Light beam-rotating galvanometer-scanning focused processing system

A galvanometer scanning and processing system technology, which is applied in the fields of laser processing, laser milling, cutting and drilling, can solve the problems of high cost, slow acceleration and deceleration, and complicated control of two-dimensional work platform, and achieves low cost, addition and subtraction. Fast, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

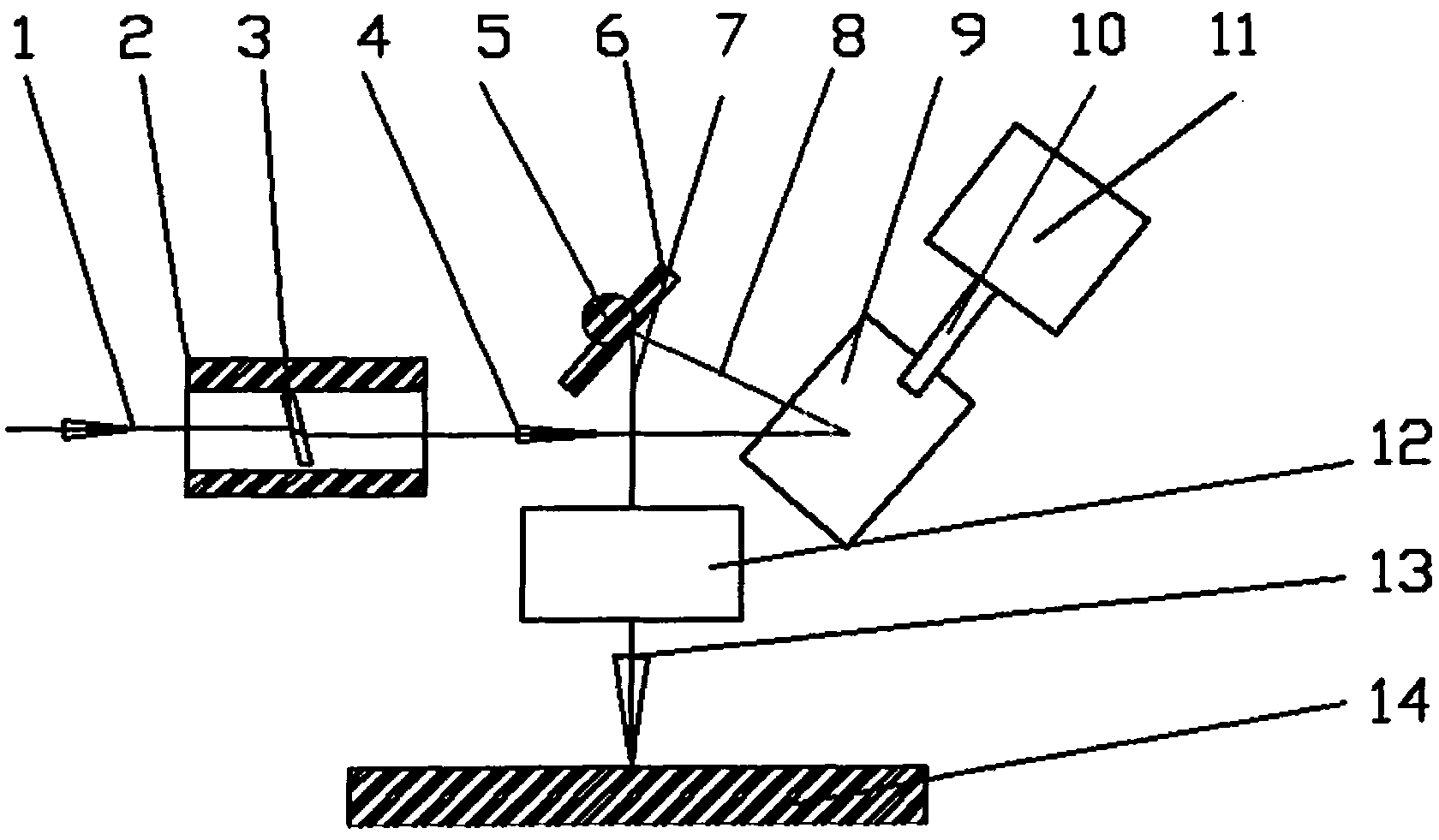

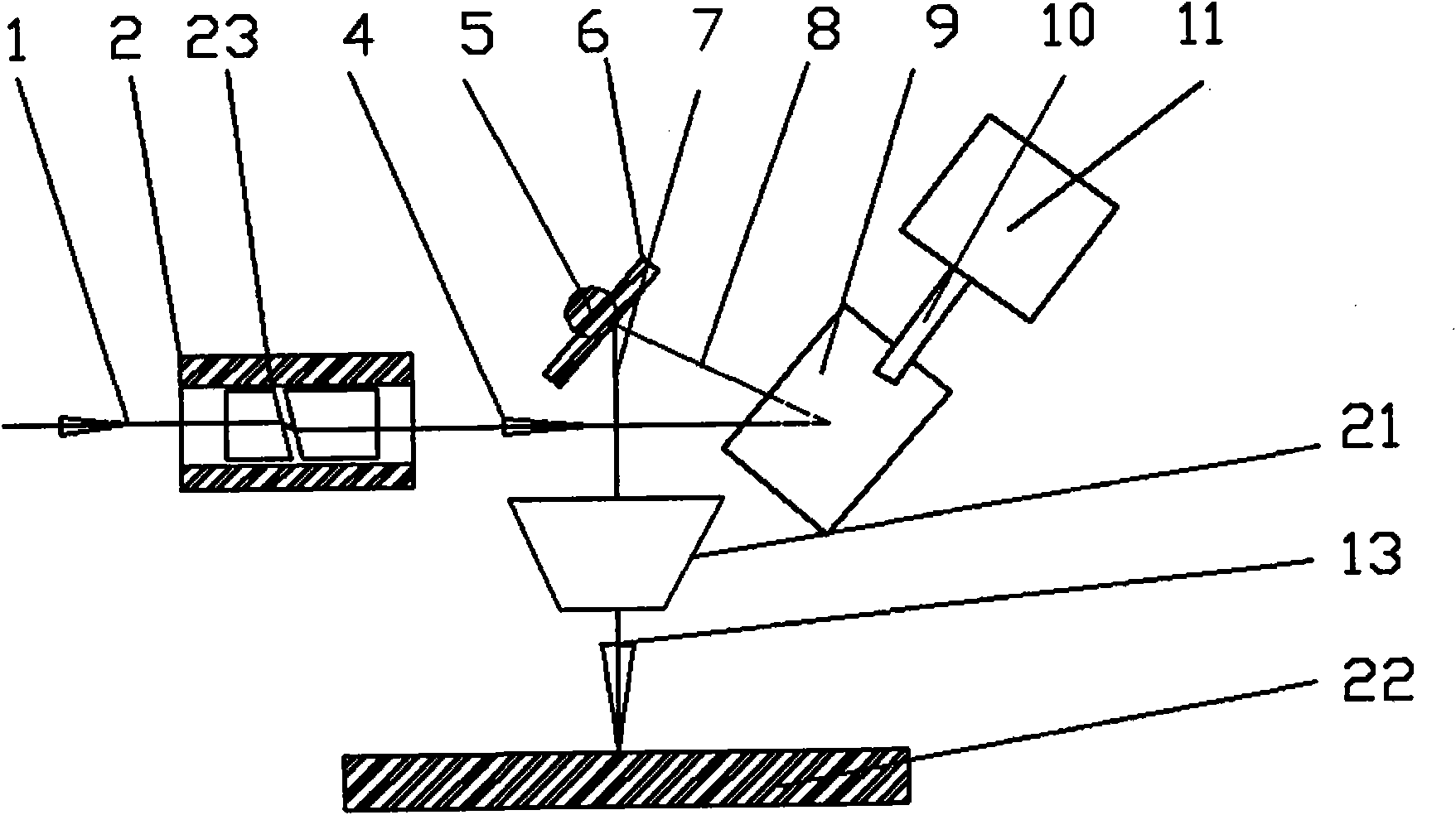

[0017] See figure 1 As shown, this is an embodiment of a beam rotating galvanometer scanning focusing processing system of the present invention, and the material to be processed is a stainless steel sheet with a thickness of 1 mm. 1 is the incident beam expansion collimated beam, the beam diameter is 5 mm, 3 is the inclined flat glass, the thickness is 1 mm, and the inclination angle is 18 degrees, 4 is the collimated output beam, the collimated beam 1 and 4 are parallel, and the distance is 100 microns, and 2 is The beam rotator barrel, 3 is fixed inside 2, and 2 is fixed inside the high-speed hollow motor, which can rotate at high speed, so that the beam 4 actually rotates at high speed around the centerline of the beam 1 as the axis, and the rotation diameter is 200 microns. 9 is the first mirror of the vibrating mirror, which is clamped by the main shaft 10 of the vibrating mirror motor 11, and 4 is reflected by 9 to output a collimated beam 8. When the beam 4 rotates in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com