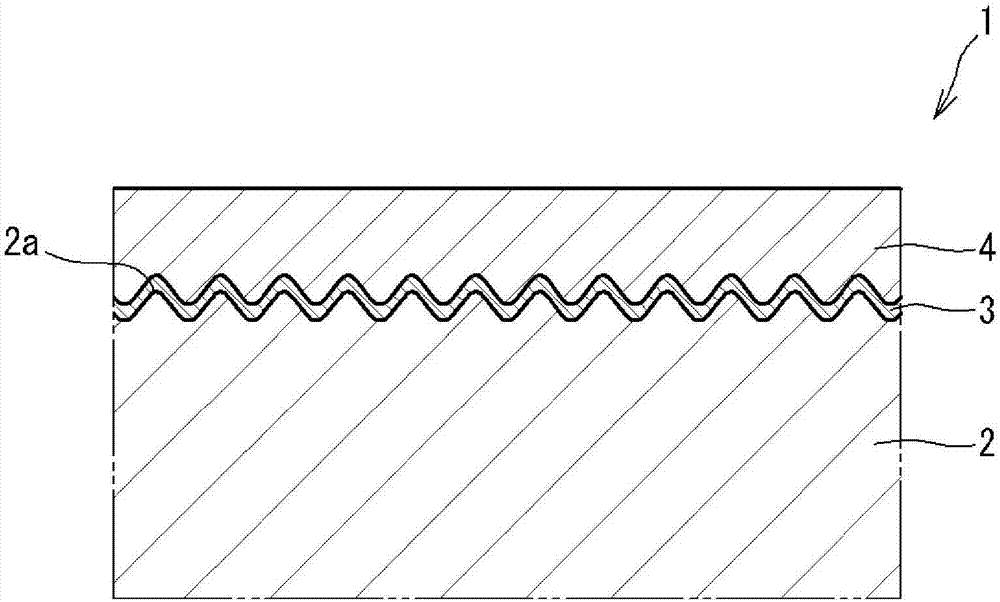

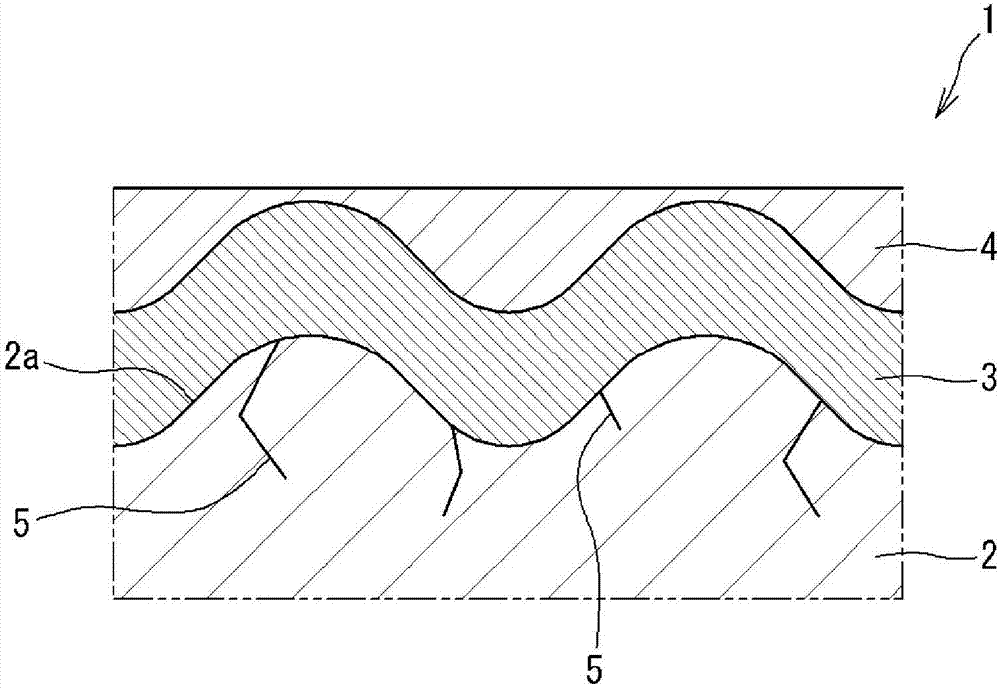

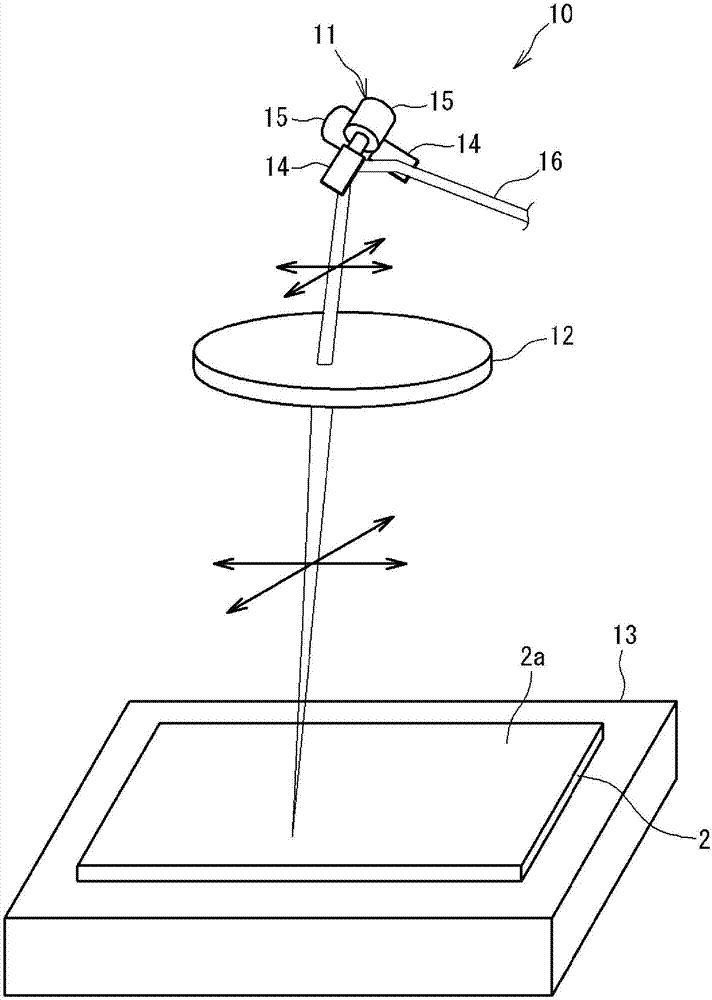

Method for roughening substrate, method for surface-treating substrate, method for producing spray-coated member, and spray-coated member

一种表面粗化、表面处理的技术,应用在基材的表面粗化、基材的表面处理、喷涂覆膜被覆部件及其制造领域,能够解决残留物密合性下降等问题,达到优异密合性、密合性高、抑制强度下降的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0104] Examples 1-8: Obtained a good rough surface with an oxide film formed.

Embodiment 12

[0119] In Example 12, after the surface roughening treatment was performed by laser irradiation, the surface roughening treatment surface was further oxidized by heat treatment before the coating of the spray coating was formed, and the adhesion and bending strength were improved. On the other hand, in Comparative Example 11, after the surface roughening treatment by spraying, the surface roughening treatment surface was oxidized by heat treatment before the spray coating was formed, and the bending strength was slightly improved but still insufficient. In addition, as for the adhesion, since the surface roughening treatment was performed by the blasting treatment so as not to damage the base material, unevenness was not formed, and good adhesion was not obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com