Nanosecond-picosecond-femtosecond laser technology based metal product 3D printing method

A femtosecond laser and metal product technology, applied in the field of 3D printing of metal products, can solve the problems of destroying the artwork itself, cumbersome cleaning process, and low 3D printing accuracy, achieving high efficiency, improving printing efficiency, and precise size control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

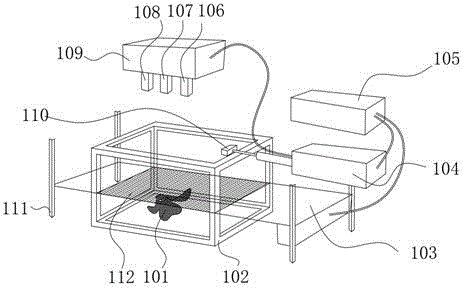

[0028] See figure 1 , the printing system of the present invention includes a workbench (103) on a fixed bracket (102), a CCD-assisted femtosecond laser locator (104), a control center (105), a laser scanning mirror (110), an integrated fiber laser (109), track (111) and real-time monitoring system (not shown in the figure), workbench (103), CCD-based femtosecond laser locator (104), laser scanning mirror (110), integrated fiber laser (109) and the real-time monitoring system are connected with the control center (105) signal; the raw material (112) is placed on the workbench (103), and the movement track of the workbench (103) is restricted by the track (111), that is, it can only be along The track (111) moves up and down, and the control center (105) controls the movement of the workbench (103) through a motion mechanism. Integrated fiber laser (109) including laser controller, nanosecond laser probe (108), picosecond laser probe (107) and femtosecond laser probe (106), na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com