Nanosecond laser welding method and nanosecond laser welding system for metal sheets

A nanosecond laser welding and metal sheet technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large thermal deformation due to thermal influence, poor welding strength, and different fusion physical properties, etc., and achieve high peak power , small pulse width, strong bite force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

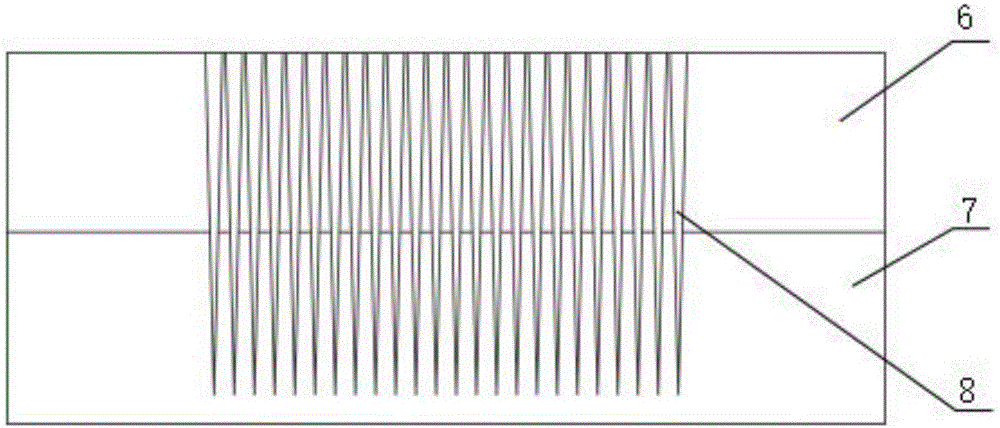

[0023] A method of performing nanosecond laser welding on thin metal plates. The laser beam emitted by the nanosecond laser 1 is emitted to the stacked metal thin plates to be welded to form welding points. Each laser beam penetrates the upper metal thin plate 6 and enters the lower layer. The thin metal plate 7 forms a fine soldering point 8, and the soldering point is formed by a plurality of fine soldering points 8 densely arranged.

[0024] The laser beam is scanned by the galvanometer to scan the deflection device 3 to form a laser beam of a certain size. By controlling the deflection angle of the galvanometer lens, the laser beam can be controlled to emit to the stacked metal sheets to be welded according to a specific trajectory. Several tiny solder joints 8 form nail-shaped occlusal areas at the solder joints. Specifically, each tiny solder joint 8 is filled with gasification or liquefaction of the materials of the upper layer metal sheet 6 and the lower layer metal she...

Embodiment 2

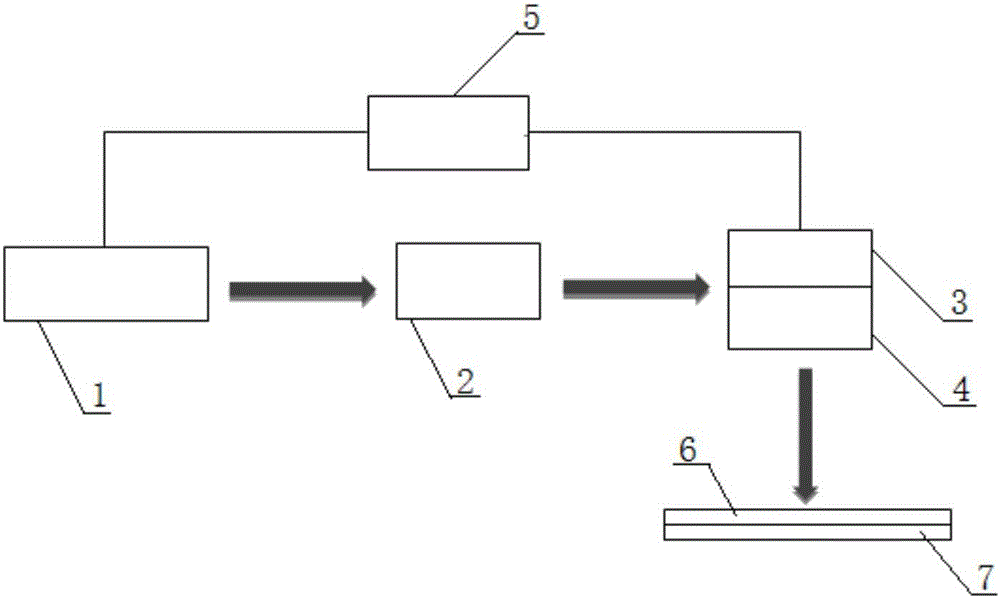

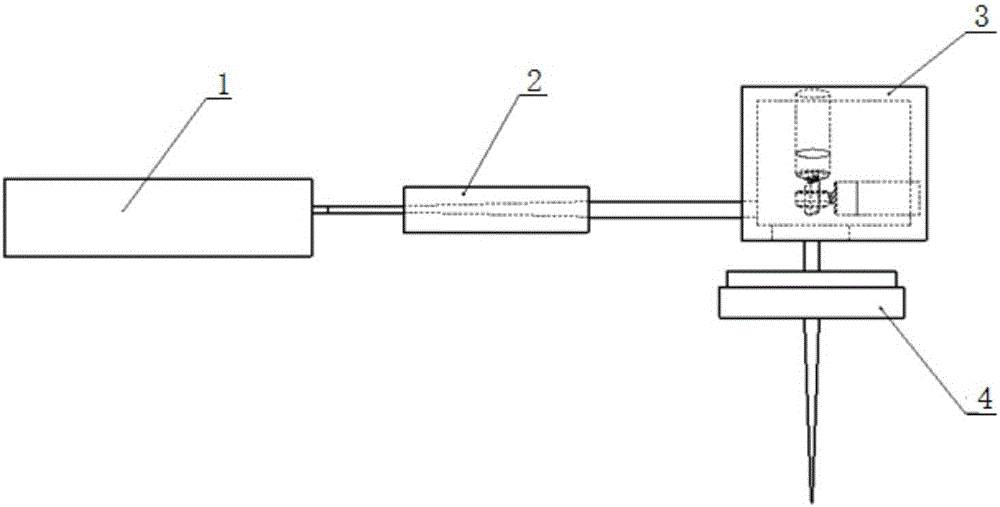

[0032] A system for nanosecond laser welding of thin metal plates, including a nanosecond laser 1, a beam expander 2, a galvanometer scanning deflection device 3, and a beam focusing lens 4 arranged sequentially through a bracket, the laser beam emitted by the nanosecond laser 1 passes through The beam expander 2, the galvanometer scanning deflection device 3, and the beam focusing lens 4 emit to several metal sheets to be welded, and the emission control end of the nanosecond laser 1 and the deflection control end of the galvanometer scanning deflection device 3 are respectively connected to the control The two signal output terminals of device 5.

[0033] The nanosecond laser 1, beam expander 2, galvanometer scanning deflection device 3, and beam focusing lens 4 are respectively arranged on the workbench through a movable bracket, and the beam focusing lens 4 and the galvanometer scanning deflection device 3 are connected by a threaded structure connected.

[0034] Several ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com