 Material (S-1).

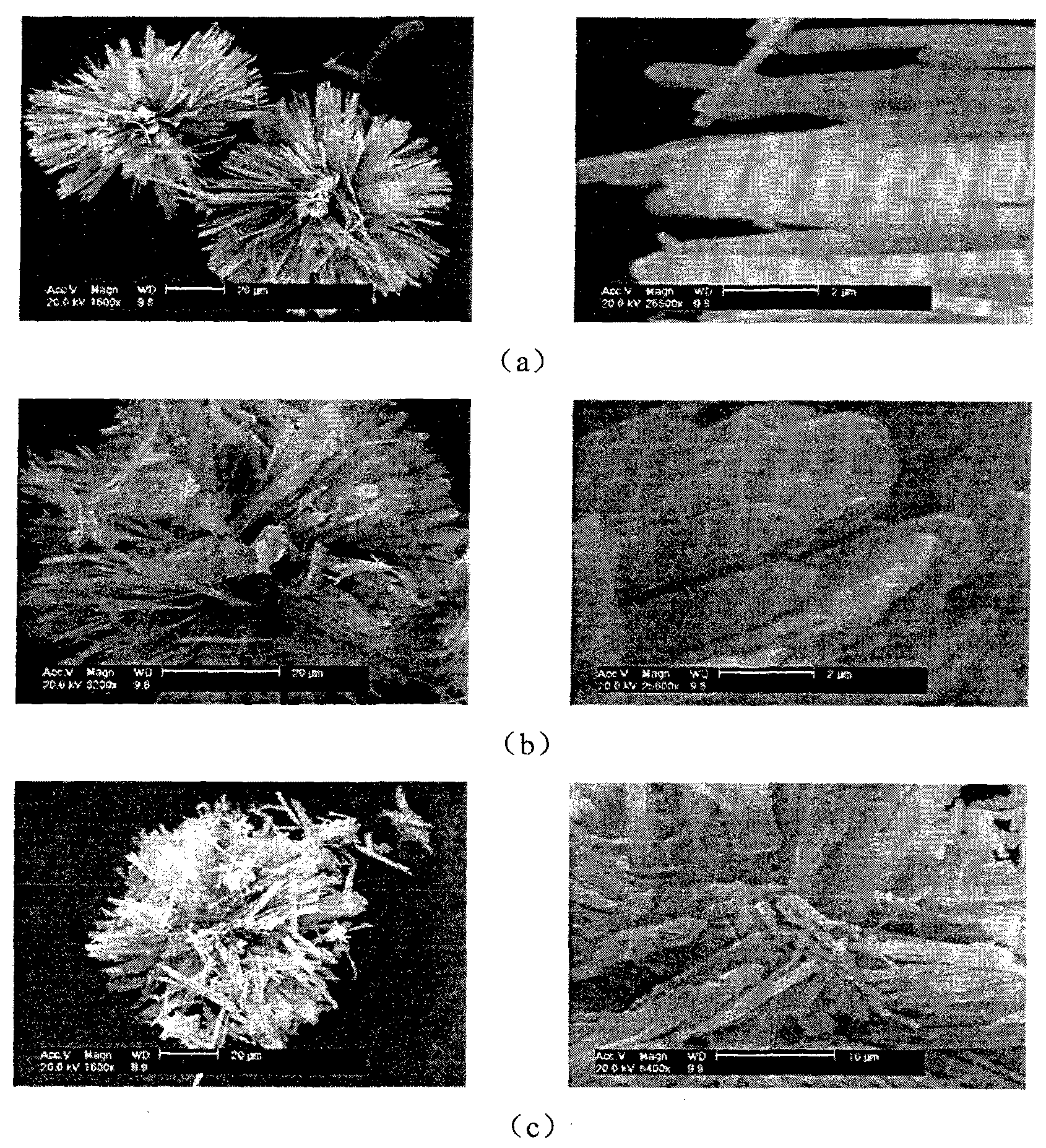

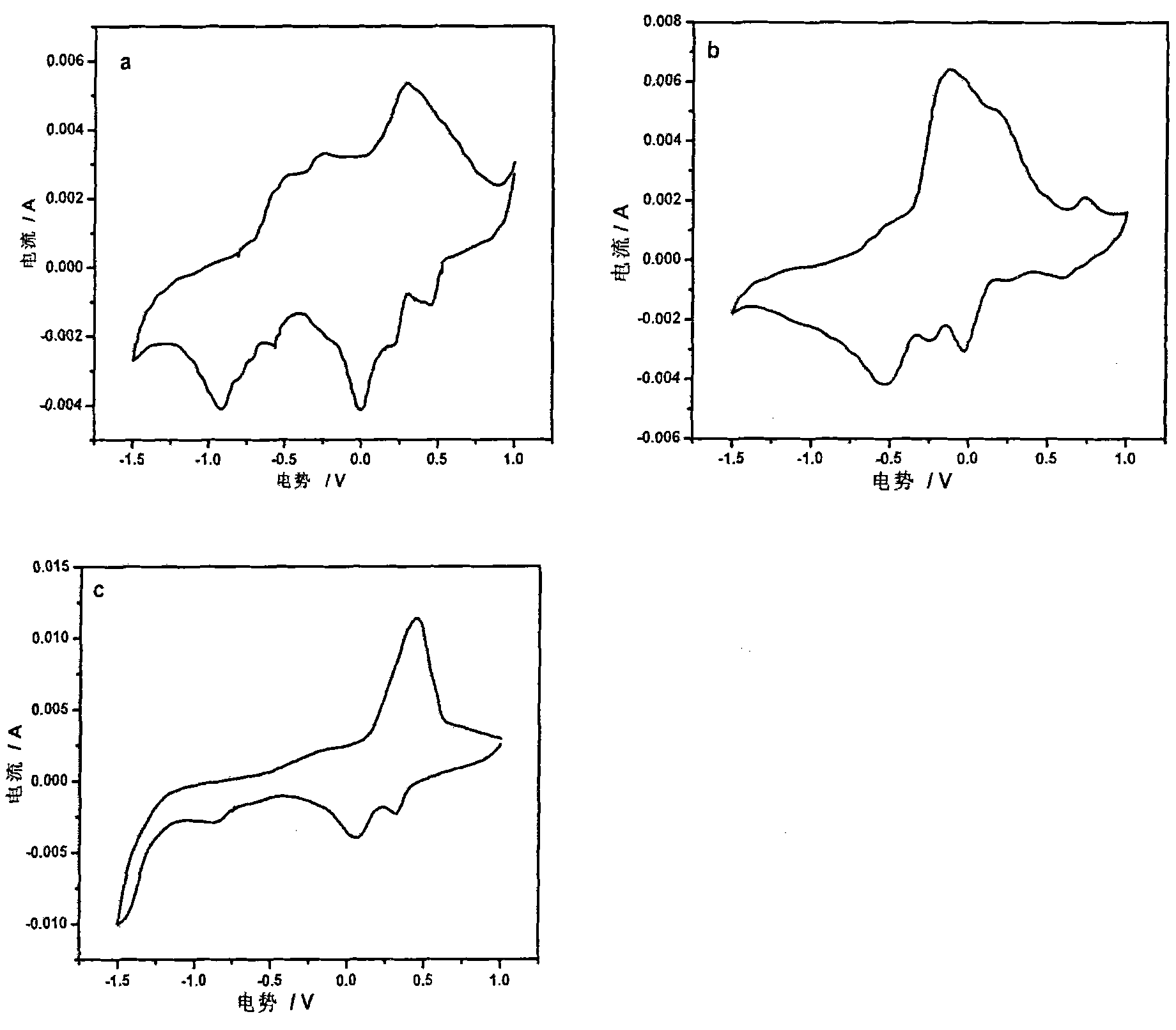

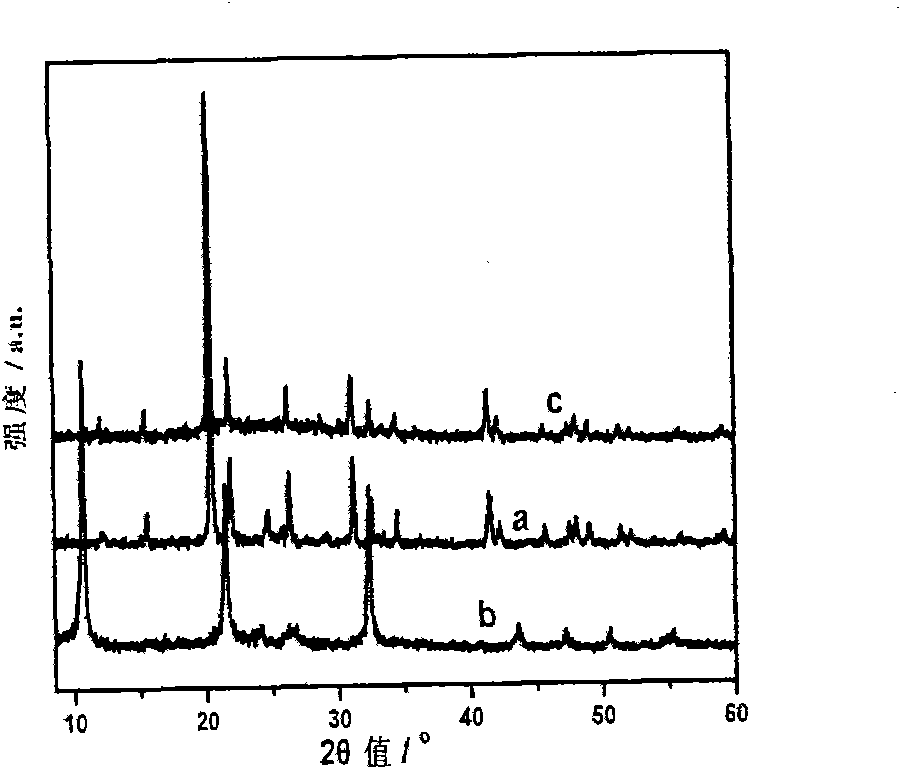

[0030] Scan the product S-1 with an electron microscope to obtain the SEM picture of the scanning electron microscope photo, such as figure ...

Embodiment 2

[0034] (1) The surfactant Pluronic P123 was dissolved in secondary deionized water to obtain a solution 1 with a concentration of 0.001M;

[0035] (2) Add NH to solution 1 obtained in step (1) 4 VO 3 powder, stirred until the solution was dissolved and turned light yellow, and a solution 2 with a concentration of 428mM was obtained;

[0036] (3) Add 4 ml of reducing agent isopropanol to 32 ml of solution 2 obtained in step (2), stir for 2 minutes, transfer to a polytetrafluoroethylene-lined reactor, keep at 180 ° C for 12 hours, cool to room temperature, and suction filter , washed 6 times with water and ethanol, and dried at 50°C to obtain dark green NH 4 V 4 o 10 precipitation;

[0037] (4) Change the dark green NH 4 V 4 o10 Precipitate in air atmosphere and heat at 400°C for 2 hours to obtain orange V 2 o 5 Material (S-2) has the same structure, properties and appearance as S-1. It is radially arranged and well dispersed, similar to flower petals. When the hydroth...

Embodiment 3

[0039] (1) The surfactant Pluronic P123 was dissolved in secondary deionized water to obtain a solution 1 with a concentration of 0.005M;

[0040] (2) Add NH to solution 1 obtained in step (1) 4 VO 3 powder, stirred until the solution was dissolved and turned light yellow, and a solution 2 with a concentration of 30mM was obtained;

[0041] (3) Add 4ml of reducing agent isopropanol to 40ml of solution 2 obtained in step (2), stir for 8min, then transfer to a Teflon-lined reactor, keep at 160°C for 15h, cool to room temperature, and filter with suction , washed 6 times with water and ethanol, and dried at 100°C to obtain dark green NH 4 V 4 o 10 precipitation;

[0042] (4) Change the dark green NH 4 V 4 o 10 Precipitate in air atmosphere and heat at 300°C for 3 hours to obtain yellow-green V 3 o 7 ·H 2 O material (S-3).

[0043] Scan the product S-3 with an electron microscope to obtain the SEM picture of the scanning electron microscope photo, such as figure 1 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com