Low temperature scanning probe microscope system based on pulsatron refrigeration technology

A technology of pulse tube refrigeration and microscope system, which is applied in the direction of scanning probe microscopy, scanning probe technology, instrument parts, etc., can solve the problems that limit the application of pulse tube refrigeration technology, and achieve the reduction of operating costs, operation and Simple maintenance and saving helium resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

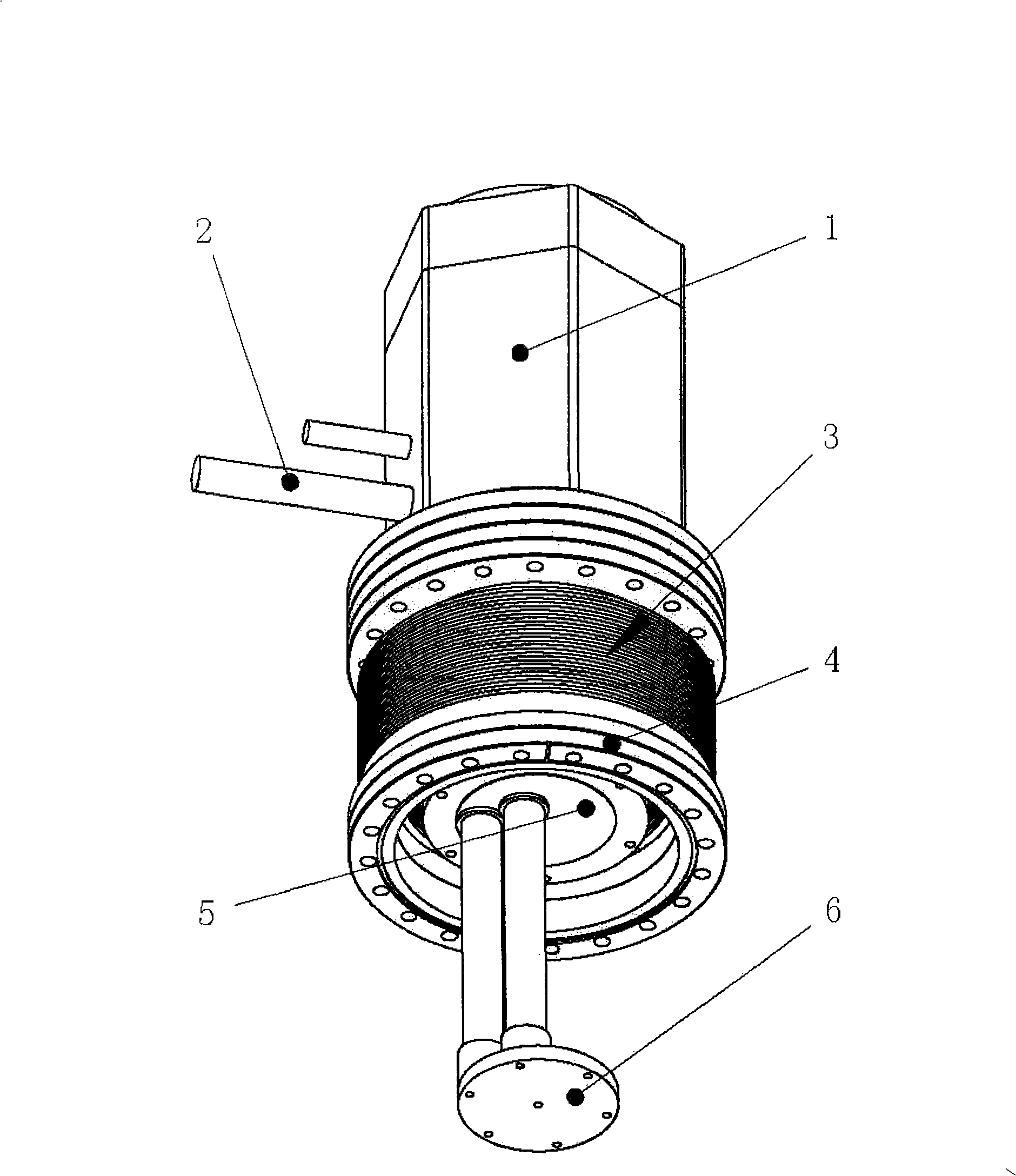

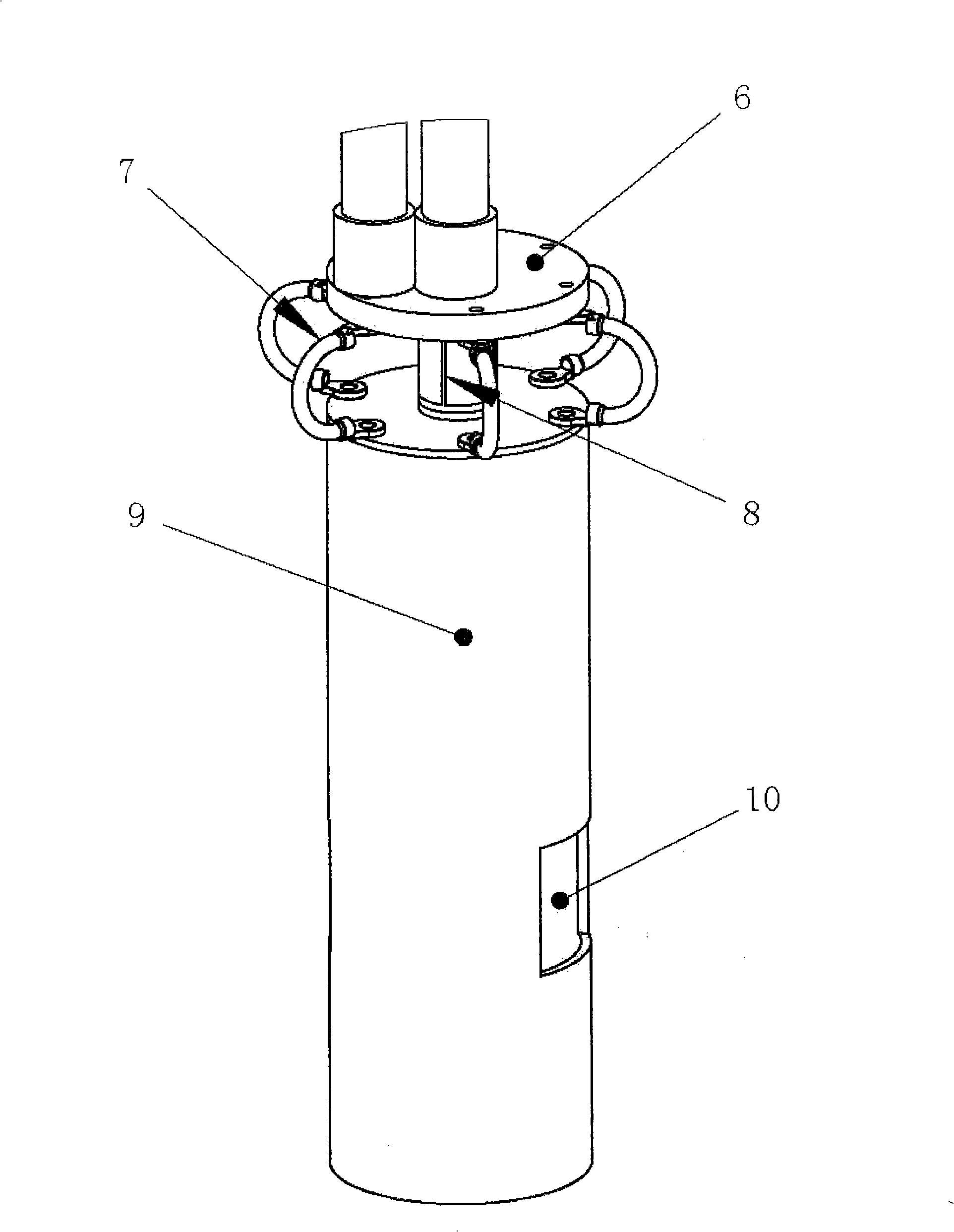

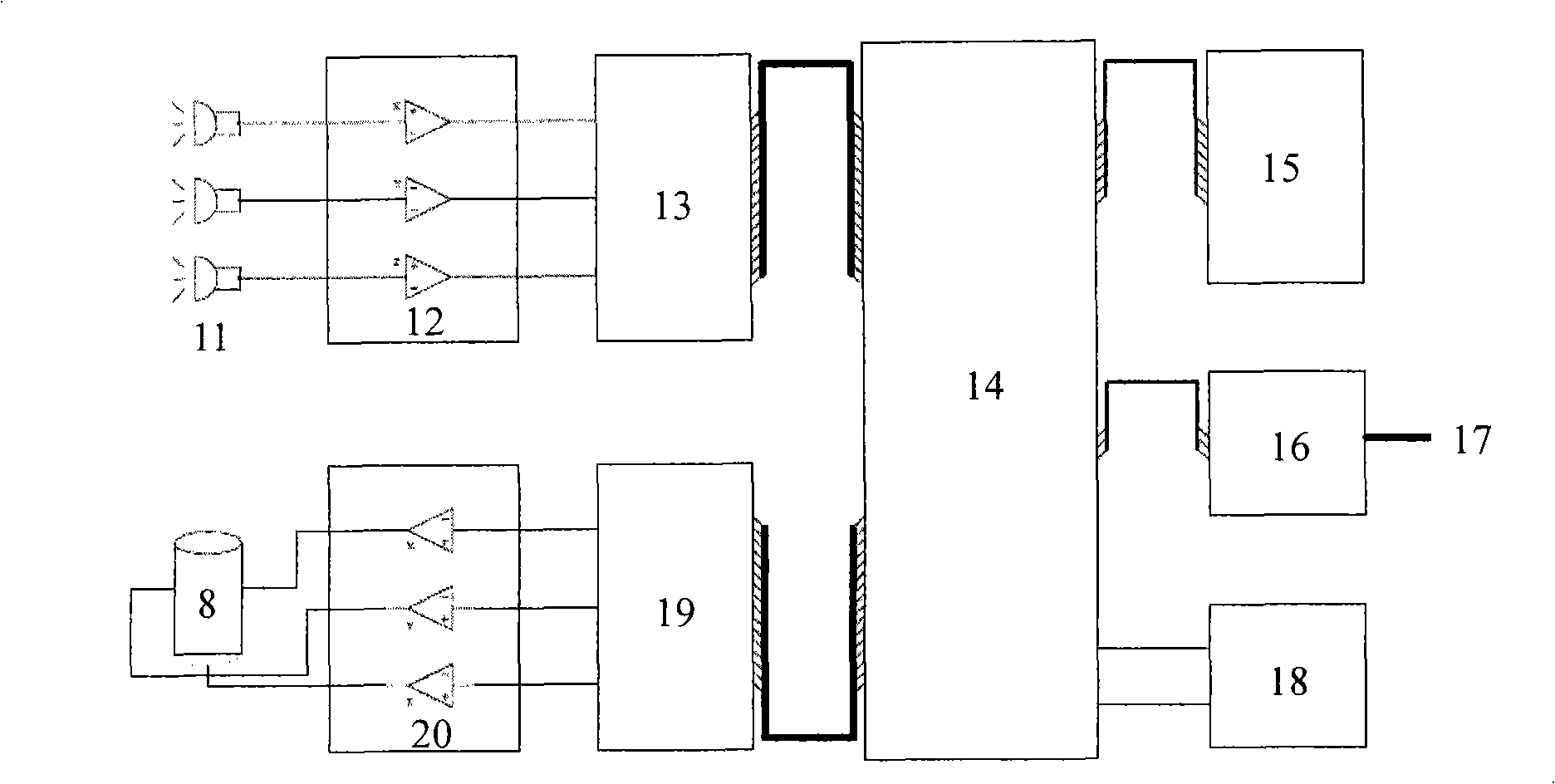

[0030] According to the vibration source and frequency characteristics of the pulse tube refrigerator, the invention adopts multi-stage active / passive vibration reduction methods such as bellows, piezoelectric ceramic tubes and springs, so that the pulse tube refrigeration technology can be applied to the scanning probe microscope system, Thereby, the operating cost of the system is greatly reduced, the operation and maintenance process of the system is simplified, and the operation of the system is no longer limited by the low temperature maintenance time.

[0031] In order to achieve effective vibration isolation, the present invention adopts a combination of two-stage passive vibration reduction and one-stage active vibration reduction. The bellows installed between the refrigeration head and the main vacuum chamber of the system is the first level of passive vibration isolation to achieve the overall vibration isolation of the system.

[0032] Further, the cooling head sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com