Method and device of laser impact and thermal spraying composite coating preparation

A laser shock and thermal spraying technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problem of wear resistance and fretting resistance performance that cannot meet the harsh environment of engineering, fracture and failure of structural metal parts, etc. Reduced engine efficiency and other problems, to achieve the effects of small plastic deformation, reduced porosity, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

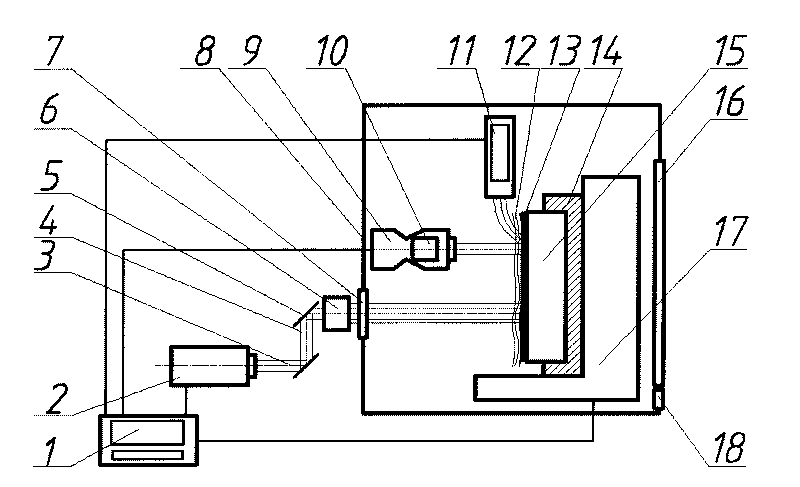

[0031] The following is an example of coating prepared by combining laser shock and thermal spraying. Using thermal spraying equipment to spray NiCrBSiC (Ni60AA) powder on the surface of quenched 45 steel, the composition is Cr-18.09, Si-4.84, Fe-15.63, B-3.6, C -0.6, Ni balance (wt.%), the sprayed powder is round particles. The Nd: glass with a repetition rate of 0.5 Hz, a spot diameter of 3 mm, a pulse energy of 15 J, a laser wavelength of 1054 nm, and a laser pulse width of 20 ns are used to perform impact strengthening treatment on the metal substrate.

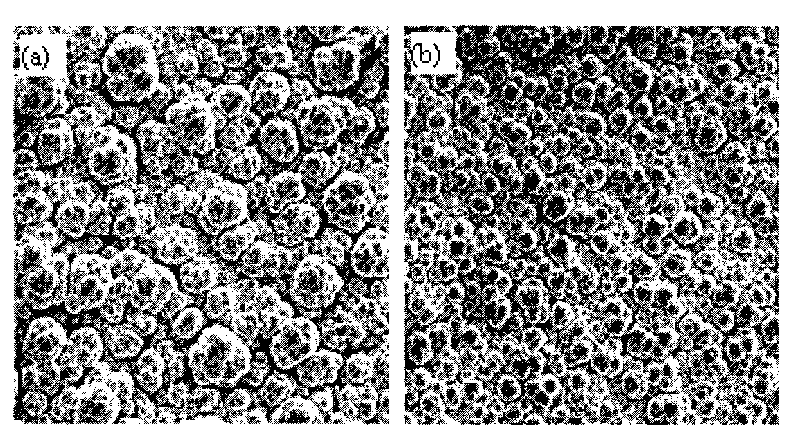

[0032] figure 2 Comparison of particle morphology of coatings prepared for laser shock and thermal spraying and thermal spraying coatings. (a) is the morphology of coating particles after thermal spraying; (b) is the morphology of coating particles prepared by laser shock and thermal spraying. It can be seen that the diameter of coating particles after thermal spraying is about 30um, and the diameter of coating particles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com