Preparation method and preparation device of high-depth-diameter ratio micropores

A technology with high aspect ratio and preparation device, applied in the application field of laser technology, can solve the problems of inability to obtain wide application, limited depth of micropores, difficult to discharge residues, etc., and achieve compact structure layout, increased depth of micropores, and optimized auxiliary function. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

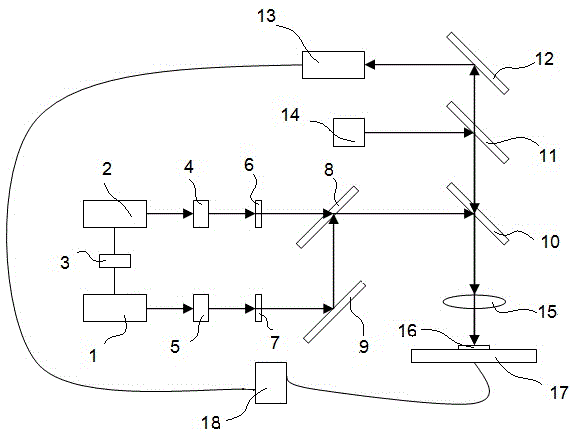

[0022] Below we will further describe the present invention in conjunction with the embodiments and accompanying drawings in order to understand its structural composition and working process more clearly, but this should not limit the protection scope of the present invention.

[0023] The patent of the present invention first pointed out a preparation method of micropores with high aspect ratio. The preparation method is to prepare micropores with high aspect ratio by means of double pulse combination. The laser light source contains two kinds of laser combinations with different pulse widths. A digital signal delay generator is used to control the time when the double pulse combination reaches the sample, and the laser pulses of the two lasers are focused on the sample through the combination of optical components, and the sample is directly laser etched to prepare micropores with high aspect ratio.

[0024] In the method for preparing micropores with a high depth-to-diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com