Stirling type pulse tube refrigerator of phasing device with dynamic quality module

A technology of pulse tube refrigerator and dynamic mass, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of small dissipation of sound power, large loss of viscous resistance, and failure to provide the best phase angle, etc., to achieve refrigeration Efficiency improvement, reliability and life improvement, vibration reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

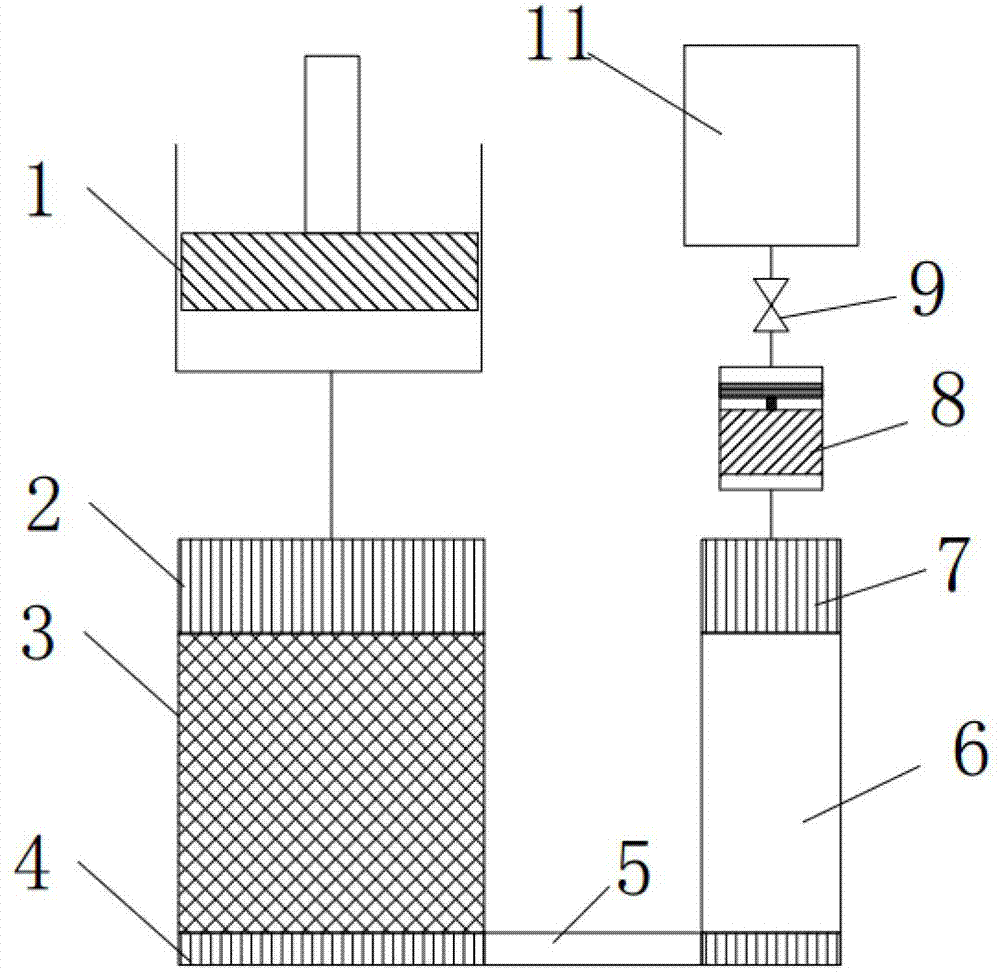

[0027] The Stirling-type pulse tube refrigerator driving the mass module phase modulation device of the present embodiment 1, such as figure 1 As shown, it consists of a pressure wave generator 1, a room temperature heat exchanger 2, a regenerator 3, a cold end heat exchanger 4, a cold head connecting pipe 5, a pulse tube 6, and a pulse tube hot end heat exchanger connected in sequence. 7 and a phase modulation device; the phase modulation device is connected to the heat exchanger 7 at the hot end of the pulse tube through a connecting pipe; the pressure wave generator 1 is connected to the heat exchanger 2 at the room temperature end through a connecting pipe; figure 2 As shown, the phasing device in this embodiment is a mass module phasing device, and the mass module phasing device includes a dynamic mass module 8, a valve 9 and a gas storage 11 connected to the heat exchanger 7 at the hot end of the pulse tube in sequence; figure 2 As shown, the moving mass module 8 is co...

Embodiment 2

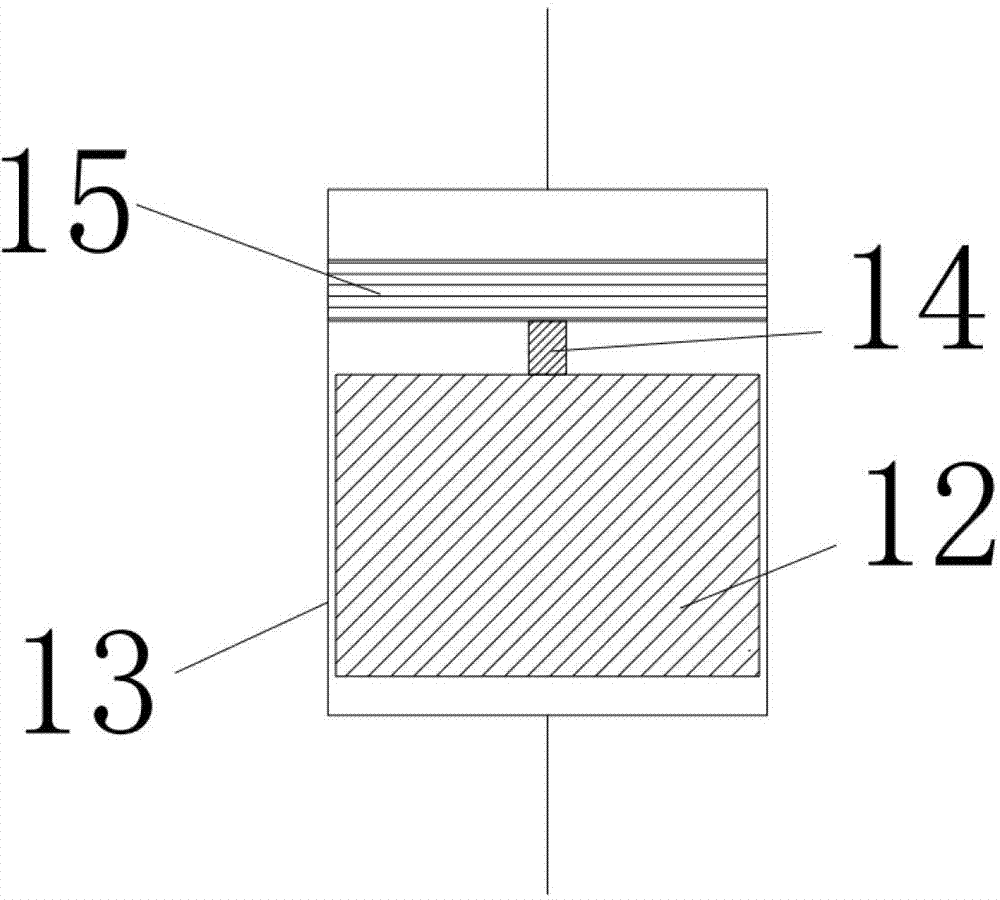

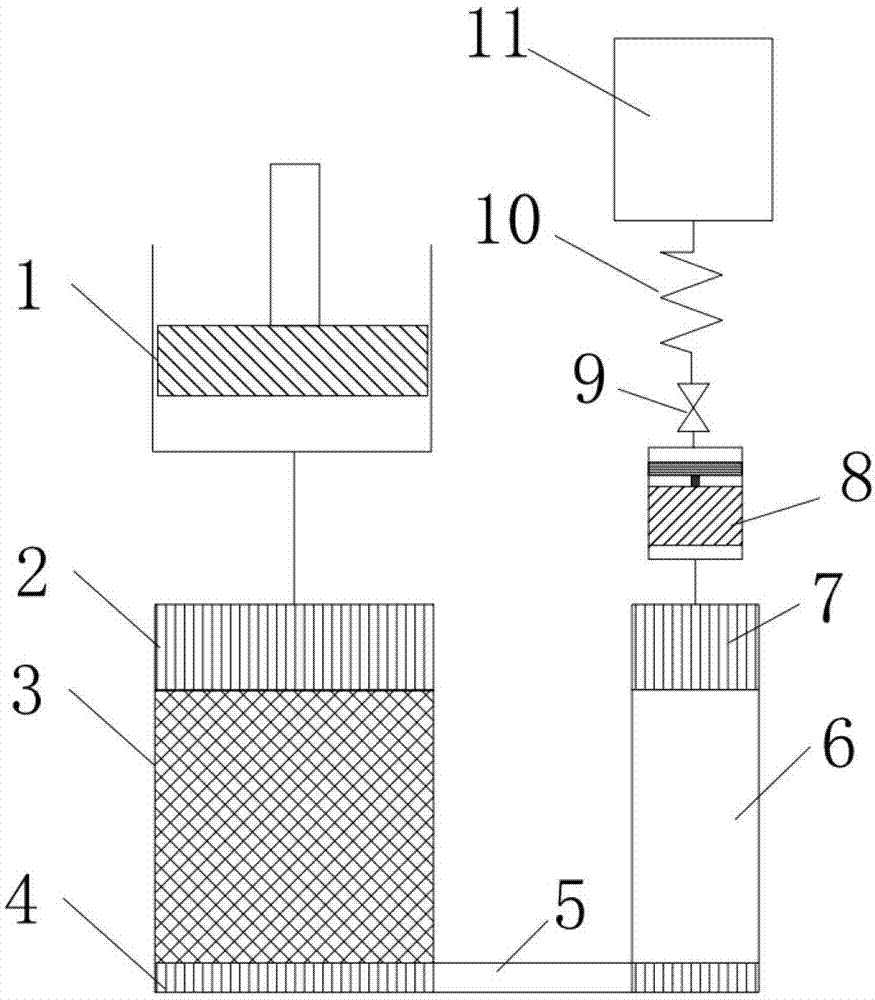

[0029] The Stirling type pulse tube refrigerator that drives the mass module phase modulation device of embodiment 2, such as image 3 As shown, the phasing device for driving mass modules also includes an inertia tube 10 installed between the valve 9 and the gas storage 11 . The rest are the same as the examples. The moving mass piston 12 is cantilever supported by the supporting leaf spring 15 and the central connecting rod 14, and can perform reciprocating motion under the drive of pressure fluctuations; a gap seal is used between the moving mass piston 12 and the cylinder wall of the cylinder 13 to isolate the two side gas, while the surface of the moving mass piston 12 is coated with a self-lubricating material to reduce friction.

Embodiment 3

[0031] The Stirling type pulse tube refrigerator driving the quality module phase modulation device of embodiment 3, such as Figure 4As shown, it consists of a pressure wave generator 1, a room temperature heat exchanger 2, a regenerator 3, a cold end heat exchanger 4, a cold head connecting pipe 5, a pulse tube 6, and a pulse tube hot end heat exchanger connected in sequence. 7 and a phasing device; the phasing device is connected to the pulse tube hot end heat exchanger 7 through a connecting pipe; the pressure wave generator 1 is connected to the room temperature heat exchanger 2 through a connecting pipe; the phasing device To drive the mass module phasing device, the phasing device is to drive the mass module phasing device, the driving mass module phasing device includes a dynamic mass module 8, an inertial tube 10 and a gas tube connected to the pulse tube hot end heat exchanger 7 in sequence. library 11; the moving mass module 8 is composed of a cylinder 13, a moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com