Dissimilar metal micro welding method

A welding method and technology of dissimilar metals, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of reduced mechanical properties of welded joints, large differences in physical properties, and high production costs, so as to avoid micro-cracks and small size , The effect of improving welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

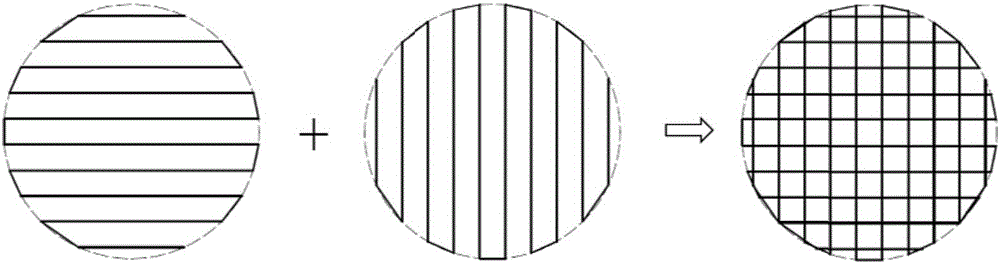

[0036] Such as figure 1 As shown, the high-speed scanning oscillating head adopts the filling line high-speed scanning method: first scan along the continuous horizontal line a direction, and then scan along the continuous vertical line b direction to form solder joints when the molten pool metal is not completely solidified after the previous welding ; Or first scan along the continuous vertical line b direction, and then scan along the continuous horizontal line a direction to form solder joints when the molten pool metal is not completely solidified after the previous welding. Wherein, the distance between the horizontal lines a is the same as the distance between the vertical lines b, so that the scanning welding is relatively uniform, which is conducive to the formation of solder joints with better mechanical properties.

[0037] Specifically, when welding 316L stainless steel with a thickness of 0.15 mm and a 6063 aluminum alloy plate with a thickness of 0.6 mm, a nanose...

Embodiment approach 2

[0040] Such as Figure 4As shown, the high-speed scanning oscillating head adopts the helical high-speed scanning method: first scan along the smaller-diameter helix to form the first circular solder spot, and then scan along the larger-diameter helix when the metal in the molten pool is not completely solidified after the previous welding. Scanning forms a second circular solder joint, and the circular solder joints formed by the two scans overlap each other. In this embodiment, the diameter of the smaller helix is 0.5 mm, the diameter of the larger helix is 0.7 mm, the energy of the previous scan is greater than the energy of the next scan, and the above helixes are formed from inside to outside. The previous welding energy is greater than the subsequent welding energy, so the thermal influence is greater than that of the latter, the previous welding trajectory is smaller than the latter welding trajectory, and the size of the solder joints formed in the final two times ...

Embodiment approach 3

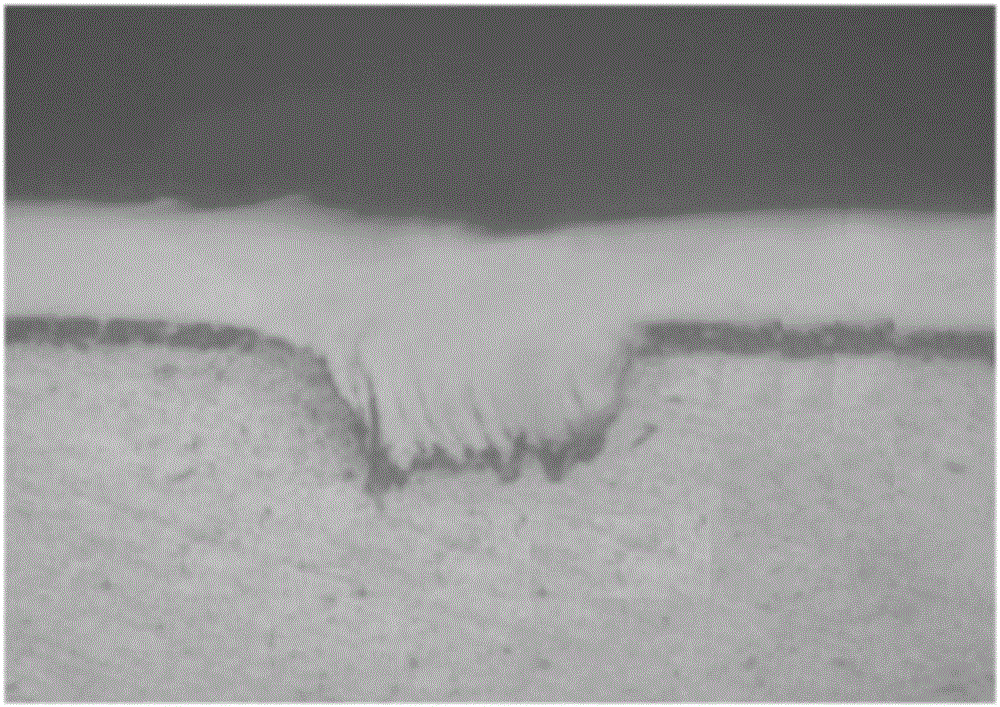

[0043] Such as Image 6 As shown, the high-speed scanning vibrating head adopts a spiral progressive high-speed scanning method: scan a circle around the center point in a spiral manner to form solder joints. During the aluminum-steel dissimilar metal welding process, a large number of brittle (Fe, Al) intermetallic compound layers will be formed near the fusion line, and the thermal expansion coefficient of aluminum-steel has a large difference. During the aluminum-steel welding process, a large thermal stress is generated near the fusion line and acts on the brittle intermetallic compound layer to cause thermal cracks. Direct welding with a large heat input will increase the penetration depth and fusion width of the weld, and the increase of the interface joint surface will improve the mechanical properties of the joint. However, due to the violent reaction between metal atoms in the molten pool, a large number of brittle compounds are generated. Larger internal stress is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com