Method for preparing micro-nano composite structure through nanosecond laser induced cracks

A composite structure, laser-induced technology, applied in laser welding equipment, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effect of simple operation, high processing efficiency, and reduced reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A method for preparing a micro-nano composite structure using nanosecond laser-induced cracks, comprising the following steps:

[0018] 1) Polish the surface of industrial pure titanium TA18 to a surface roughness of 100-120nm;

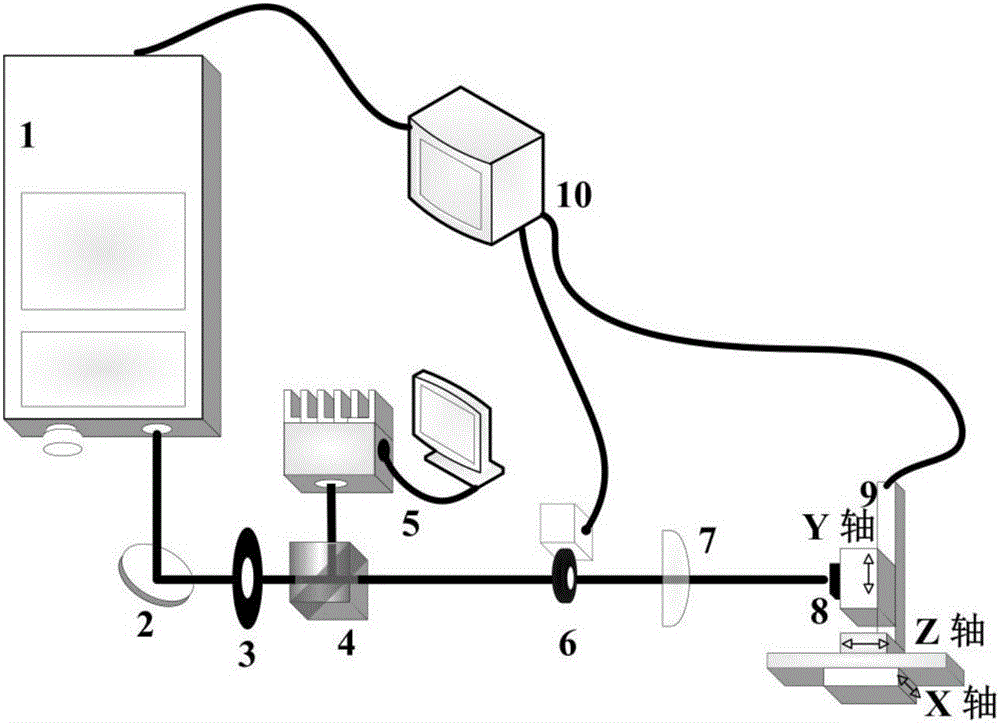

[0019] 2) Build the optical path, refer to figure 1 , the optical path includes a nanosecond laser 1, the output light of the nanosecond laser 1 passes through the mirror 2 to turn the optical path by 90°, and the reflected light passes through the aperture diaphragm 3, the beam splitting prism 4, the shutter 6, and the focusing lens 7 to irradiate vertically on the moving object On the processing station of stage 9, nanosecond laser 1, shutter 6, mobile stage 9 and computer 10 are connected, and the combination of beam splitter prism 4 and power meter 5 is used to detect the laser power. cut off, adjust the size of the light aperture through the small hole diaphragm 3, and use a focusing lens 7 with a focal length of 100 mm for focusing the o...

Embodiment 2

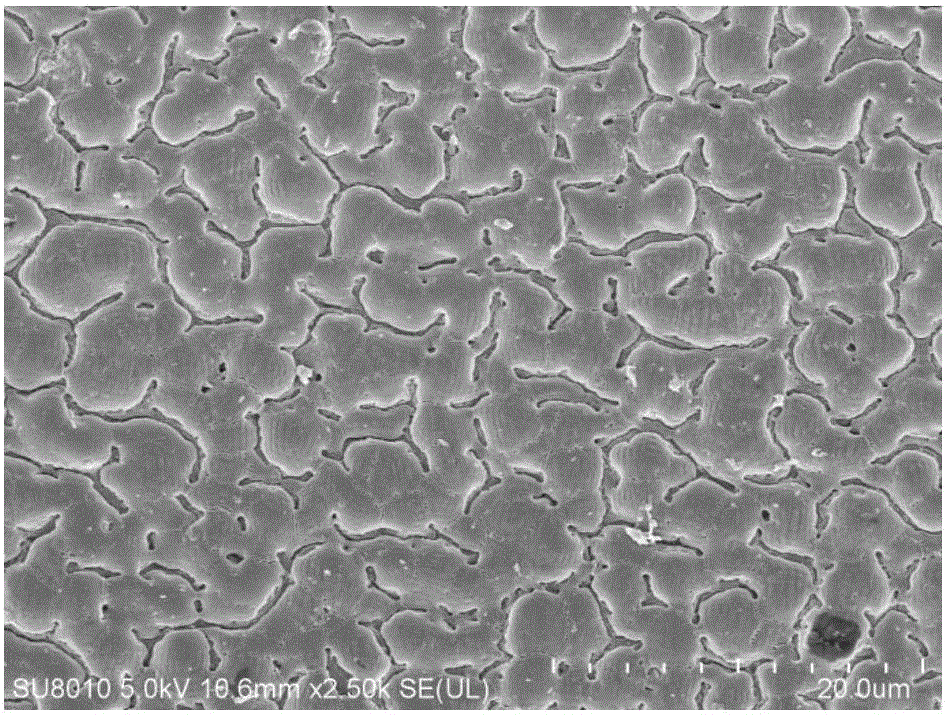

[0024] Move the mobile stage in step 4) of Example 1 along the horizontal direction, and change the speed to 0.01mm / s to obtain a surface composite structure in which microstructures below 5 μm are combined with nanostructures below 1 μm, refer to image 3 , the edges and corners of the surface of the composite structure are initially obvious.

Embodiment 3

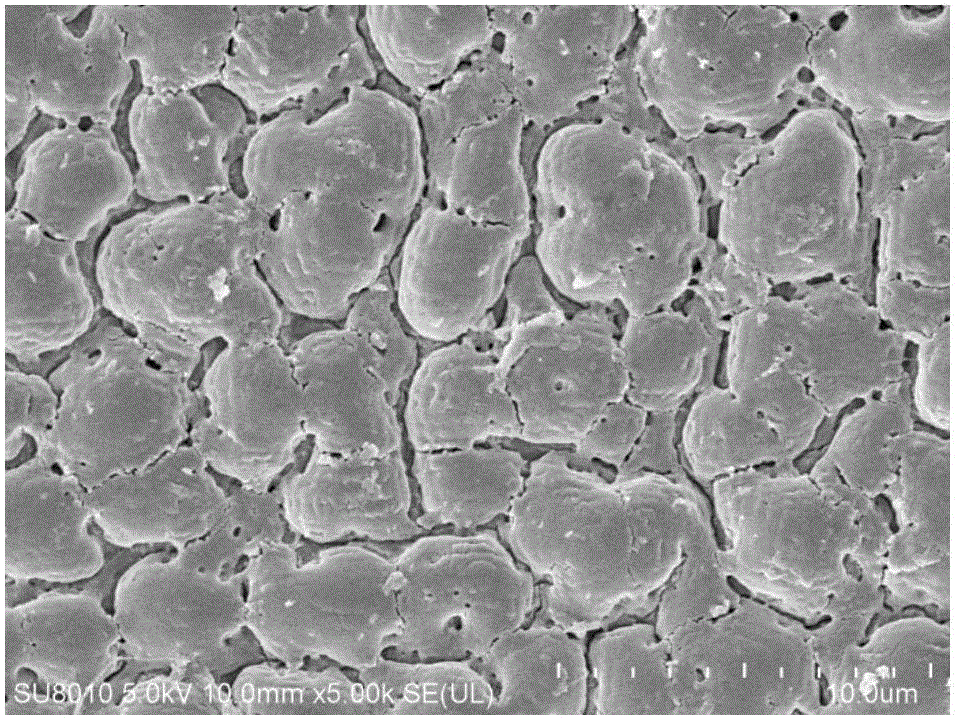

[0026] Move the mobile stage in the step 4) of Example 1 along the horizontal direction, and the speed becomes 0.004mm / s to obtain a surface composite structure in which microstructures below 5 μm are combined with nanostructures below 1 μm, refer to Figure 4 , the surface of the composite structure is angular.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com