Dual-way air-intake vascular refrigeator with corrugated pipe direct-current blocking-up structure

A pulse tube refrigerator and bellows technology, which is applied in gas cycle refrigerators, refrigerators, refrigeration and liquefaction, etc., can solve problems such as hindering the practical process of pulse tube refrigerators, unstable operation status of refrigerators, affecting refrigeration temperature, etc. problems, to achieve the effect of solving operational stability problems, avoiding inconvenience, and eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

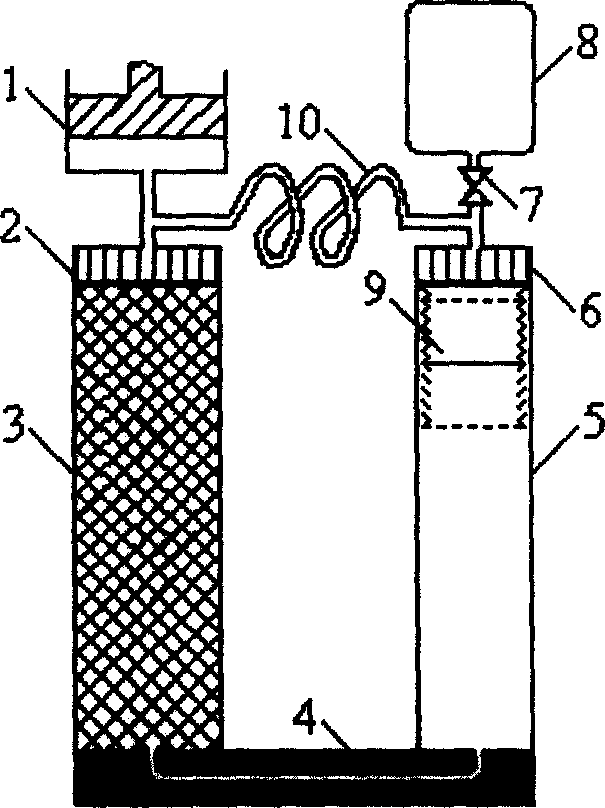

[0009] As shown in the attached figure, the two-way inlet pulse tube refrigerator with bellows DC blocking structure includes a compressor 1, a heat exchanger 2 at the hot end of a regenerator, a regenerator 3, a cold head 4, The pulse tube 5, the heat exchanger 6 at the hot end of the pulse tube, the small hole valve 7, and the gas storehouse 8 are provided with a bellows DC blocking structure 9 at the hot end of the pulse tube 5. A capillary 10 is provided between the hot ends of 5 .

[0010] The bellows DC blocking structure 9 is a section of bellows with one end closed, located in the vessel, arranged coaxially with the vessel, its open end close to the heat exchanger at the hot end of the vessel, and welded to the inner wall of the vessel, The inner cavity of the bellows communicates with the heat exchanger at the hot end of the pulse tube.

[0011] When the two-way inlet pulse tube refrigerator with bellows DC blocking structure is running, the pressure wave generated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com