Method for improving zirconium-based or titanium-based amorphous alloy surface hardness through laser irradiation in nitrogen

An amorphous alloy, laser irradiation technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problem of surface hardness reduction, achieve strong practicability, simple implementation process and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

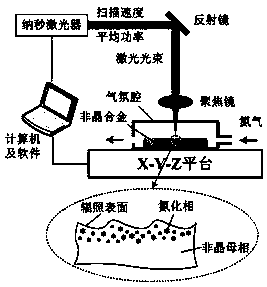

[0024] With a typical zirconium-based amorphous alloy (Zr 41.2 Ti 13.8 Cu 12.5 Ni 10 be 22.5 ) as an example, nanosecond laser irradiation was carried out in argon and nitrogen atmospheres, and the implementation process and beneficial effects of the present invention were further compared and illustrated in conjunction with the following examples.

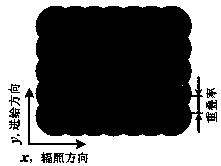

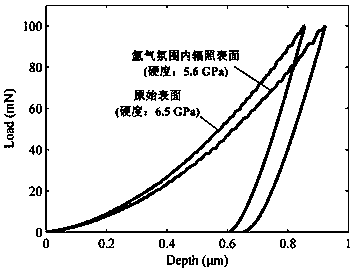

[0025] image 3 When the average laser power is 0.422W, the scanning speed is 1mm / s, the overlapping rate of adjacent scanning lines is 47%, the number of repeated scanning is 1 time, and the nitrogen pressure is 0.05MPa, after nanosecond laser irradiation on the surface of zirconium-based amorphous alloy, The indentation curve and hardness value obtained by nano-indentation test on the polished surface and the original surface can be seen that after laser irradiation in an argon atmosphere, the surface hardness is reduced by 0.9GPa compared with the original surface, which is 14% lower than that of the original surface. %, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com