Multi-beam semiconductor laser interference nanoimprinting technology and system

A technology of laser interference and nano-lithography, which is applied in the direction of semiconductor lasers, lasers, and laser components, etc., can solve the problems of difficulty in adjusting the incident angle and phase of coherent beams in the beam splitting system, large volume of lasers, and low flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

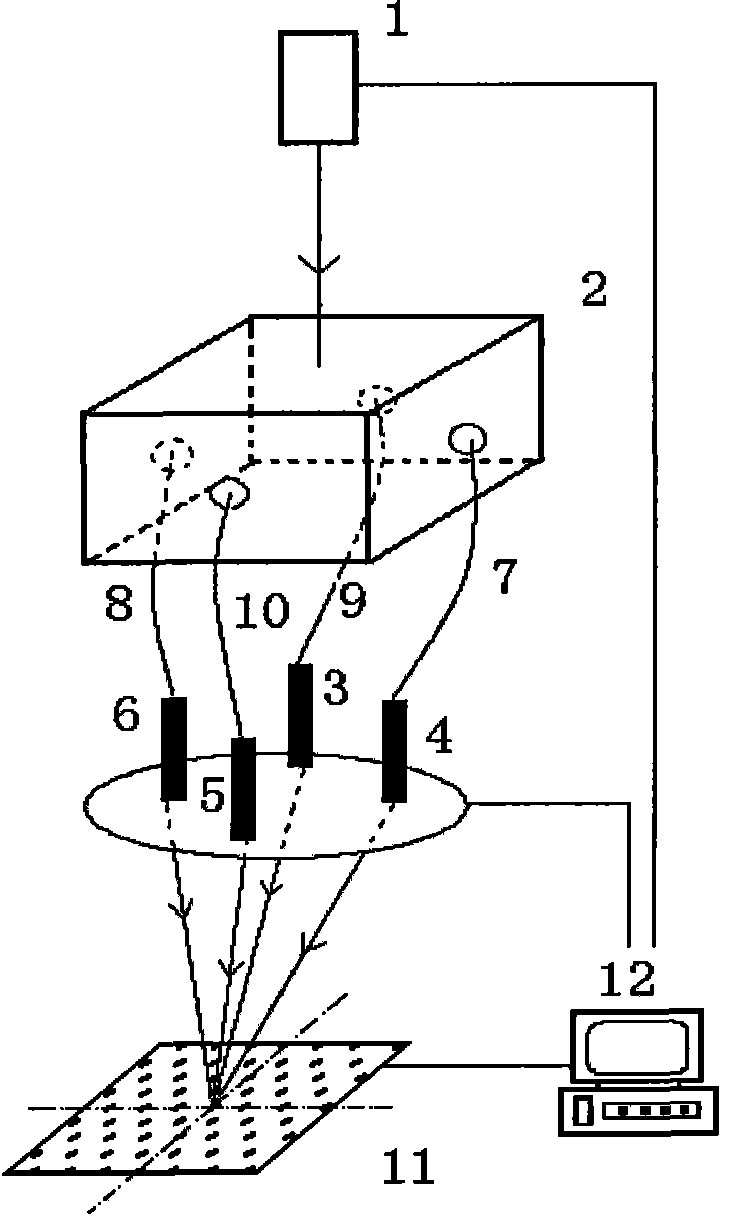

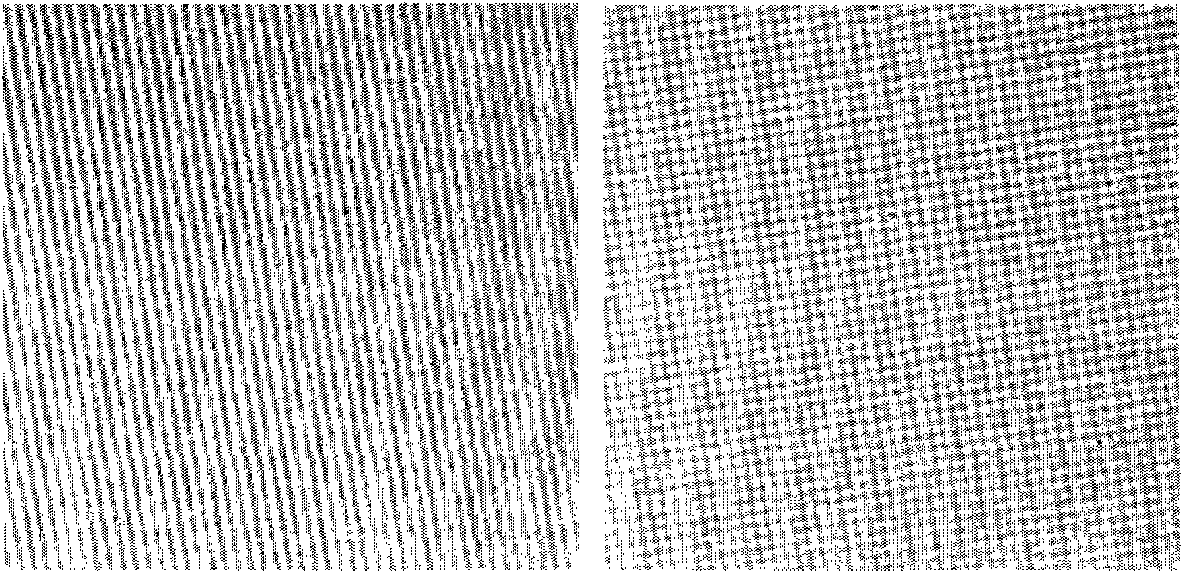

[0018] Such as figure 1 As shown, the semiconductor laser interference nanolithography system adopted in the present invention includes a semiconductor laser (wavelength 405nm) 1, a fiber coupling beam splitter 2, a beam shaping coupler and its control displacement components 3 to 6, laser fibers 7 to 10, three-dimensional Nanometer displacement and 90° horizontal rotation sample platform 11, computer 12. The laser light emitted by the computer-controlled semiconductor laser 1 is split by the beam-splitting coupler 2, and the separated four beams of coherent light are respectively transmitted by the laser fibers 7 to 10, and the four beams pass through the beam shaping coupler and its control components 3 to 6 Finally, the surface of the sample platform 11 is finally interfered, exposed on the sample coated with photoresist to form a periodic interference pattern, and the corresponding material surface micro-nano structure is obtained by etching. figure 2 are one-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com