Method and device for improving corrosion resistance of stainless steel weld seams

A corrosion-resistant, stainless steel technology, applied in metal material coating process, coating and other directions, to achieve the effect of improving corrosion resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

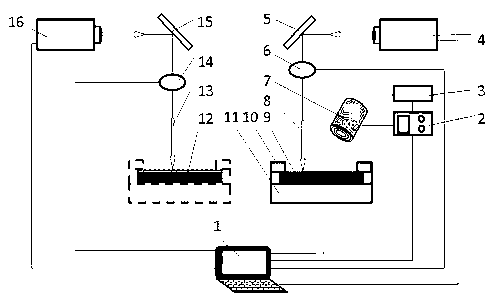

[0030] The device of the present invention is as figure 1 , including laser melting injection unit, laser shock strengthening unit, computer control system and numerical control working system. The laser melting injection unit includes a carbon dioxide laser 4, a total reflection mirror 5, a transmission mirror 6, an argon protection device 3, a powder feeder 2 and a powder feeding nozzle 7; the laser shock strengthening unit includes a nanosecond laser 16, a total reflection mirror 15, a transmission Mirror 14; the CNC work system includes a three-axis CNC workbench 11 and a clamping device 10.

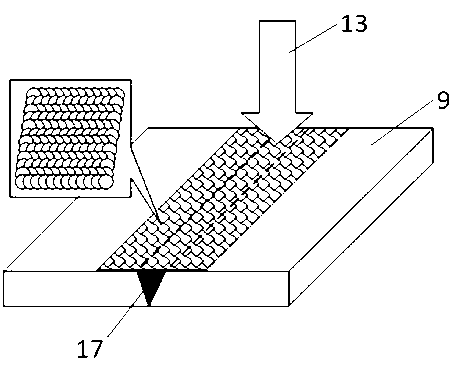

[0031] The computer control device 1 controls the three-axis numerical control workbench 11, the nanosecond laser 3, the powder feeder and the carbon dioxide laser 12, and completes the injection of metal corrosion inhibitor particles and laser shock strengthening into the stainless steel weld respectively. The spot diameters of the continuous laser 8 and the pulsed laser 13 are ad...

Embodiment 2

[0035] The specific steps for implementing a method for improving the corrosion resistance of stainless steel welds are:

[0036] (1) Firstly, the surface of the AISI304 stainless steel weldment 9 to be treated is ground and polished to reach a surface roughness of Ra1.6, then cleaned and dried with acetone, and the treated stainless steel weldment 9 is placed on a three-axis CNC work on stage 11;

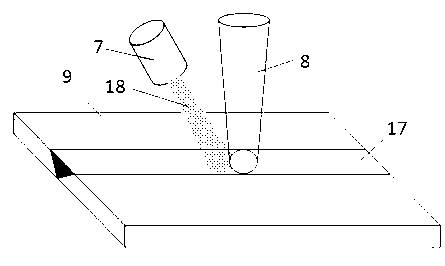

[0037] (2) Select 20 nm potassium magnesium phosphate particles, put the potassium magnesium phosphate particles into the powder feeder 2, adjust the angle between the powder feed nozzle 7 and the surface normal of the stainless steel weldment 9, so that the continuous laser 8 is on the stainless steel weld The distance between the position of the light spot and the position where the potassium magnesium phosphate particles are injected into the molten pool is 5 mm;

[0038] (3) DL-HL-T5000 carbon dioxide laser 4 is used, the preset power is 3 kW, and the laser mode is TEM 00 , th...

Embodiment 3

[0043] The parameters of the nanosecond laser 16 in Example 2 are changed to a pulse energy of 10 J, a spot radius of 3 mm, a pulse width of 20 ns and a repetition rate of 15 Hz; parameters of the carbon dioxide laser 4 are changed to a spot diameter of 3 mm, and a laser power of 5KW, the scanning speed is 0.6 m / min and the powder feeding speed is 100 mg / s; the metal corrosion inhibitor particles are 35 nm sodium magnesium phosphate; the thickness of the anti-corrosion layer after polishing is 0.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com