Thermally driven pulse tube refrigerator system

A technology of pulse tube refrigerator and thermal drive, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of increasing system complexity, reducing reliability, and large casing vibration, so as to reduce system complexity, Improve reliability, reduce process difficulty and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

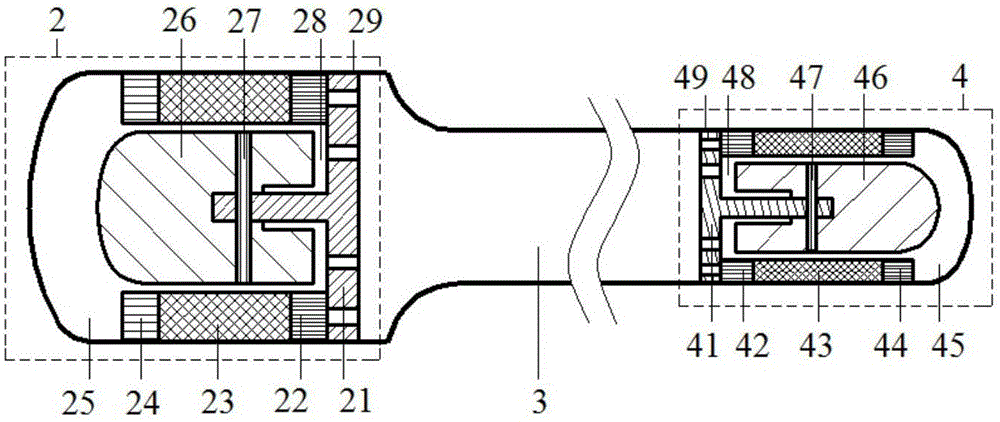

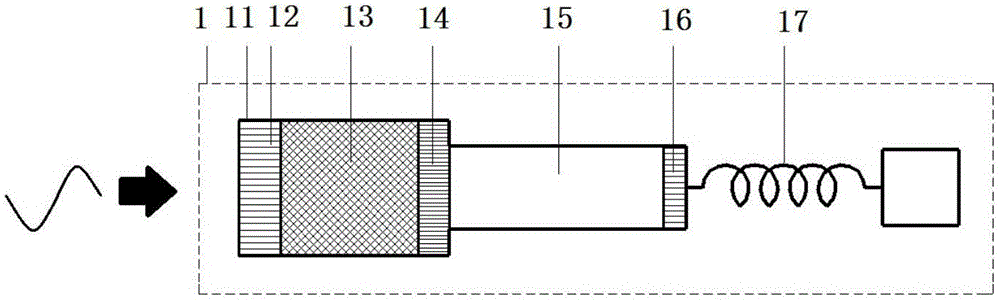

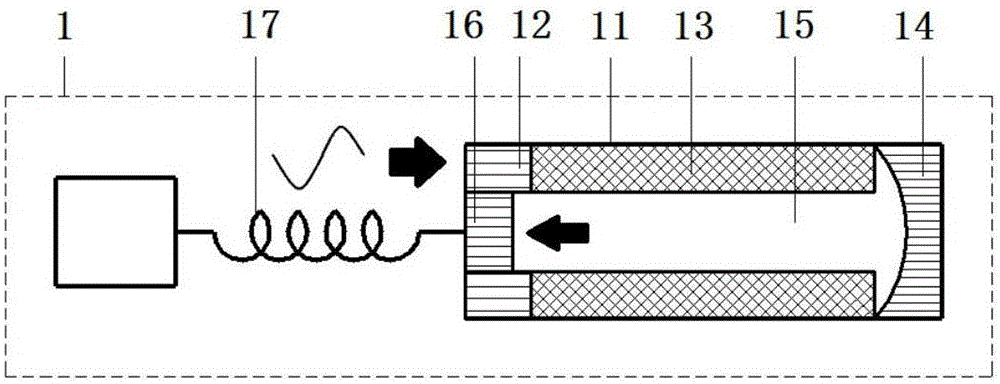

[0042] Figure 4 It is a structural schematic diagram of the heat-driven pulse tube refrigerator system (Embodiment 1) of the present invention. like Figure 4 As shown, the free-piston Stirling engine 2, the acoustic resonance tube 3 and the pulse tube refrigerator 1 of the heat-driven pulse tube refrigerator system of the present embodiment are all one; the acoustic resonance tube 3 is a pipeline of equal or reduced diameter, The free-piston Stirling engine 2 and the pulse tube refrigerator 1 are respectively connected to both sides of the acoustic resonance tube 3;

[0043] The free piston Stirling engine 2 includes:

[0044] The engine block 29 communicated with one side of the acoustic resonance tube 3;

[0045] Be fixed on the engine fixed base 21 near the side of the acoustic resonance tube 3 in the engine block 29;

[0046] The engine annular heat release end heat exchanger 22, the engine annular heat regenerator 23 and the engine annular heat absorption end heat e...

Embodiment 2

[0075] Figure 5 It is a structural schematic diagram of a heat-driven pulse tube refrigerator system according to Embodiment 2 of the present invention; Figure 5 It can be seen that the heat-driven pulse tube refrigerator system of this embodiment is composed of two free-piston Stirling engines 2 and one pulse tube refrigerator 1 located on both sides of the acoustic resonance tube 3; the two free-piston Stirling engines 2 are Arranged oppositely; the engine fixed base 21 of the two free-piston Stirling engines 2 and the acoustic resonance tube 3 are connected by a three-way tube.

[0076]The working principle of embodiment 2 is the same as that of embodiment 1, the difference is that there are two free-piston Stirling engines in embodiment 2, and the structural parameters are exactly the same, and they are arranged oppositely; as Figure 5 As shown, two free-piston Stirling engines 2 are on the same axis, and the engine fixed base 21 is connected by a tee pipe. This arrang...

Embodiment 3

[0078] Image 6 It is a structural schematic diagram of the coupled opposed arrangement of the heat-driven pulse tube refrigerator system in Embodiment 3 of the present invention; as Image 6 As shown, the two pulse tube refrigerators 1 and the acoustic resonance tube 3 are independent, while the two free-piston Stirling engines 2 share the same expansion chamber, and the coupled opposed arrangement system is symmetrically arranged along the axial direction.

[0079] The working principle of embodiment 3 is the same as that of embodiment 1, the difference is that embodiment 3 adopts two sets of systems with identical structural parameters arranged symmetrically along the axial direction; as Image 6 As shown, the engines of the two systems share the same engine expansion chamber, which can make the motion phase difference of the two engine ejectors 180°, thereby completely canceling the body vibration of the two systems. Compared with embodiment 1, embodiment 3 has less vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com