Nanolithography method and nanolithography device

A technology of photoresist and photolithography mask, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

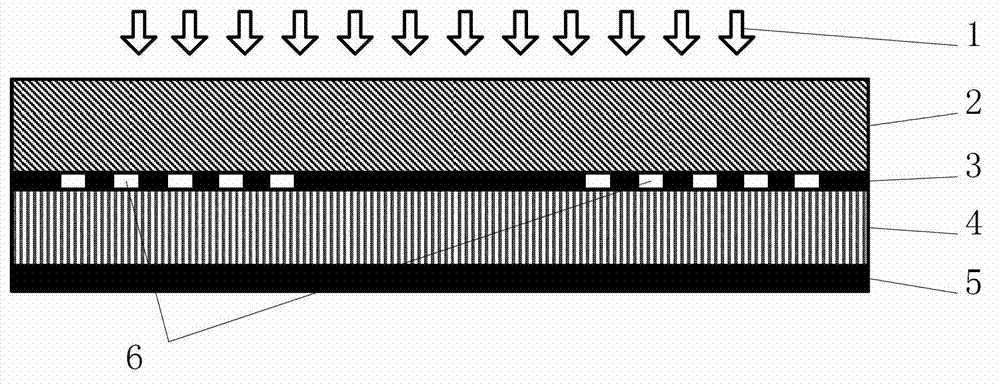

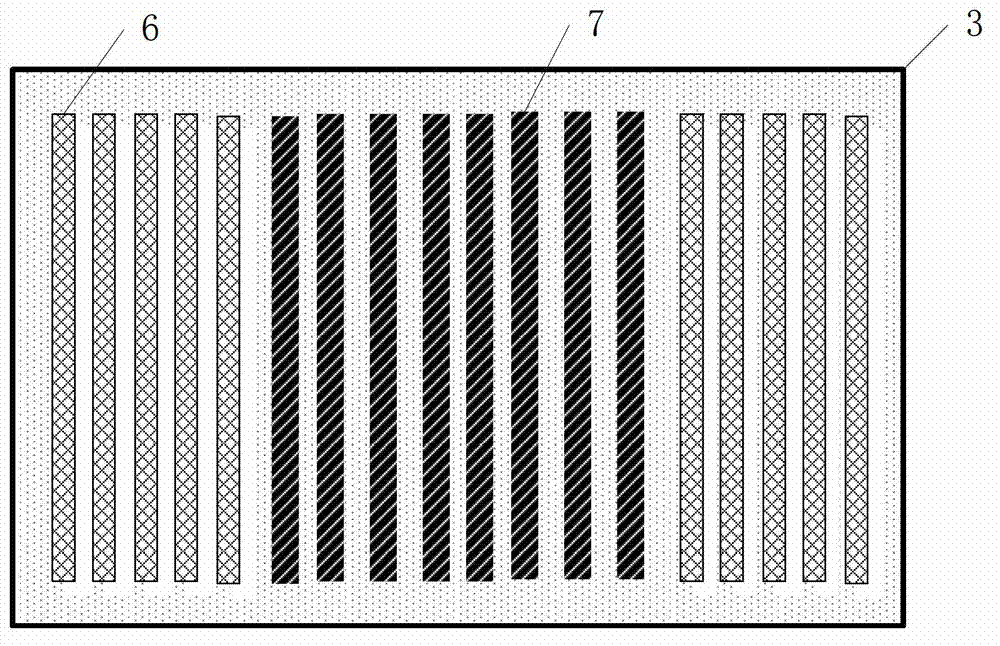

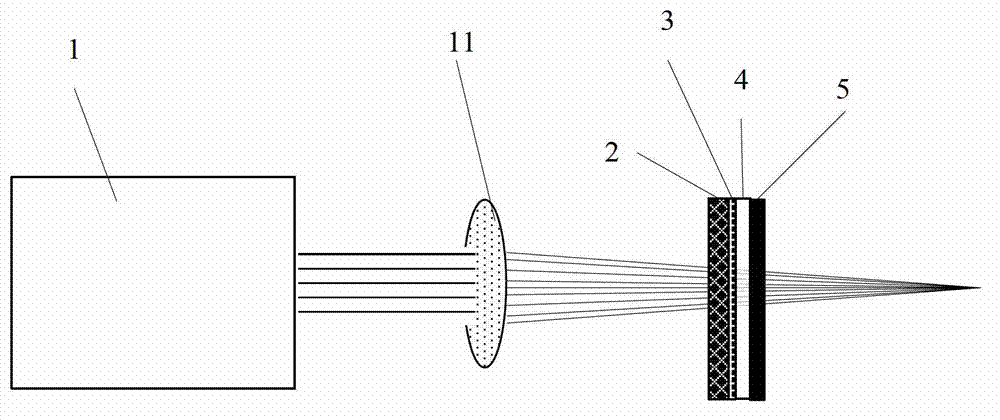

[0059] figure 1 A schematic diagram of nanolithography according to an embodiment of the present invention is shown. Among them, the meaning of each mark is: 1-femtosecond laser; 2-flat light-transmitting substrate; 3-lithography mask, with surface plasmon effect; 4-photoresist, with two-photon absorption effect, (here In the embodiment, it is specifically a negative photoresist, such as SU-82000, SU-82002); 5-substrate; 6-metal structure (the specific structure in this embodiment is a periodic metal grating).

[0060] First, a gold thin film layer of about 100 nm is grown on the flat transparent substrate 2 by magnetron sputtering, vapor deposition, electron beam evaporation and other methods. Then it is prepared by focused ion beam etching, reactive ion etching (RIE) and other methods. figure 2 The metal structure (periodic metal grating) 6 in the photolithography mask 3 with surface plasmon effect is prepared. The metal grating has a period of 480nm and a duty cycle of ...

Embodiment 2

[0062] figure 1 A schematic diagram of nanolithography according to an embodiment of the present invention is shown. First, a gold thin film layer of about 100 nm is grown on the flat transparent substrate 2 by magnetron sputtering, vapor deposition, electron beam evaporation and other methods. Then it is prepared by focused ion beam etching, RIE etching and other methods. figure 2 The metal structure (periodic metal grating) 6 in the photolithography mask 3 with the surface plasmon effect is prepared. figure 2 The period of the metal grating in the middle and the distance between the two groups of gratings are determined according to actual needs. At the same time, a layer of photoresist (positive type) 4 with two-photon absorption effect is spin-coated on the substrate 5 . The substrate 5 coated with the photoresist 4 is placed on a hot plate for baking, and the baking temperature and time depend on the photolithographic conditions. Then the prepared photoresist mask 3...

Embodiment 3

[0064] figure 1 A schematic diagram of nanolithography according to an embodiment of the present invention is shown. The wavelength of the femtosecond laser 1 used in this embodiment can be set according to actual conditions. By changing the wavelength, the dielectric constant of the stencil material is matched with the dielectric constant of the photoresist, so as to further reduce the period of the photolithographic pattern, such as Figure 5 shown. According to the wavelength of the selected light source, the corresponding structural parameters, such as the thickness of the gold film and the period of the metal grating, are designed through theoretical calculations. A gold thin film layer with a certain thickness is grown on the flat transparent substrate 2 by means of magnetron sputtering, evaporation, electron beam evaporation and the like. Then it is prepared by focused ion beam etching, RIE etching and other methods. figure 2 The metal structure (periodic metal gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com