Multi-layer wiring board and method of producing the same

a wiring board and multi-layer technology, applied in the direction of insulating substrate metal adhesion improvement, printing element electric connection formation, transportation and packaging, etc., can solve the problem of low polarity of resin which absorbs water little, low polarity of resin, and poor wettability of metal surface of metal with high polarity, etc. problem, to achieve the effect of reducing the thickness reducing the resistance of the wire board, and improving the adhesion of the metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

[0086]

[0087] An arylated polyphenylene ether resin (A-PPE) or a BT resin was used as a thermosetting resin and a spherical silica was used as an inorganic filler.

[0088] A resin composition was prepared containing the above thermosetting resin and the inorganic filler at a volume ratio of 50:50, and from which an insulating sheet in the B-stage having a thickness of 40 .mu.m was prepared based on the doctor blade method.

[0089] By using a CO.sub.2 laser, through-holes having a diameter of 100 .mu.m or 50 .mu.m were formed in the insulating sheet. Then, the through-holes were filled with an electrically conducting paste obtained by mixing a copper powder of which the surfaces are coated with silver and a binder, thereby to prepare an insulating sheet B for forming an insulating layer.

[0090] On the other hand, a film with a copper foil for transfer was prepared by sticking an electrolytic copper foil of a thickness of 12 .mu.m to a PET film of a thickness of 38 .mu.m. A dry film resist ...

experiment 2

[0107]

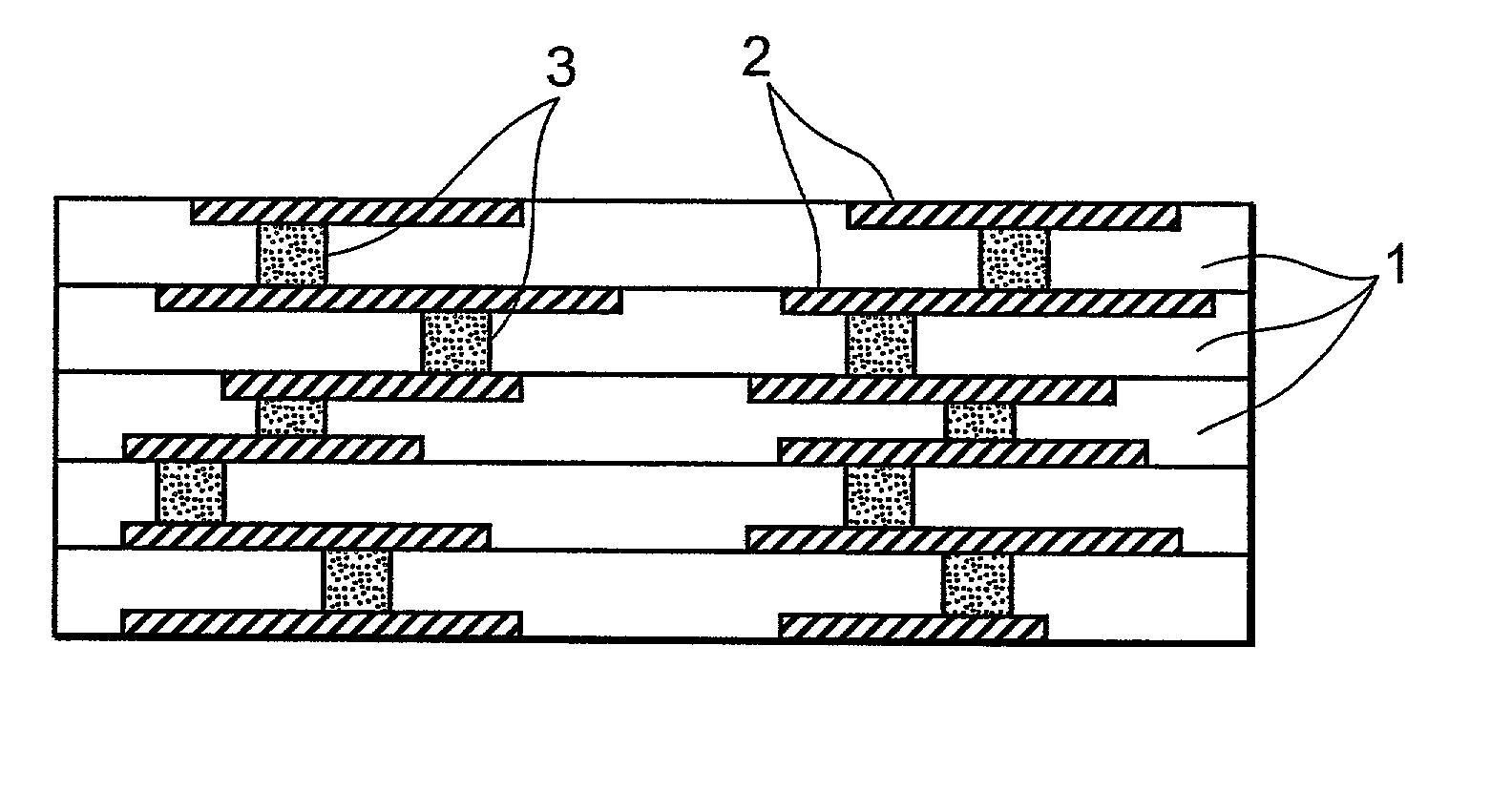

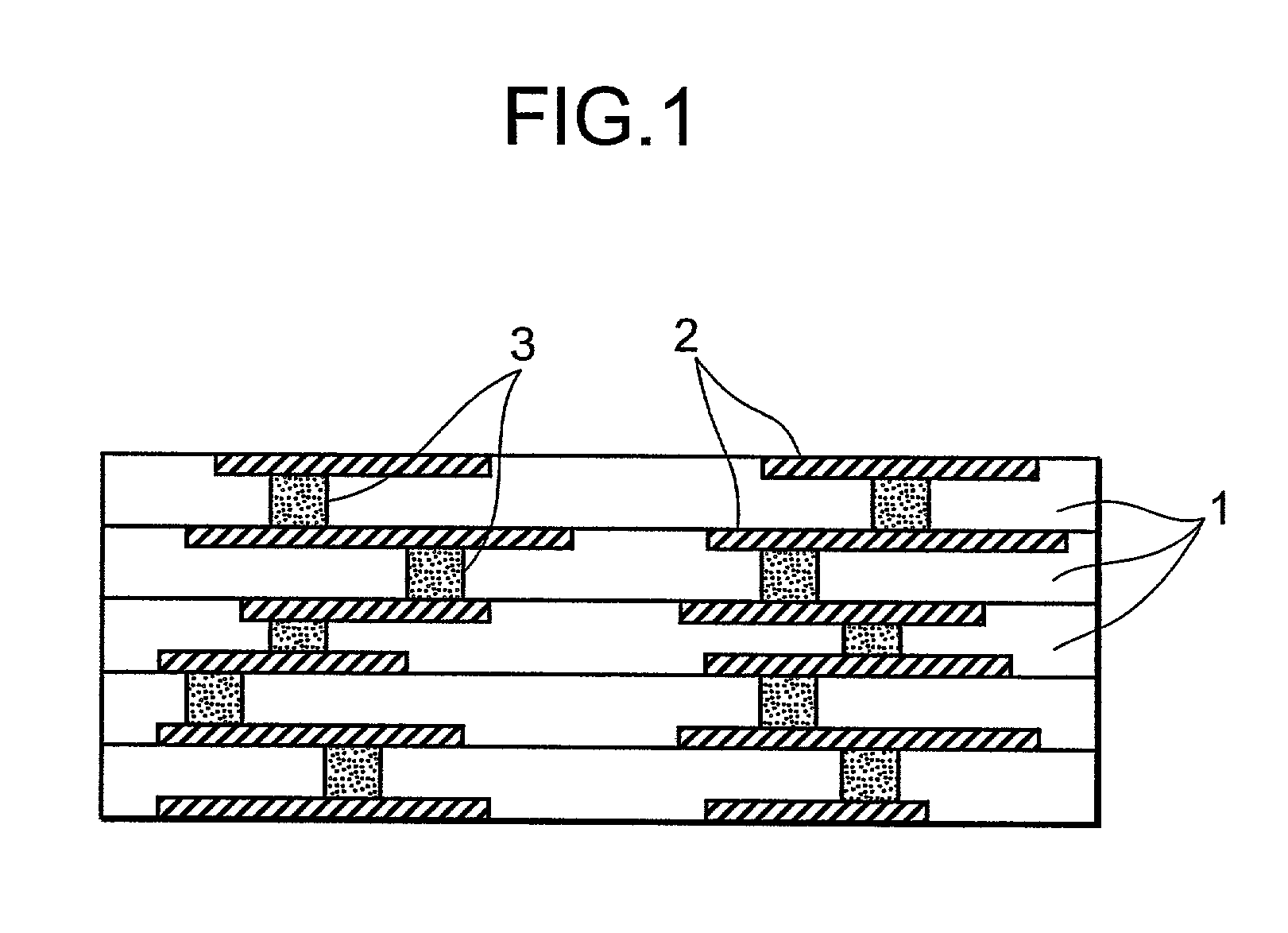

[0108] (Fabrication of the Multi-layer Wiring Board)

[0109] The following materials were used as insulating sheets for forming the insulating layers.

[0110] A prepreg comprising a glass fabric and an arylated polyphenylene ether resin (A-PPE resin);

[0111] A prepreg comprising a glass fabric and a BT resin;

[0112] A sheet in the B-stage having a thickness of 40 .mu.m prepared by using a resin composition containing the A-PPE resin and the spherical silica (inorganic filler) at a volume ratio of 50:50 relying upon the doctor blade method; and

[0113] A sheet in the B-stage having a thickness of 40 .mu.m prepared by using the BT resin and the spherical silica (inorganic filler) at a volume ratio of 50:50 relying upon the doctor blade method;

[0114] Via-conductors were formed in the above insulating sheets in the same manner as in Experiment 1.

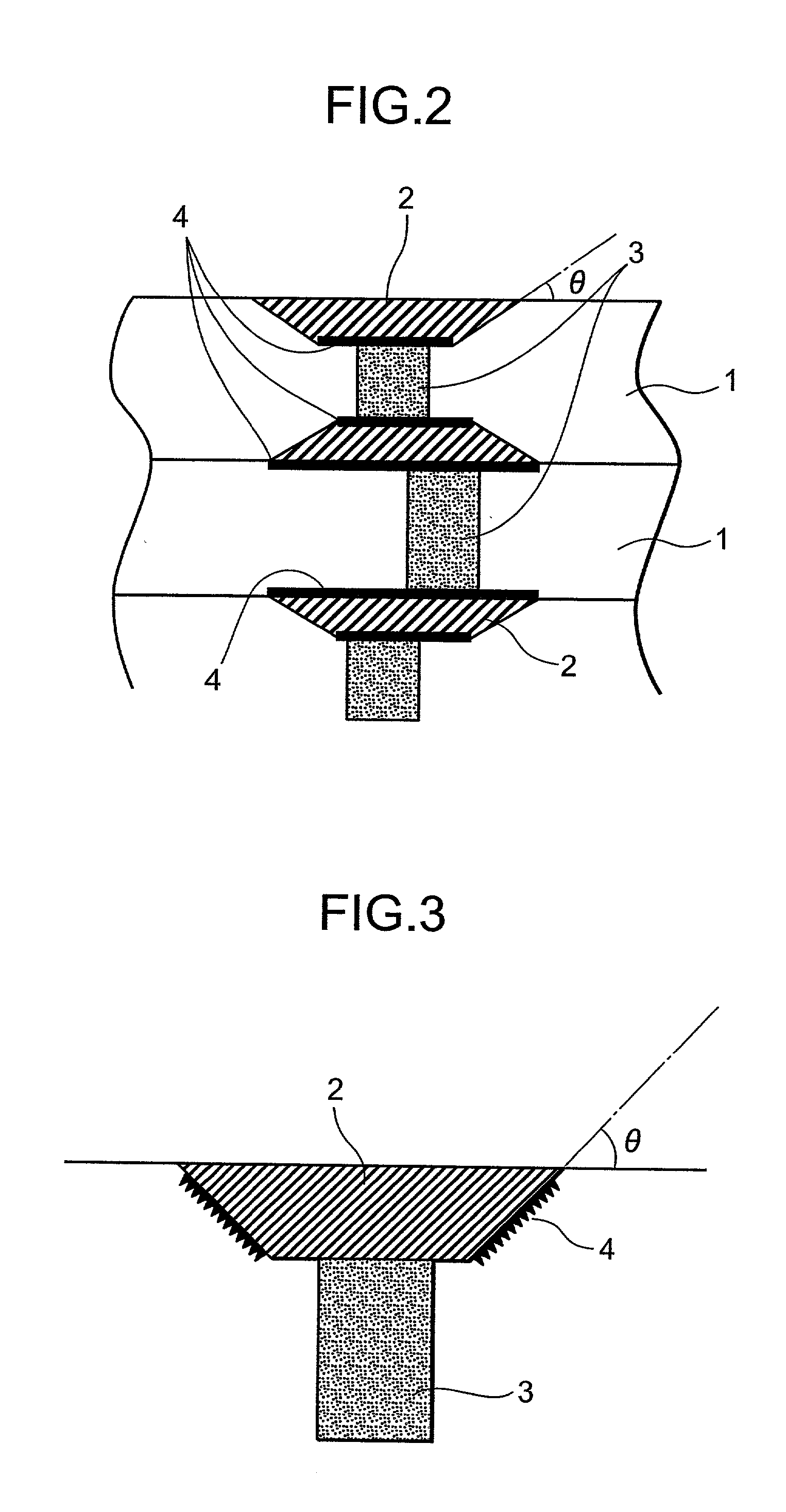

[0115] A conductor wiring layer of a trapezoidal shape with a side surface of an angle of inclination of 45.degree. to 80.degree. was formed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com