Patents

Literature

118results about How to "Suppress relative displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

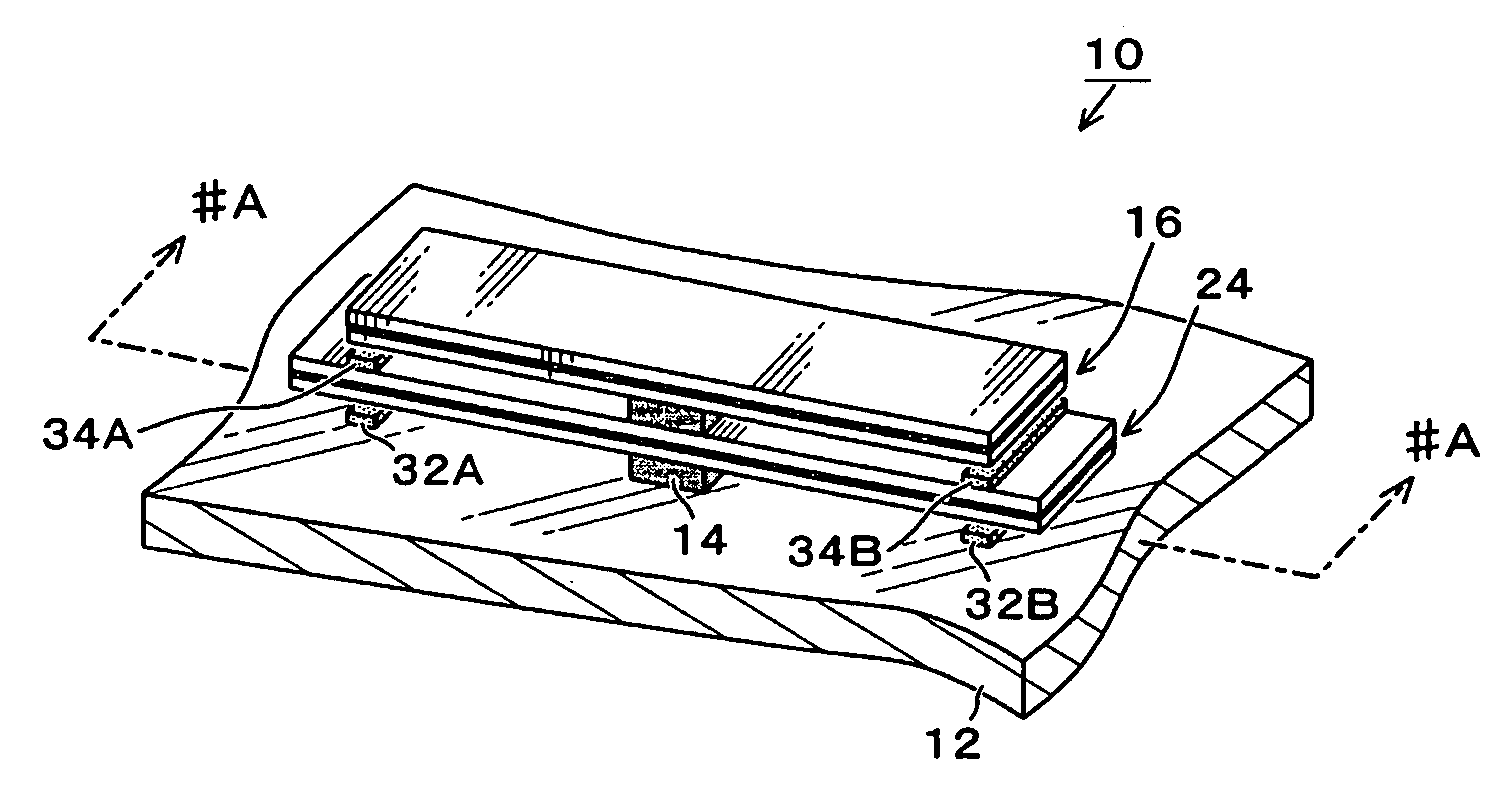

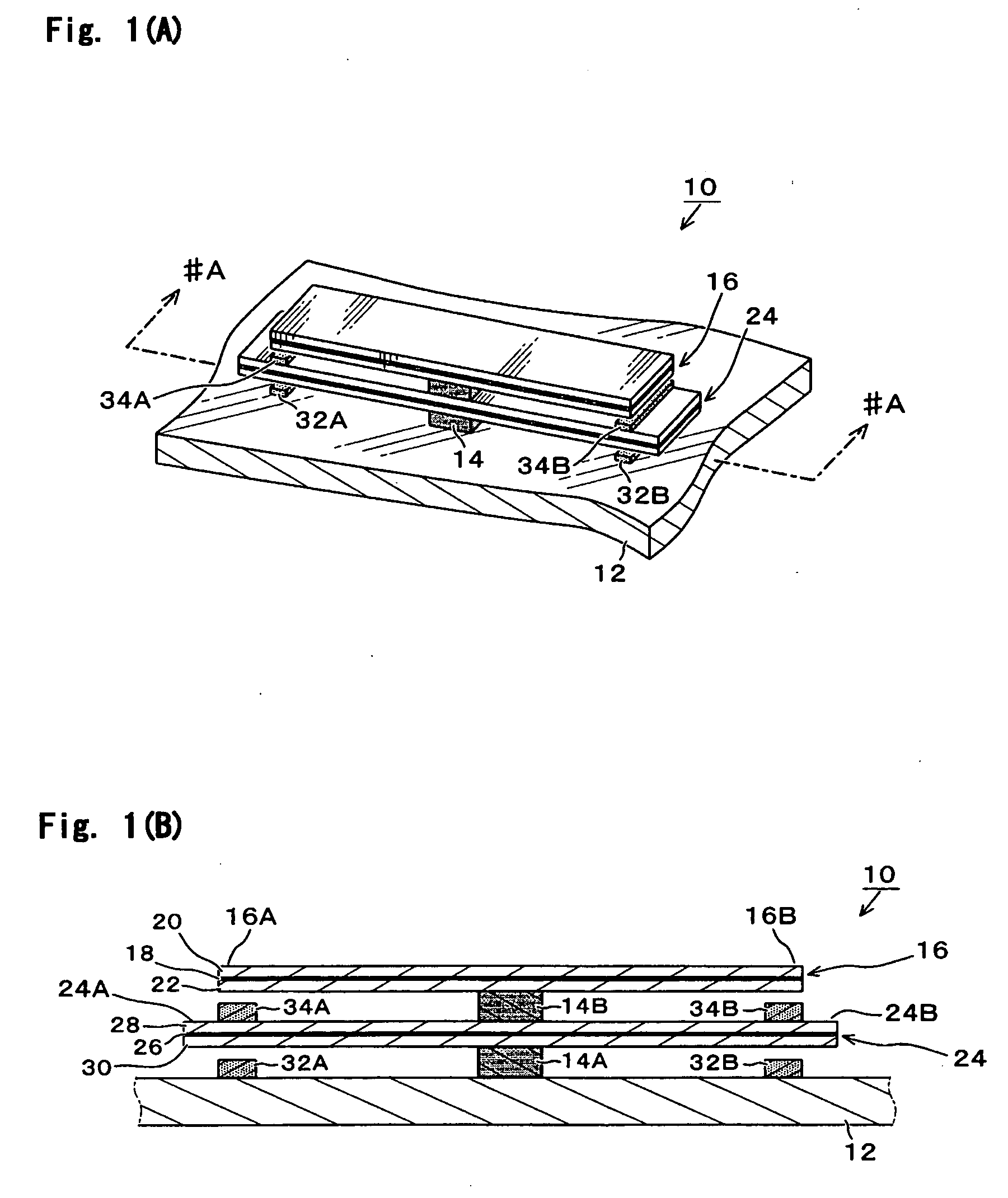

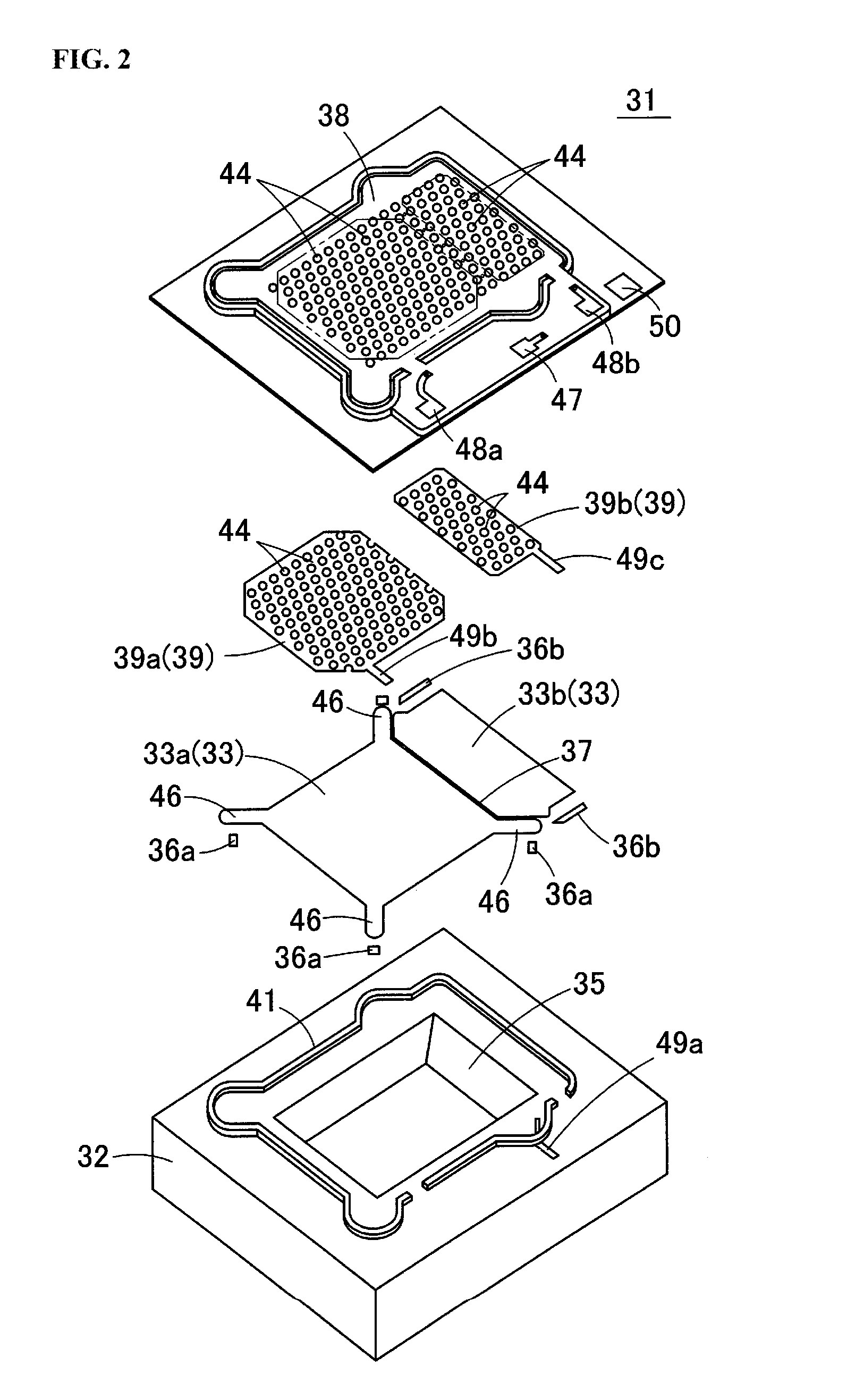

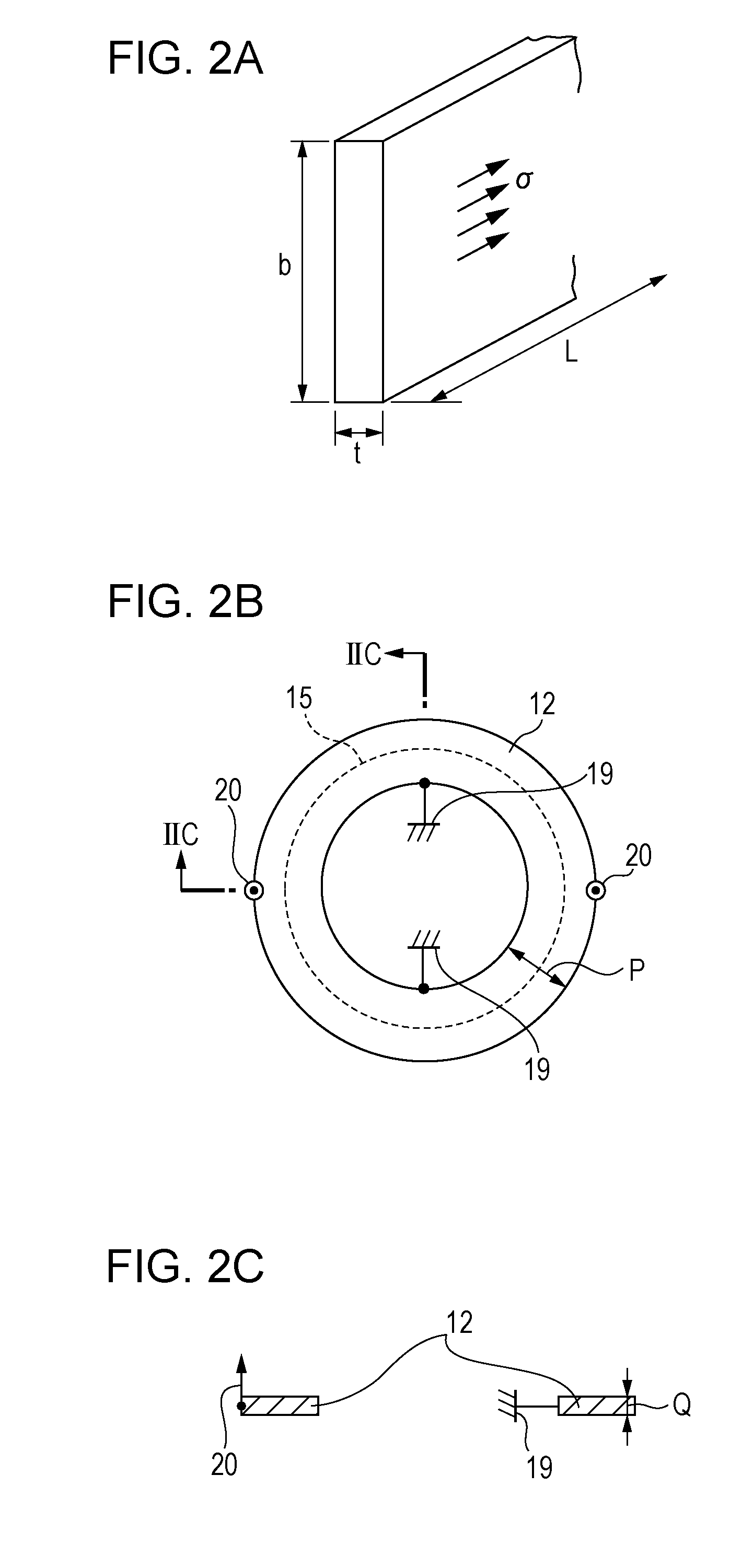

Piezoelectric vibrator

InactiveUS20050023937A1Improve seismic performanceImproved mountabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersEngineeringYoung's modulus

A piezoelectric vibrator having excellent shock resistance and high reliability is offered. The centers of first and second piezoelectric vibrating plates are supported by pillars on a main surface of an enclosure and nearly or substantially parallel to the main surface of the enclosure. Spacers having a Young's modulus of less than 2 GPa are mounted on both end sides of the second piezoelectric vibrating plate to prevent contact between the vibrating plates, thus preventing damage. Other spacers are mounted on the main surface of the enclosure in positions corresponding to the first-mentioned spacers to prevent contact with the main surface of the enclosure, thus preventing damage to the second piezoelectric vibrating plate.

Owner:TAIYO YUDEN KK

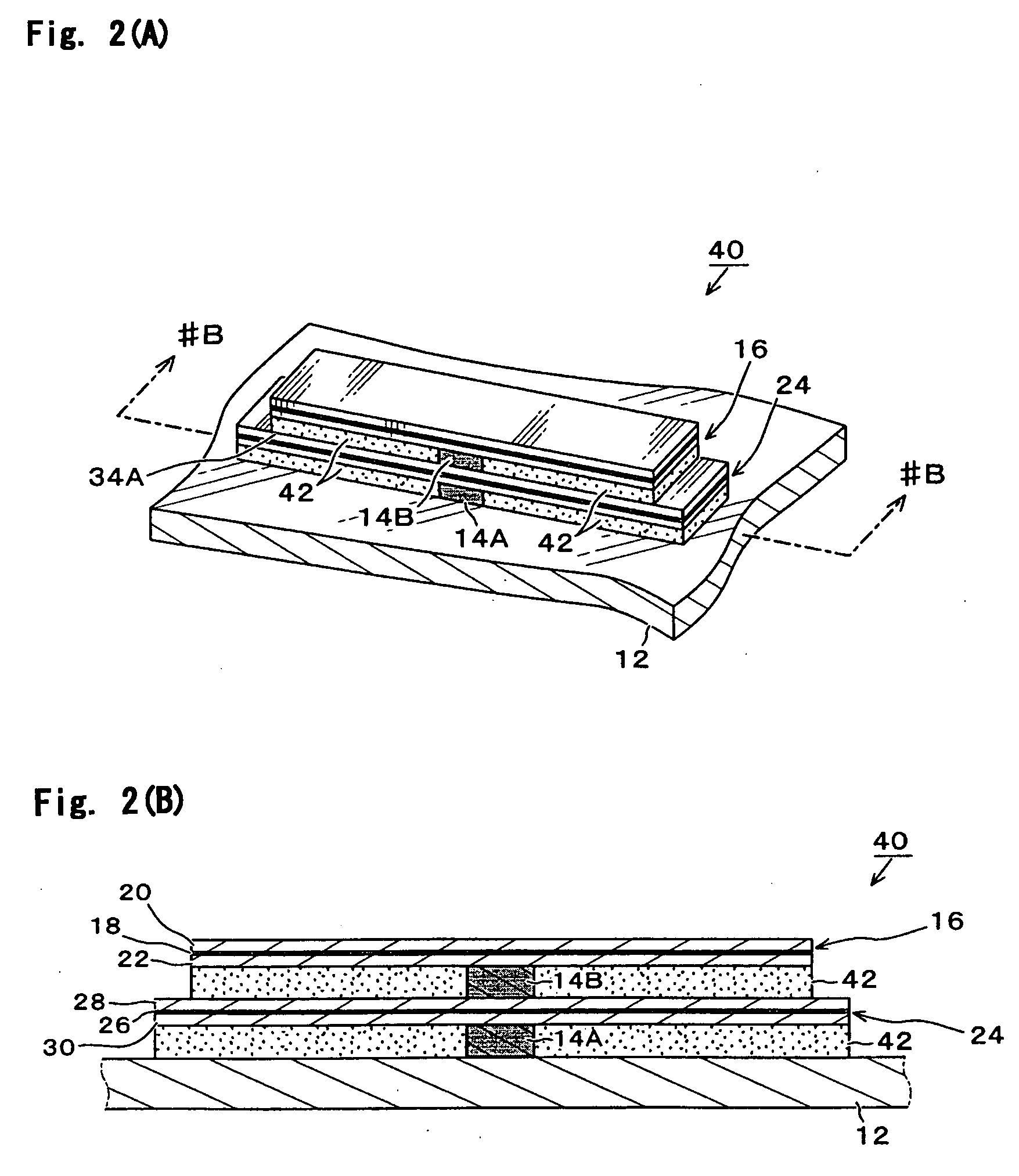

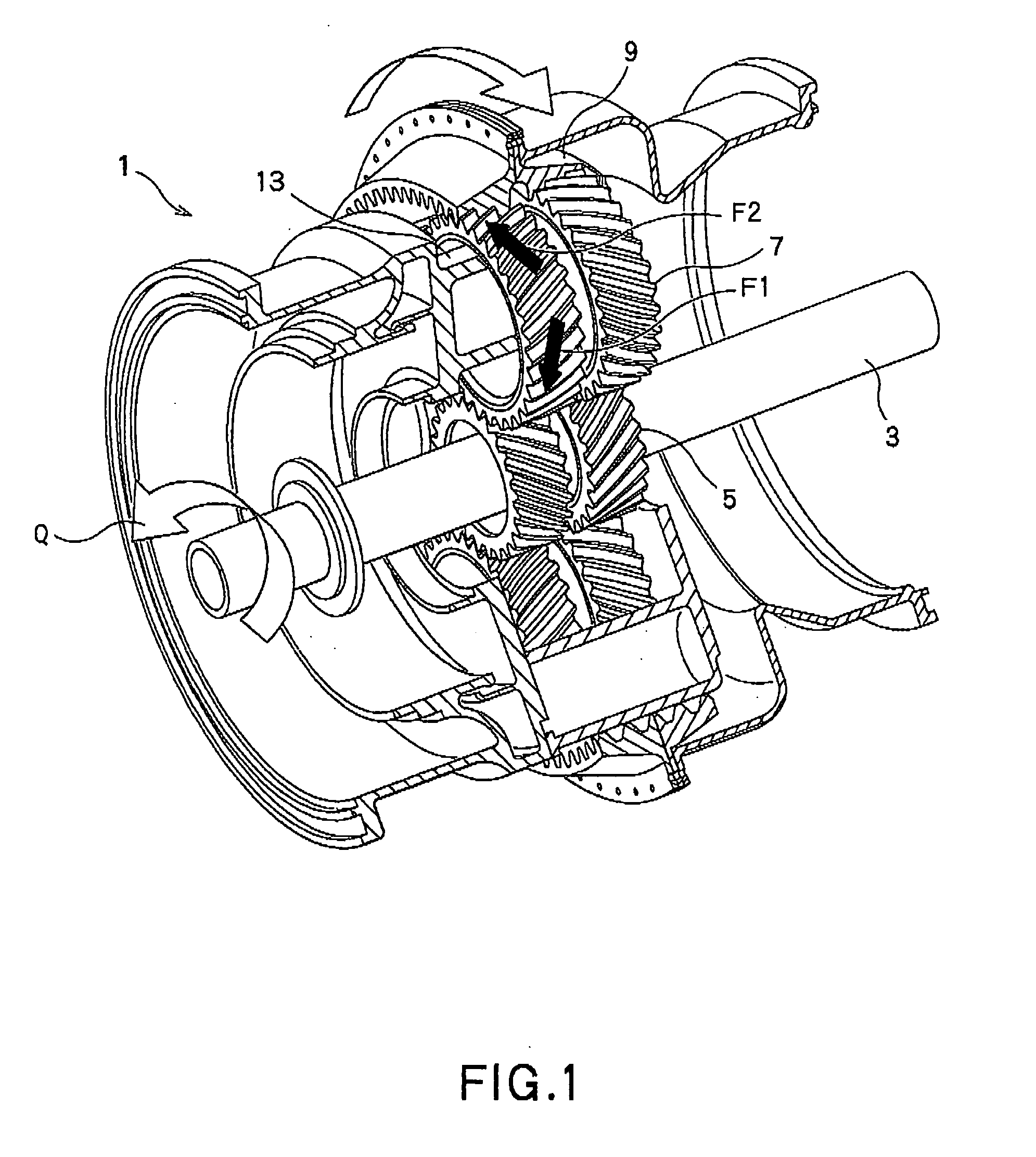

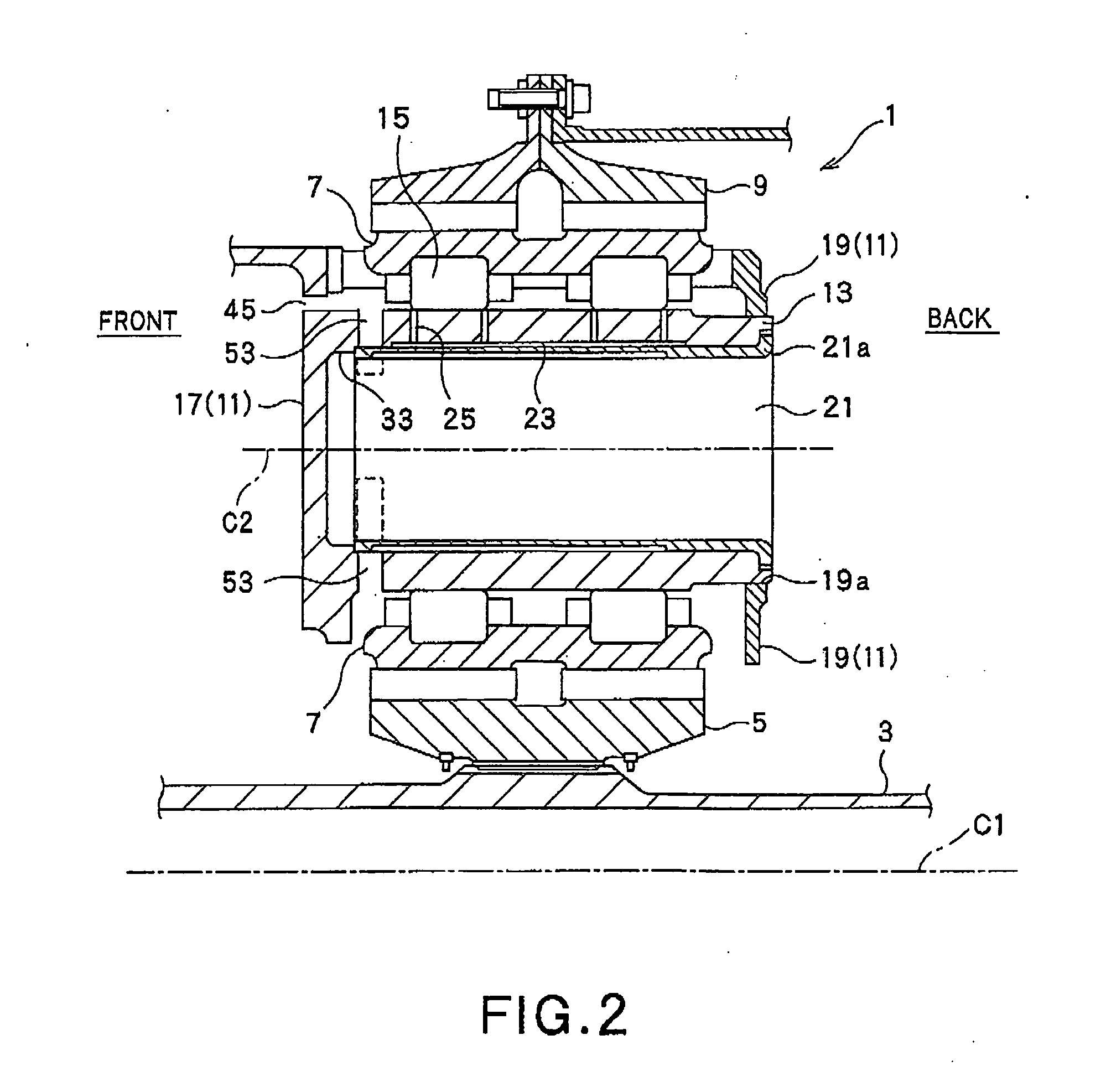

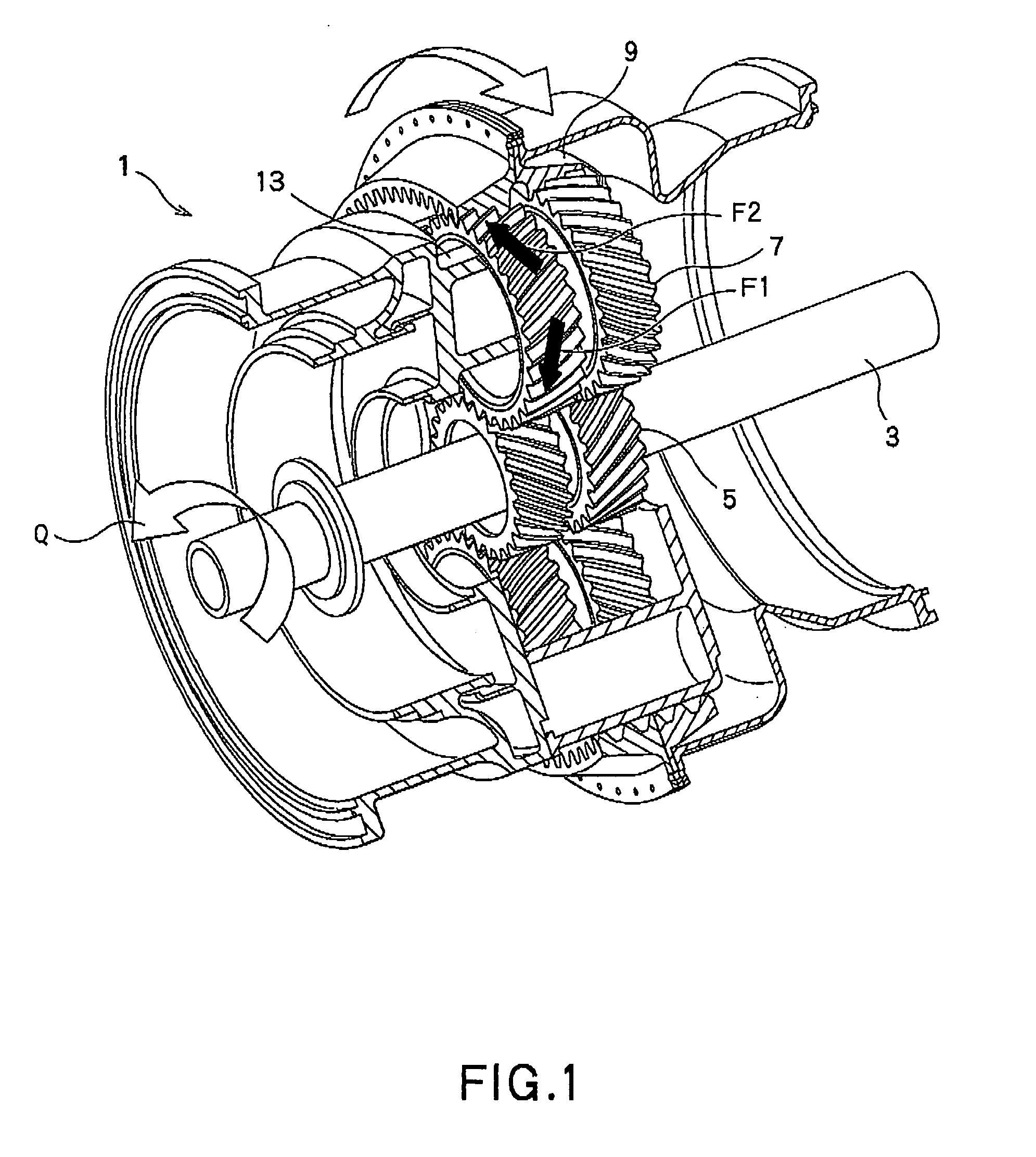

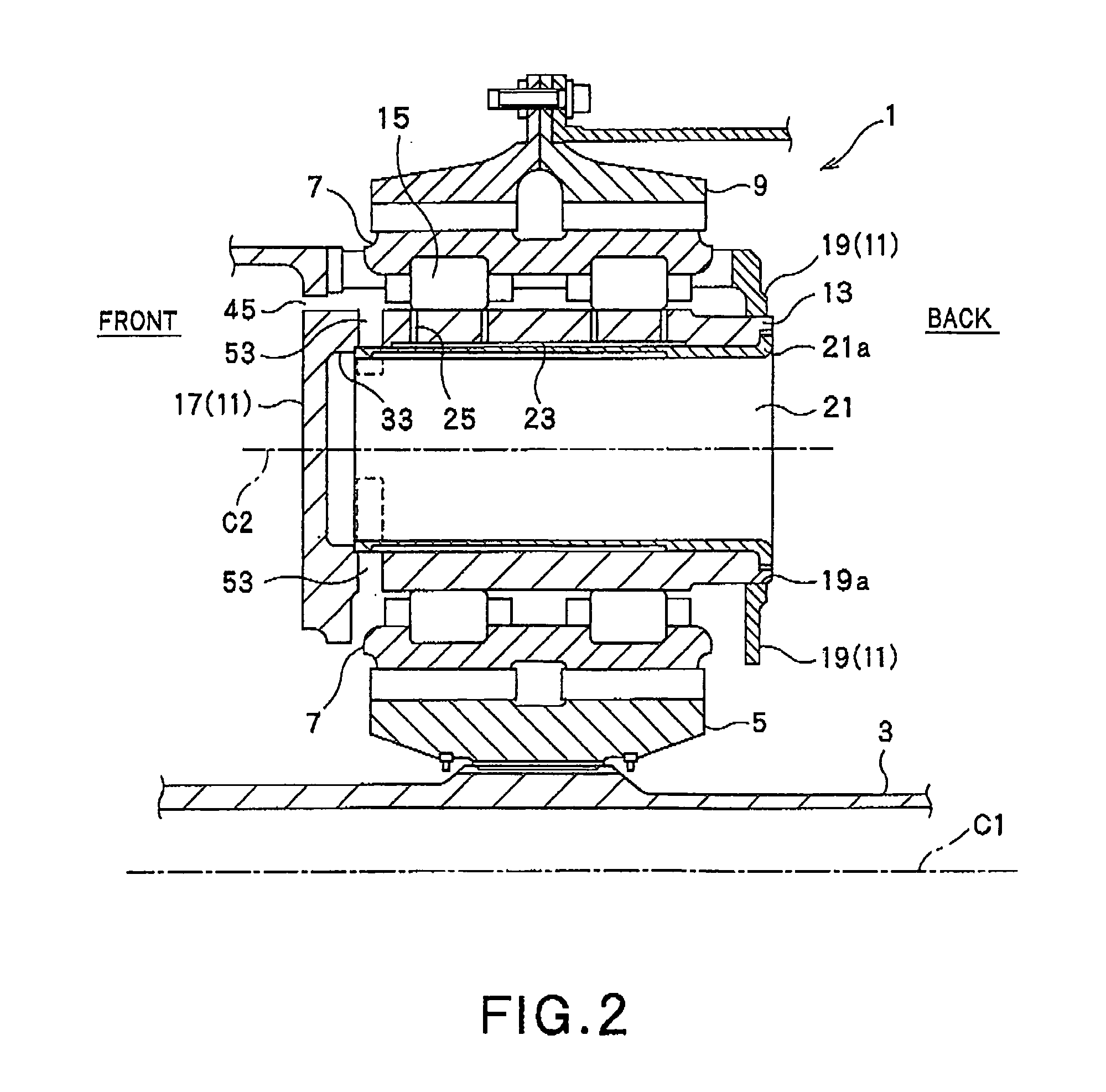

Planetary reduction gear apparatus

ActiveUS20100261571A1Reduce material usageReduce weightToothed gearingsGearing detailsGear wheelEngineering

Owner:KAWASAKI HEAVY IND LTD

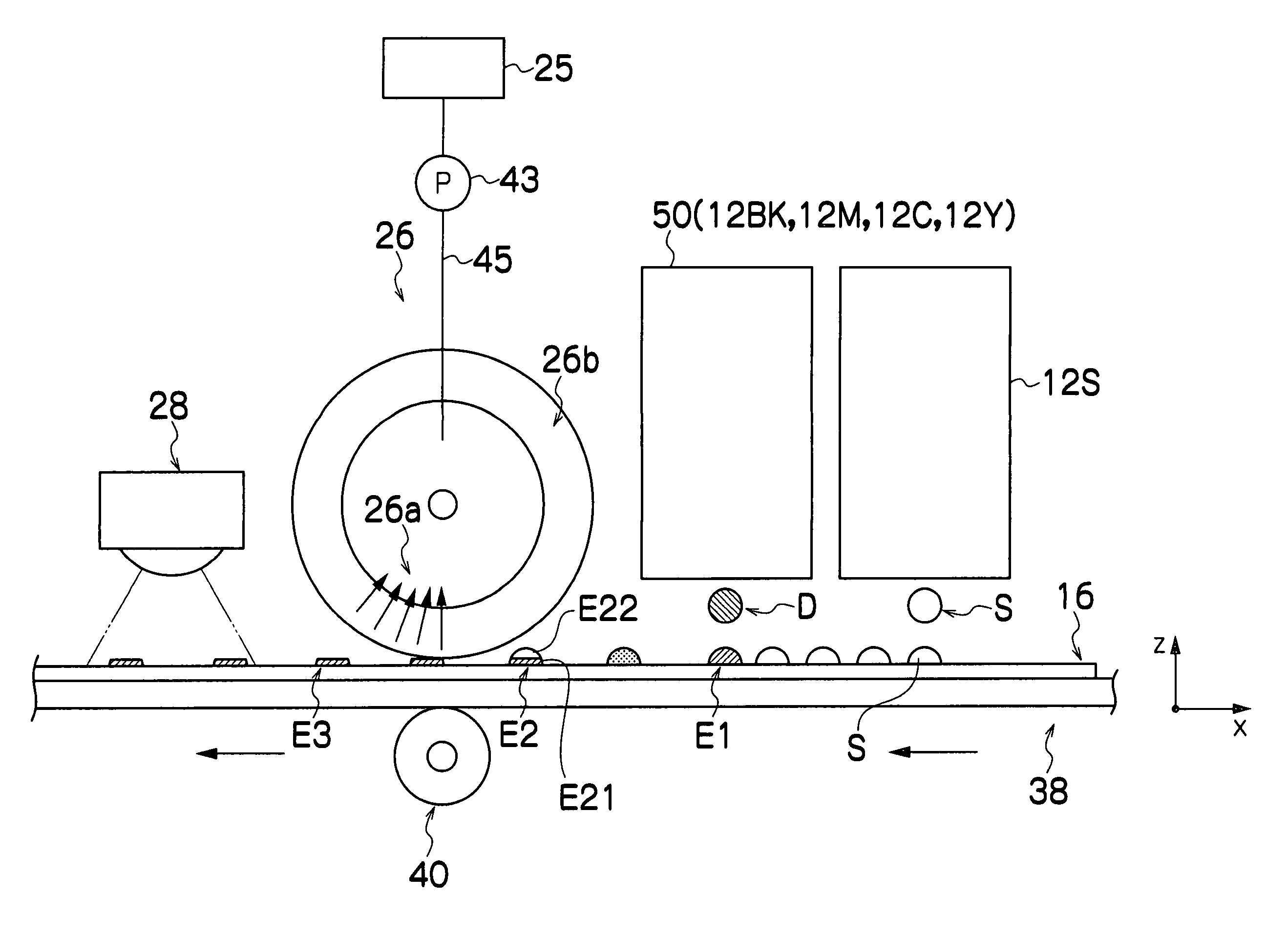

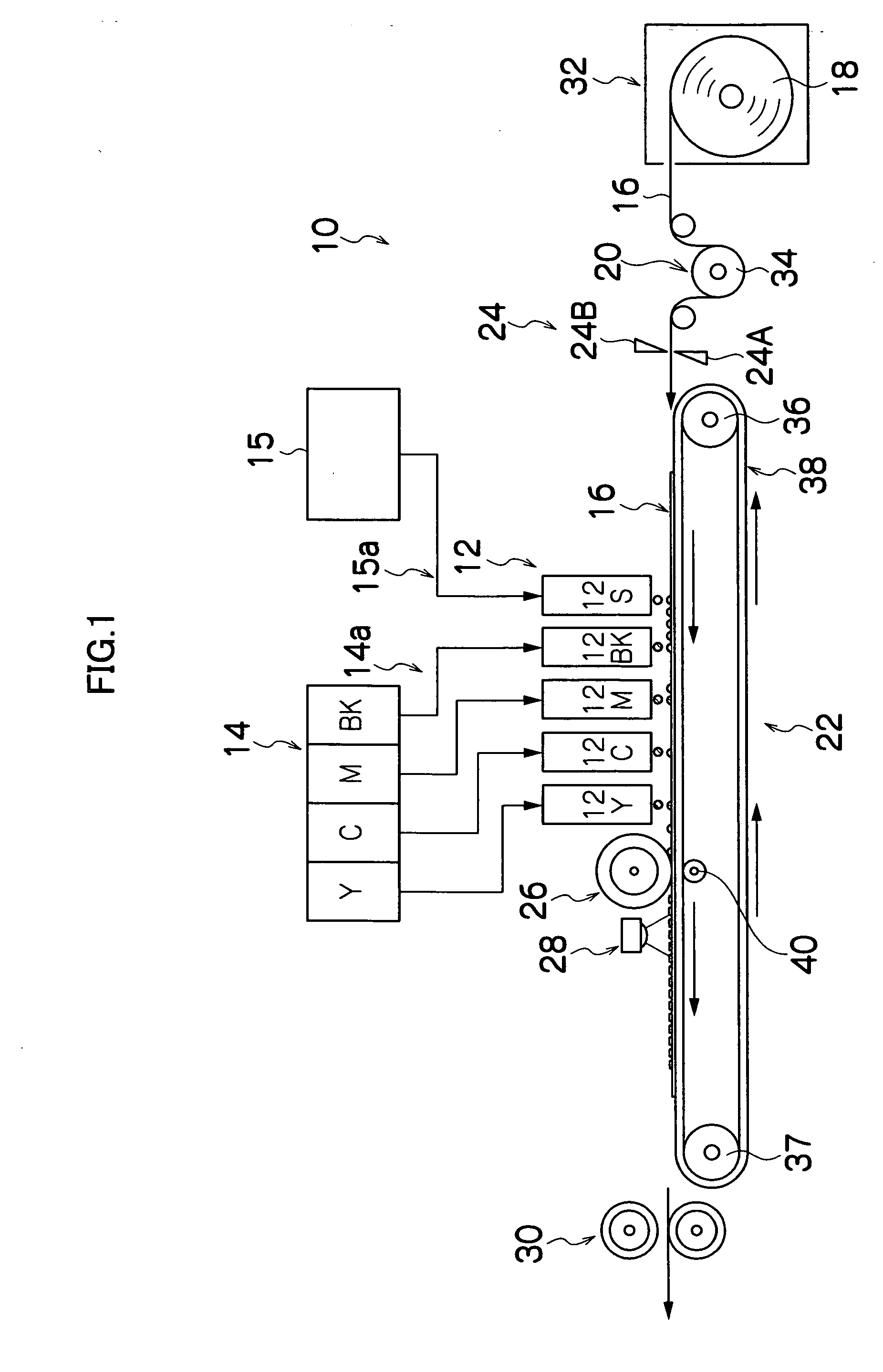

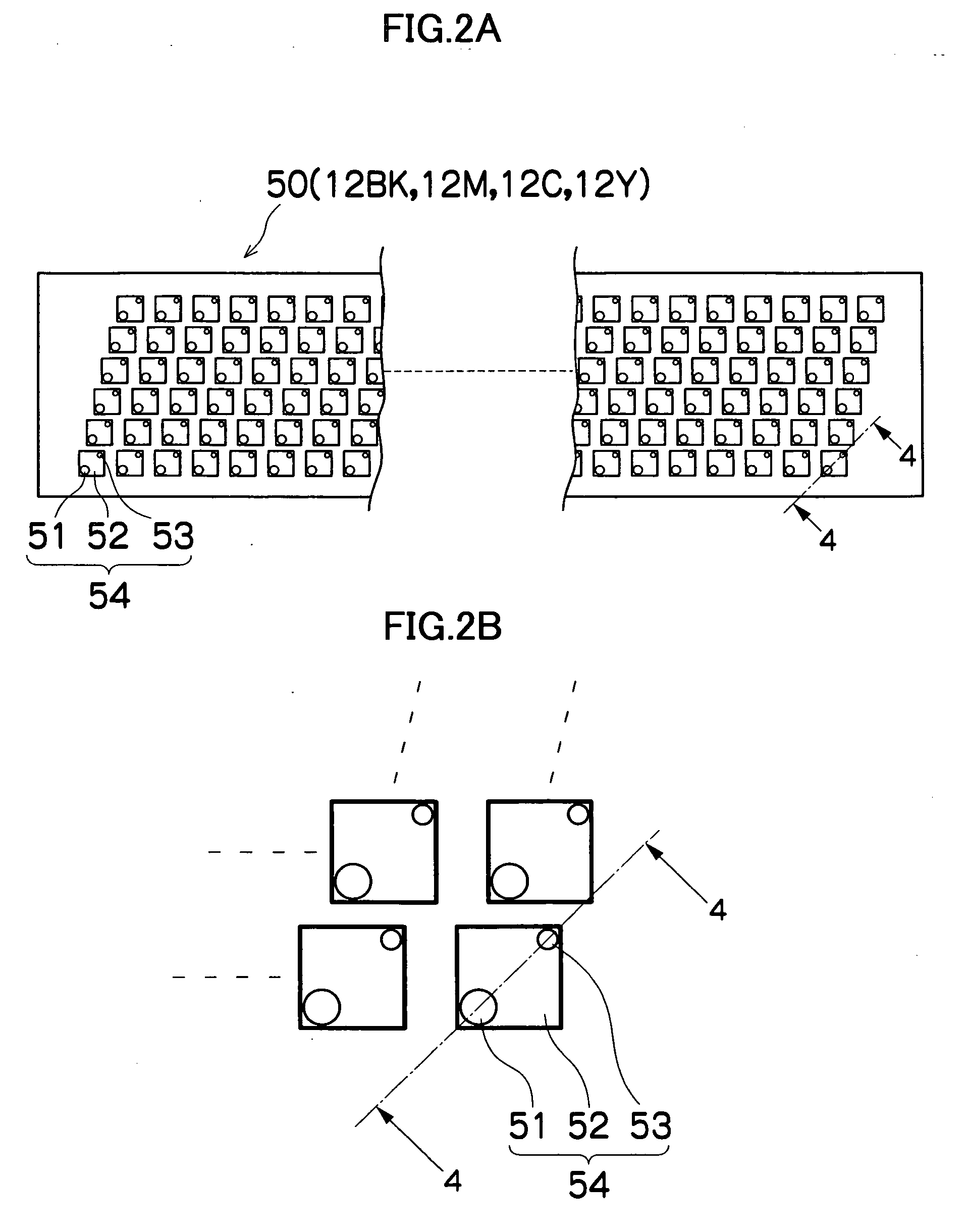

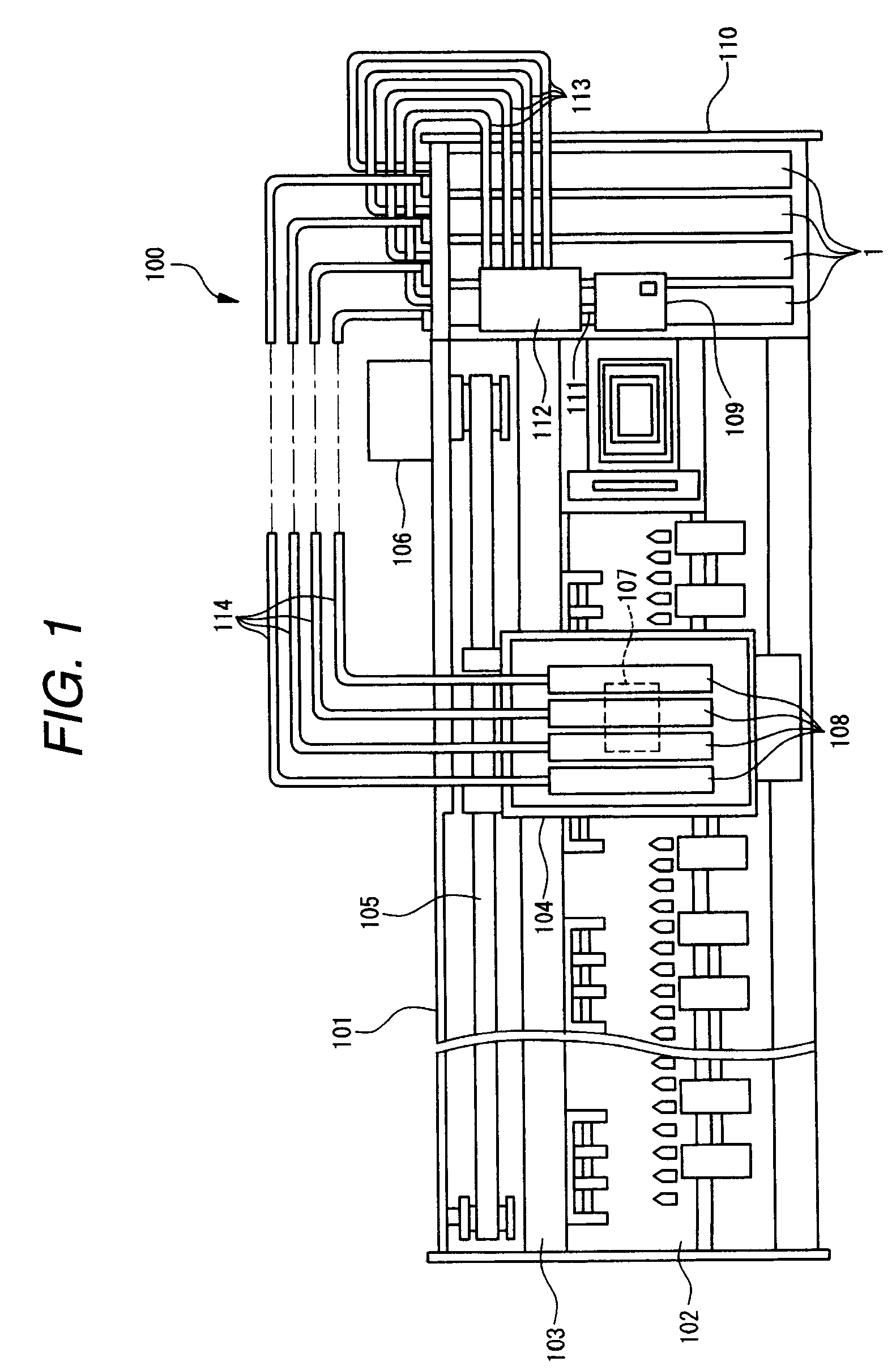

Image forming apparatus

InactiveUS20060214984A1Invention easilyEnsure elasticityOther printing apparatusPrinting after-treatmentImage formationSolvent

The image forming apparatus comprises: an object liquid ejection device which ejects object liquid containing coloring material and solvent, onto a recording medium; a separating device which separates the coloring material and the solvent in the object liquid ejected on the recording medium; and a solvent removal device including an absorbing body which absorbs the solvent, the absorbing body being pressed against the object liquid in which the coloring material and the solvent are separated by the separating device, wherein an elastic modulus En of the absorbing body in a pressing direction in which the absorbing body is pressed against the object liquid ejected on the recording medium, and an elastic modulus Es of the absorbing body in an orthogonal direction perpendicular to the pressing direction, satisfy the following relationship: En<Es.

Owner:FUJIFILM CORP

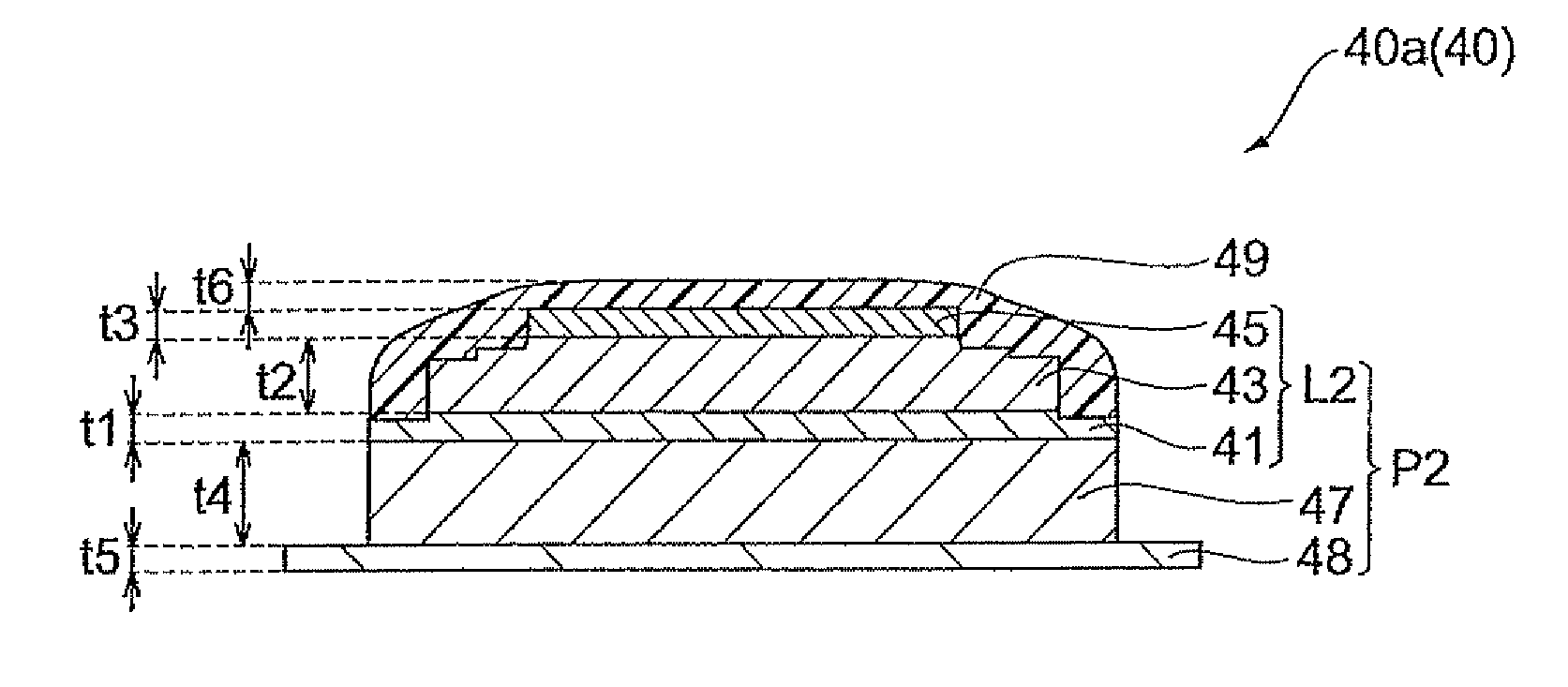

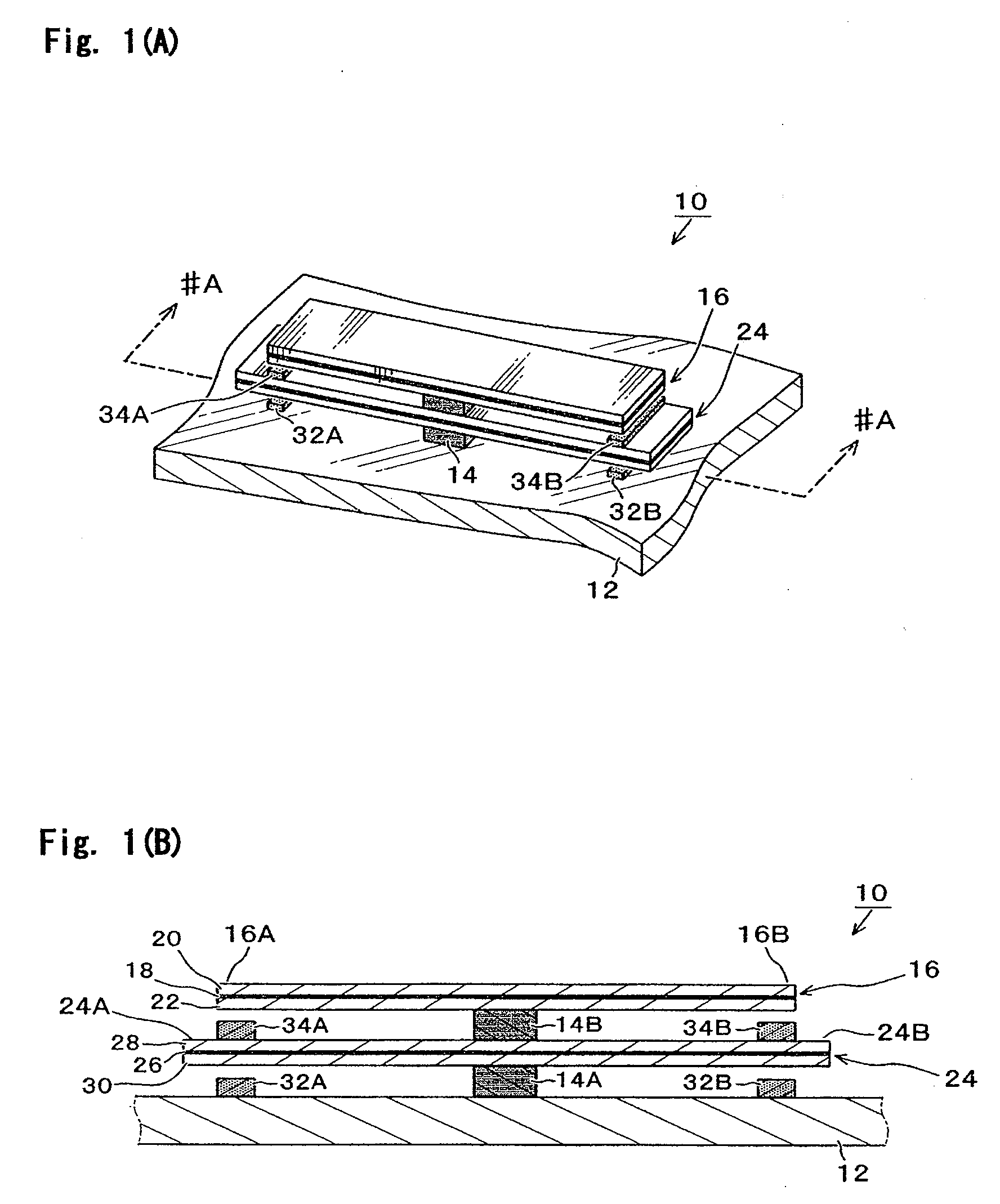

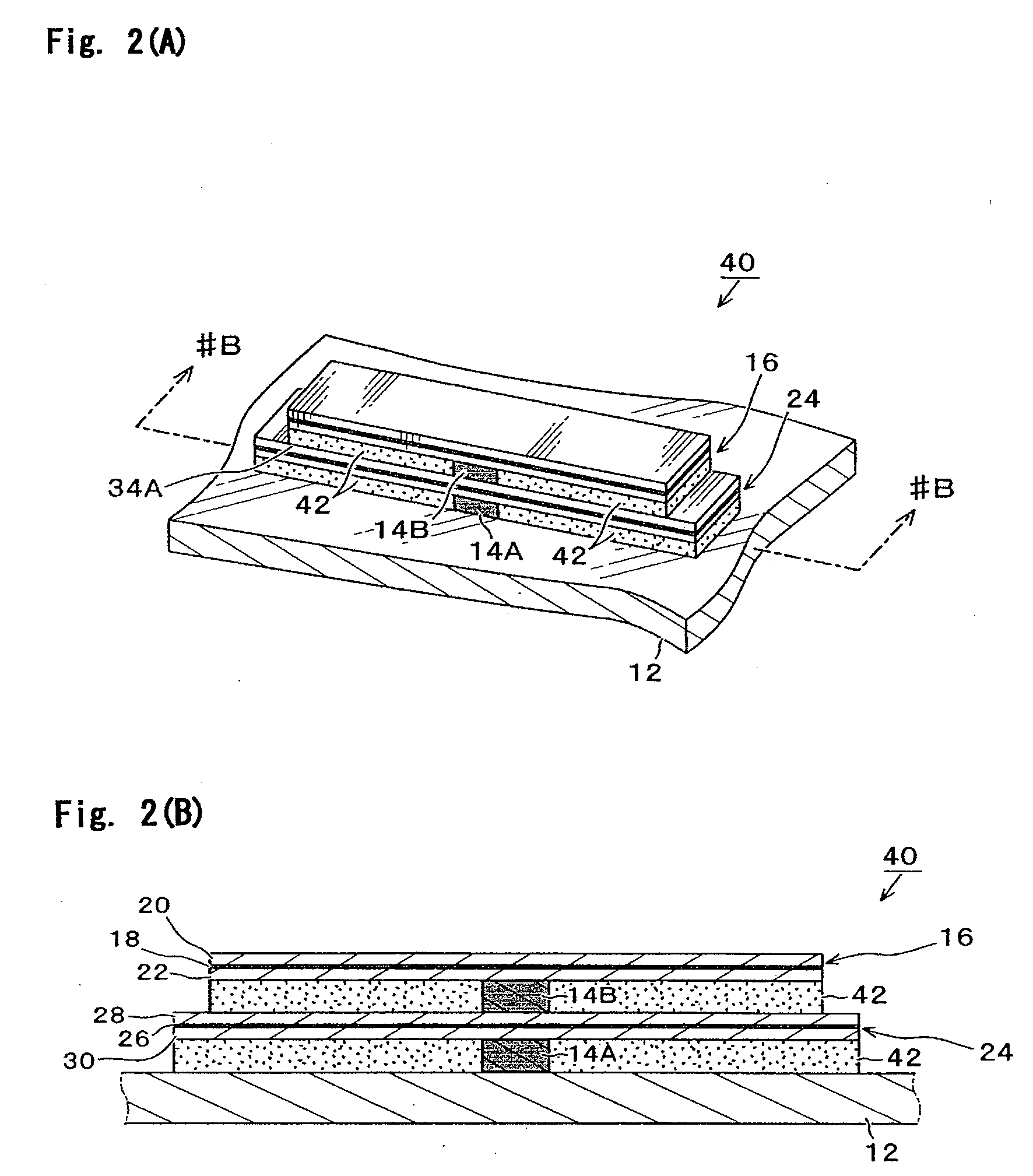

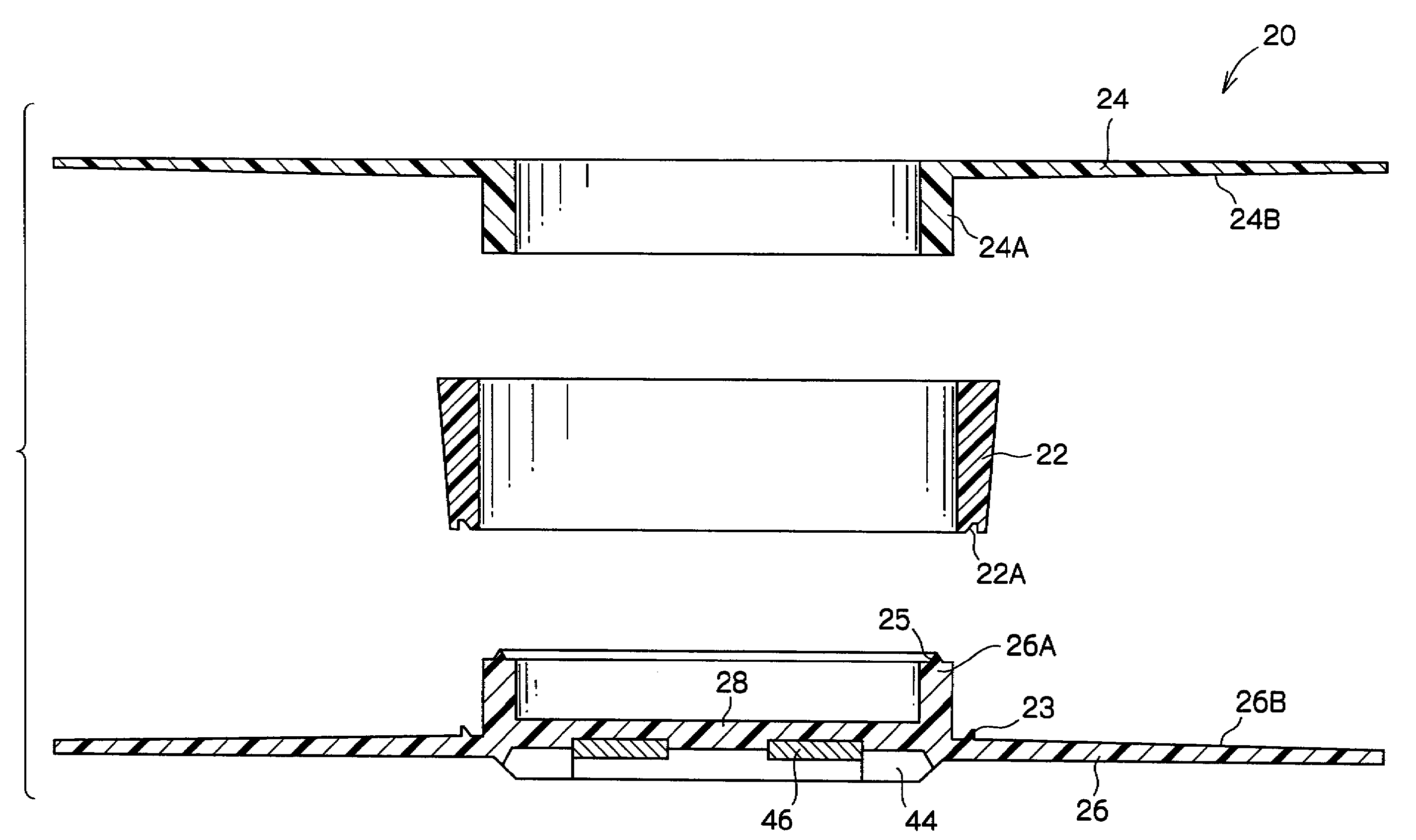

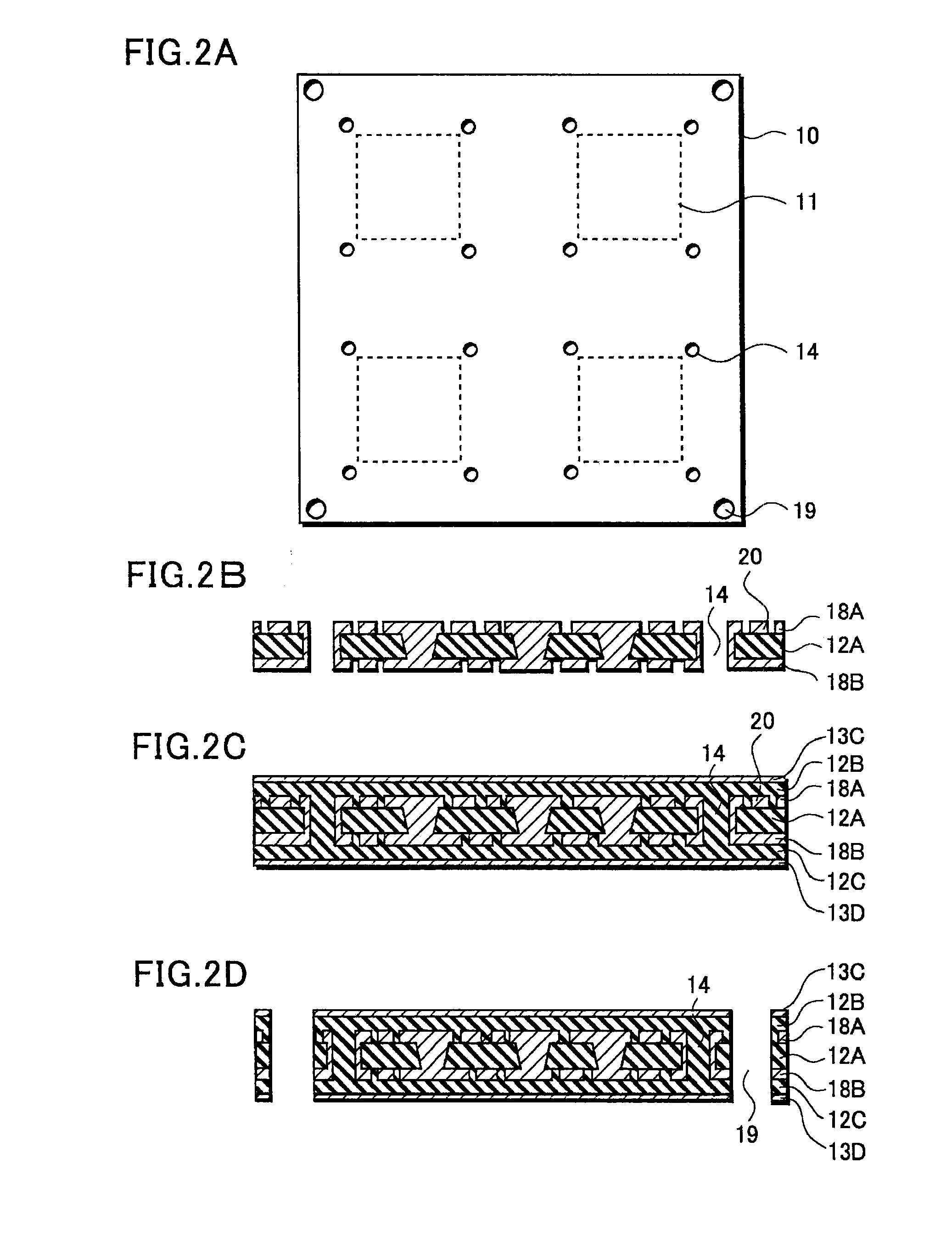

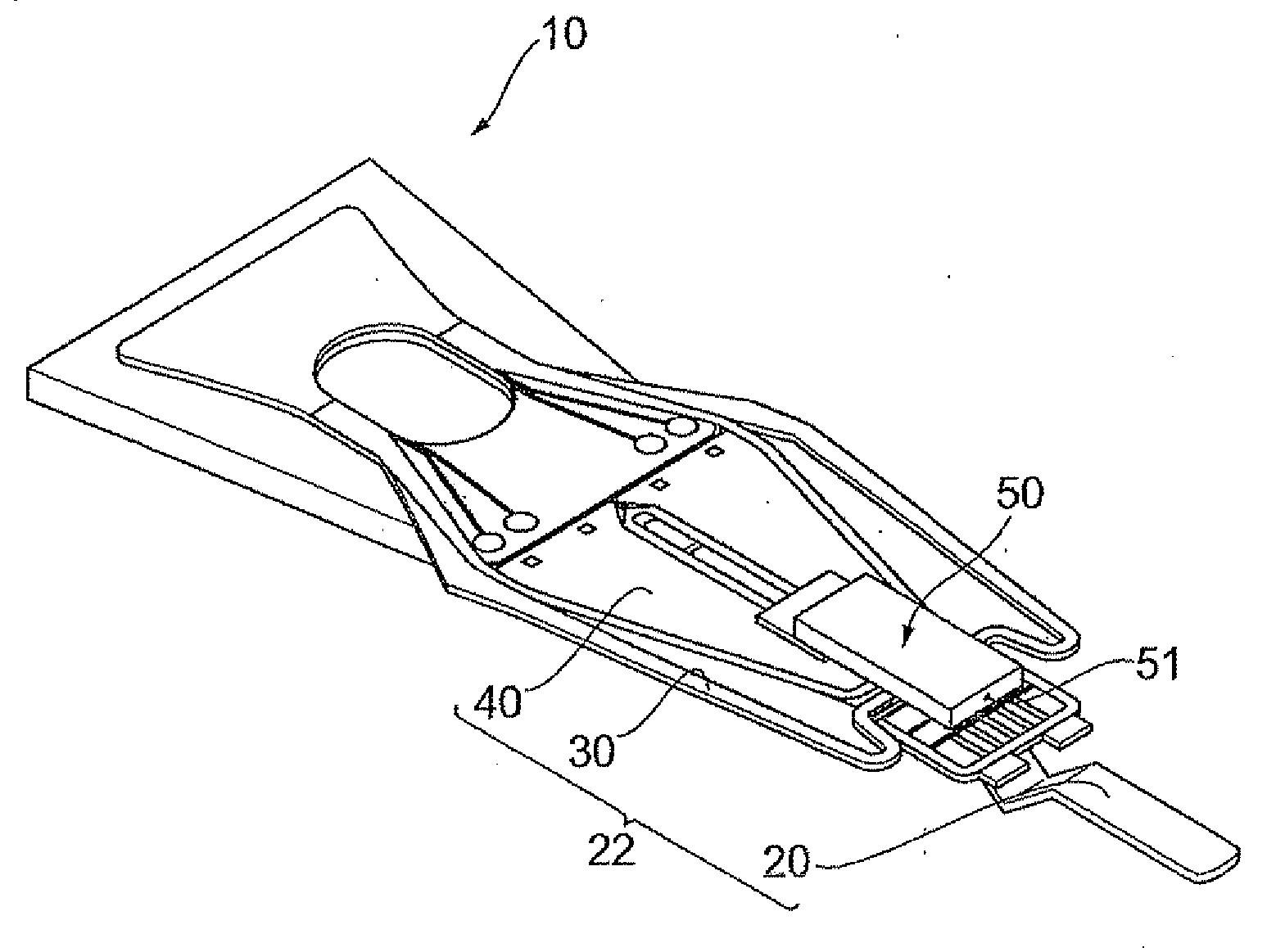

Thin-film piezoelectric device, production method thereof, head gimbals assembly using the thin-film piezoelectric device, and hard disk using the head gimbals assembly

ActiveUS8189296B2Improve performanceLow costPiezoelectric/electrostrictive device manufacture/assemblyTrack finding/aligningYoung's modulusEngineering

A method includes a step of stacking a first electrode layer, a piezoelectric layer, and a second electrode layer on a first substrate to form a first laminate; a step of stacking a support layer on a second substrate to form a second laminate; a step of bonding the first and second laminates through an adhesive layer to form a third laminate; a step of removing the first substrate from the third laminate; a step of processing the third laminate in a desired shape; and a step of removing the second substrate. A Young's modulus of the adhesive layer is smaller than a Young's modulus of the piezoelectric layer. Respective Young's moduli of the second electrode layer and the support layer are larger than the Young's modulus of the adhesive layer. The third laminate has no other piezoelectric layer except for the aforementioned piezoelectric layer.

Owner:TDK CORPARATION +1

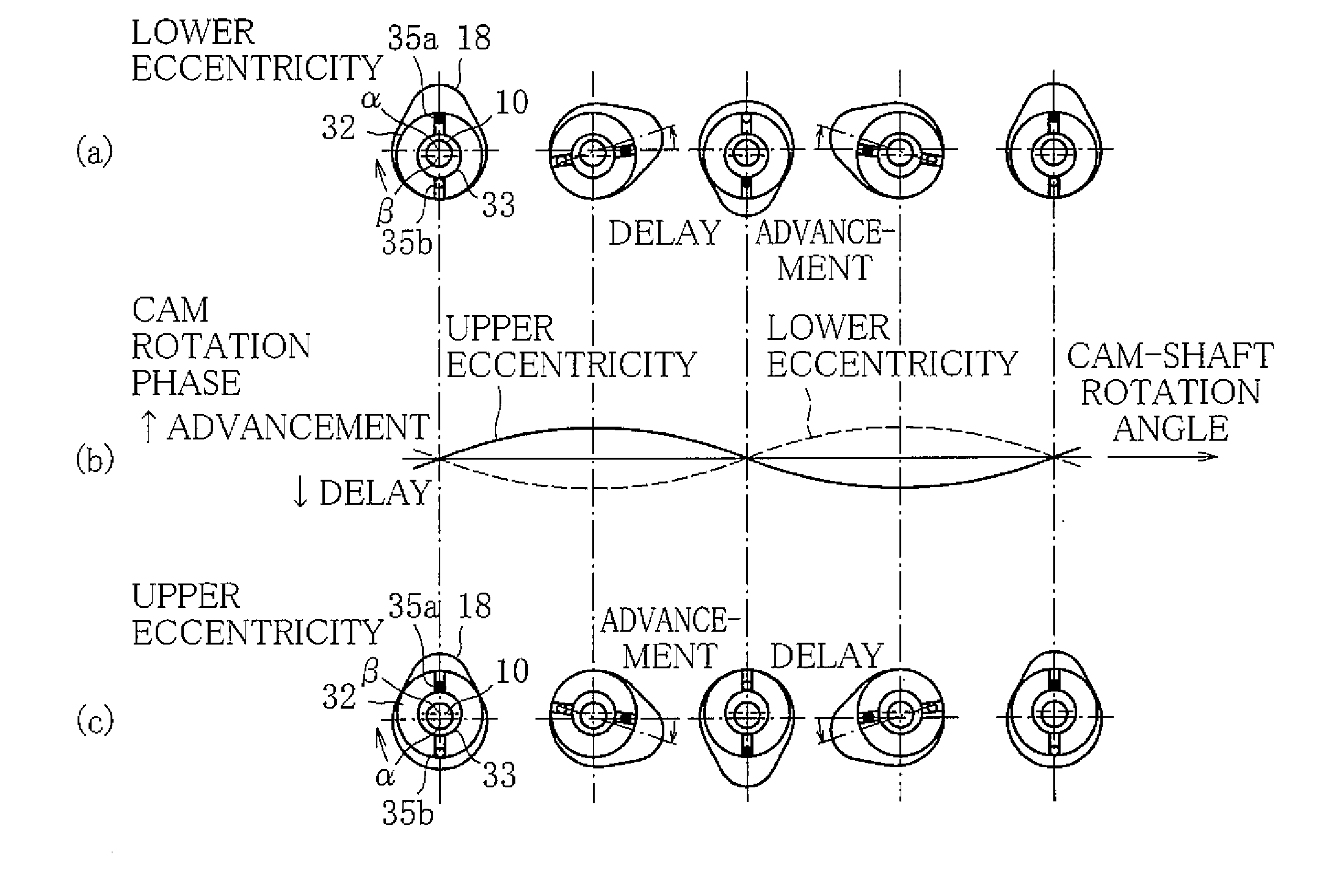

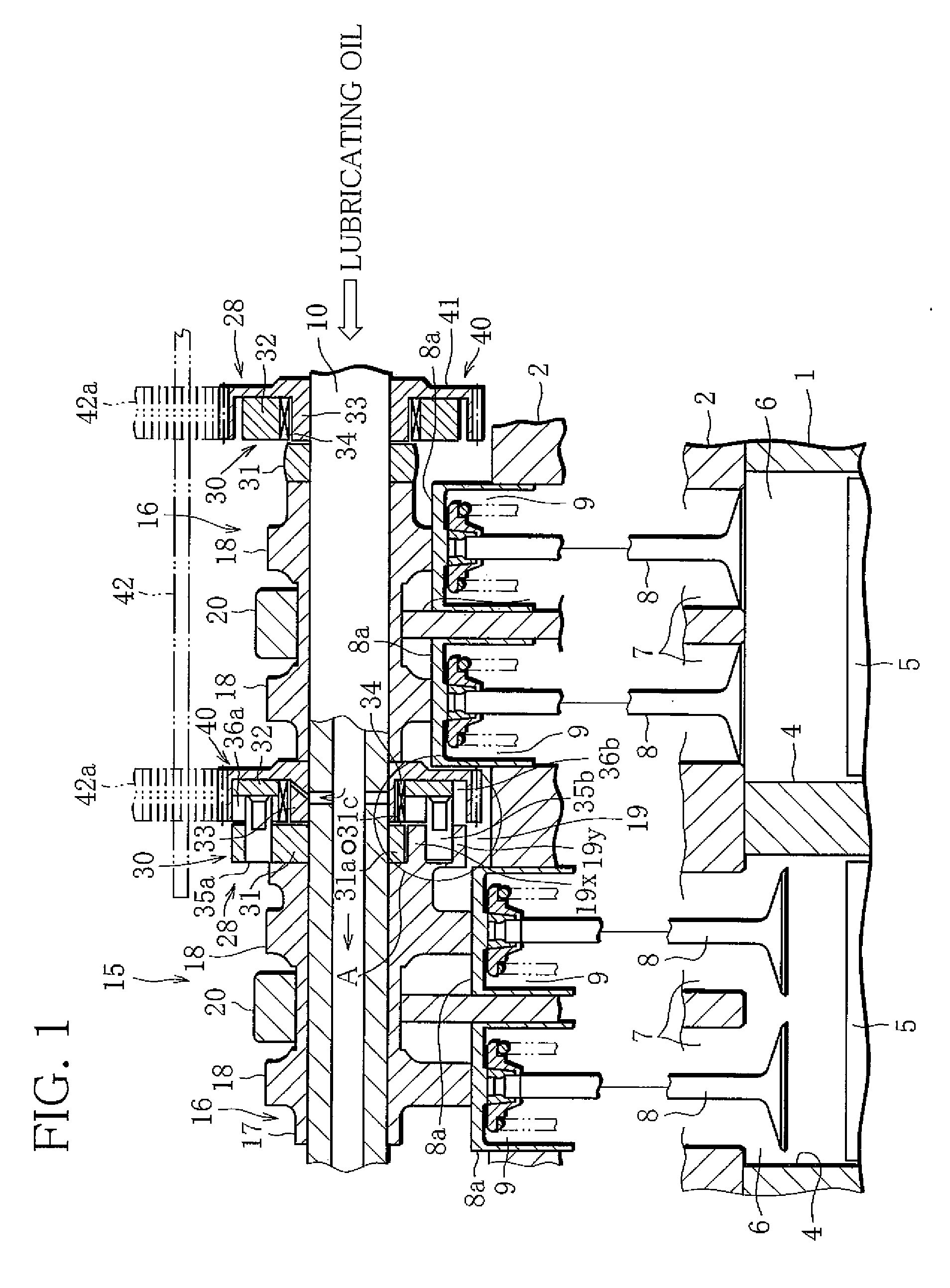

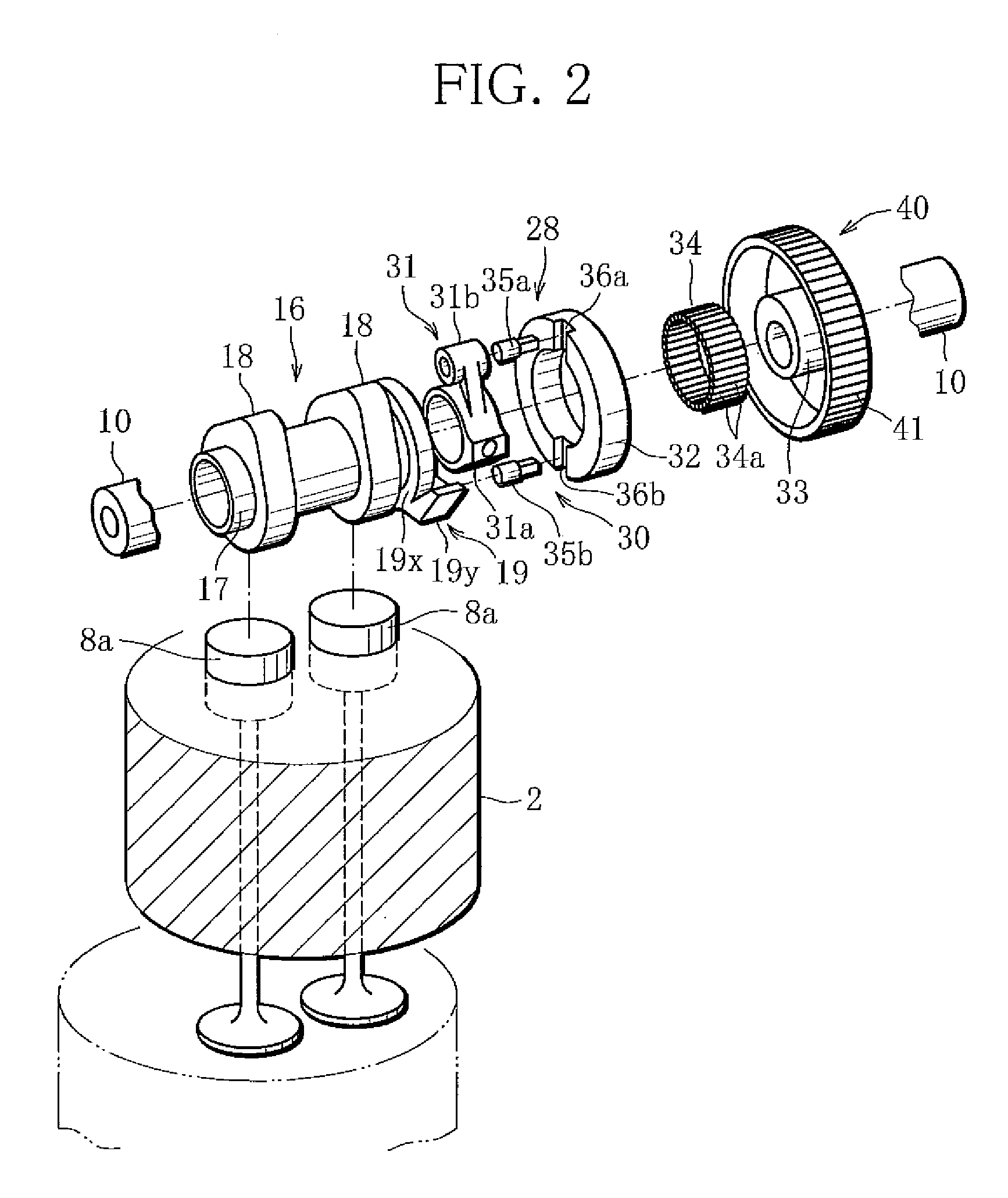

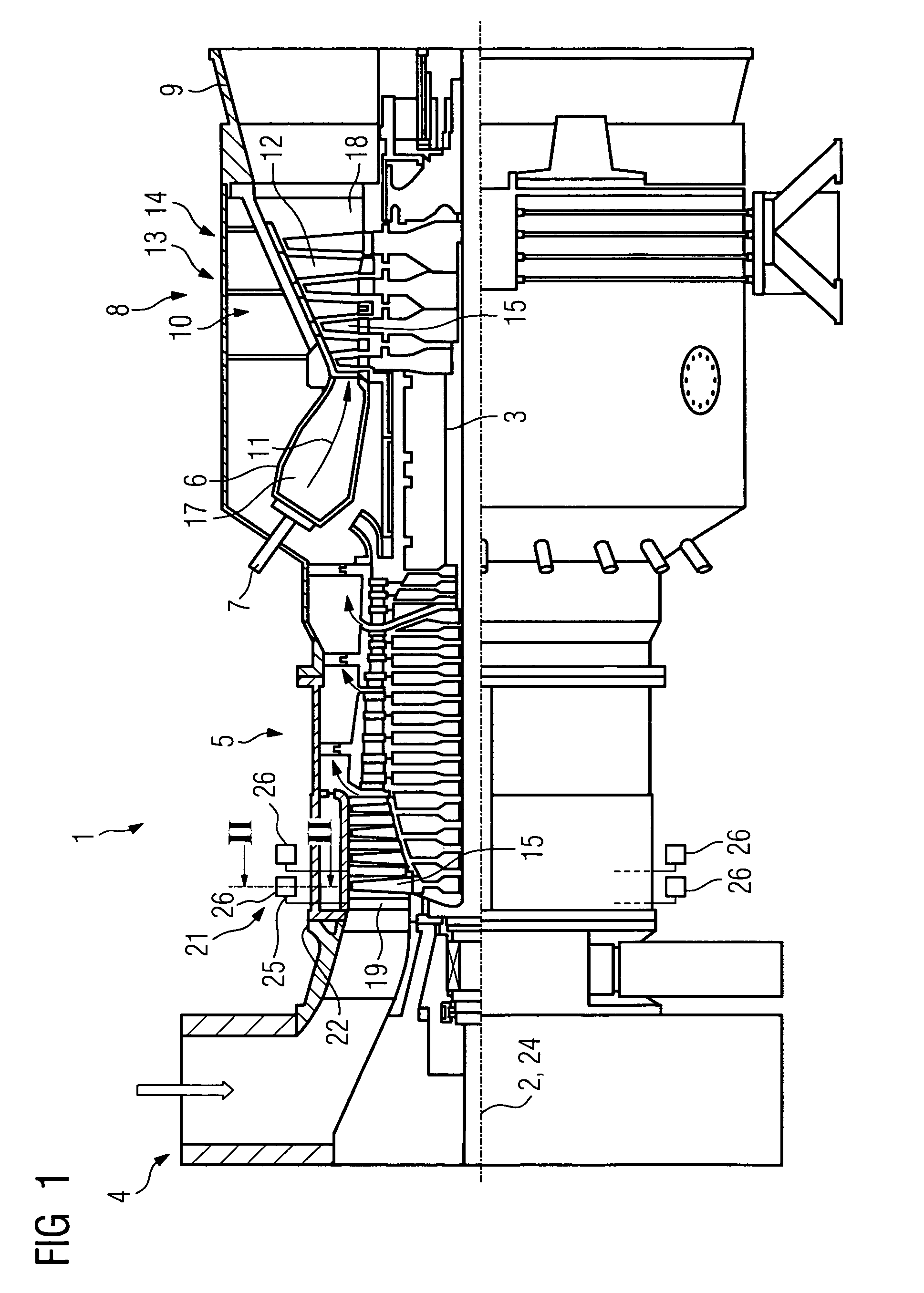

Variable valve gear for an internal combustion engine

InactiveUS20090241877A1Simple structureRestrict movementValve drivesMachines/enginesDrive shaftEngineering

The variable valve gear for an internal combustion engine includes a cam lobe that is rotatably supported by a cam drive shaft, and a variable valve mechanism that includes a drive arm fixed adjacent to one end of the cam lobe in the cam drive shaft, an eccentric shaft member that is swivelably supported at a position opposite to the cam lobe with respect to the drive arm in the cam drive shaft, has an outer circumferential surface eccentric to an axis of the cam drive shaft, and is adjustable in eccentricity, and an intermediate rotary member that is rotatably supported through a bearing member around the eccentric shaft member, and is connected to the drive arm, wherein the drive arm includes an end face that overlaps with an end face of the bearing member, when projecting along the axis of the cam drive shaft, and the end face of the drive arm is protruding further than the end face of the cam lobe toward the bearing member.

Owner:MITSUBISHI MOTORS CORP

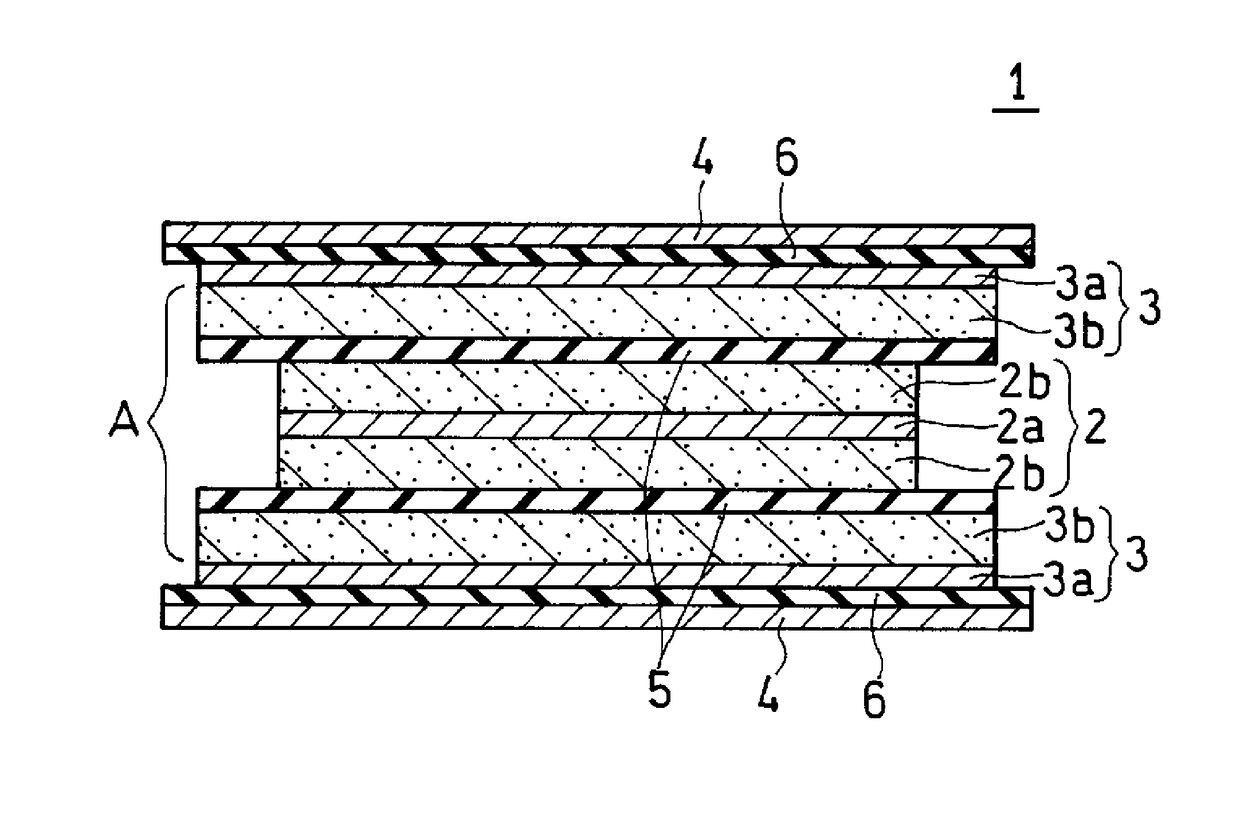

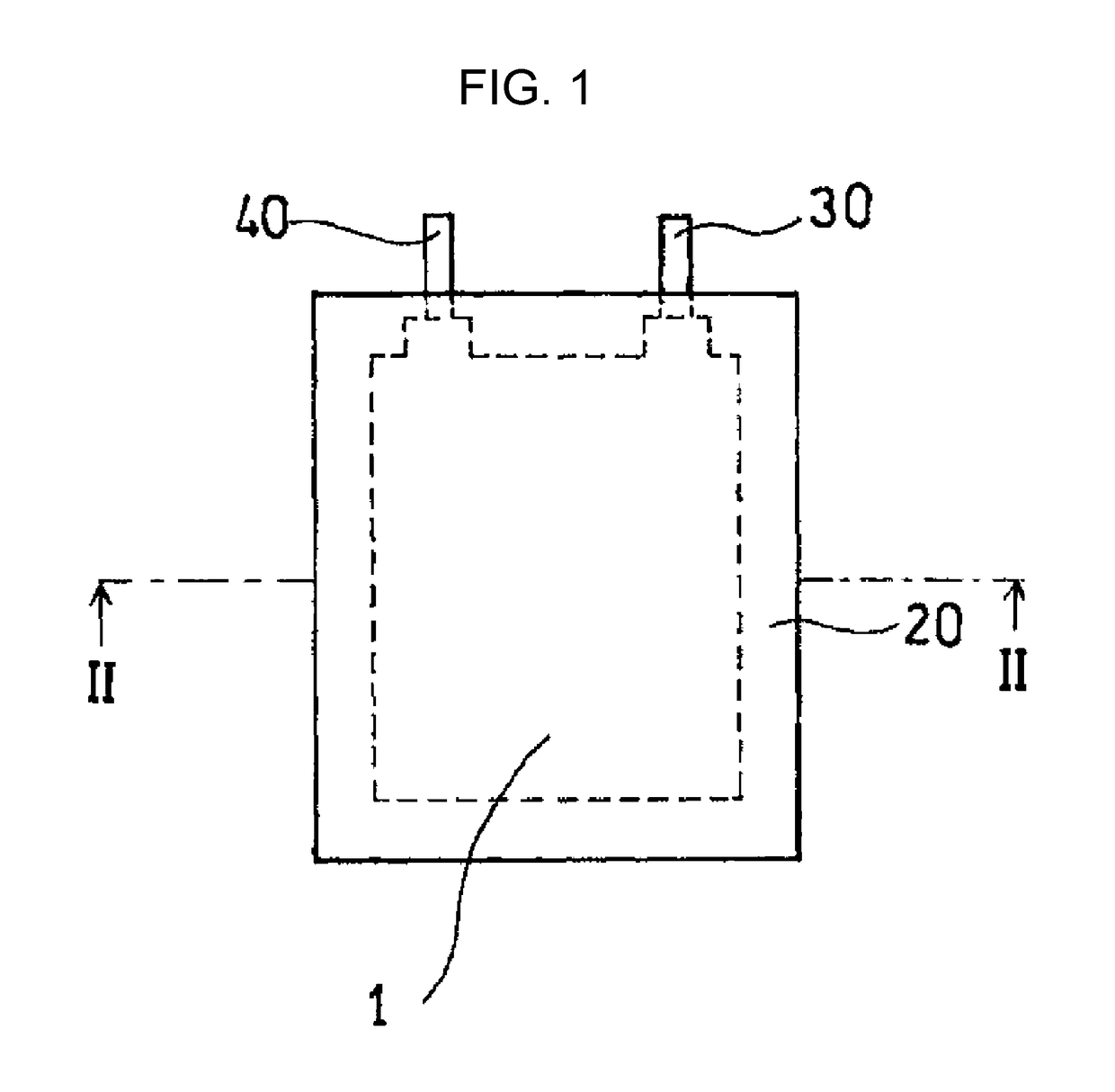

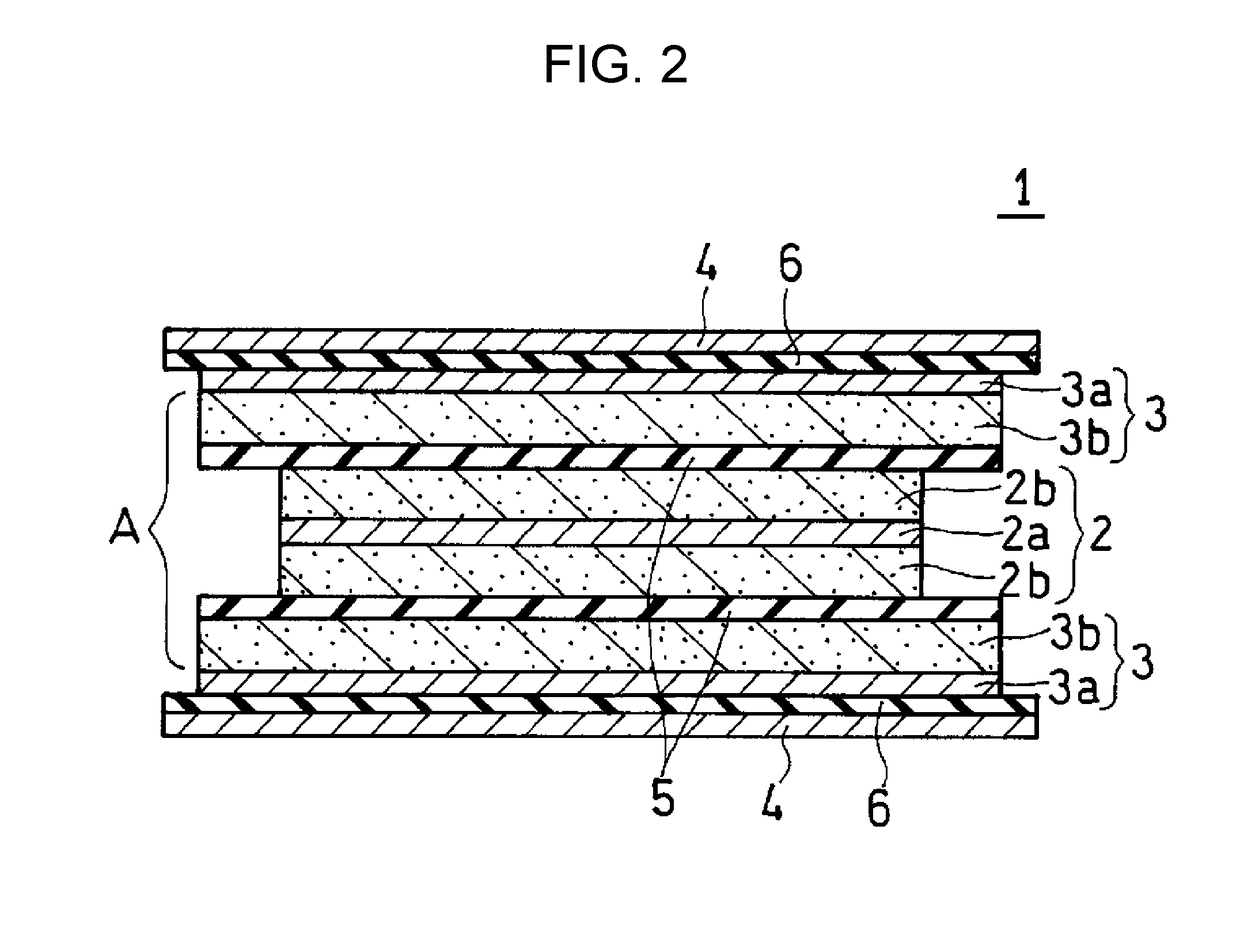

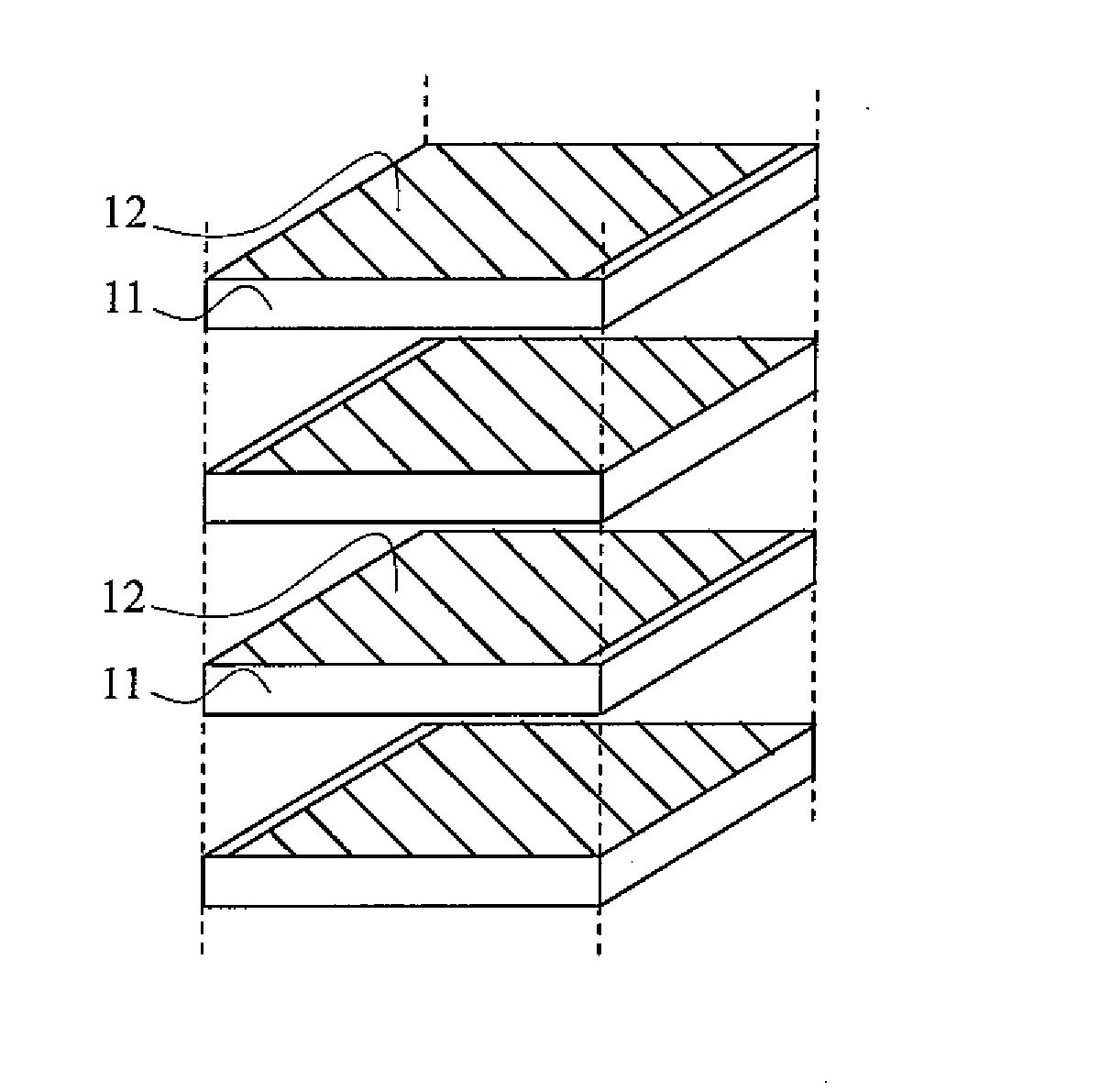

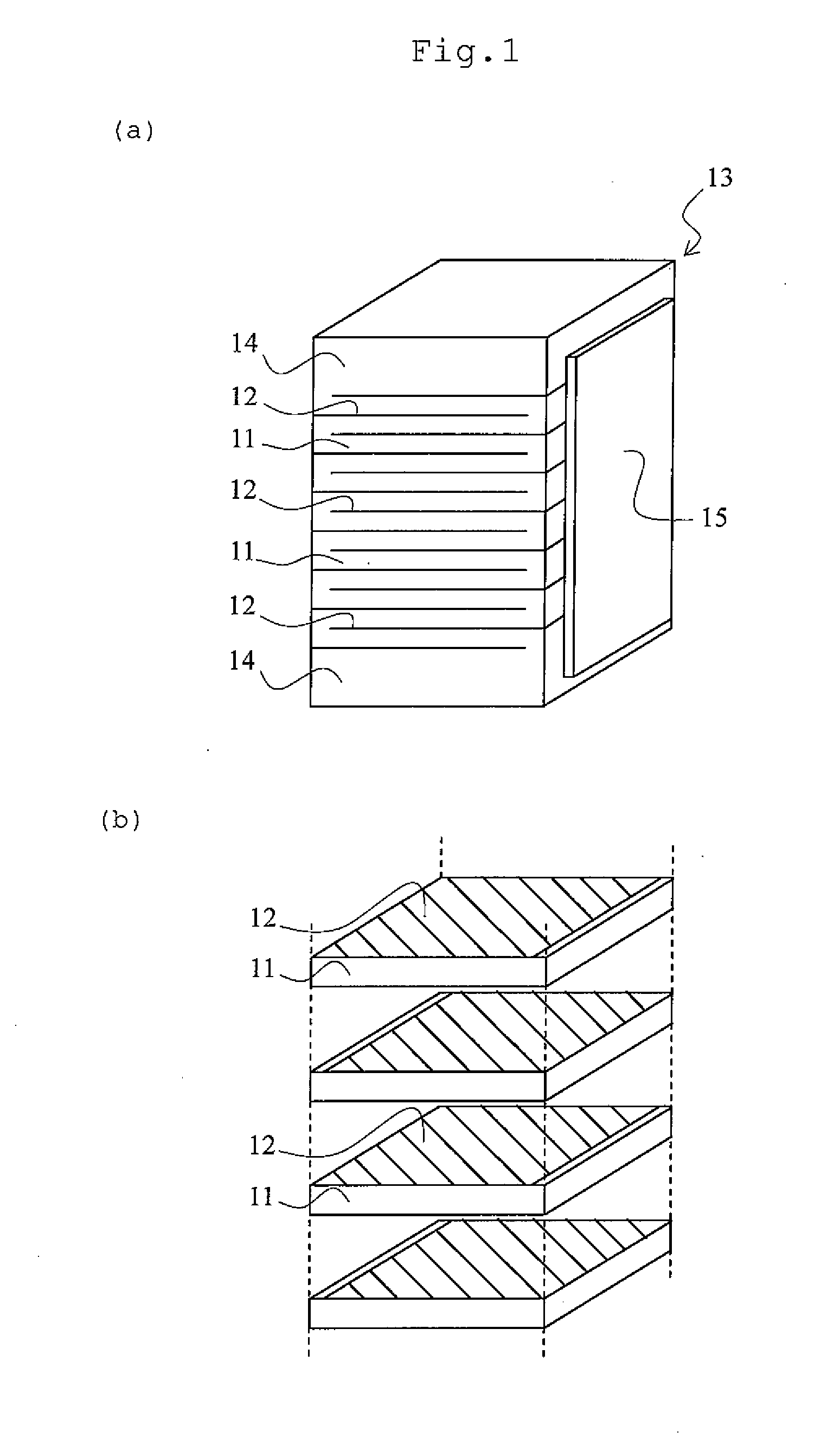

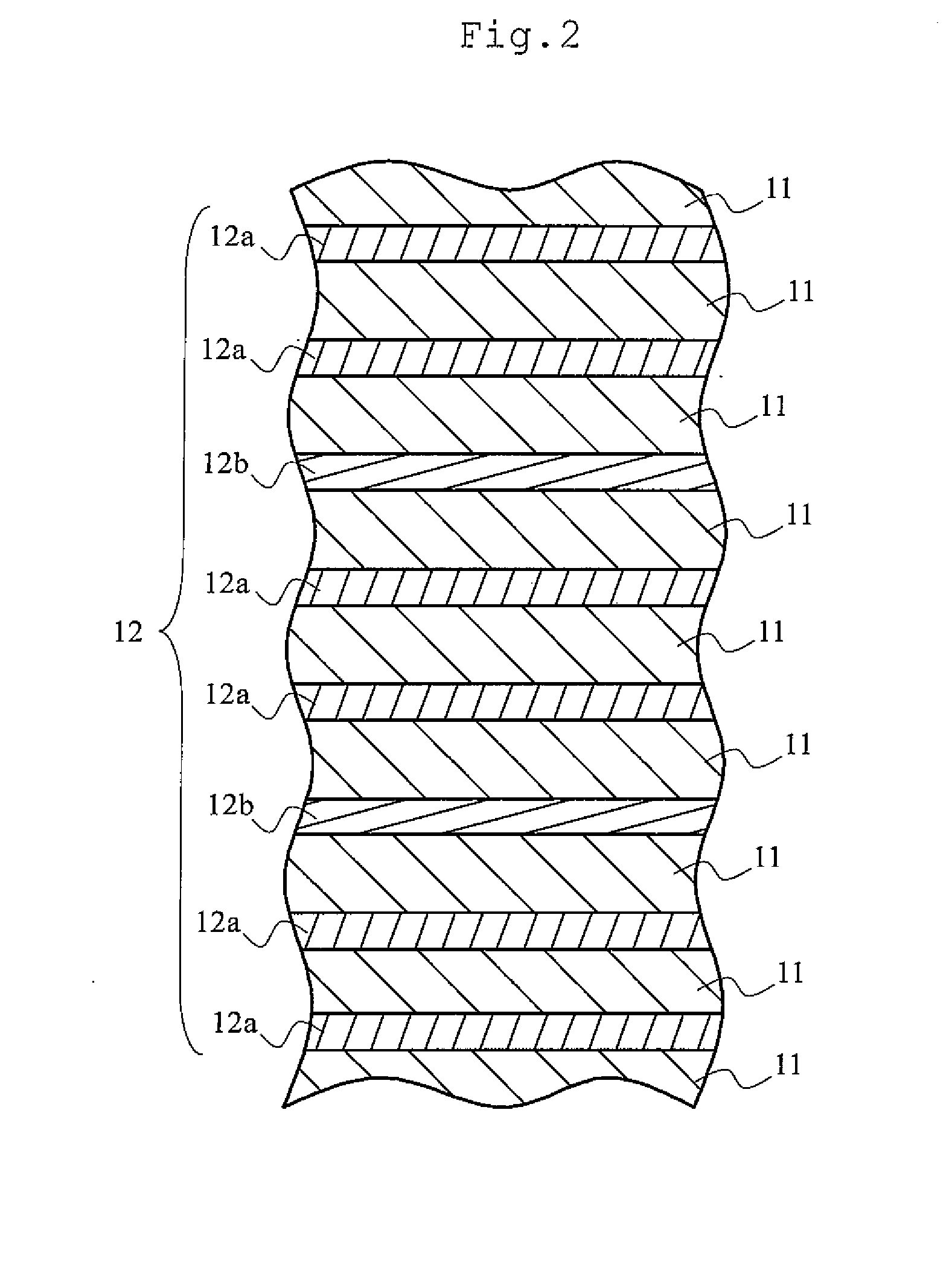

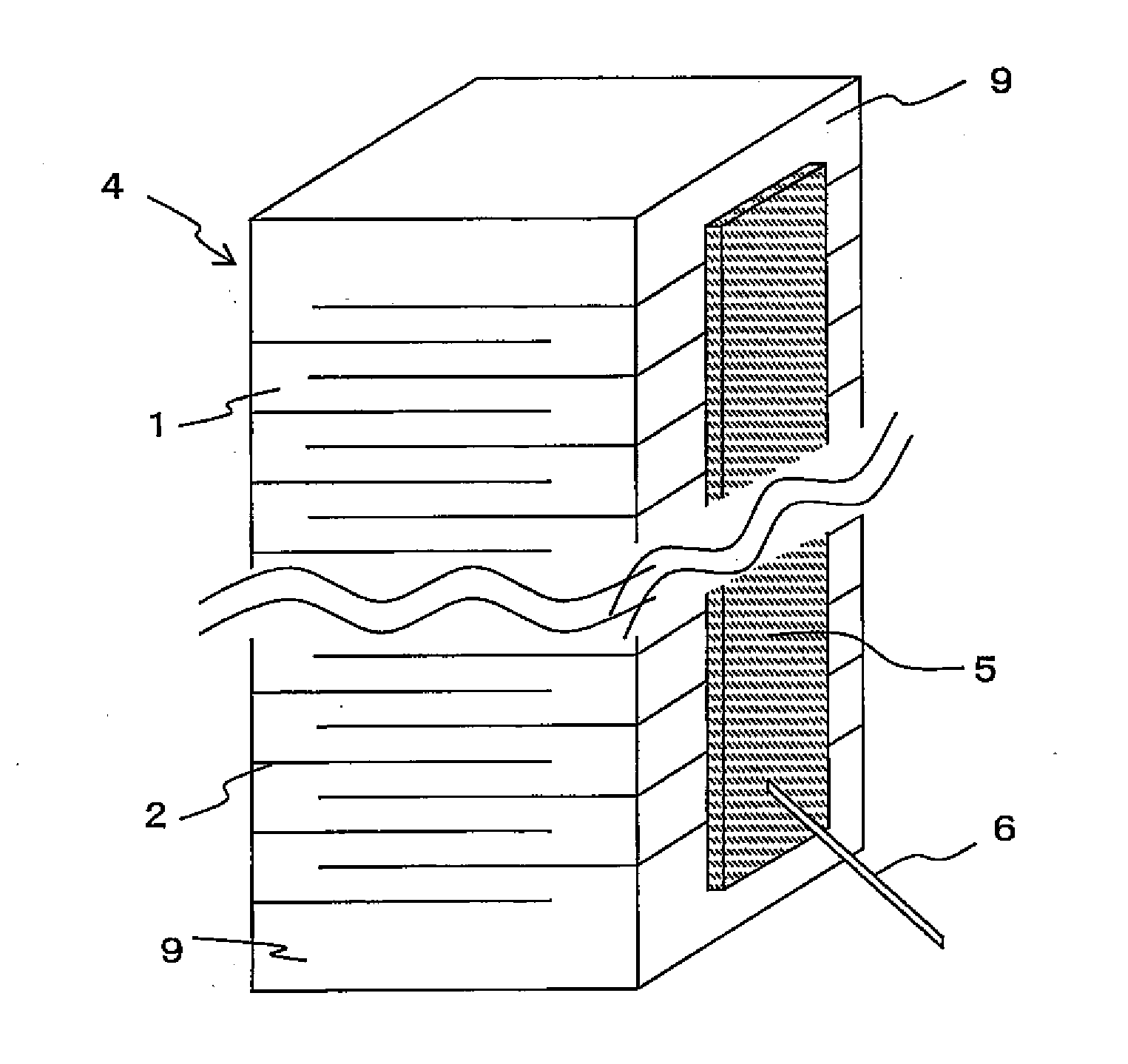

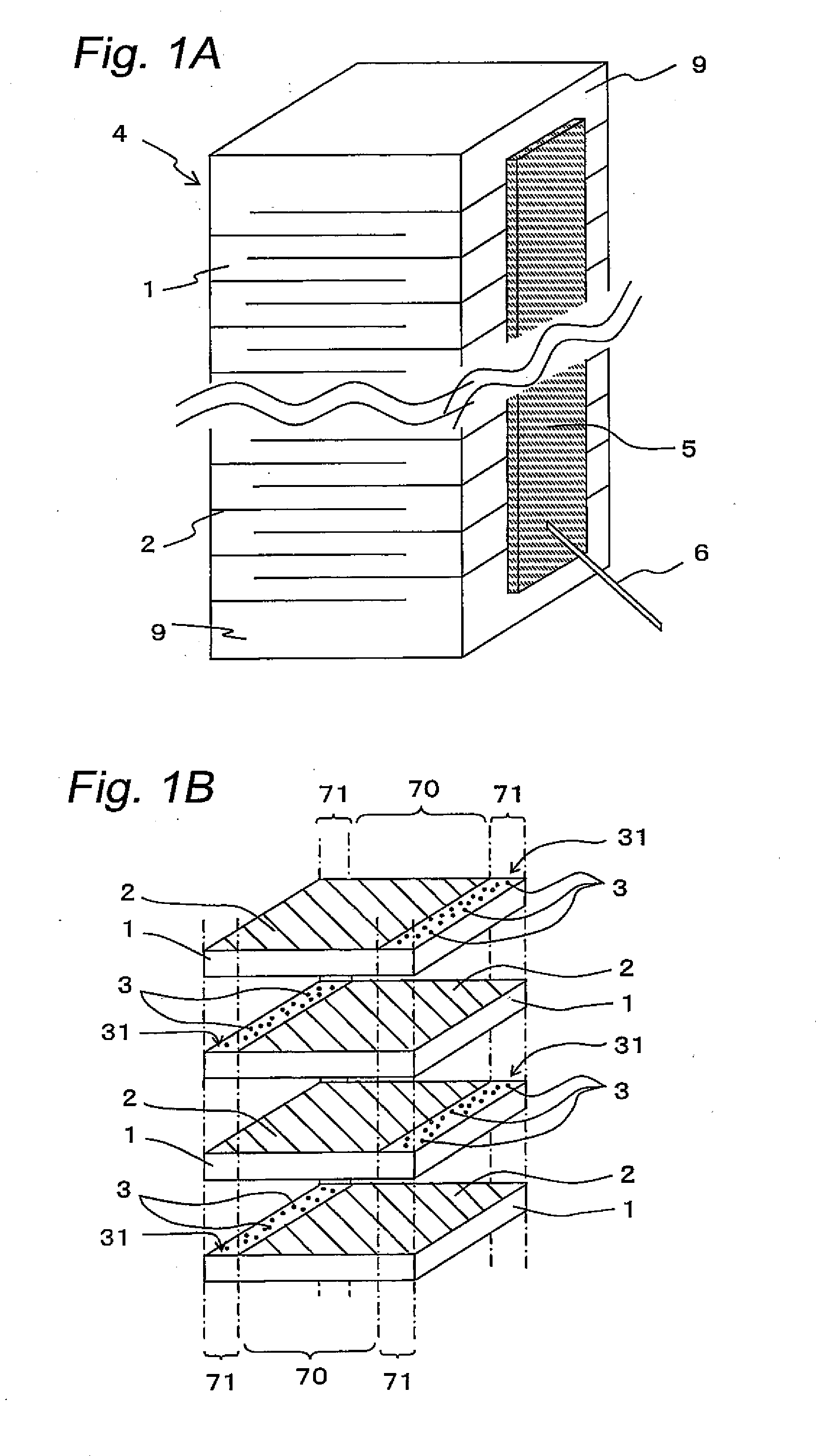

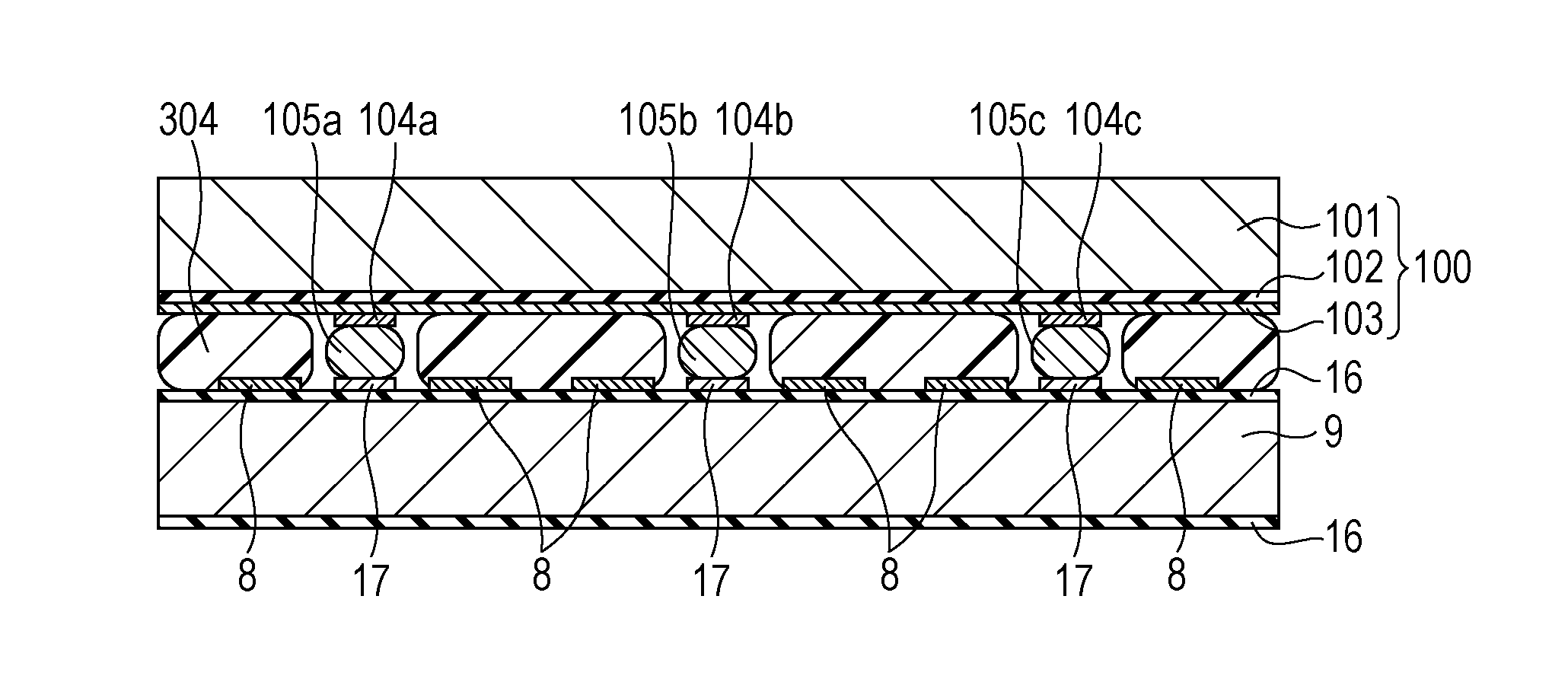

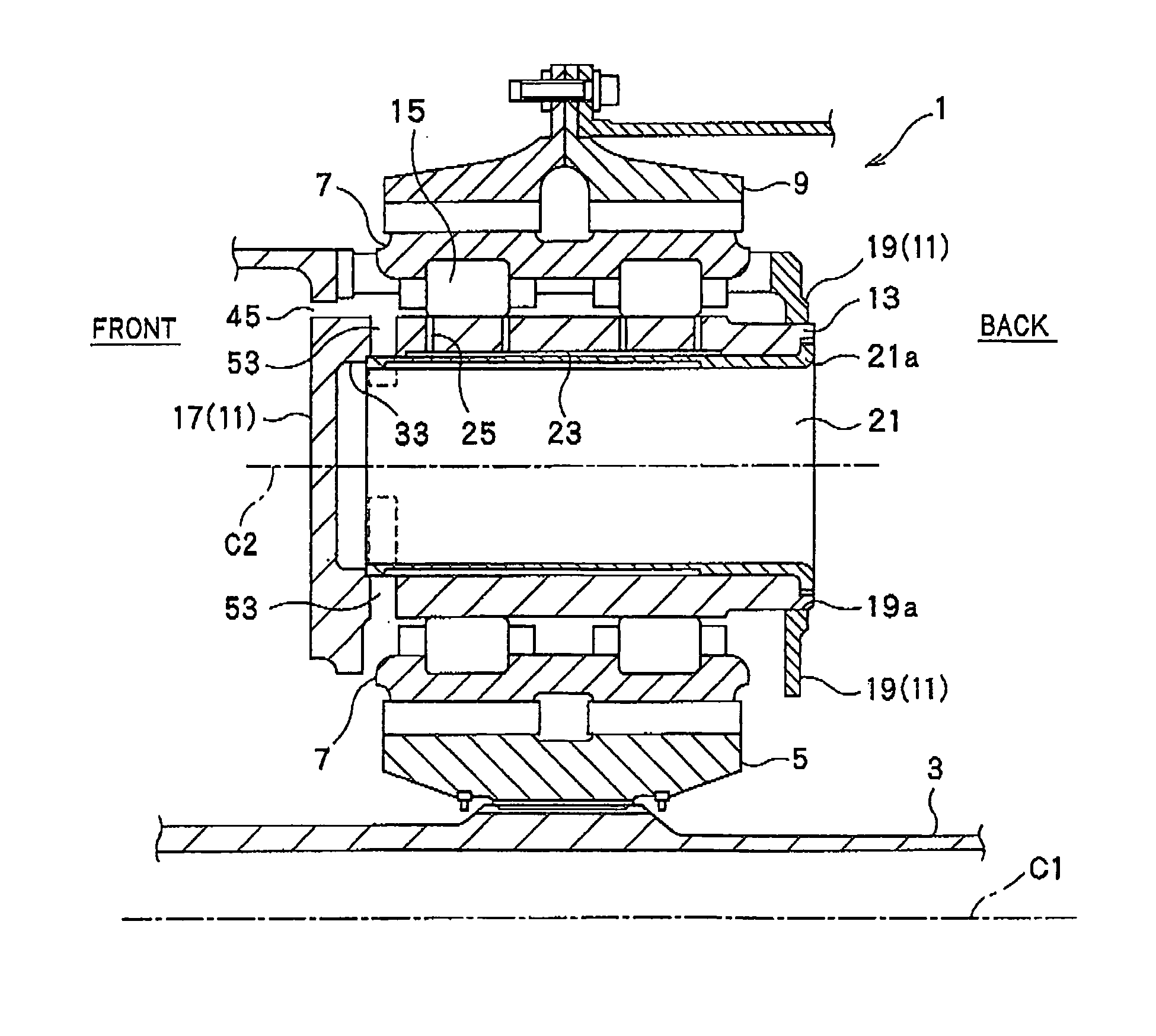

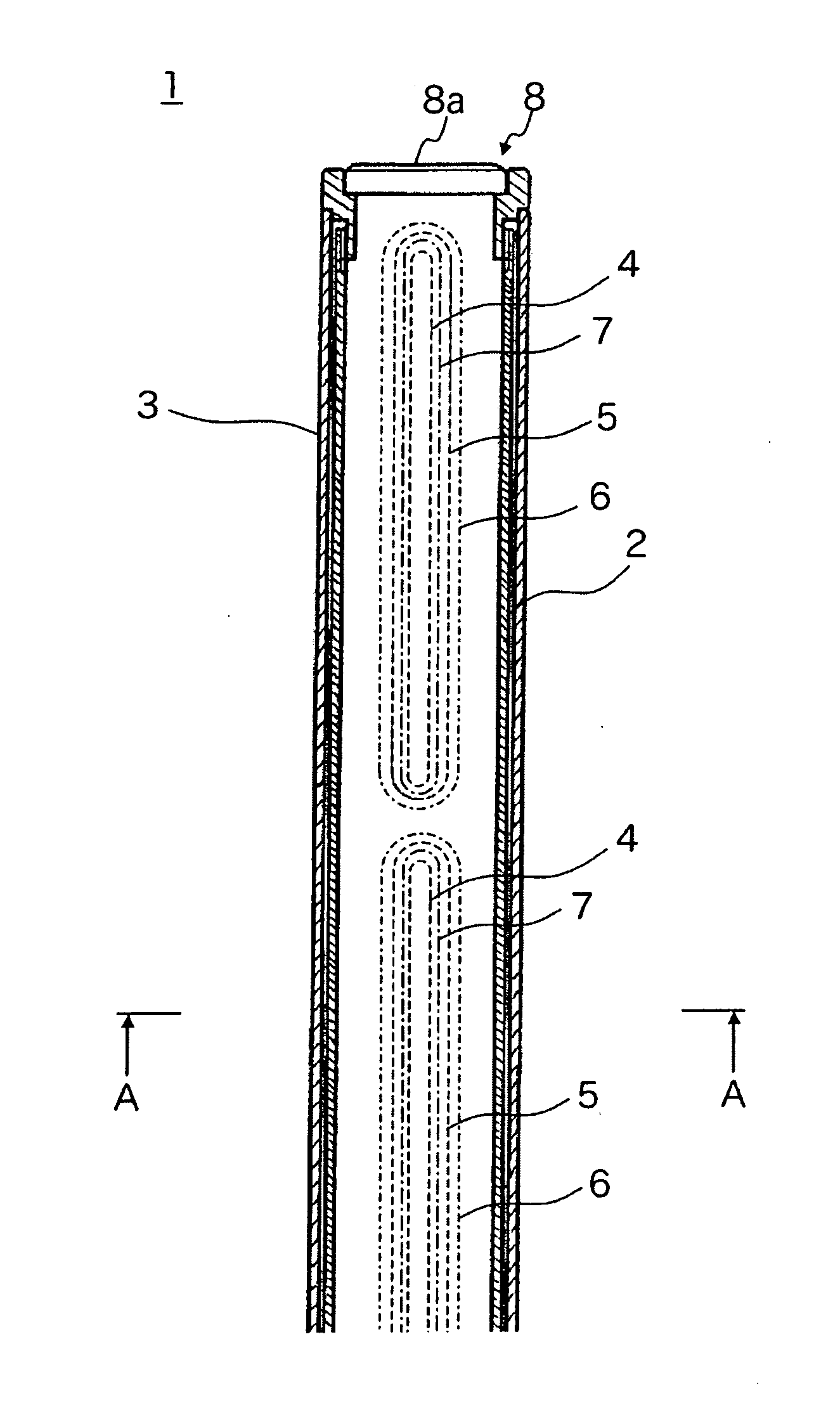

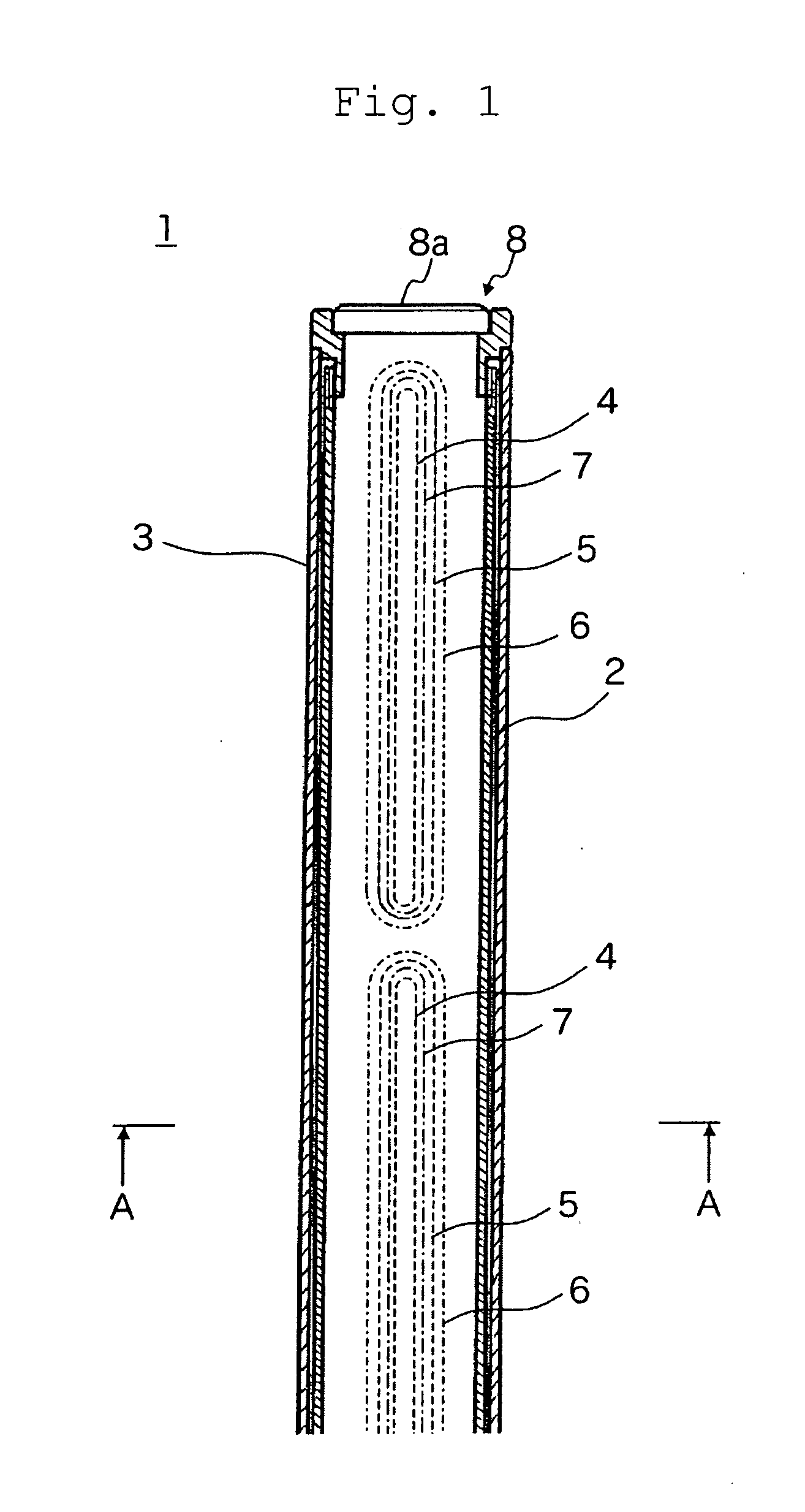

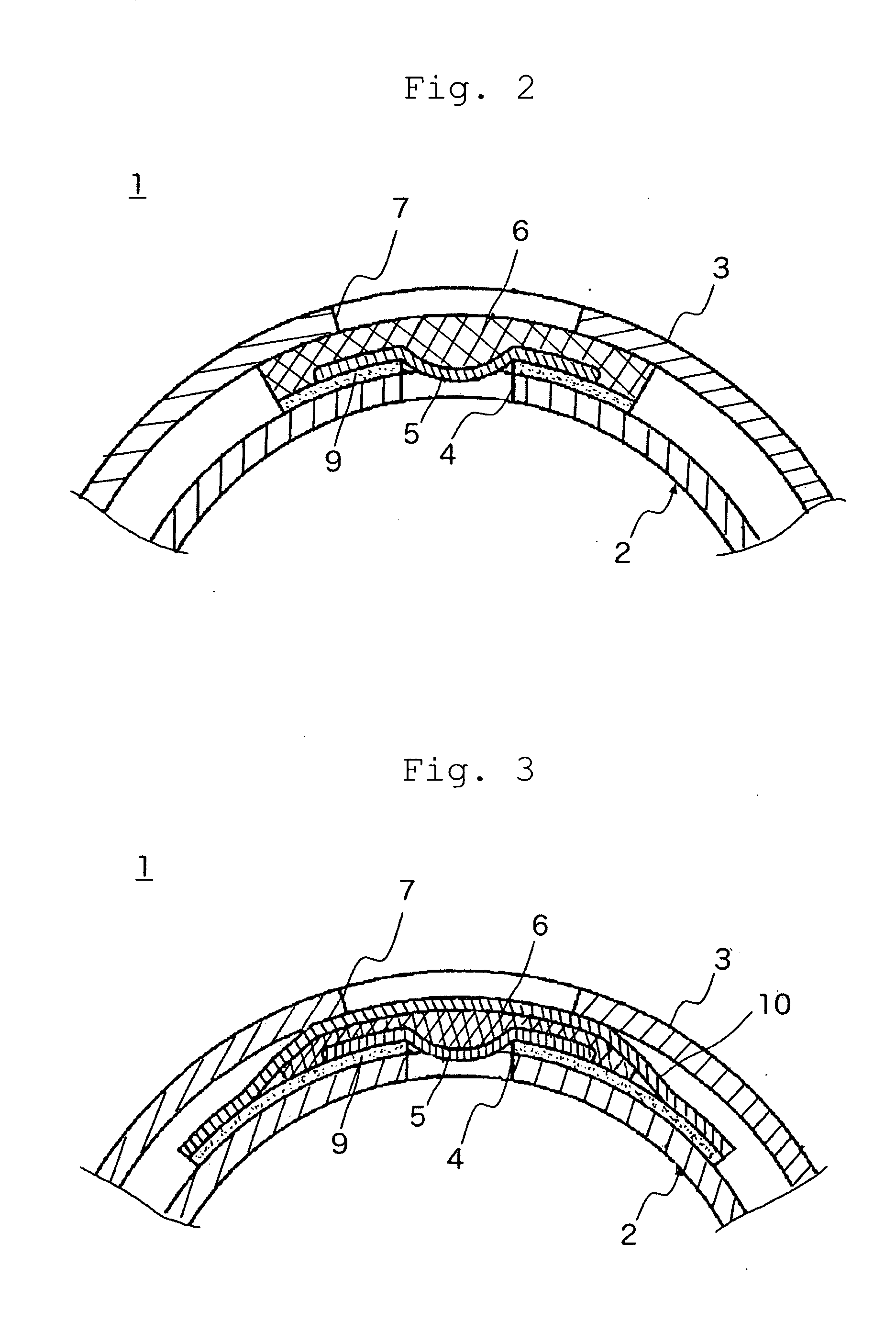

Laminated battery

InactiveUS20170222280A1Suppress relative displacementSuppress contractionFinal product manufactureElectrode carriers/collectorsMetal foilElectrical polarity

A laminated battery includes a stacked electrode group including a positive electrode, a negative electrode, a dummy electrode, a first separator interposed between the positive and negative electrodes, and a second separator interposed between the positive and / or negative electrode and the dummy electrode; and an electrolyte. At least one positive electrode and / or at least one negative electrode includes a single-sided electrode including a current collector and an electrode active material layer formed on a first surface of the current collector. A second surface of the current collector is exposed. The dummy electrode is a metal foil facing the second surface of the current collector of the single-sided electrode and having a polarity opposite to that of the single-sided electrode. Adhesive strengths F1 and F2 on both sides of the first separator and adhesive strengths F3 and F4 on both sides of the second separator satisfy F1+F2>F3+F4.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

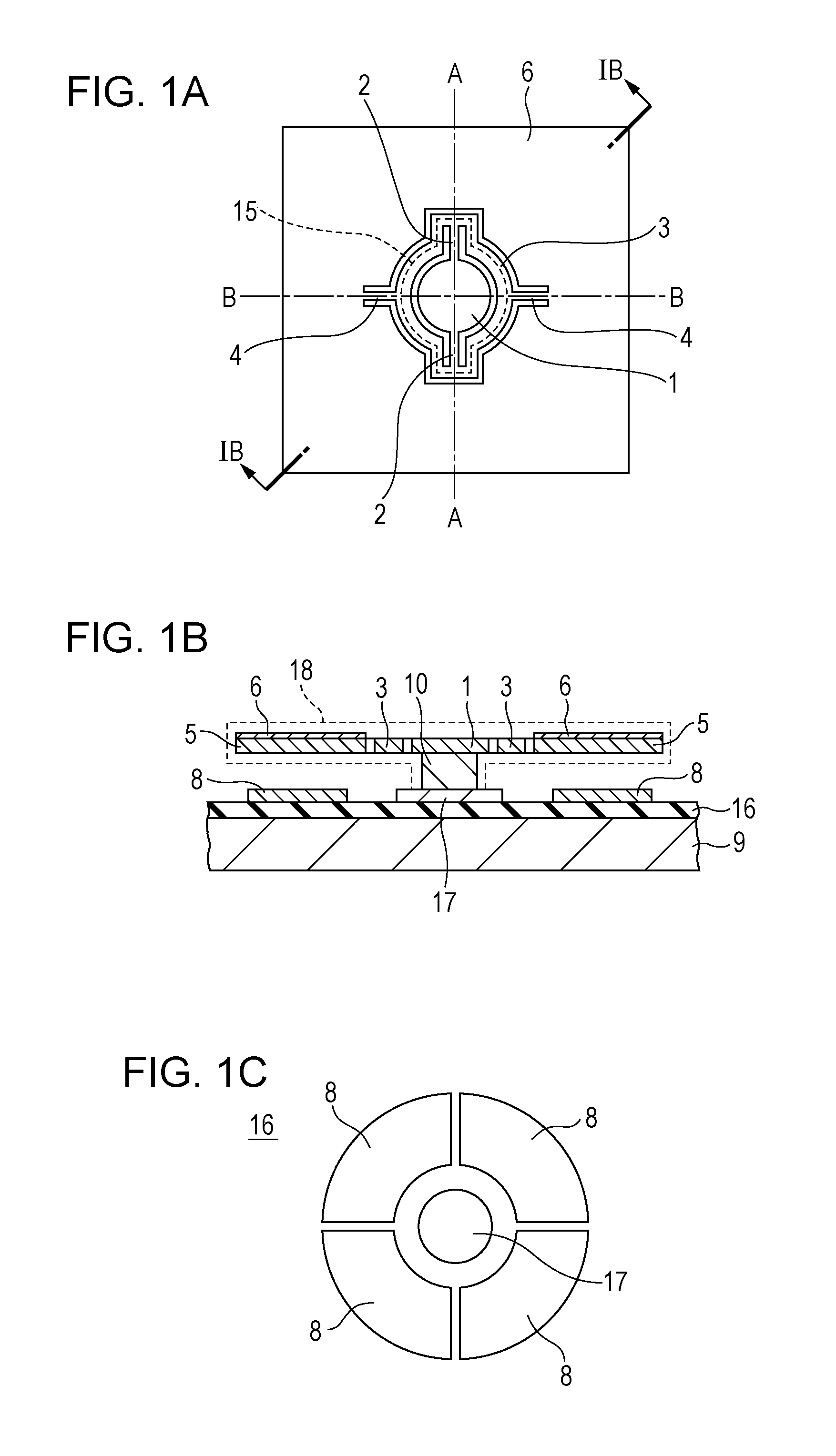

Capacitance-type transducer

A capacitance-type transducer has a back plate having a fixed electrode, a diaphragm that opposes the back plate via an air gap and serves as a movable electrode, and at least first stoppers having a first projection length and second stoppers having a second projection length that project from at least one of a surface of the back plate on the air gap side and a surface of the diaphragm on the air gap side. At least one of the diaphragm and the fixed electrode is divided into at least a first region having a first surface area and a second region having a second surface area, a first sensing portion made up of the diaphragm and the fixed electrode is constituted in the first region, and a second sensing portion made up of the diaphragm and the fixed electrode is constituted in the second region.

Owner:MMI SEMICON CO LTD

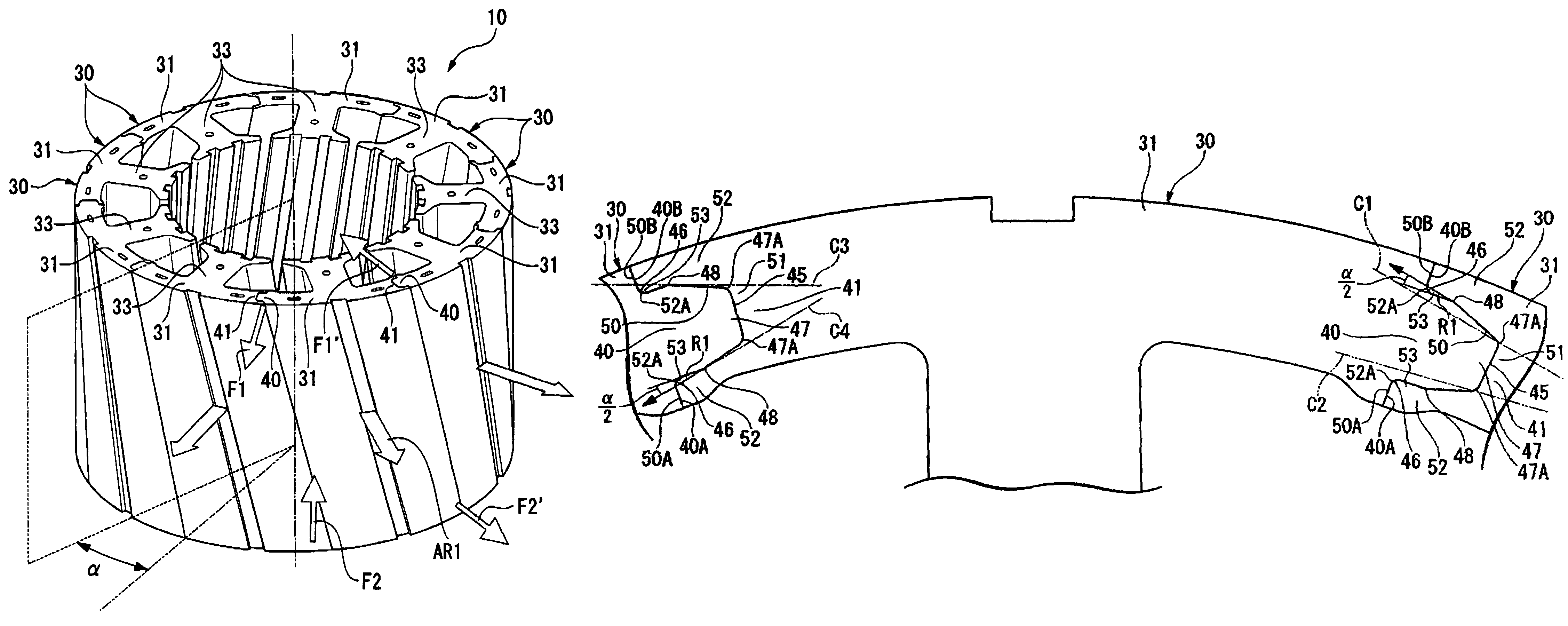

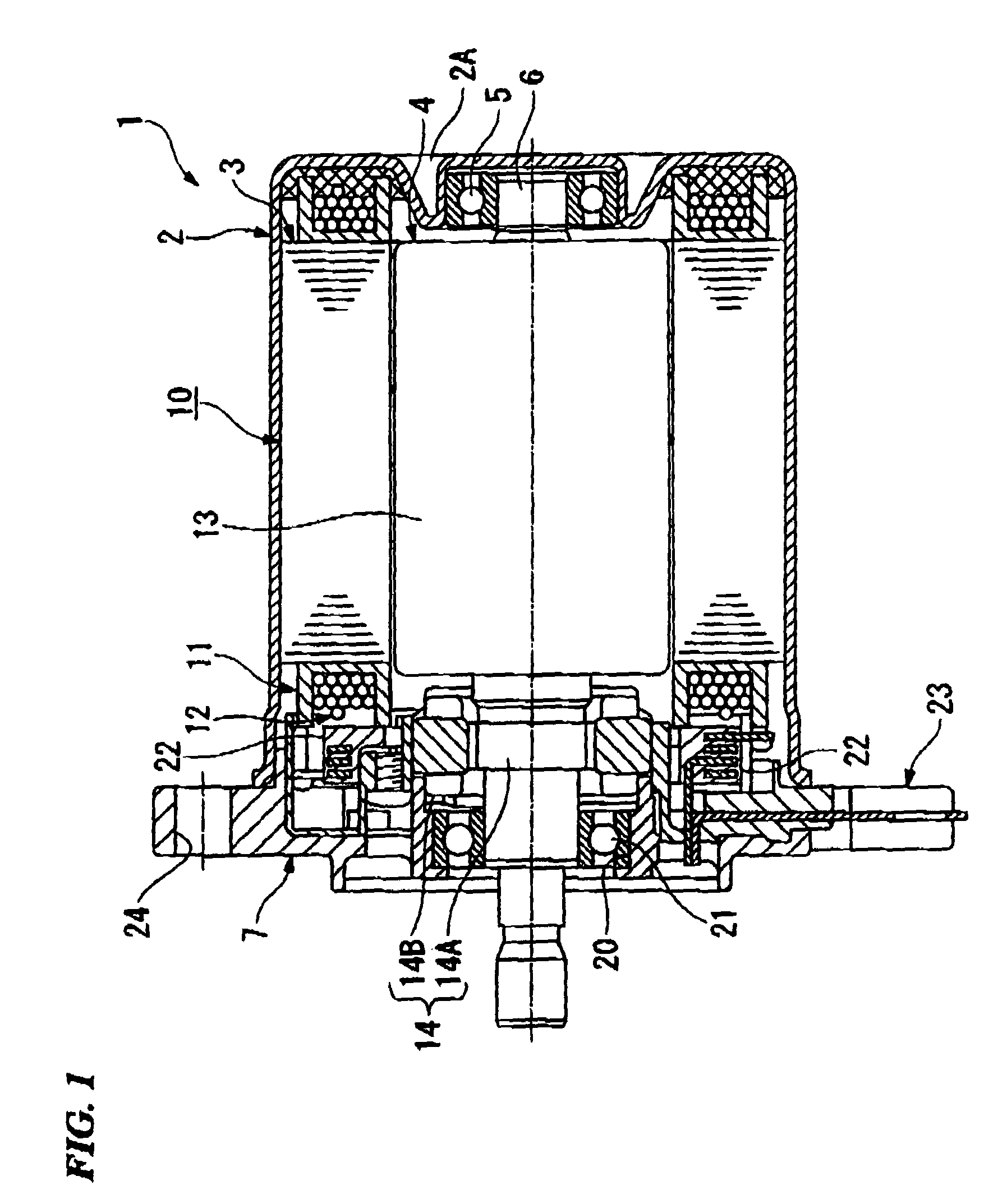

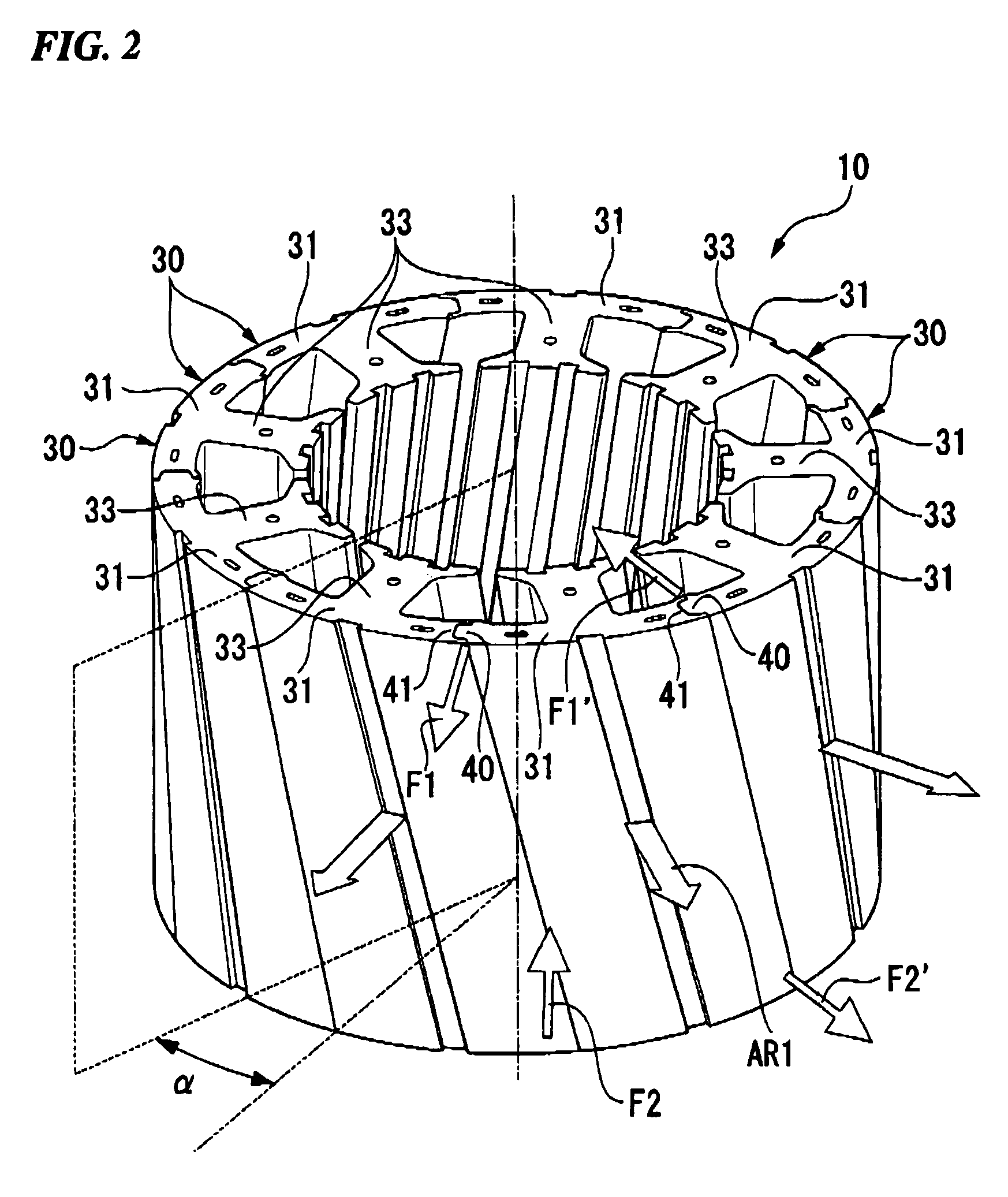

Motor, rotary electric machine and its stator, and method for manufacturing the stator

ActiveUS7595578B2Easy to assembleOptimize connection structureElectrical transducersMagnetic circuit stationary partsElectric machineEngineering

Owner:MITSUBA CORP

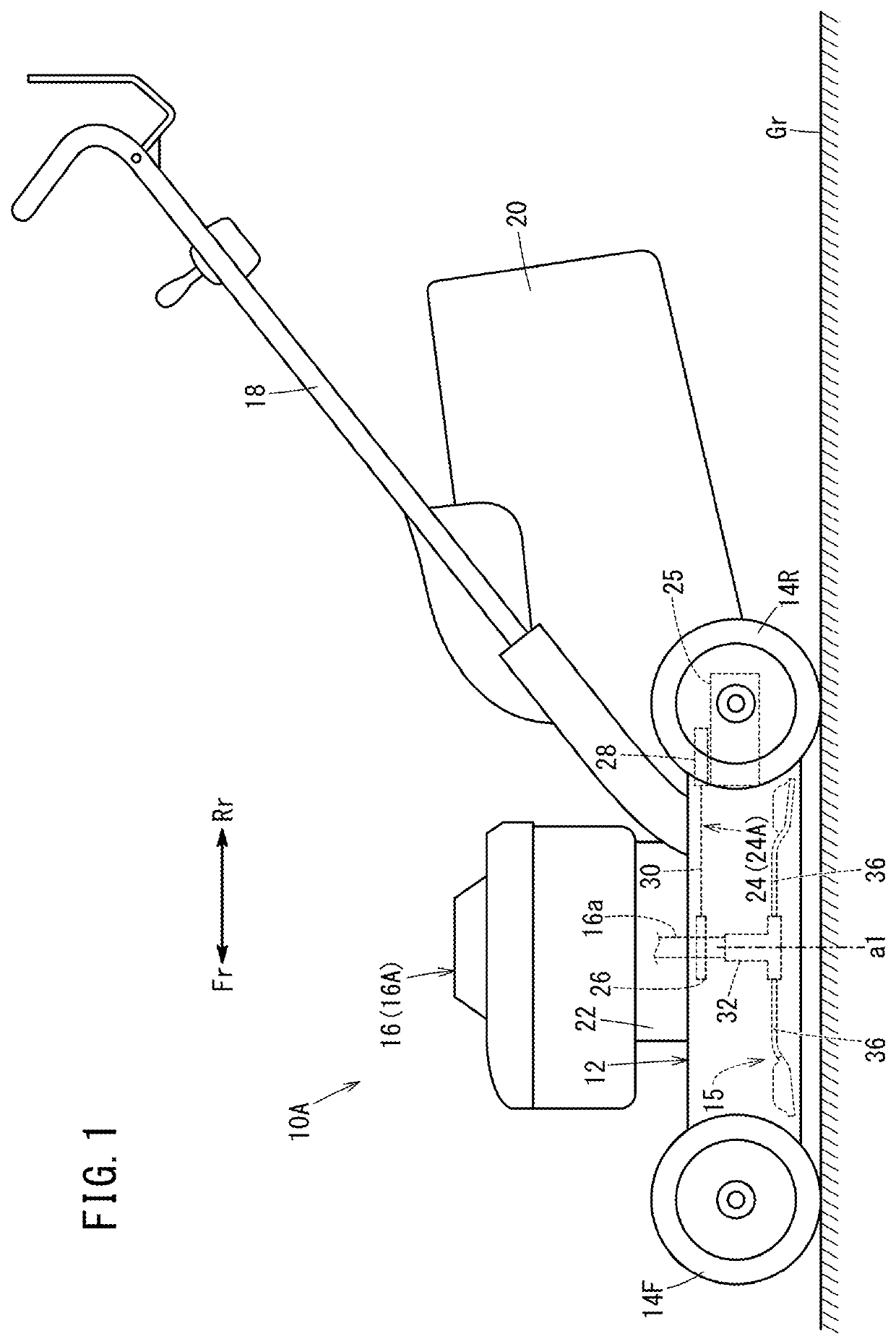

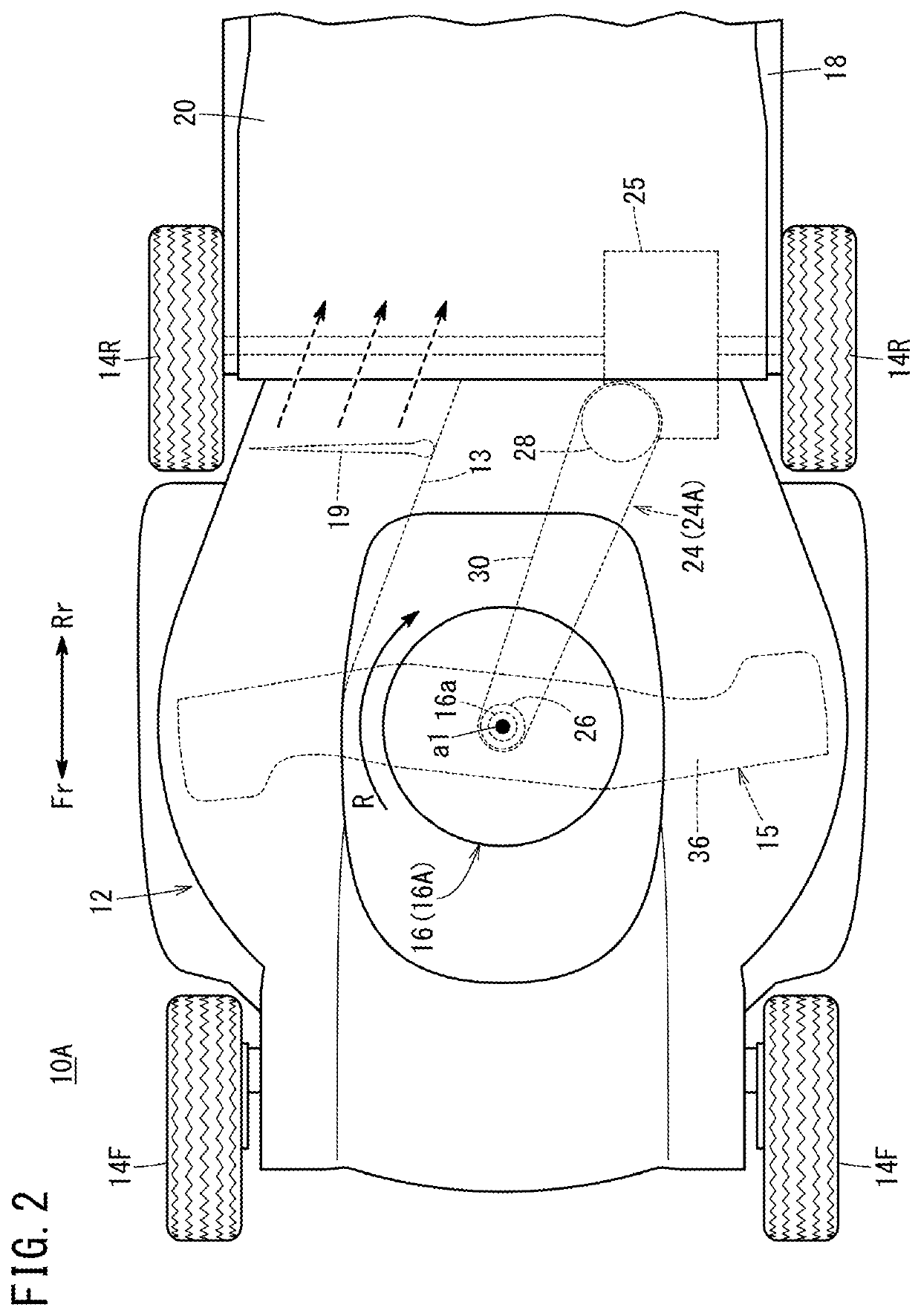

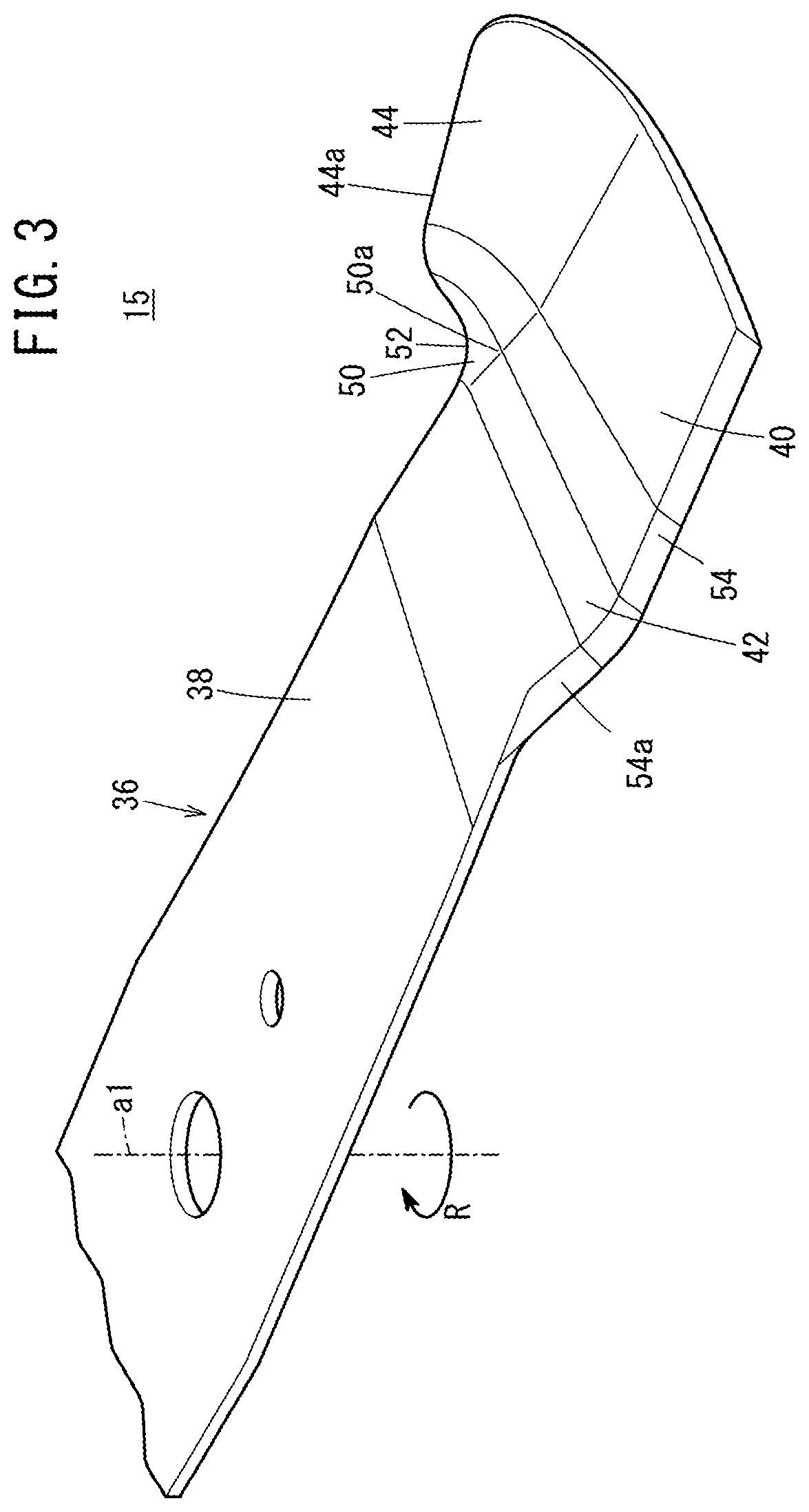

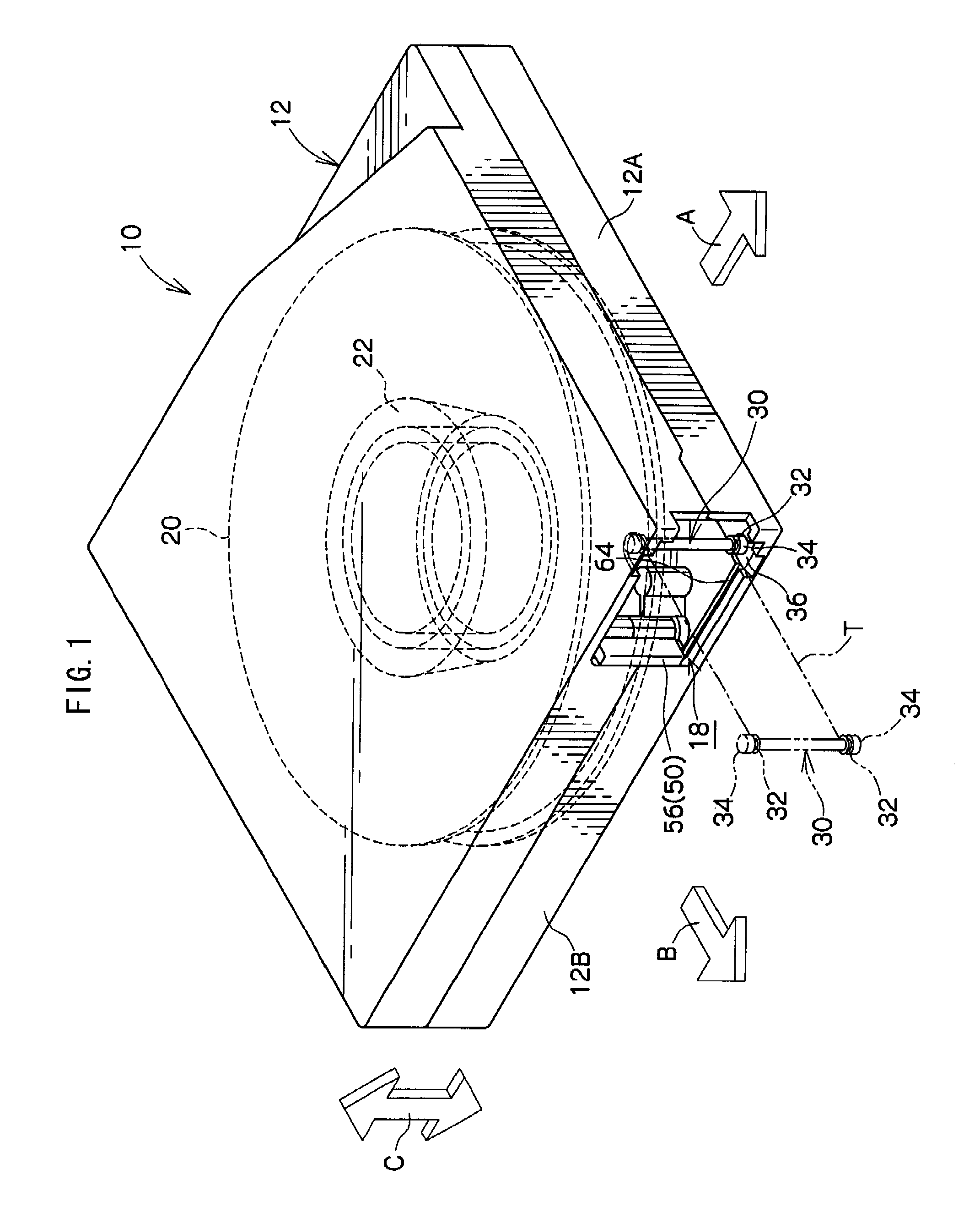

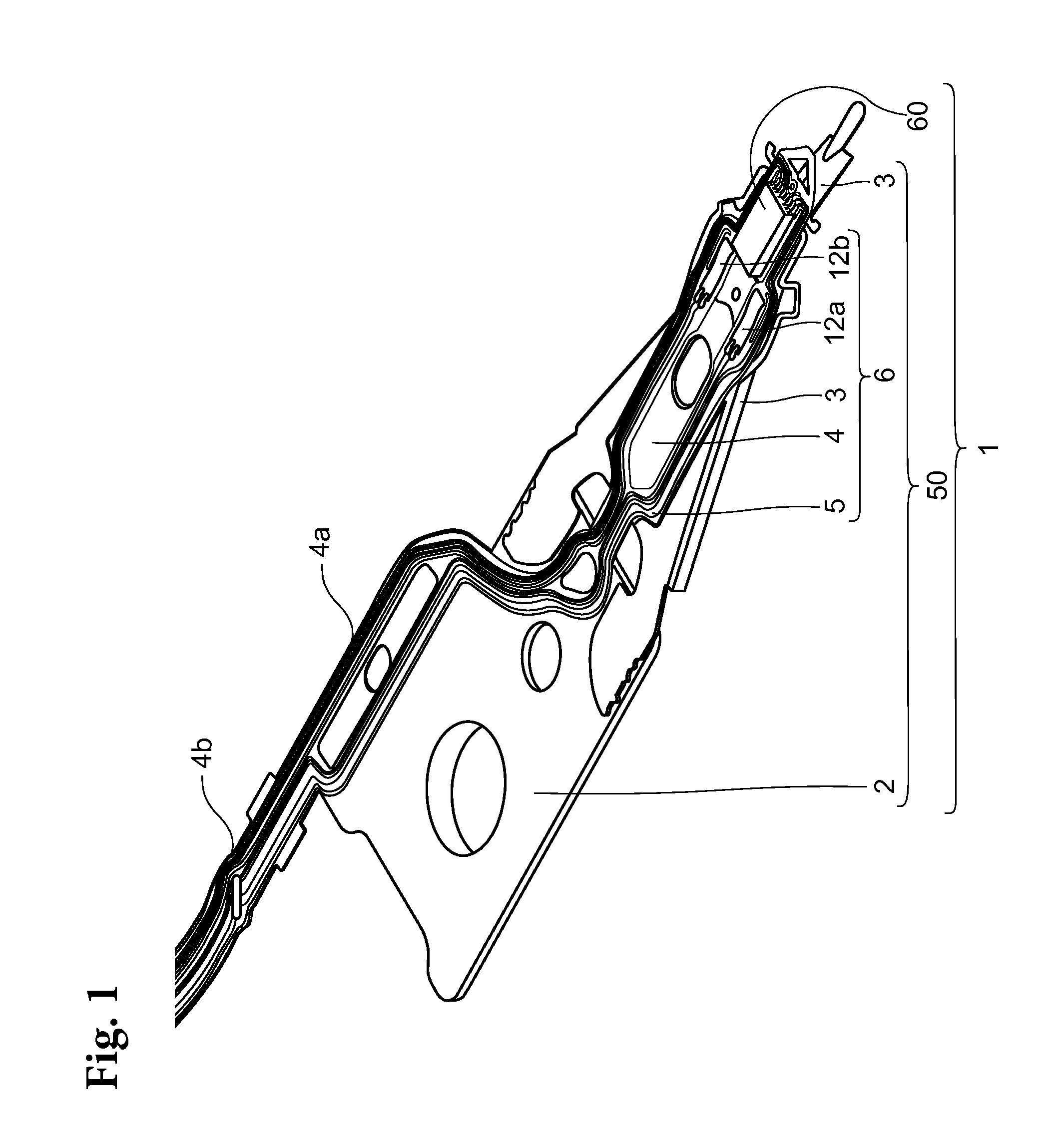

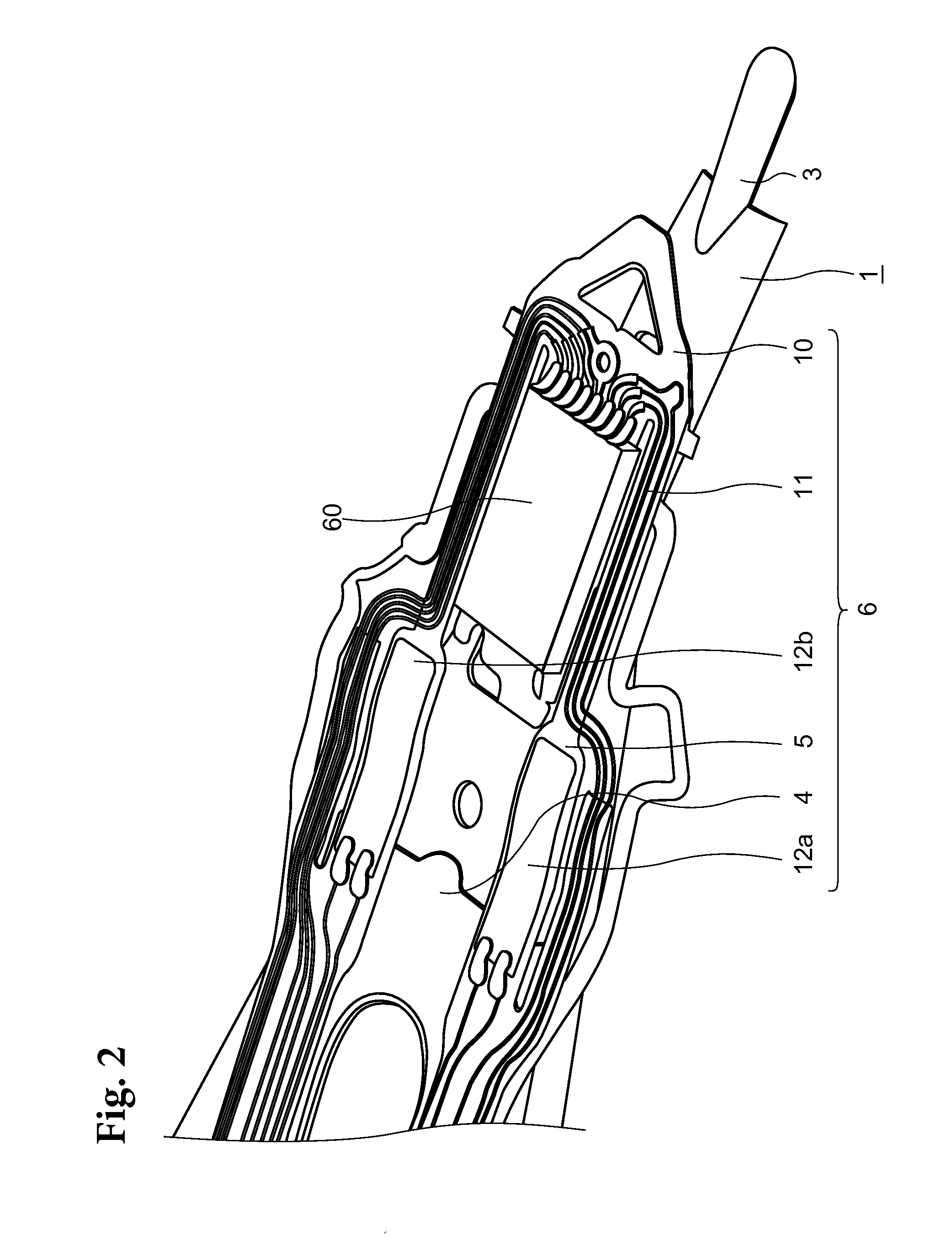

Cutter blade and lawn mower

ActiveUS20200100426A1Suppress relative displacementImprove rigidityMowersClassical mechanicsEngineering

A cutter blade for a lawn mower is provided with an upper blade and a lower blade. The upper blade has an upper blade base and an upper outer end positioned above and further radially outward than the upper blade base. The lower blade has a lower blade base and a mowing section positioned below and further radially outward than the lower blade base. The upper blade base overlaps the lower blade base.

Owner:HONDA MOTOR CO LTD

Multilayer Piezoelectric Element and Injector Using the Same

ActiveUS20090295256A1Large displacementIncreased durabilityPiezoelectric/electrostriction/magnetostriction machinesSpray nozzlesThin metalFilling rate

In a multilayer piezoelectric element in which a plurality of piezoelectric layers and a plurality of metal layers are stacked alternately, the plurality of metal layers include a plurality of low-filled metal layers having a lower filling rate of metal composing the metal layers than oppositely disposed metal layers adjacent to each other in a stacking direction. In a multilayer piezoelectric element in which a plurality of piezoelectric layers and a plurality of metal layers are stacked alternately, the plurality of metal layers include a plurality of thin metal layers having a smaller thickness than oppositely disposed metal layers adjacent to each other in a stacking direction. In a multilayer piezoelectric element in which a plurality of piezoelectric layers and a plurality of metal layers composed mainly of an alloy are stacked alternately, the plurality of metal layers include a plurality of high-ratio metal layers having a higher ratio of a component constituting the alloy than oppositely disposed metal layers adjacent to each other in a stacking direction.

Owner:KYOCERA CORP

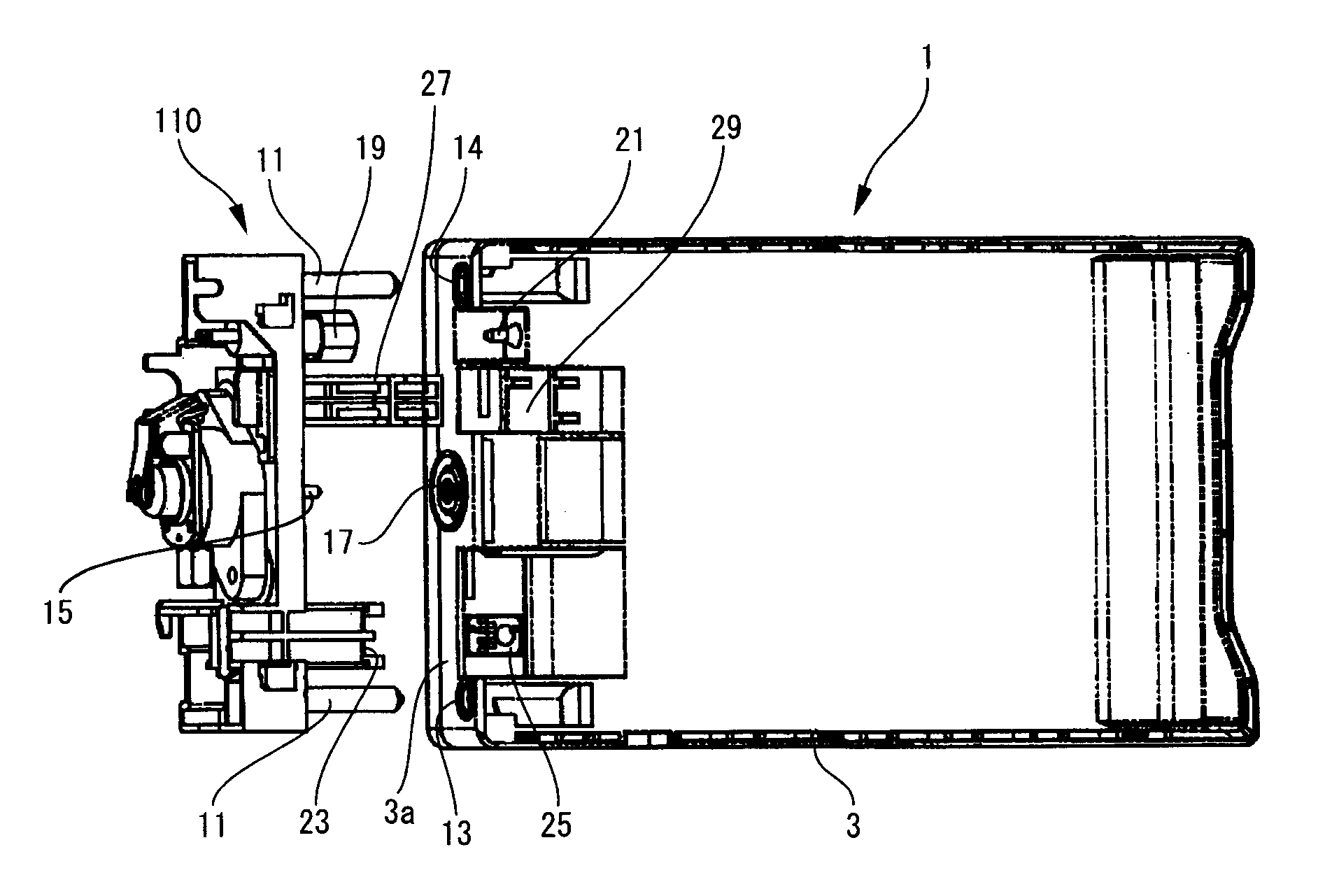

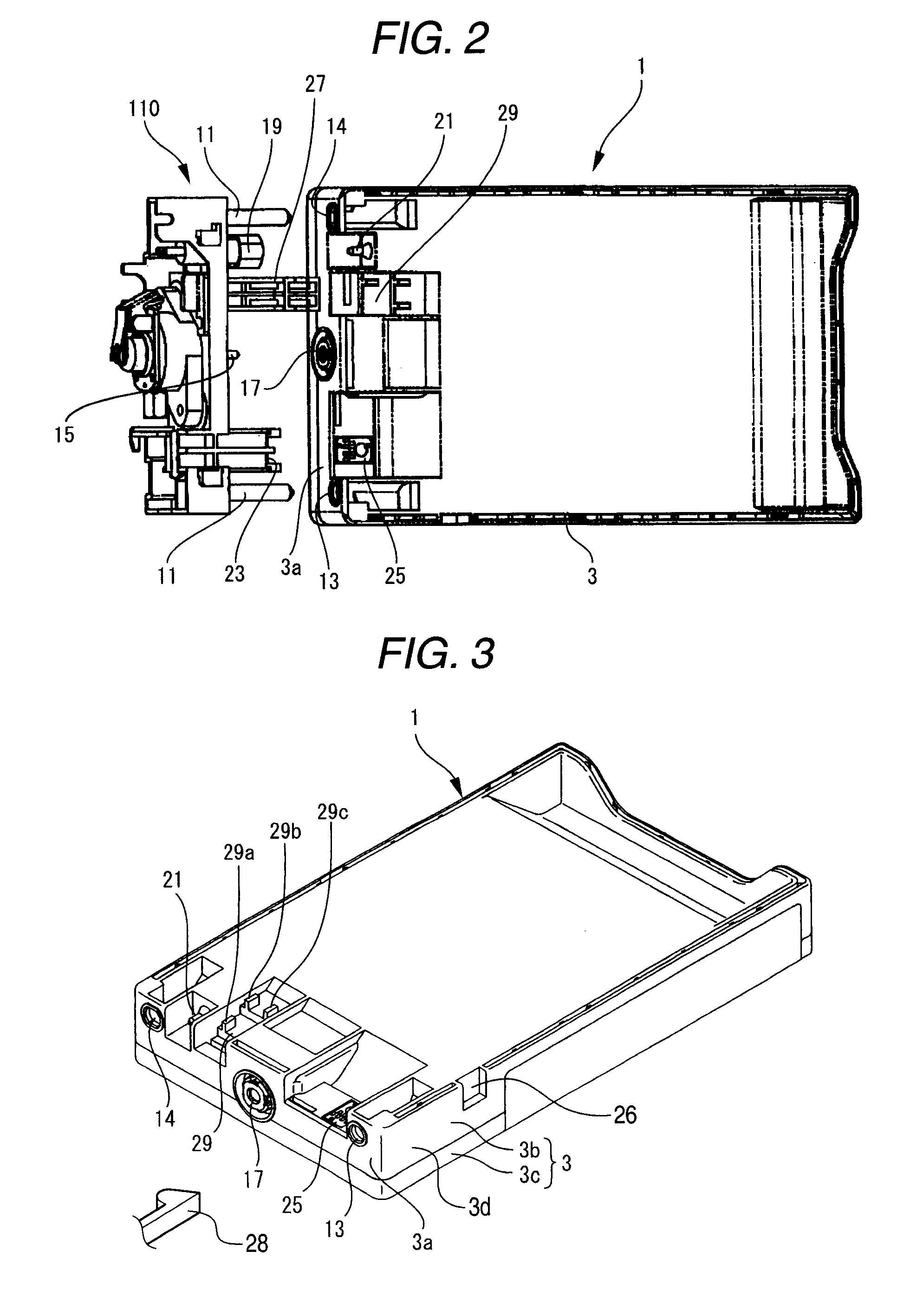

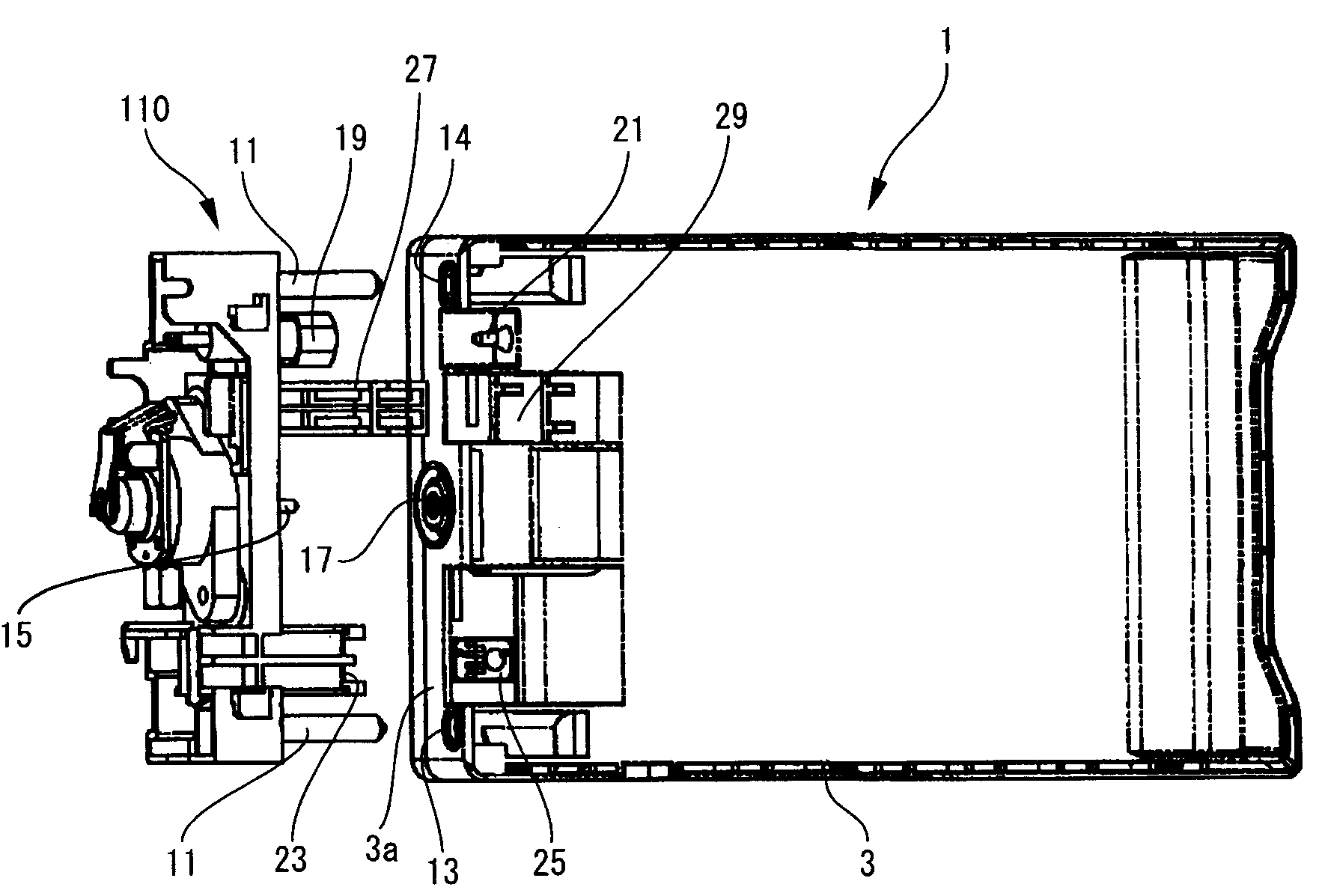

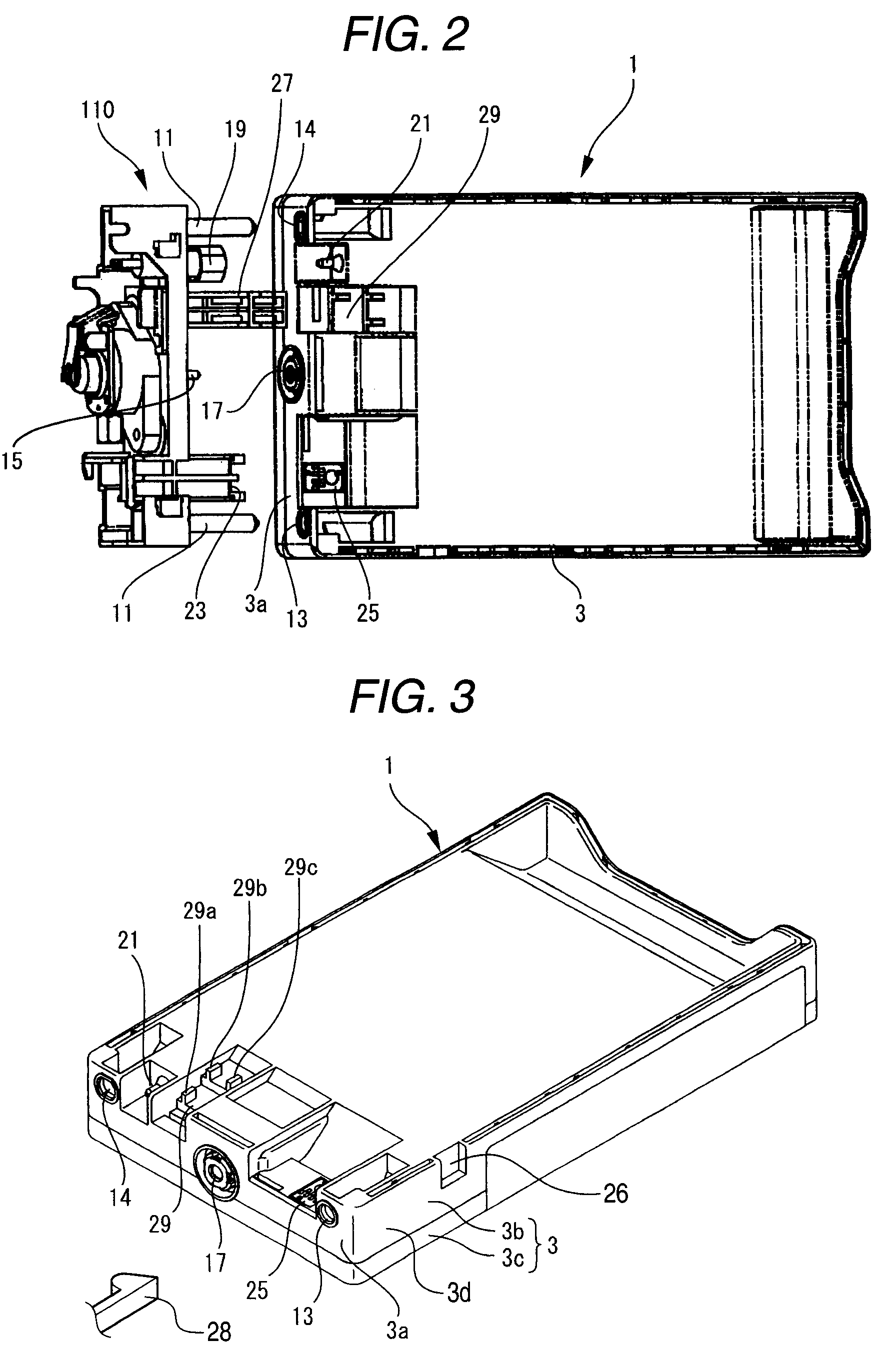

Liquid container

In an ink cartridge (liquid container) 1 of the invention, an ink delivery port 17 that connects an ink supply needle 15 of a cartridge holder 110 to an ink containing chamber 7 is disposed at an substantially central position in a shorter side direction of a container front surface 3a. Two positioning portions 13 and 14 that fit to positioning pins 11 provided at two places in the cartridge holder 110 so as to position a container main body 3, a pressurized air introduction portion 21 that connects a pressurized air supply path 19 of the cartridge holder 110 to a pressure chamber 5, and a data storage unit 25 that is connected to a connection terminal 23 of the cartridge holder 110 are disposed toward one side in a shorter side direction of the container front surface 3a with respect to the ink delivery port 17.

Owner:SEIKO EPSON CORP

Multi-Layer Piezoelectric Element and Injection Apparatus Using the Same

ActiveUS20100013359A1Reducing restrictive forceImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEngineeringInjection device

Owner:KYOCERA CORP

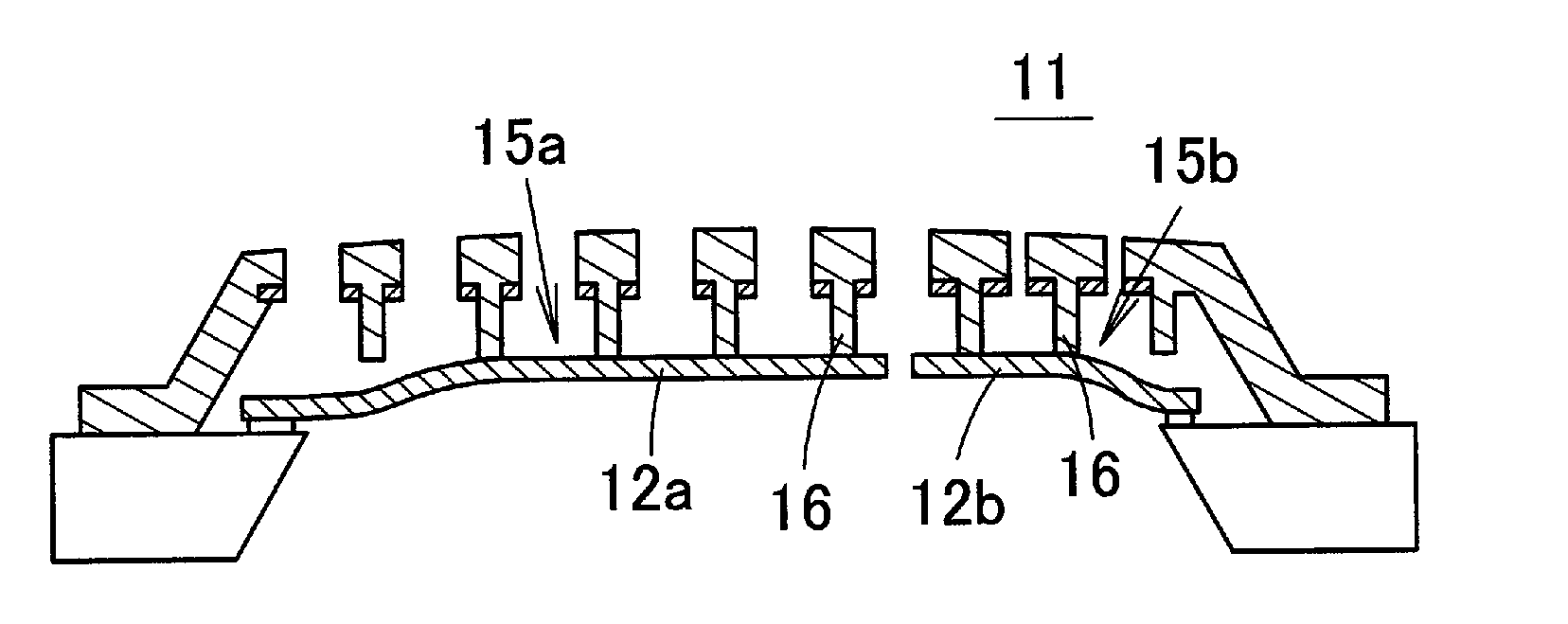

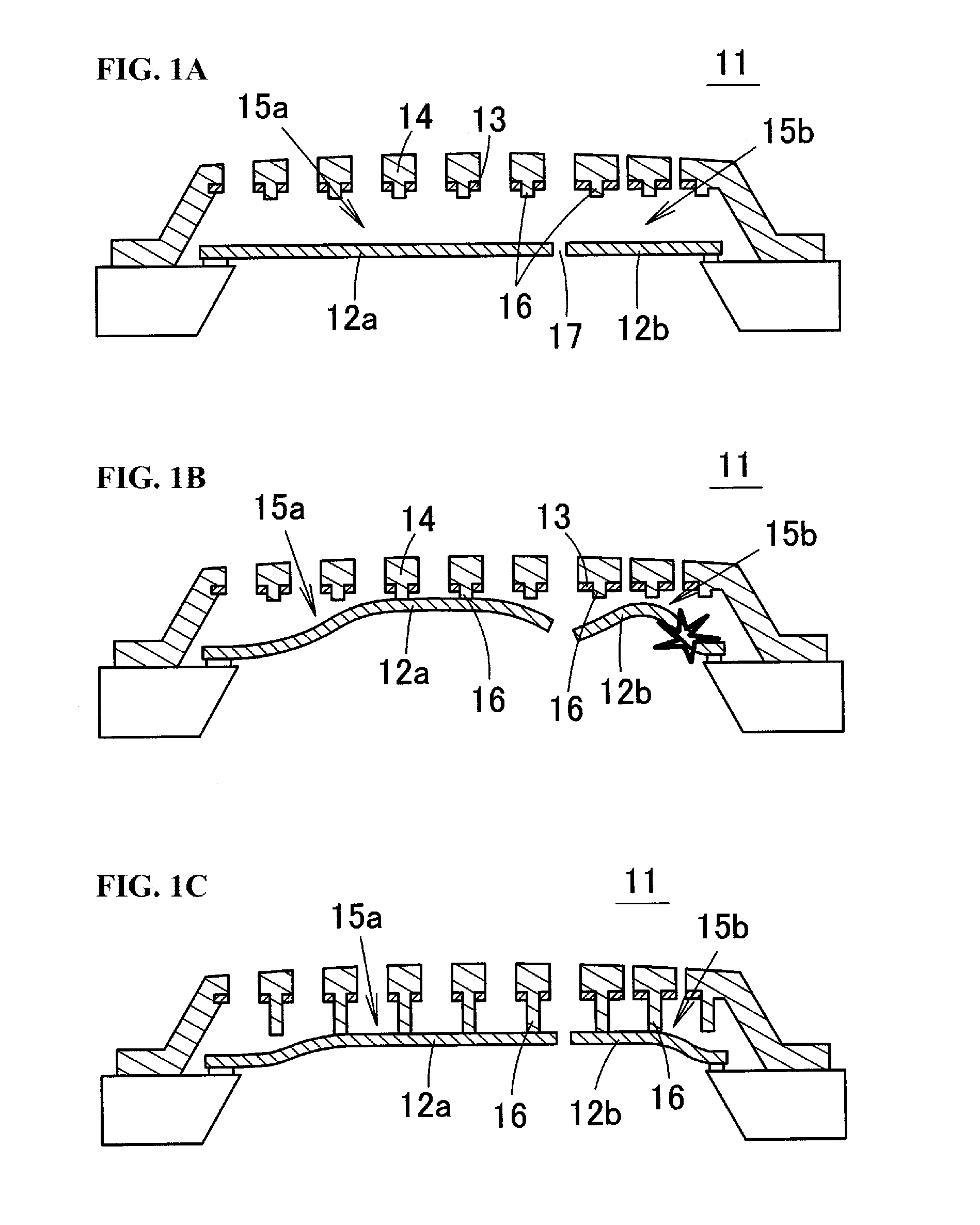

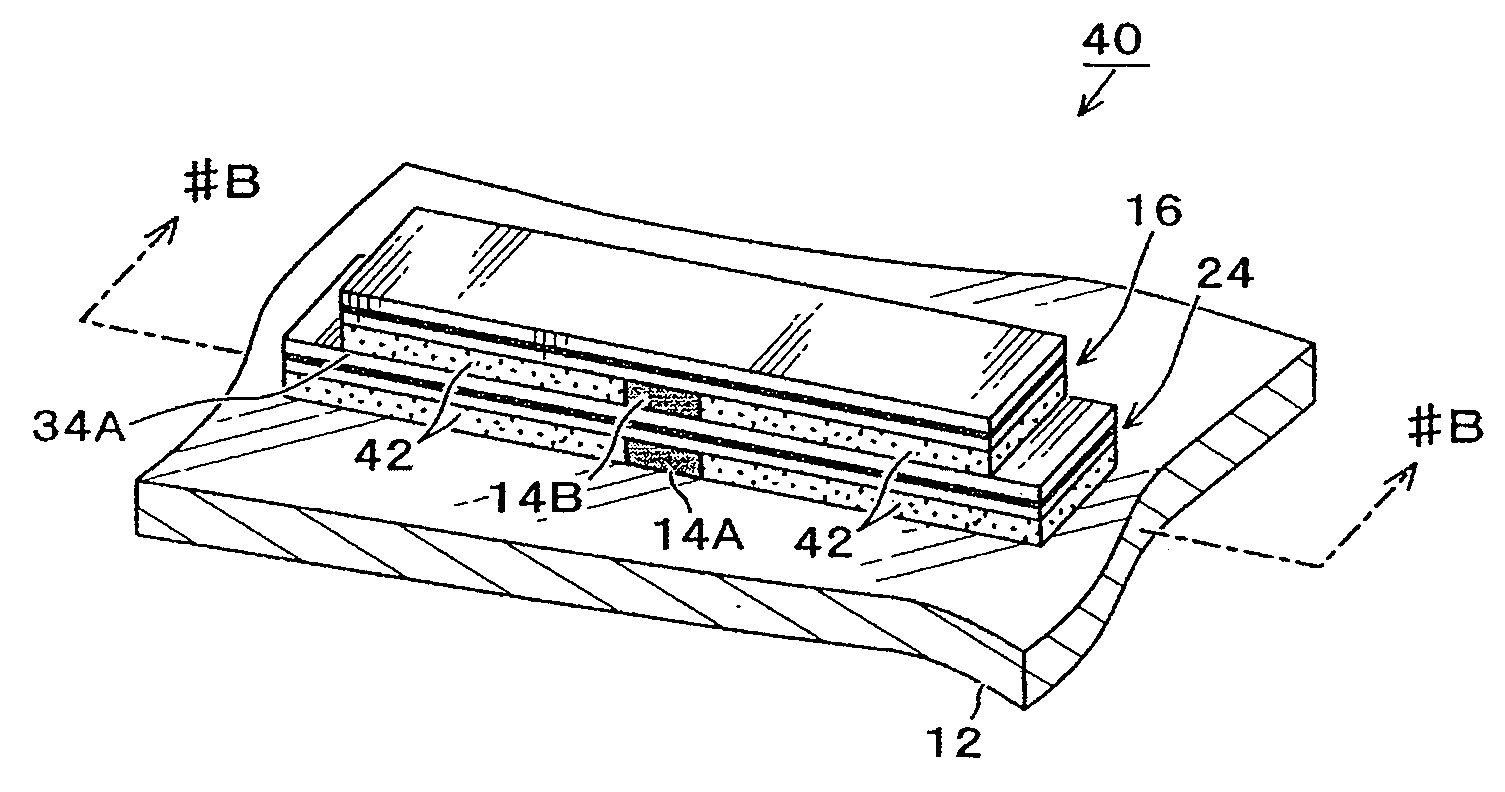

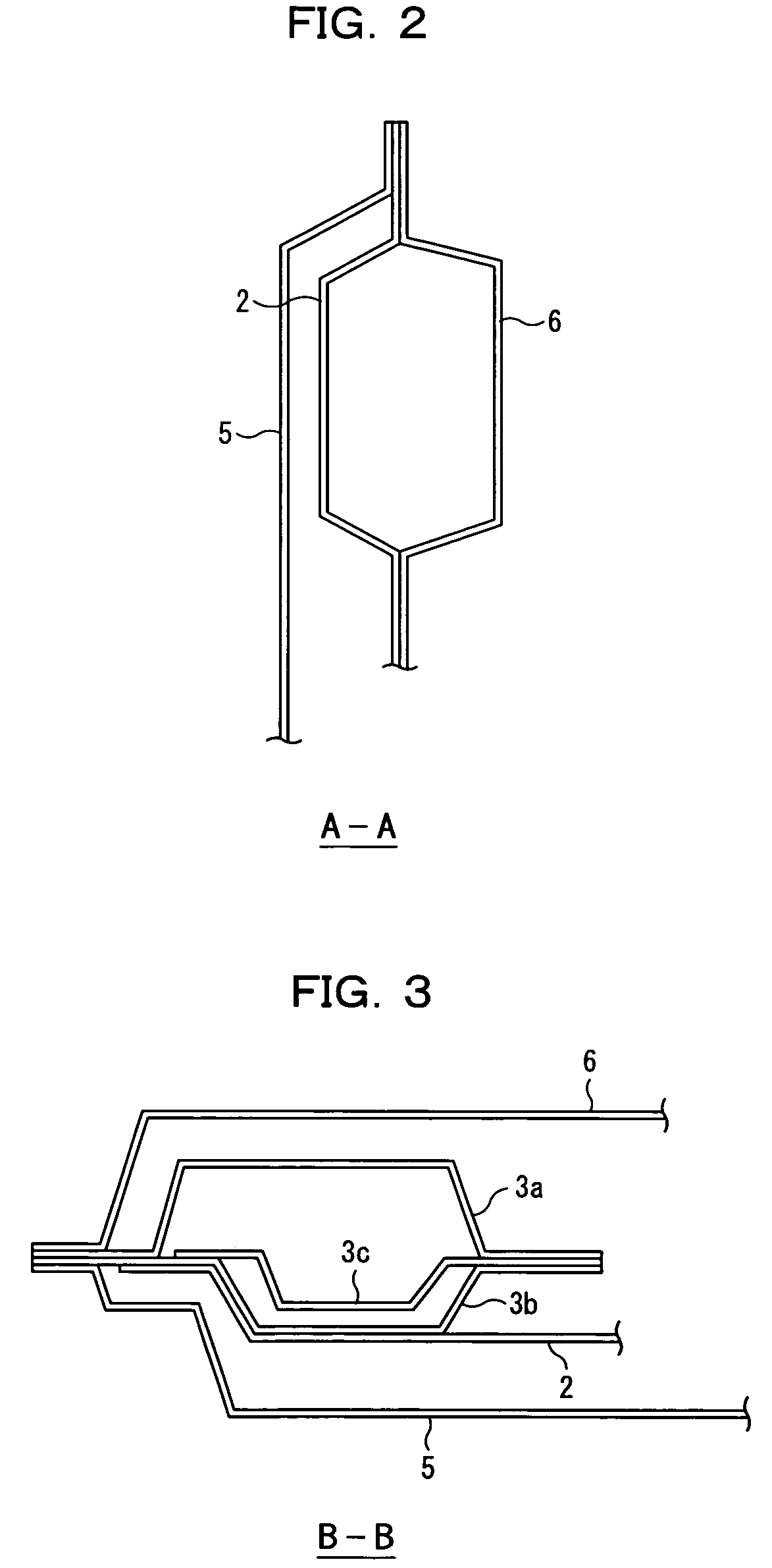

Piezoelectric vibrator

InactiveUS20070013270A1Improve seismic performanceImproved mountability and reliabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersEngineeringYoung's modulus

A piezoelectric vibrator having excellent shock resistance and high reliability is offered. The centers of first and second piezoelectric vibrating plates are supported by pillars on a main surface of an enclosure and nearly or substantially parallel to the main surface of the enclosure. Spacers having a Young's modulus of less than 2 GPa are mounted on both end sides of the second piezoelectric vibrating plate to prevent contact between the vibrating plates, thus preventing damage. Other spacers are mounted on the main surface of the enclosure in positions corresponding to the first-mentioned spacers to prevent contact with the main surface of the enclosure, thus preventing damage to the second piezoelectric vibrating plate.

Owner:TAIYO YUDEN KK

Liquid container

In an ink cartridge (liquid container) 1 of the invention, an ink delivery port 17 that connects an ink supply needle 15 of a cartridge holder 110 to an ink containing chamber 7 is disposed at an substantially central position in a shorter side direction of a container front surface 3a. Two positioning portions 13 and 14 that fit to positioning pins 11 provided at two places in the cartridge holder 110 so as to position a container main body 3, a pressurized air introduction portion 21 that connects a pressurized air supply path 19 of the cartridge holder 110 to a pressure chamber 5, and a data storage unit 25 that is connected to a connection terminal 23 of the cartridge holder 110 are disposed toward one side in a shorter side direction of the container front surface 3a with respect to the ink delivery port 17.

Owner:SEIKO EPSON CORP

Microstructural body and production method therefor

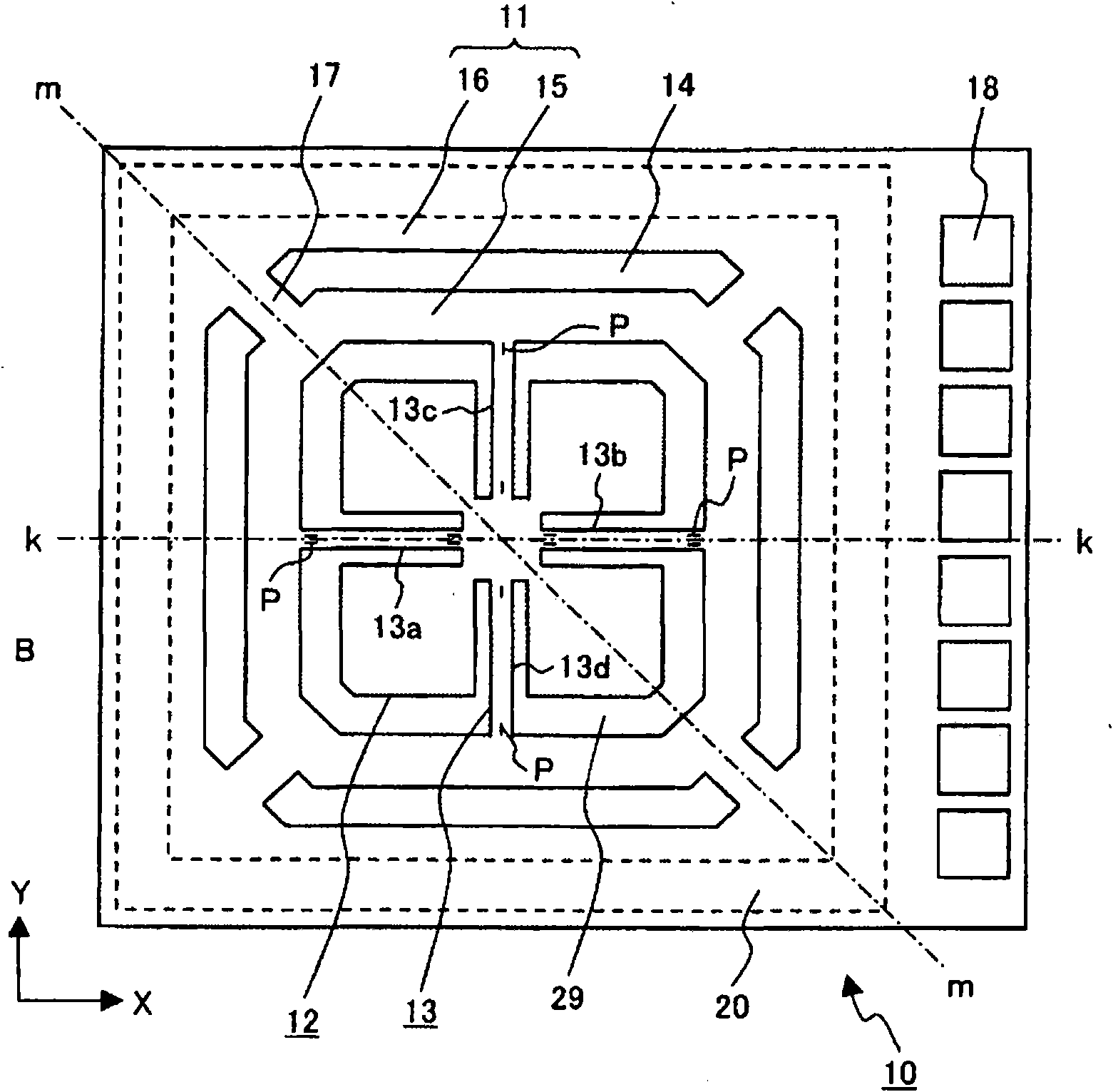

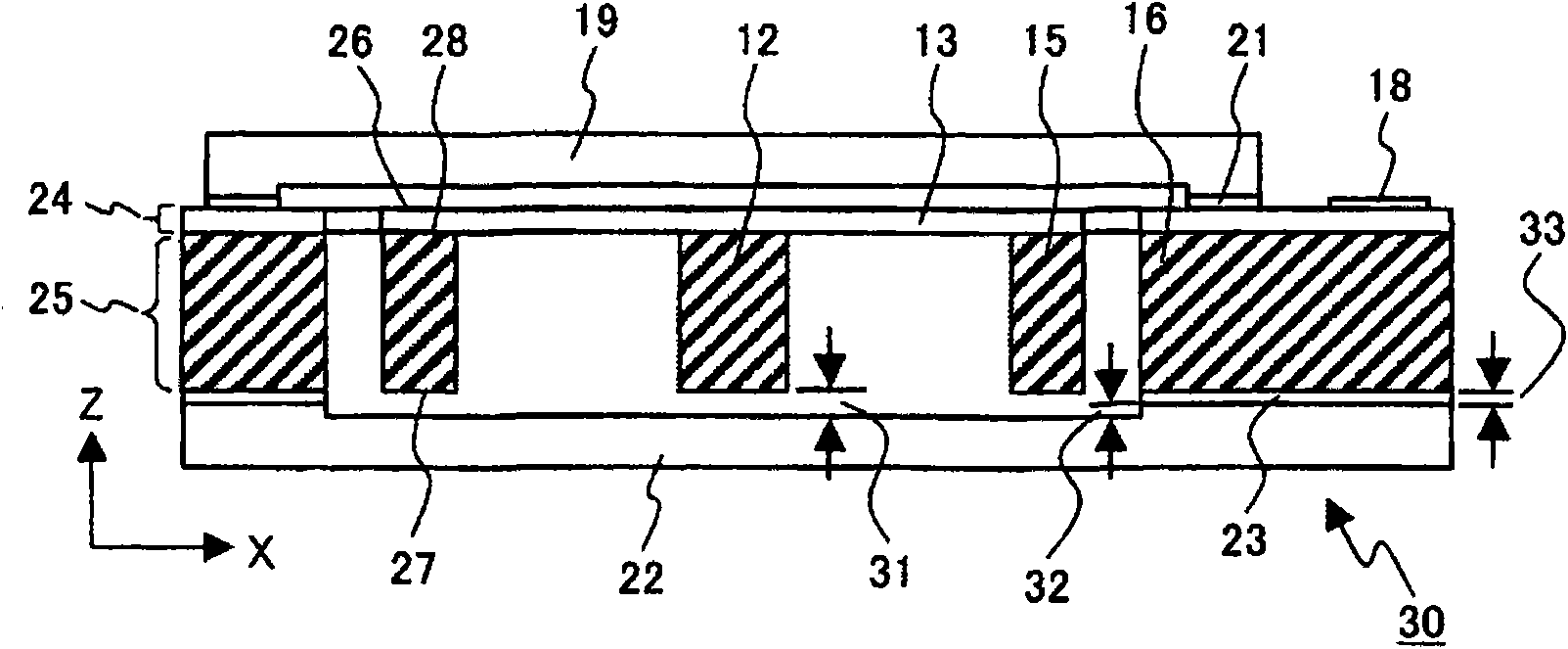

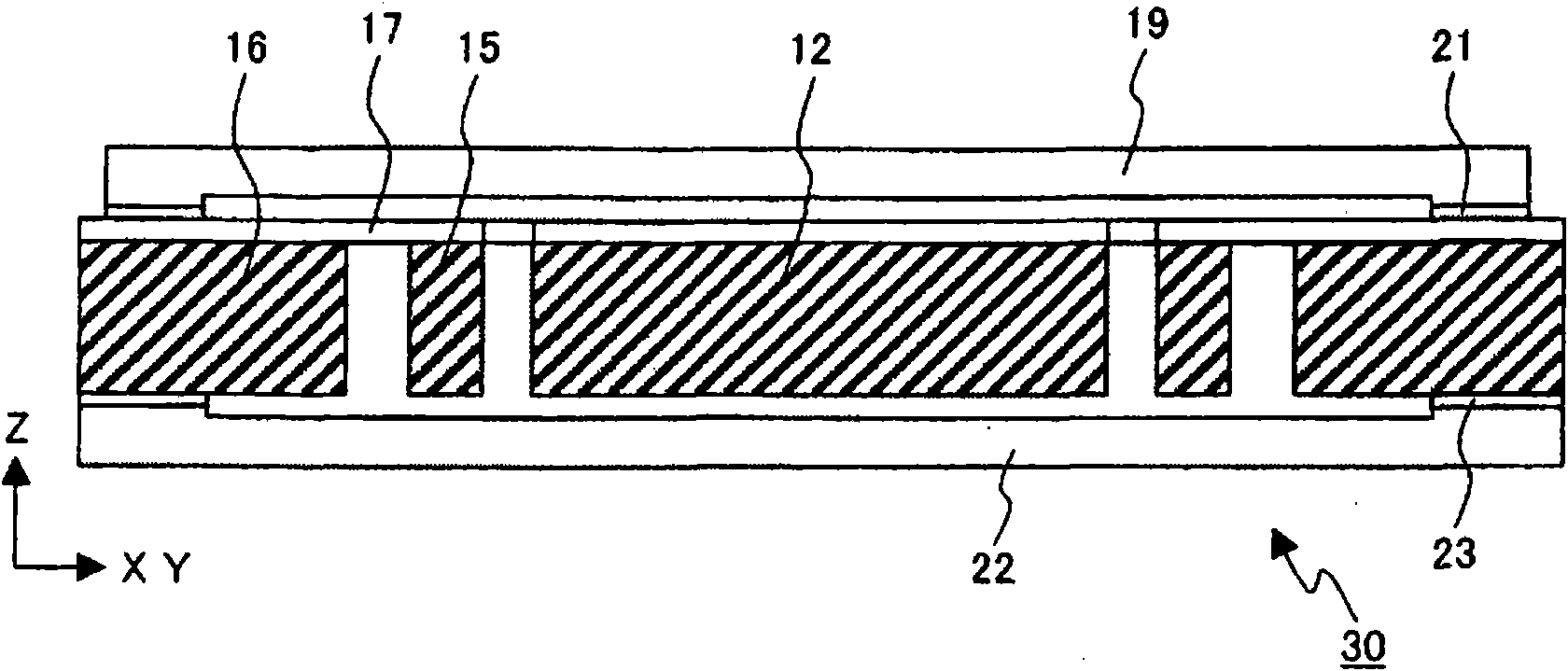

InactiveUS20110228440A1Suppress transmission of stressReduce changesPrinted electric component incorporationForming microstructural systemsEngineeringTorsion spring

A microstructural body includes a substrate such as an electrode substrate, a support portion, one post that fixes the support portion to the substrate, a frame-shaped movable portion provided around outer periphery of the support portion, and an elastic support portion that elastically connects the movable portion and the support portion. The elastic support portion supports the frame-shaped movable portion such that the movable portion is movable relative to the support portion. The elastic support portion includes torsion springs and an elastically deformable connecting portion.

Owner:CANON KK

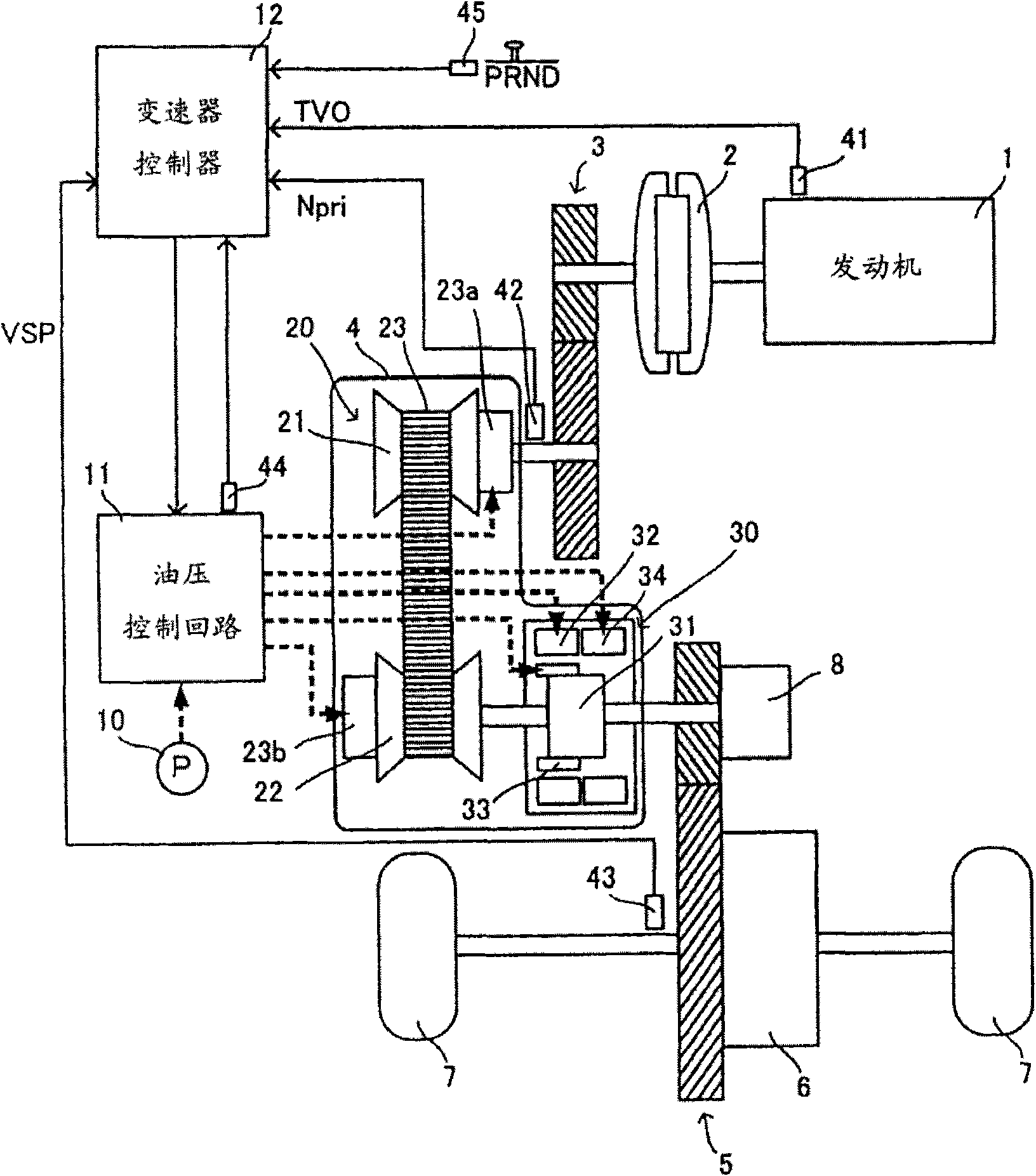

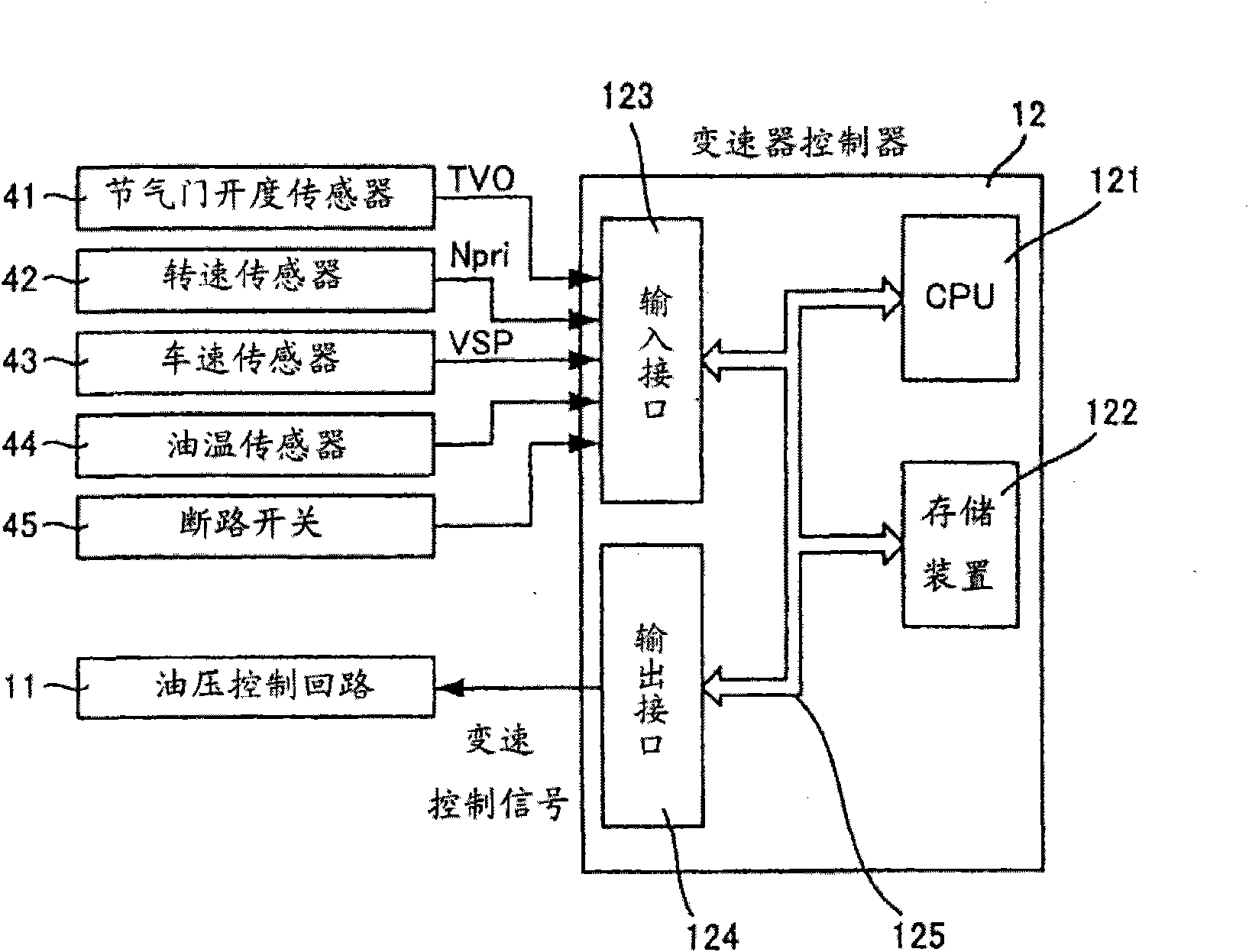

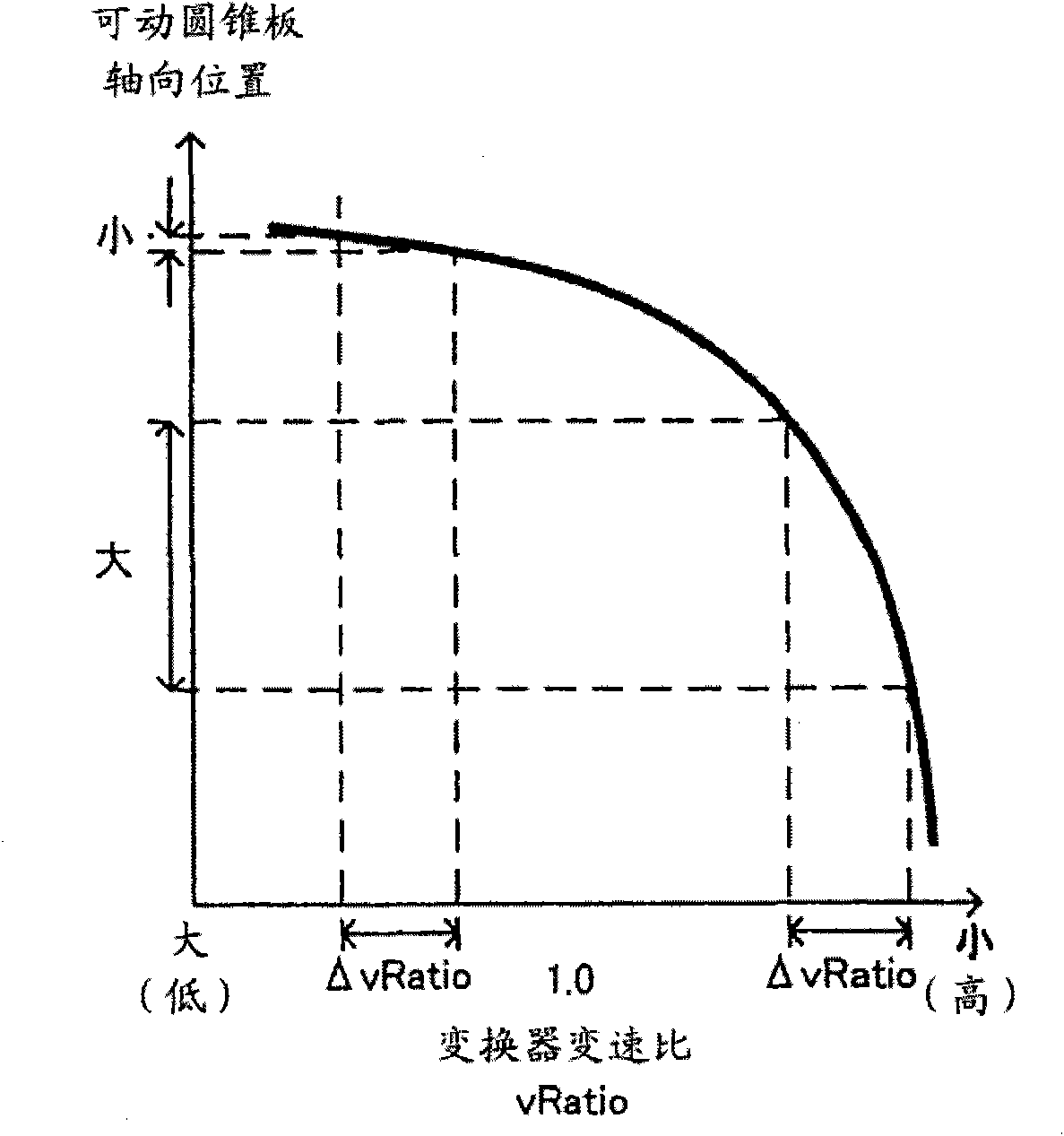

Continuously variable transmission and control method thereof

InactiveCN101684855ASave energySuppress relative displacementGearingRoad transportLow speedControl theory

Owner:JATCO LTD

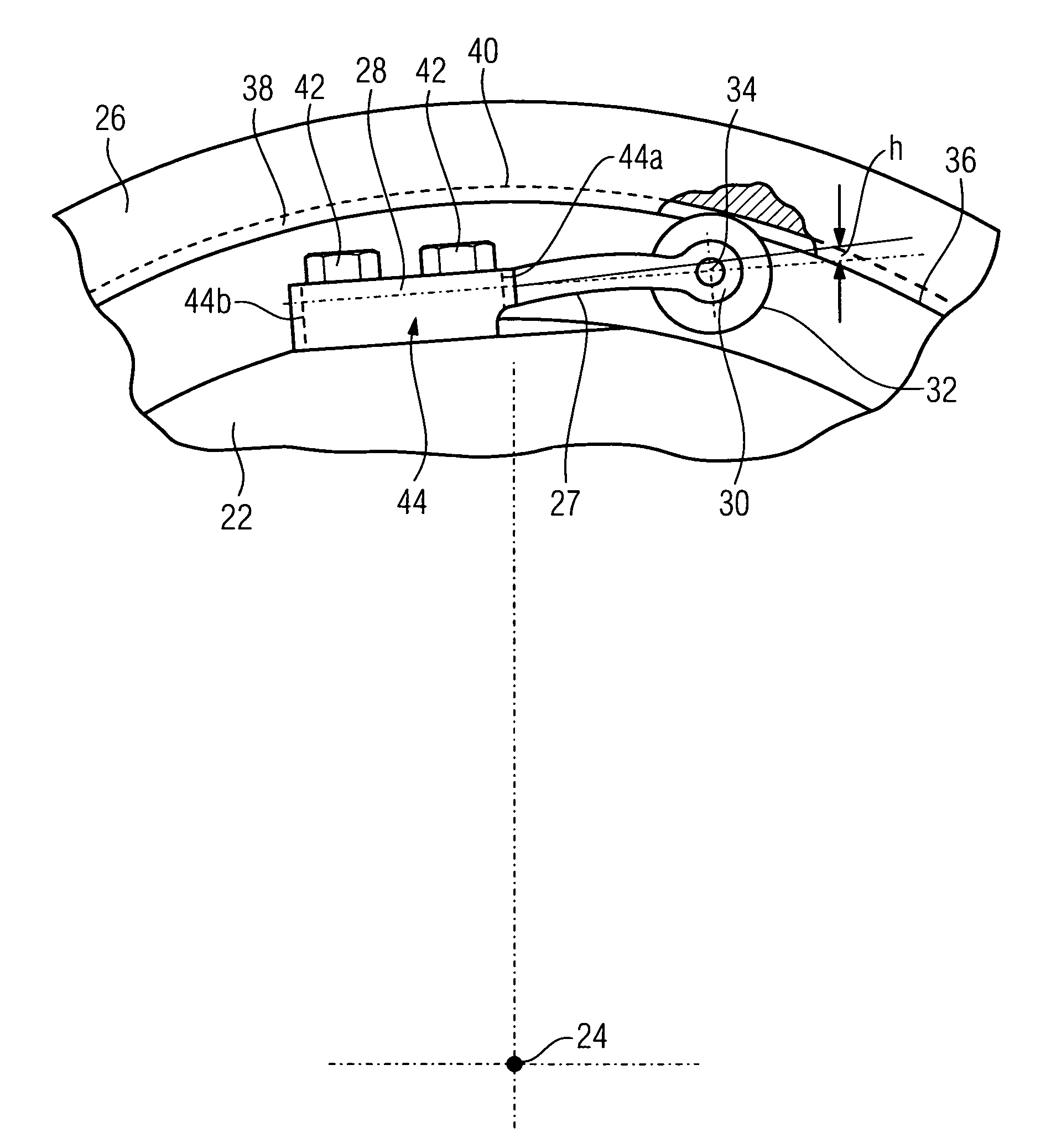

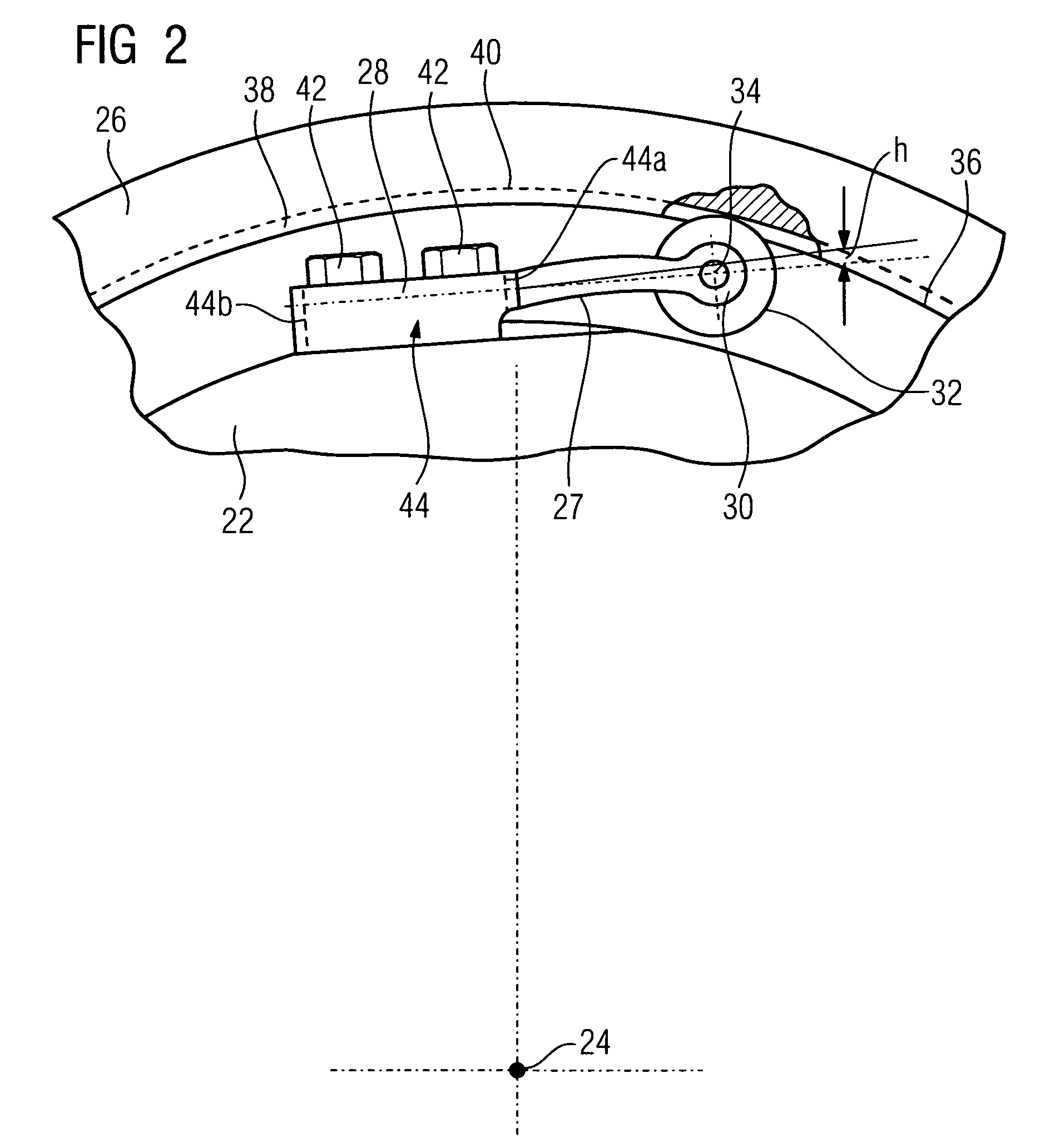

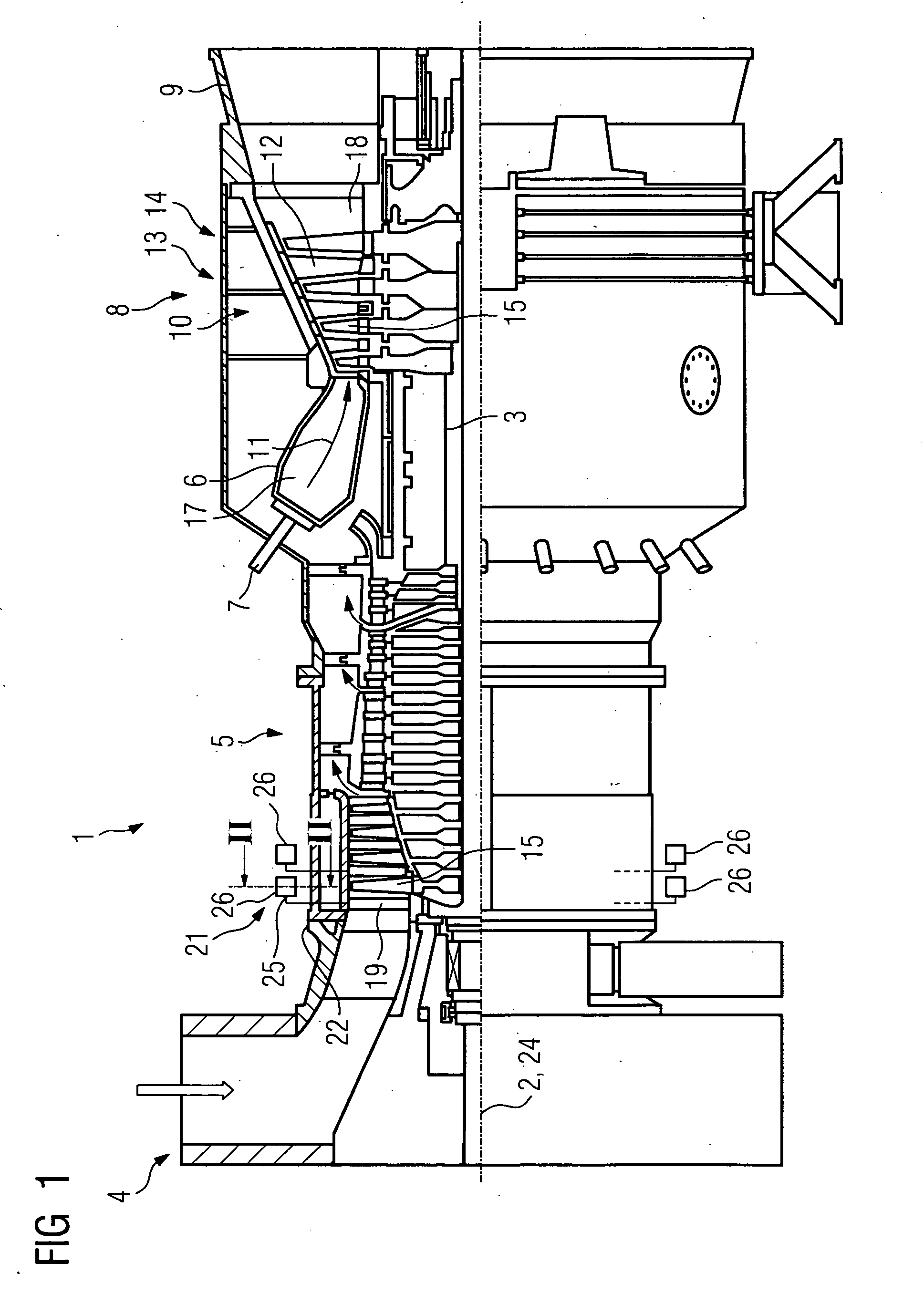

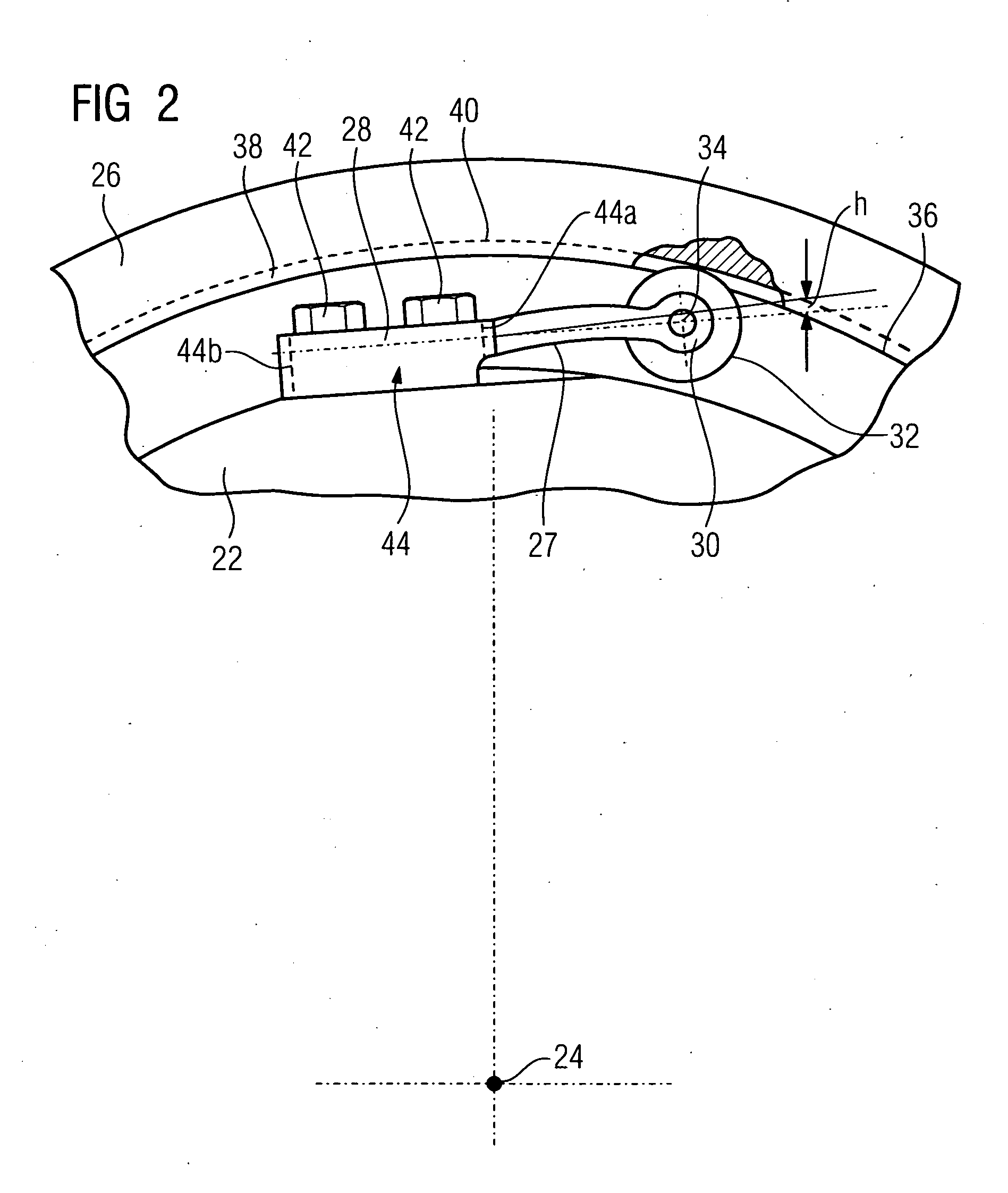

Device for support of an adjusting ring which encompasses at a distance a circular blade carrier

InactiveUS7828516B2Suppress relative displacementEffective maintenancePump componentsWind motor controlEngineeringTurbine

Owner:SIEMENS AG

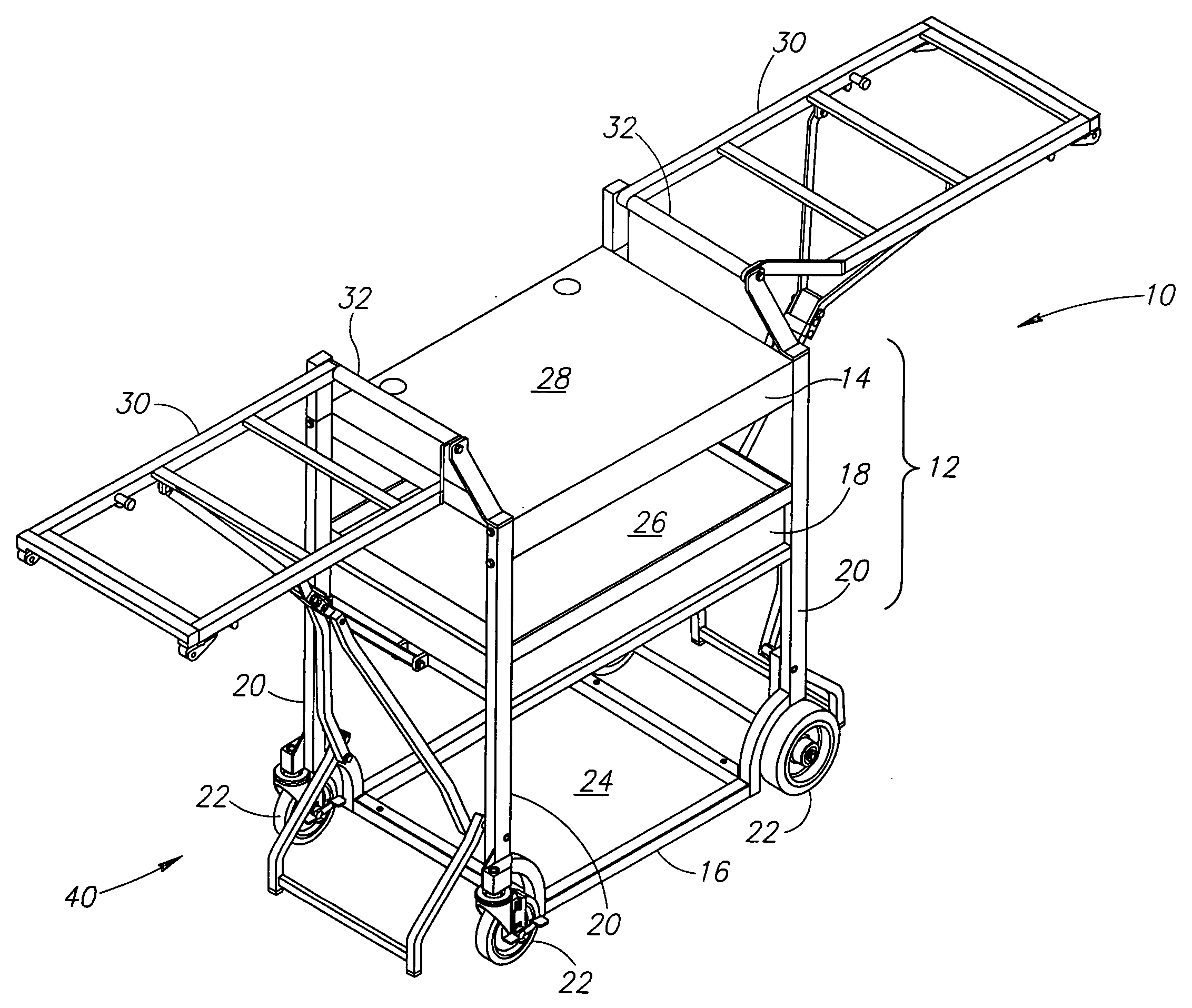

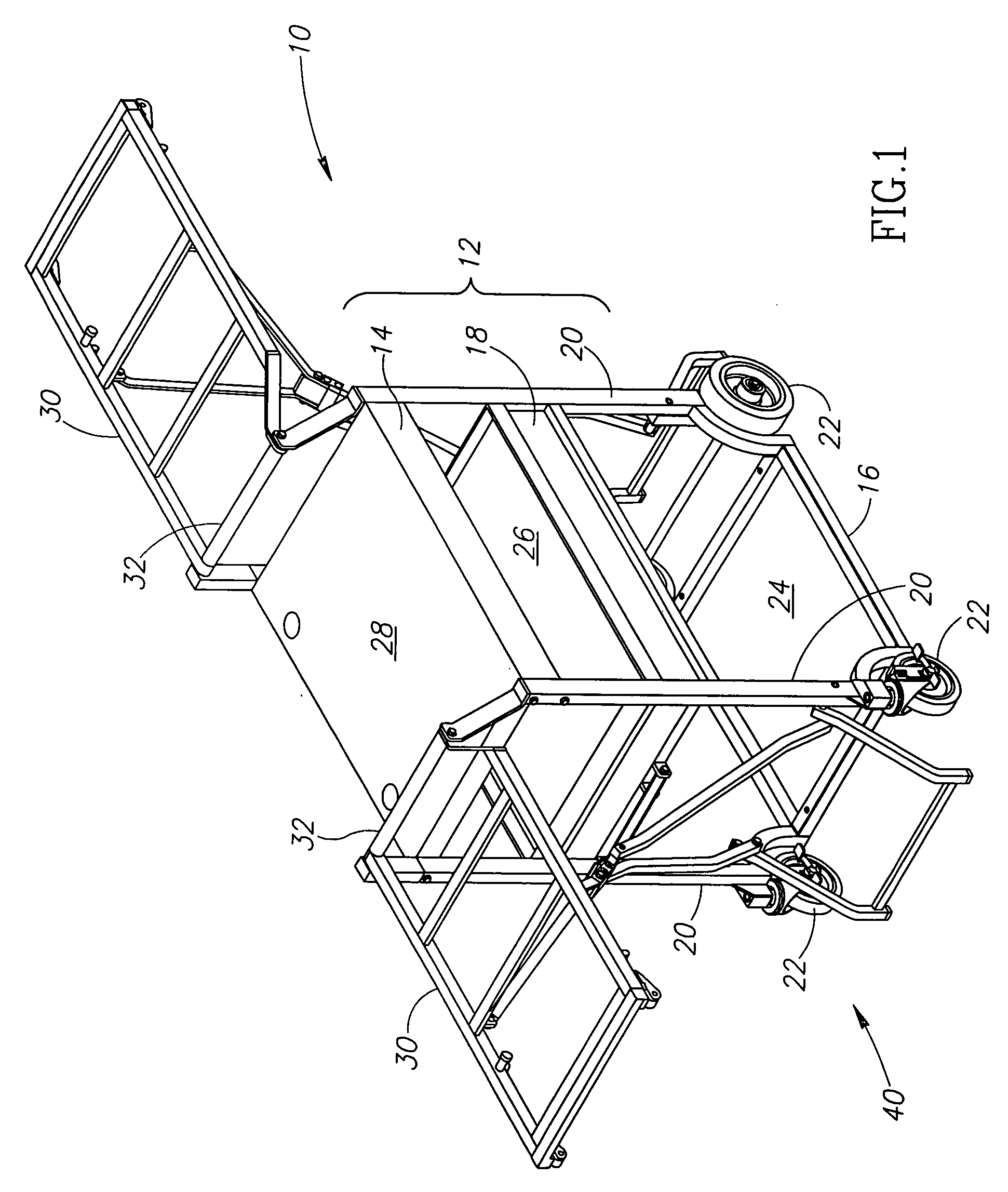

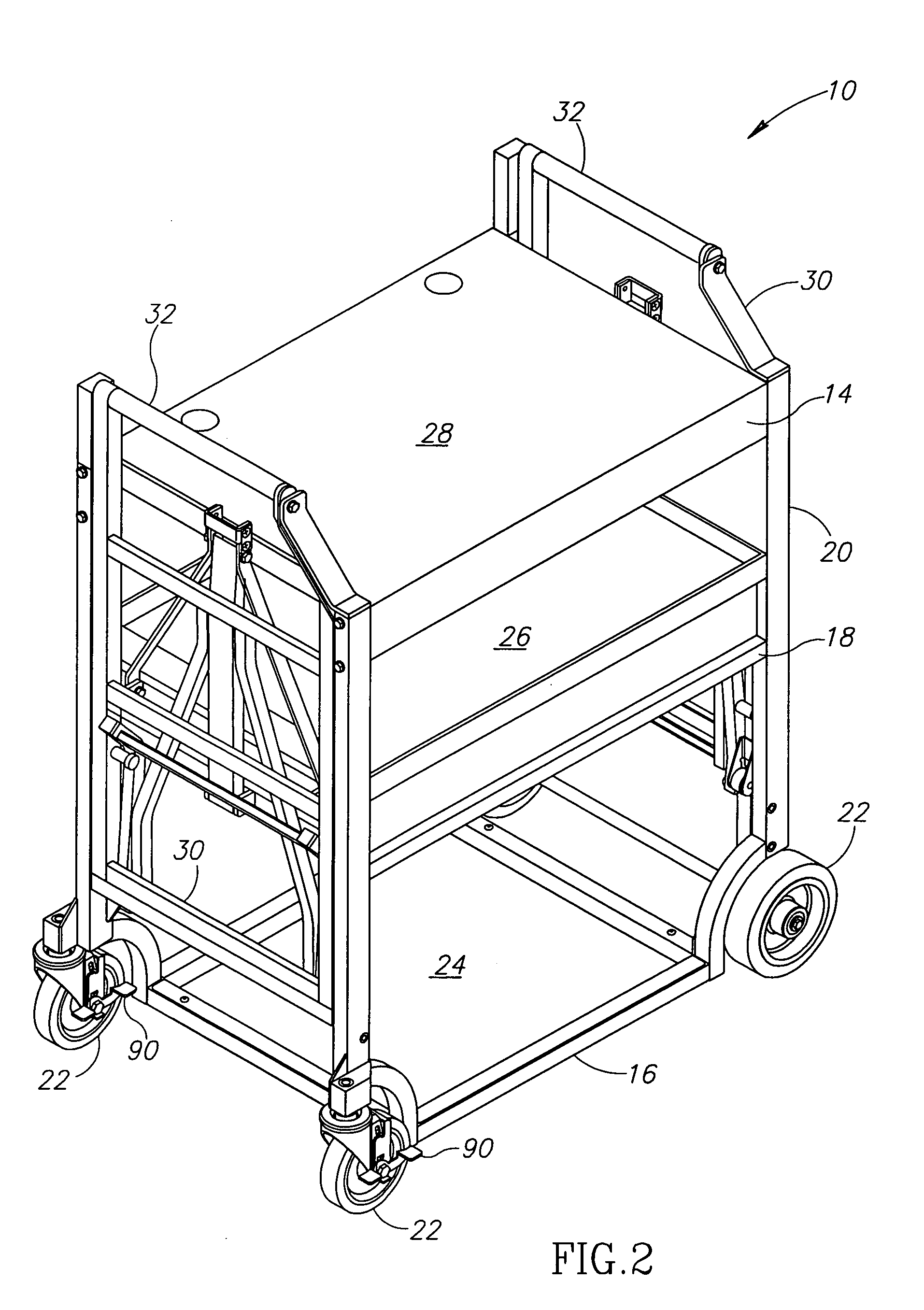

Multiple link, self-jacking work cart wa002

InactiveUS20100276910A1Prevent tippingExpand the scope ofWash-standsUnderstructuresControl armEngineering

A multiple link, self-jacking mobile work cart includes the main body defining upper and lower portions supported by the plurality of rotating wheels. A multiple link, self-jacking mechanism is provided in connection with two laterally deployable work tables which can serve as infeed / outfeed tables for a power tool or the like supported by the main body of the cart. The multiple link mechanism includes an actuator arm, a linkage arm, a control arm and moveable support legs all pivotally connected to one another such that when the work tables are deployed, substantial weight placed on the tables is transferred to the support legs, rather than the wheels which support the main body.

Owner:WISE ROBERT W

Planetary reduction gear apparatus

ActiveUS8348803B2Extend your lifeAvoid successionToothed gearingsGearing detailsGear wheelEngineering

Owner:KAWASAKI HEAVY IND LTD

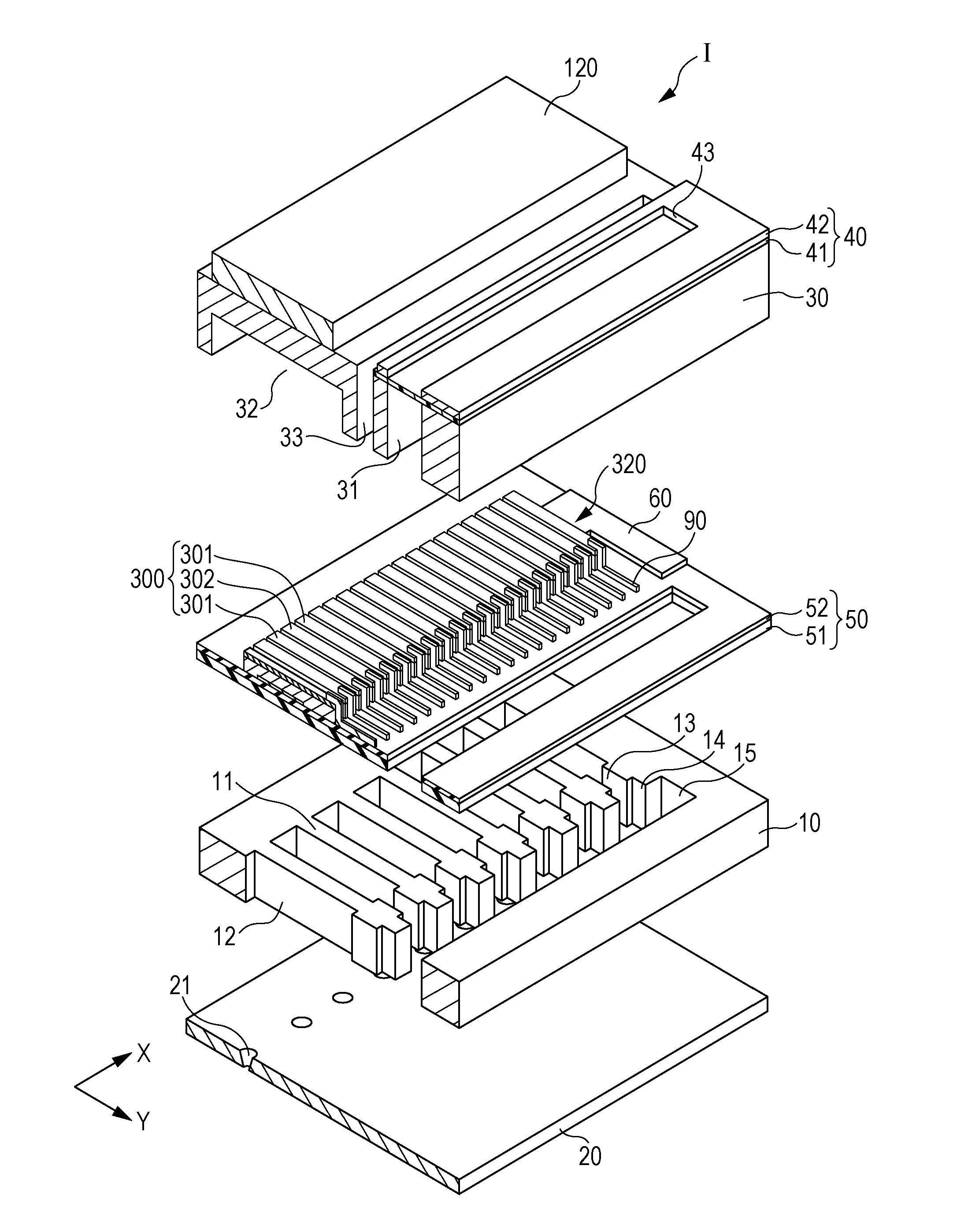

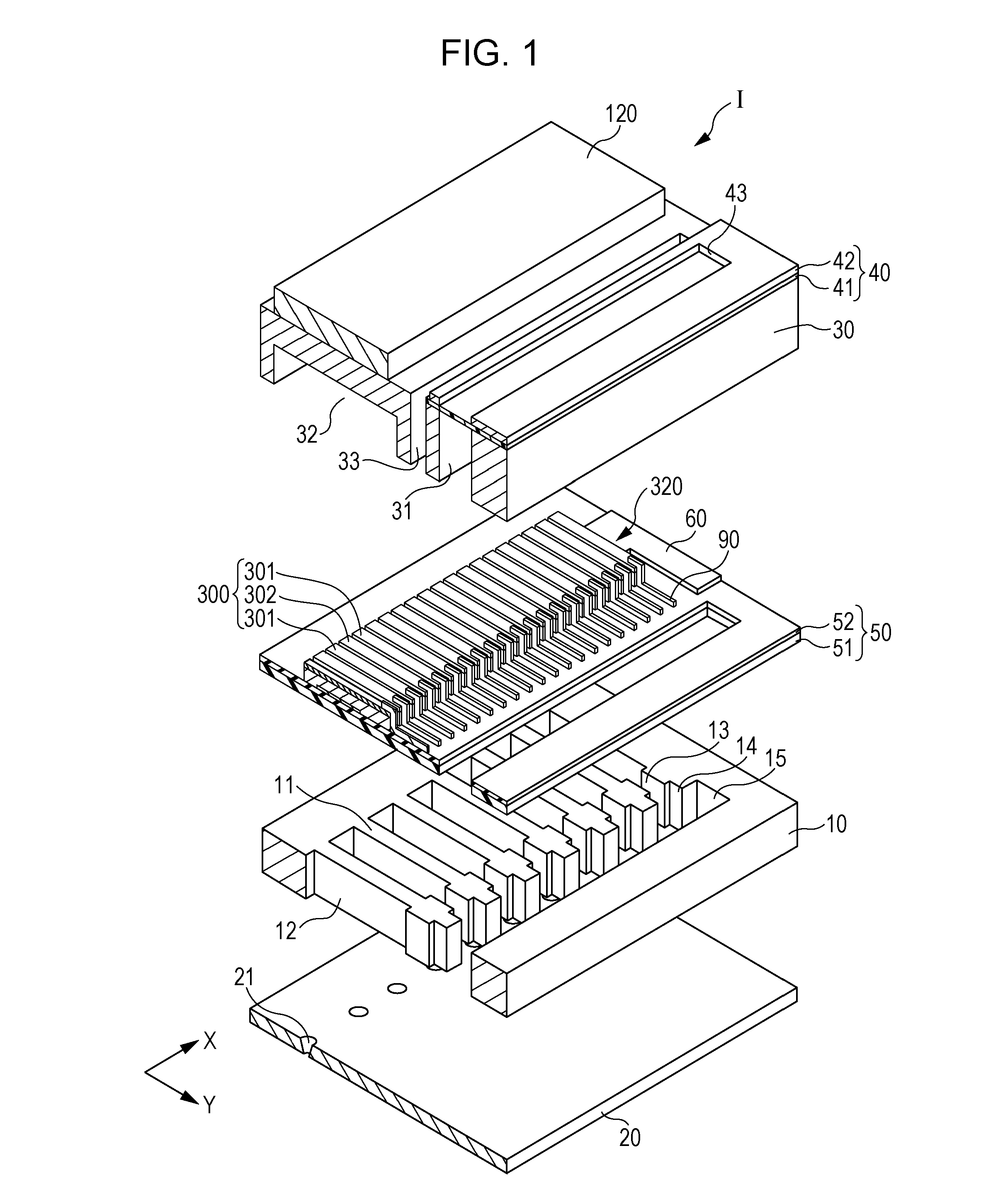

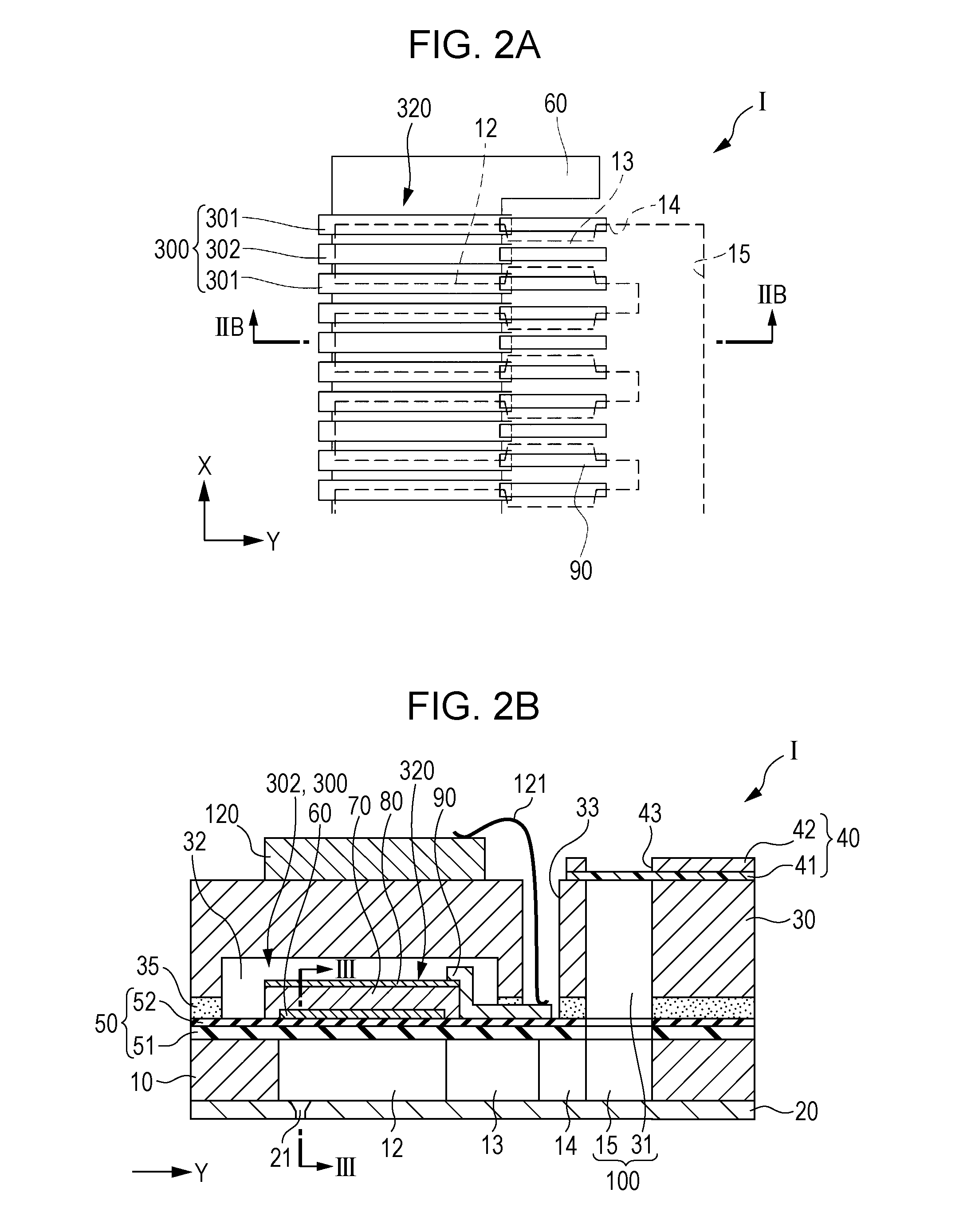

Liquid ejecting head, liquid ejecting apparatus and actuator apparatus

InactiveUS20140267478A1Improve distortionImprove reliabilityInking apparatusPiezoelectric/electrostriction/magnetostriction machinesPressure generationEngineering

A liquid ejecting head includes a flow path formation substrate provided with a pressure generation chamber communicated with at least one nozzle opening through which liquid is ejected; and an actuator apparatus including a vibration plate provided at one face side of the flow path formation substrate and a plurality of piezoelectric elements being formed on the vibration plate. The actuator apparatus includes two first piezoelectric elements arranged at positions facing edge portions in at least one direction of the pressure generation chamber and a second piezoelectric element arranged between the two first piezoelectric elements.

Owner:SEIKO EPSON CORP

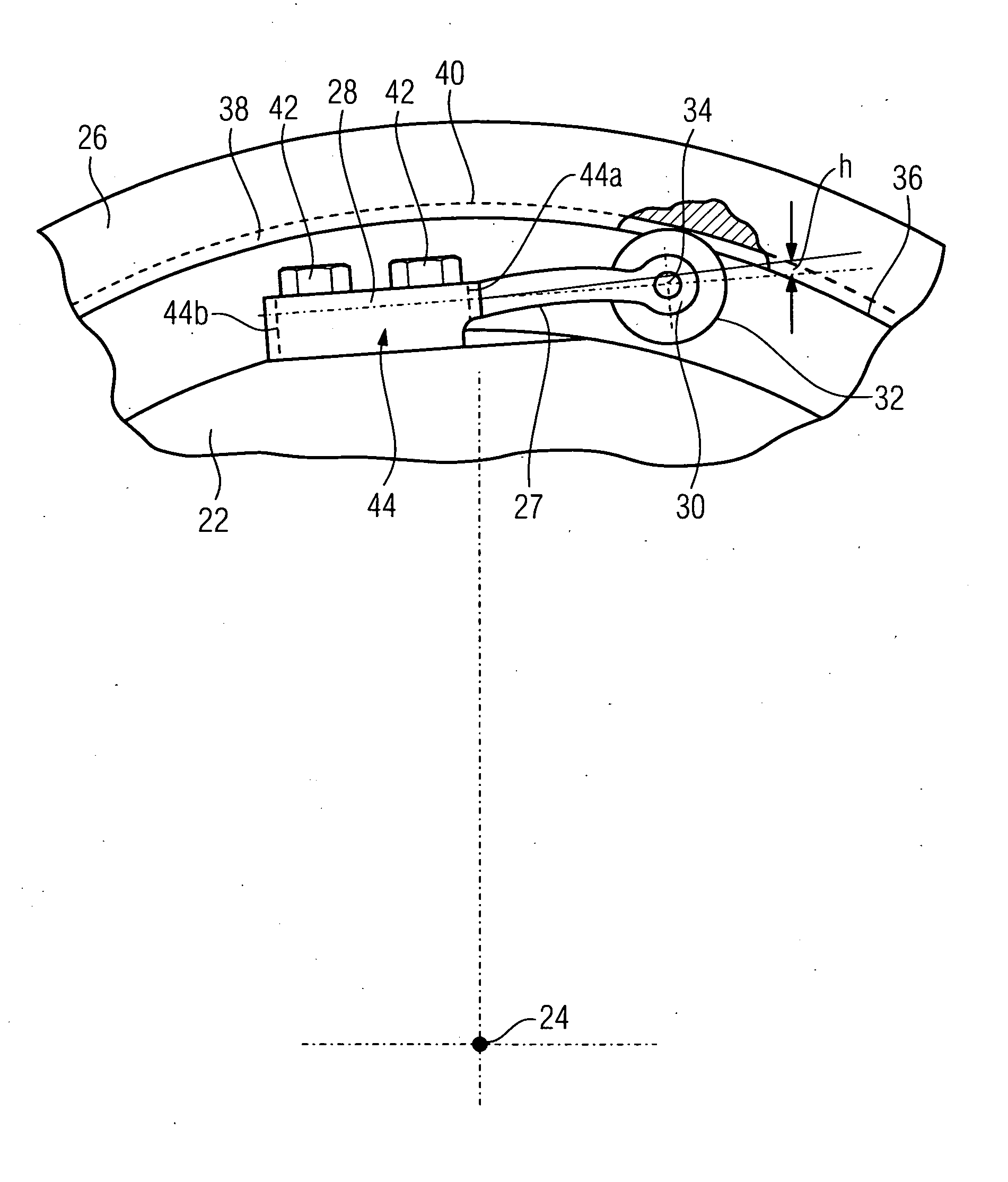

Acceleration sensor element and acceleration sensor having same

InactiveCN101900746ASuppress relative displacementSuppression of resonant vibrationAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsEngineeringImpact resistance

The invention provides an acceleration sensor which does not easily change relative to the external force output and compromises the high sensitivity and impact resistance. A covered acceleration sensor element includes a weight portion, a support frame portion surrounding the weight portion, a plurality of flexible beam portions for connecting the weight portion to the support frame portion to support the weight portion, piezoresistance elements provided on the beam portions, and wirings for connecting them. An upper cover and a lower cover enclosing the periphery of the weight portion together with the support frame portion are joined to the face and back of the support frame portion. Acceleration in the directions of three axes, i.e., a first axis in the joining thickness direction, a second axis in a plane perpendicular to the first axis, and a third axis in the plane and perpendicular to the second axis, or acceleration in the direction of any of the axes, is detected from changes in the resistances of the piezoresistance elements. The support frame portion is separated by separation grooves into an inner frame and an outer frame. The upper cover and the lower cover are joined to the outer frame. The inner frame is connected to the outer frame by a plurality of inner frame support portions having flexibility. The beam portions are connected to both sides of the weight portion along the second axis and the third axis. The inner frame support portions are connected to both sides of the inner frame in a direction in which they are rotated nearly 45 degrees from the second axis and the third axis.

Owner:TOREX SEMICON LTD

Device for support of an adjusting ring which encompasses at a distance a circular blade carrier

InactiveUS20070154301A1No wearSuppress relative displacementWind motor controlPump componentsEngineeringTurbine

Owner:SIEMENS AG

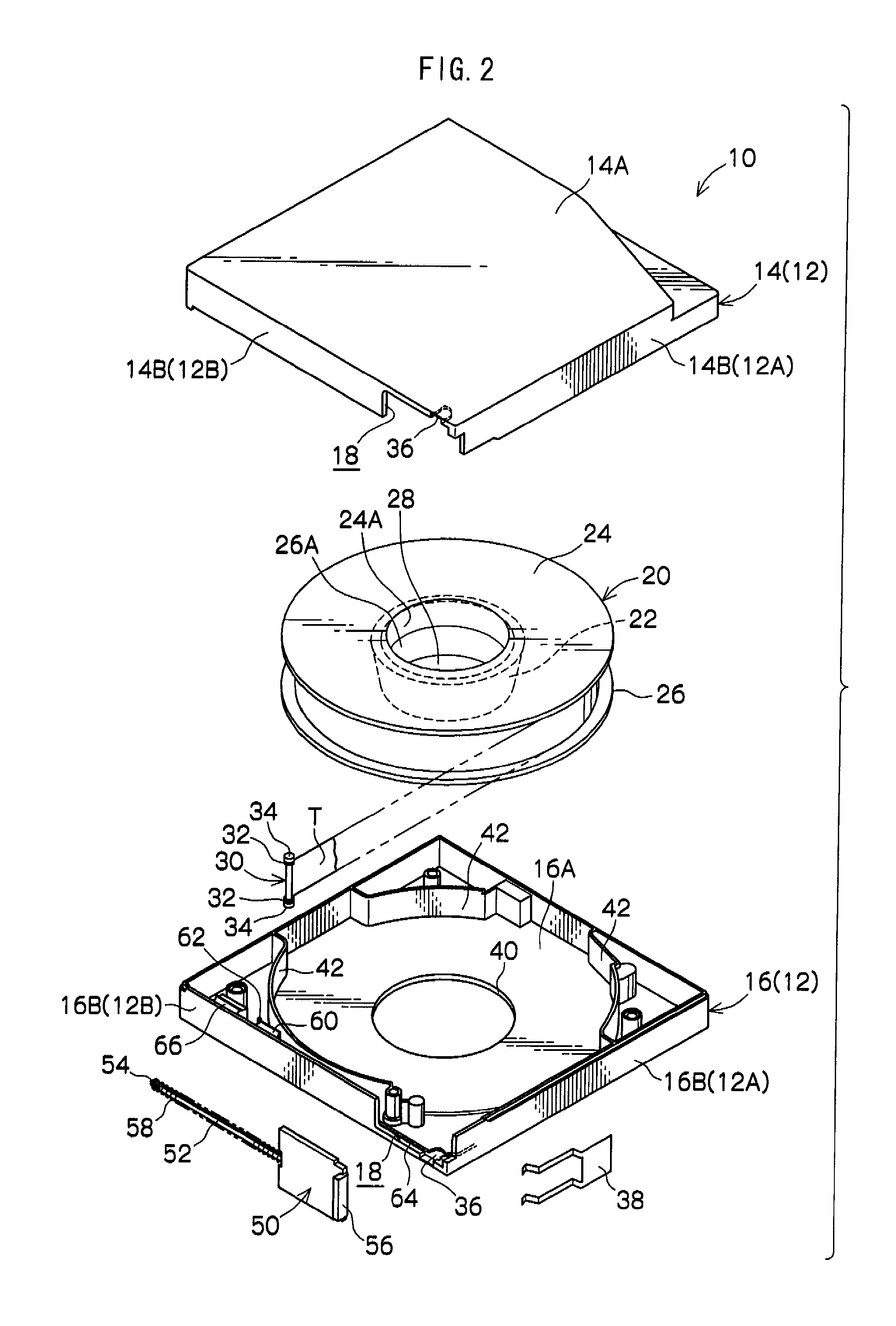

Tape reel, recording tape cartridge, take-up reel, drawing-out member, and drive device

ActiveUS7571872B2Suppress relative displacementOut distortionPicture changing apparatusRecord information storageEngineeringFlange

Owner:FUJIFILM CORP

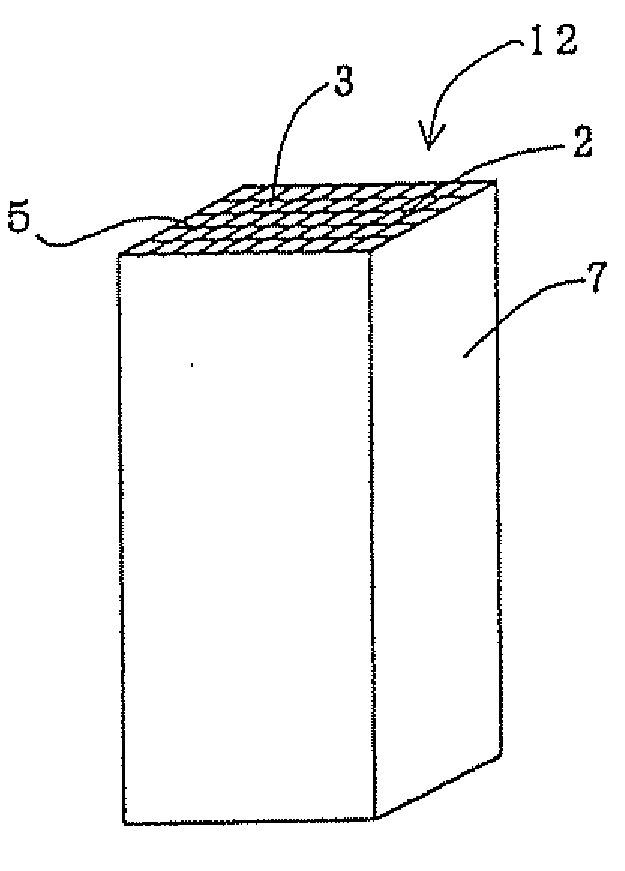

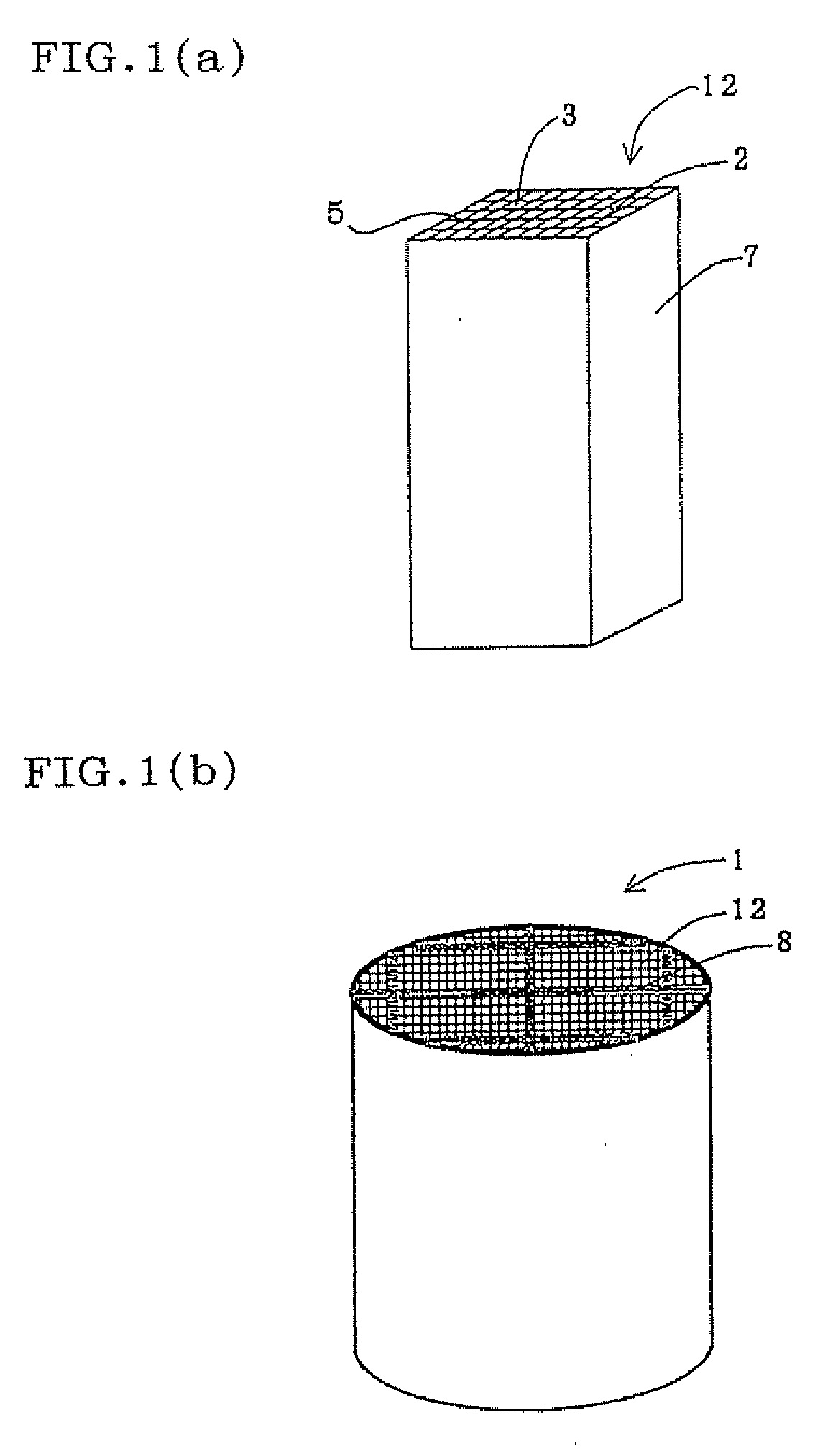

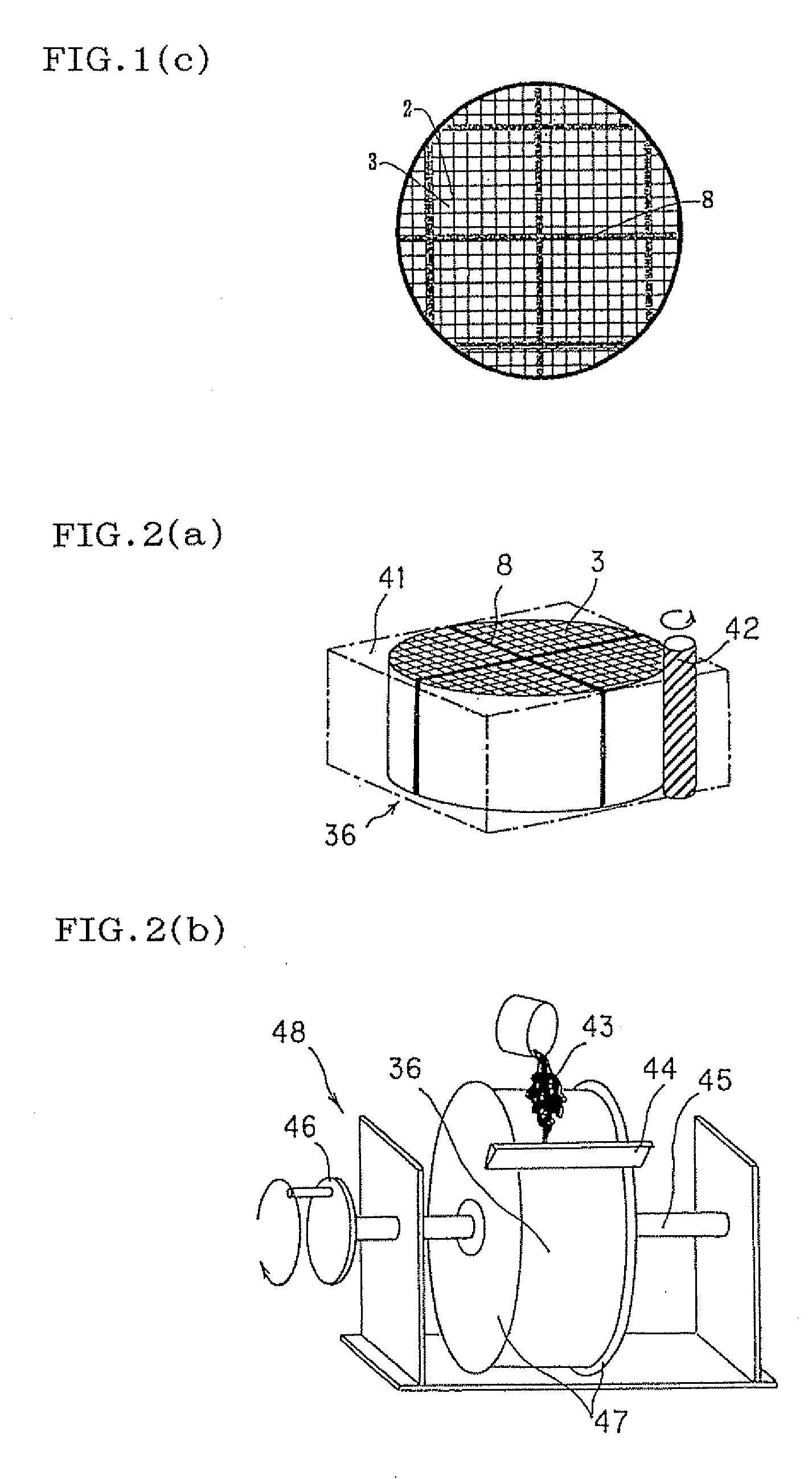

Honeycomb structure and method for producing same

ActiveUS20090029105A1Secure bondingSuppress relative displacementLaminationLamination apparatusClay mineralsHoneycomb structure

Disclosed is a honeycomb structure which is bonded with a bonding material containing 0.1 to 10 mass % of a layered clay mineral. Also disclosed are a honeycomb structure which is bonded with a bonding material containing 0.1 to 10 mass % of an organic binder, and a honeycomb structure which is bonded with a bonding material having a Casson yield value of 6 Pa or more. Further disclosed is a method for producing such a honeycomb structure.

Owner:NGK INSULATORS LTD

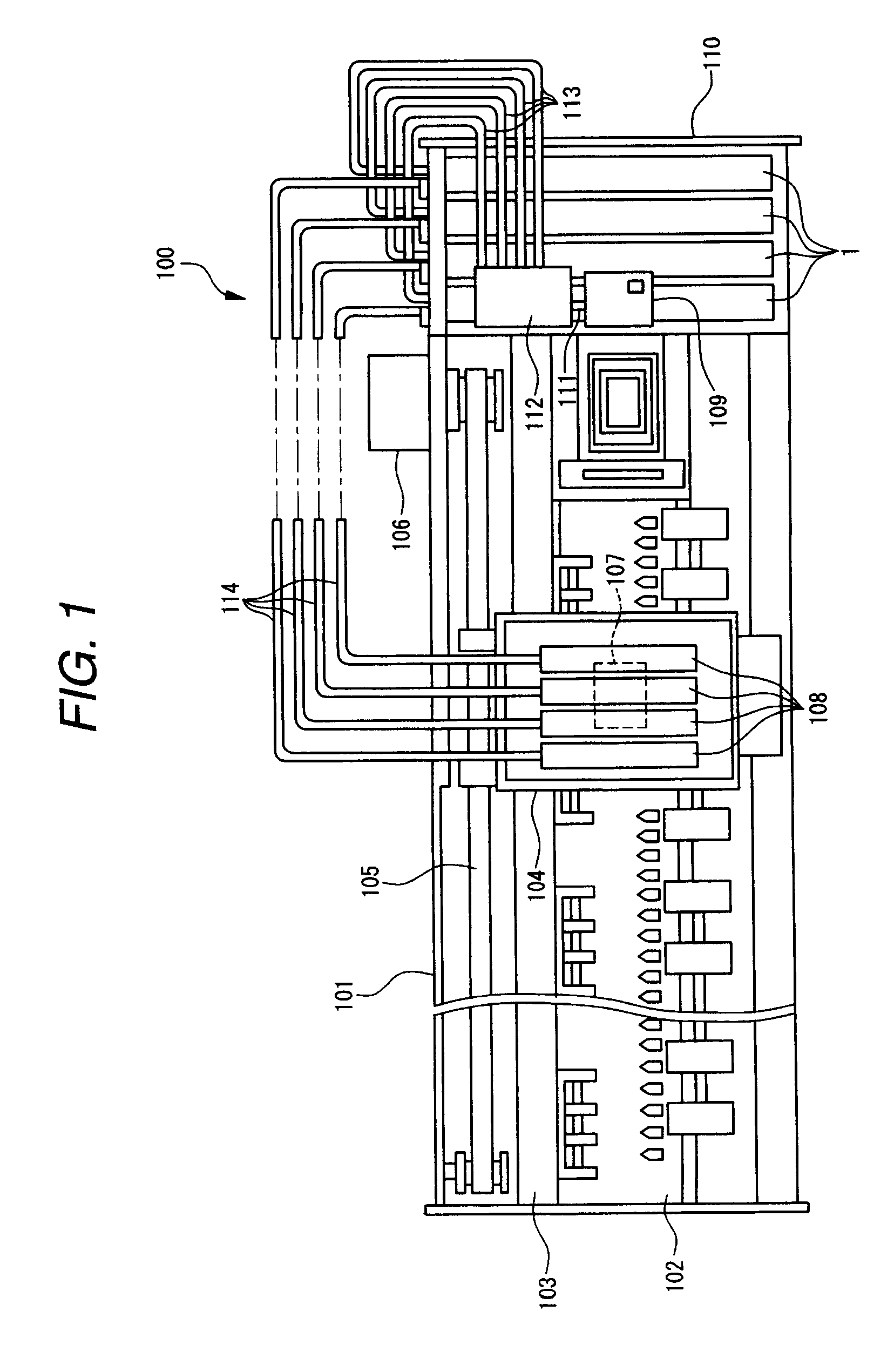

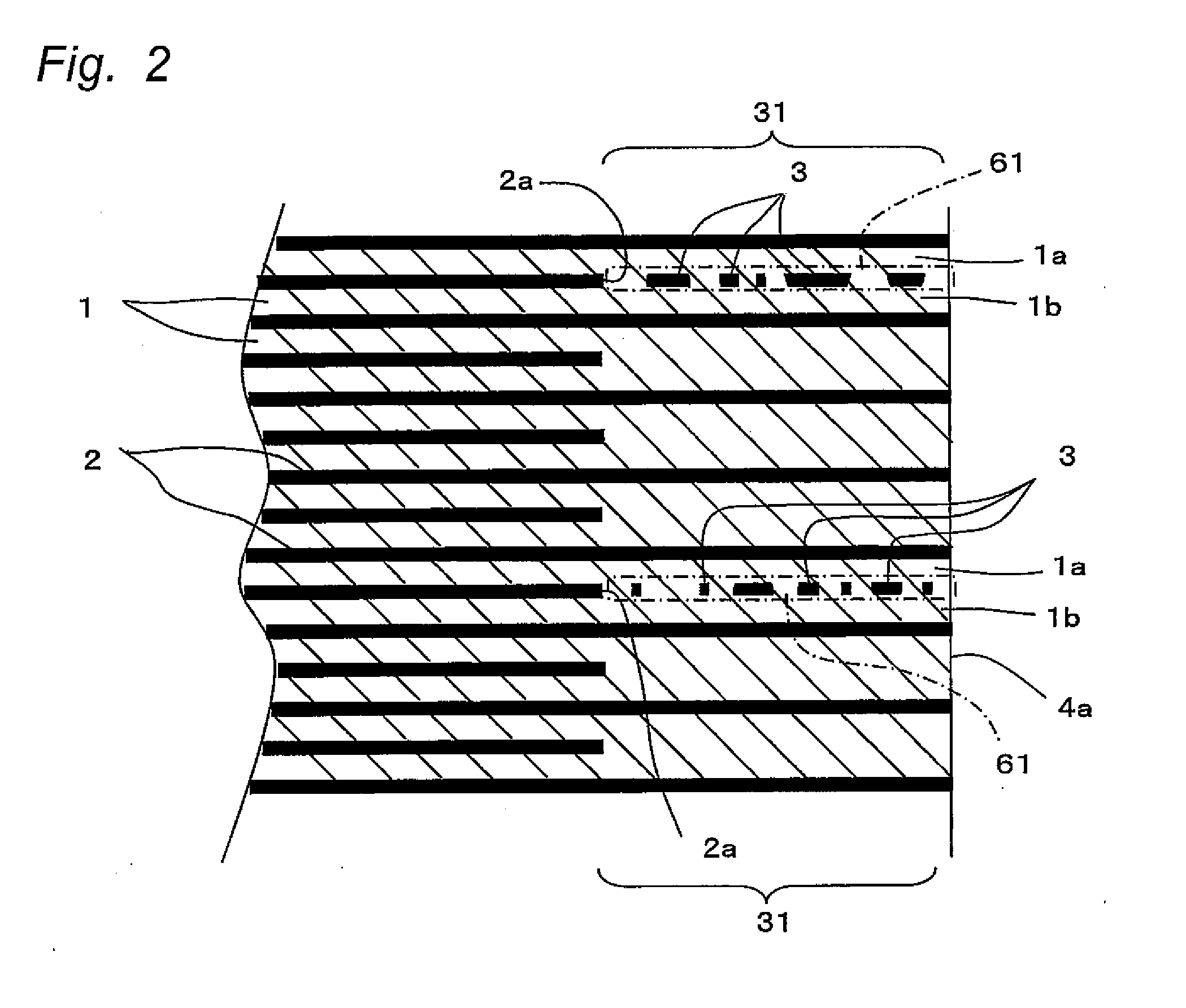

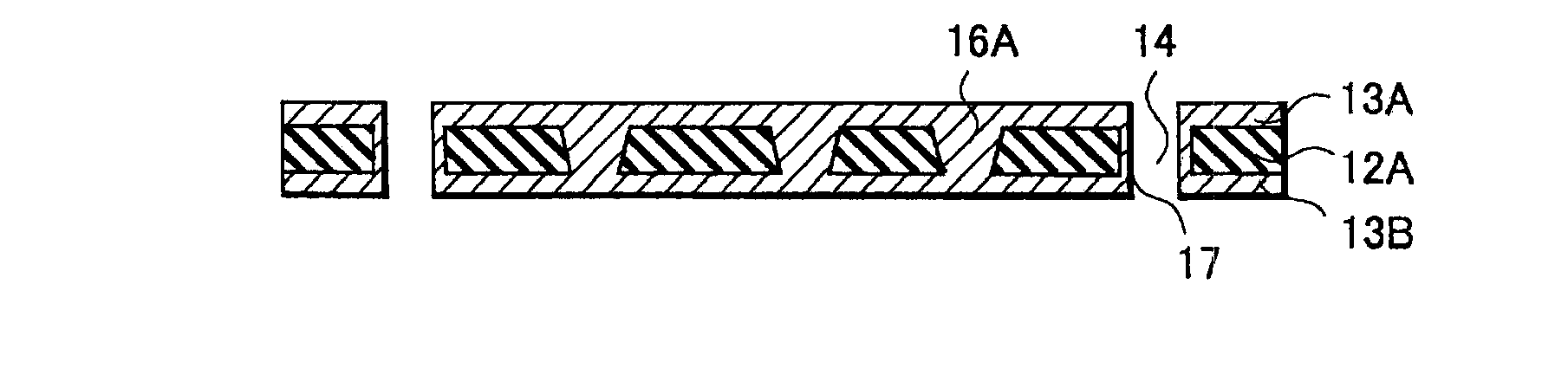

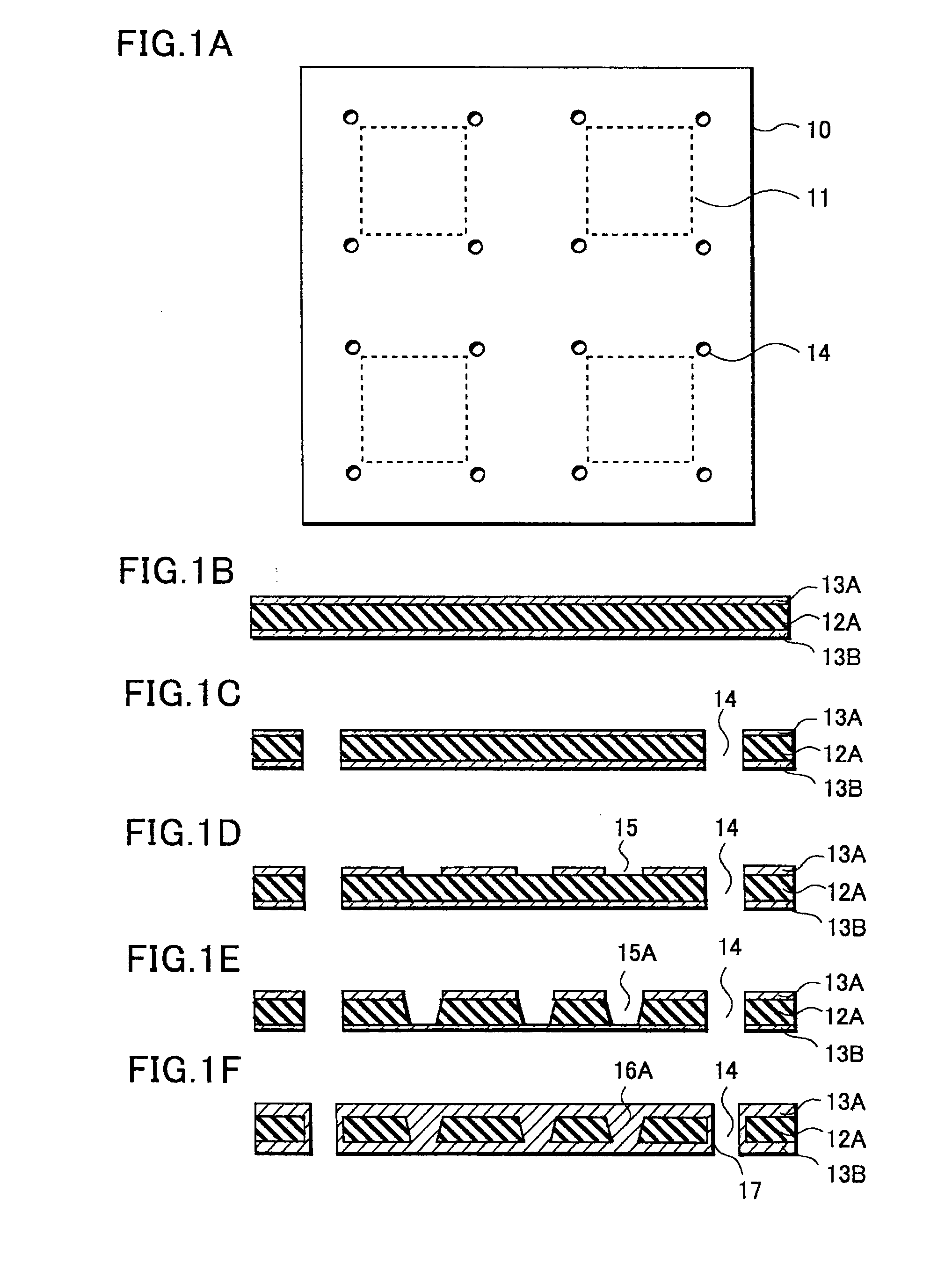

Multilayer Substrate Manufacturing Method

InactiveUS20070281459A1High positioning accuracyImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingRelative displacementEngineering

A manufacturing method of a multilayer substrate that suppresses relative displacement of layers and forms interconnecting portions electrically connecting layers having an accurate positioning. A manufacturing method of a multilayer substrate for laminating, via an insulating film, a wiring layer formed by patterning a conductive film comprises providing a positioning hole in a conductive film laminated at the beginning and patterning a second and / or any subsequent wiring layers after identifying a position of an identification section. Interconnecting sections for interconnecting wiring layers are formed using the identification section.

Owner:SANYO ELECTRIC CO LTD

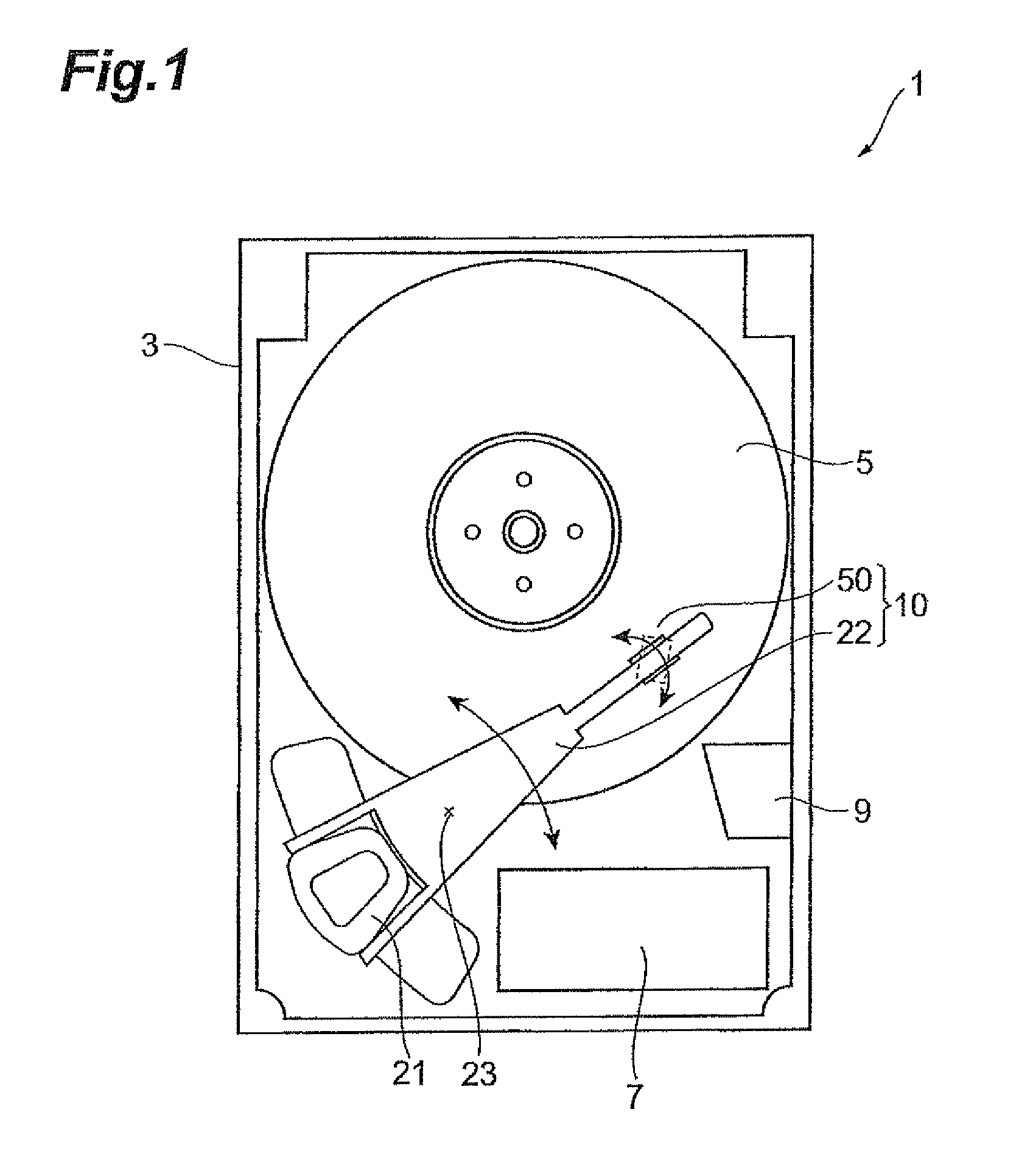

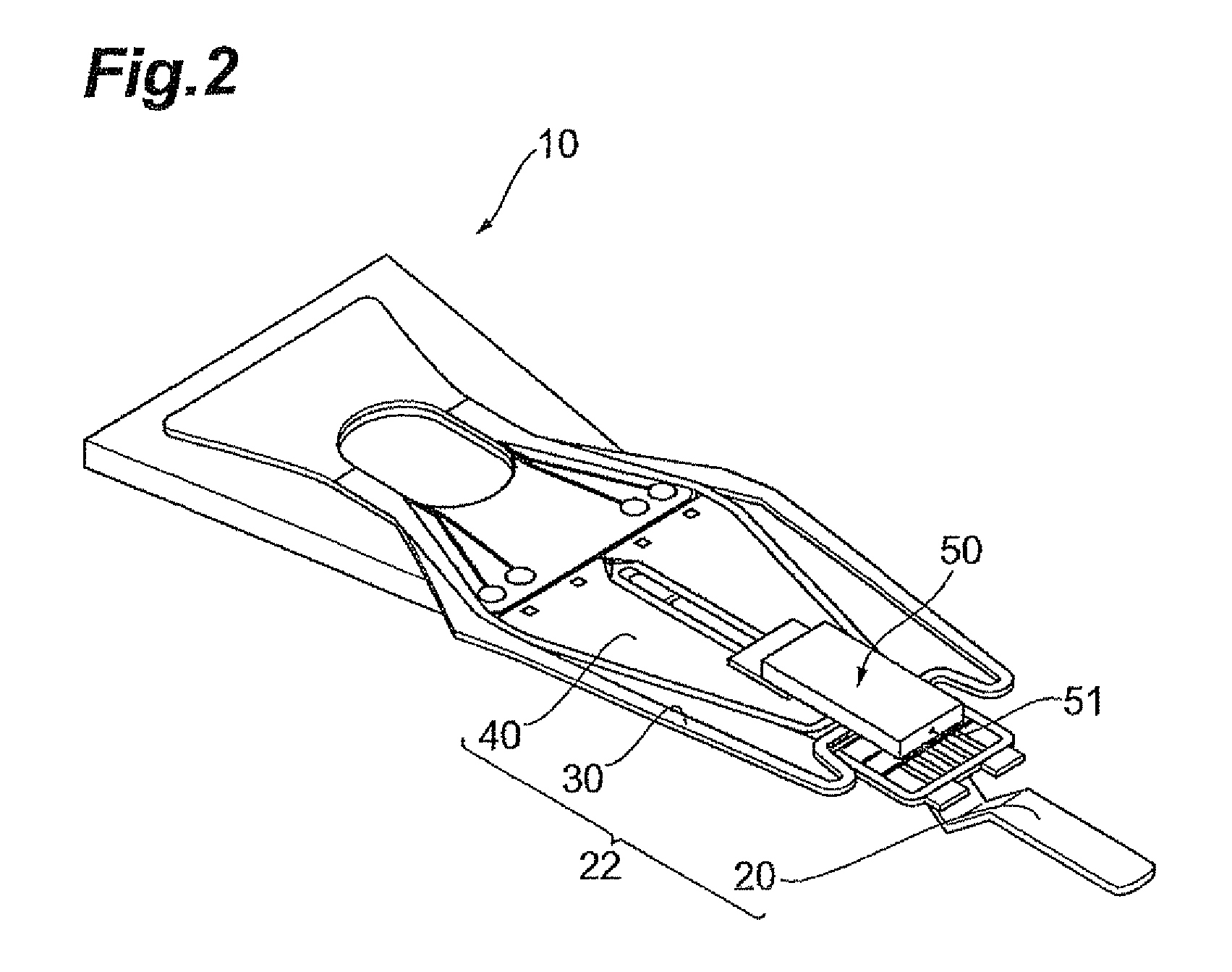

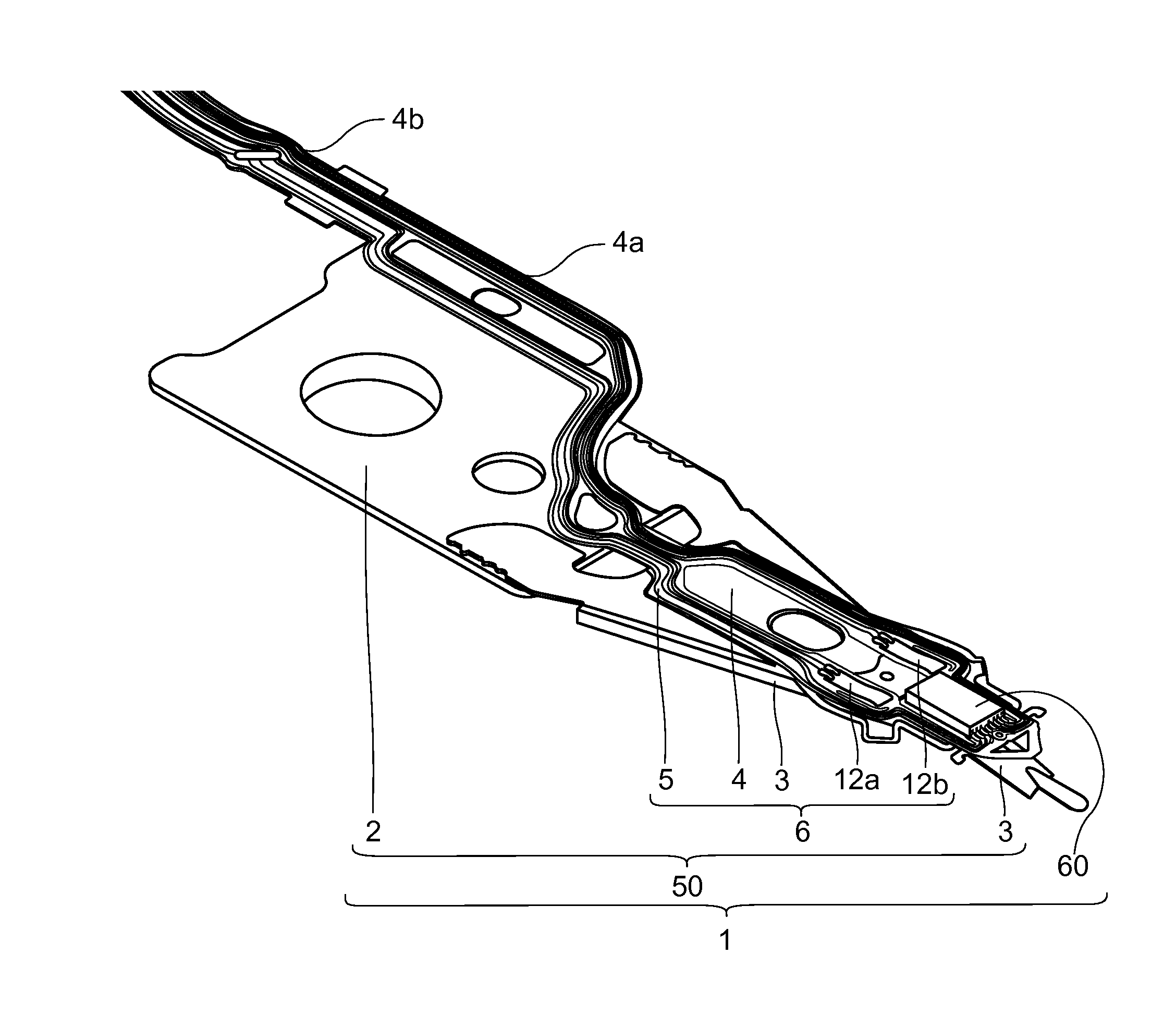

Thin-film piezoelectric material element, method of manufacturing the same, head gimbal assembly, hard disk drive, ink jet head, variable focus lens and sensor

ActiveUS20160093792A1Without loss of mass production capabilityLow costInking apparatusArm with actuatorsHard disc driveThin membrane

A thin-film piezoelectric material element includes a lower electrode film, a piezoelectric material film, and an upper electrode film, the lower electrode film, the piezoelectric material film and the upper electrode film are laminated sequentially. An upper surface of the piezoelectric material film is a concavity and convexity surface having a convex part and a concave part, the convex part is a curved surface convexly projected, and the concave part is a curved surface concavely hollowed, the upper electrode film is formed on the concavity and convexity surface. The thin-film piezoelectric material element has a stress balancing film formed with a material having an internal stress capable of cancelling an element stress, the stress balancing film is formed on the upper electrode film.

Owner:SAE MAGNETICS (HK) LTD

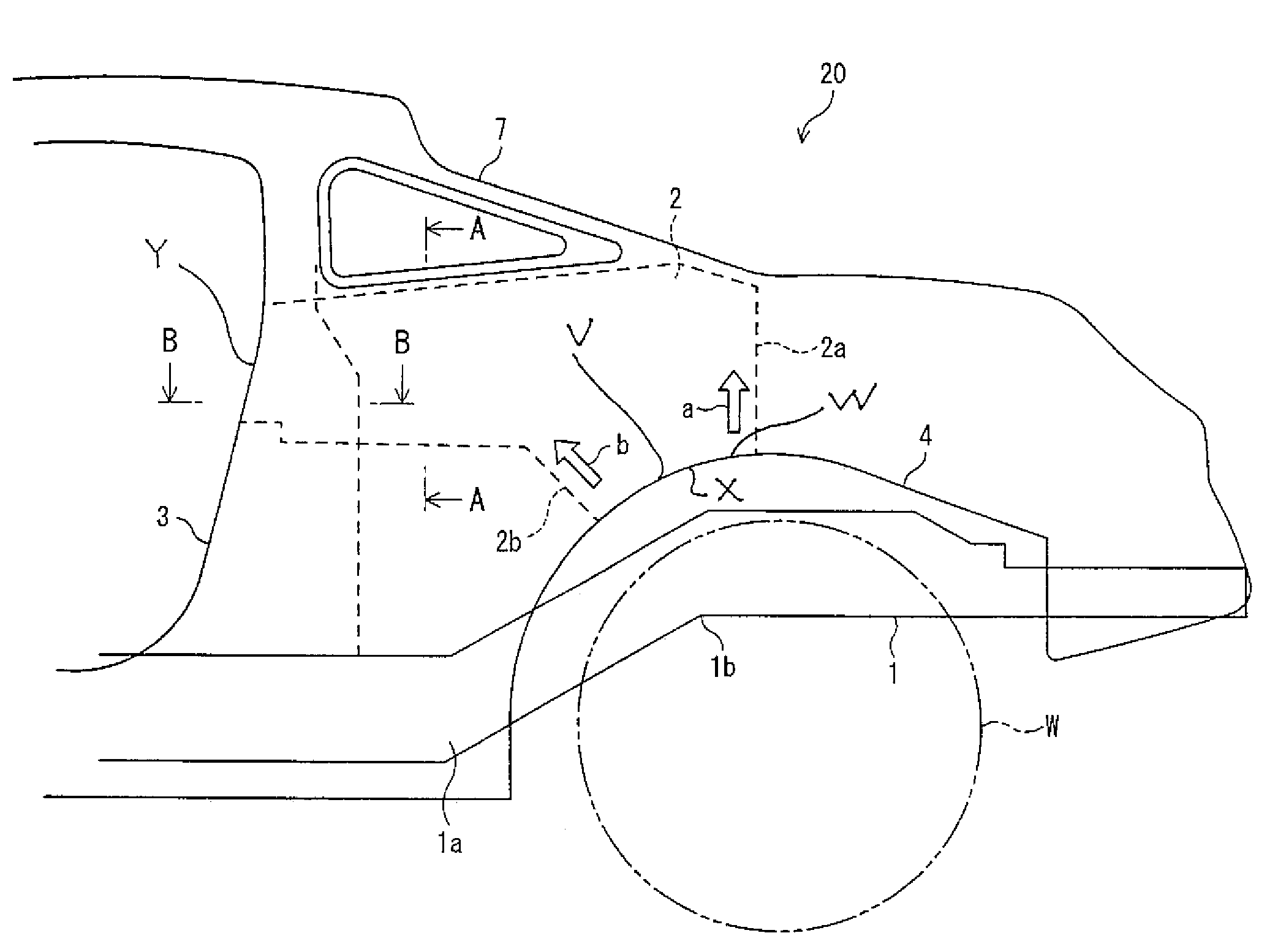

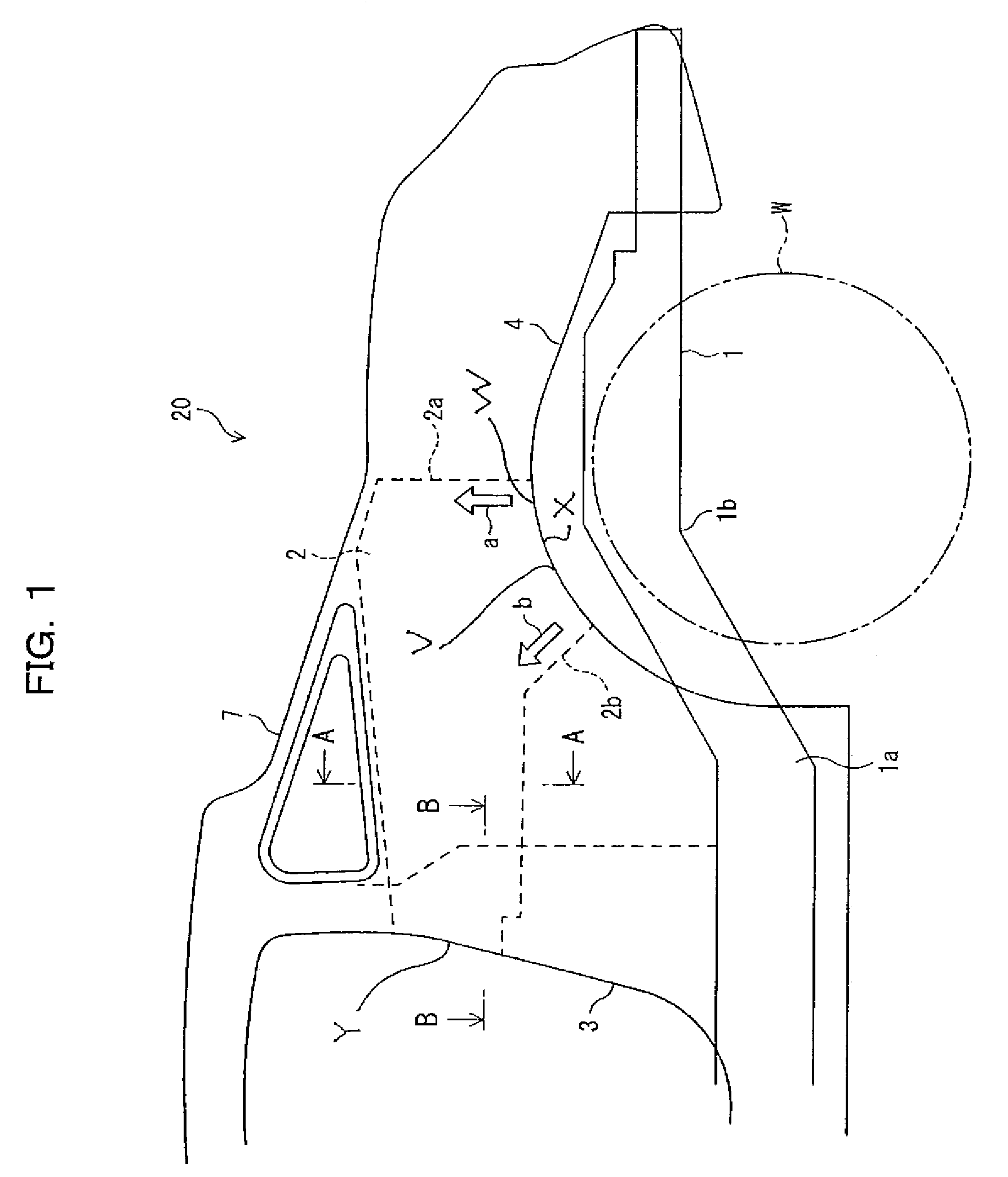

Vehicle body structure

InactiveUS7472948B2Efficient transferAvoid deformationVehicle seatsSuperstructure subunitsAutomotive engineering

Owner:MITSUBISHI MOTORS CORP

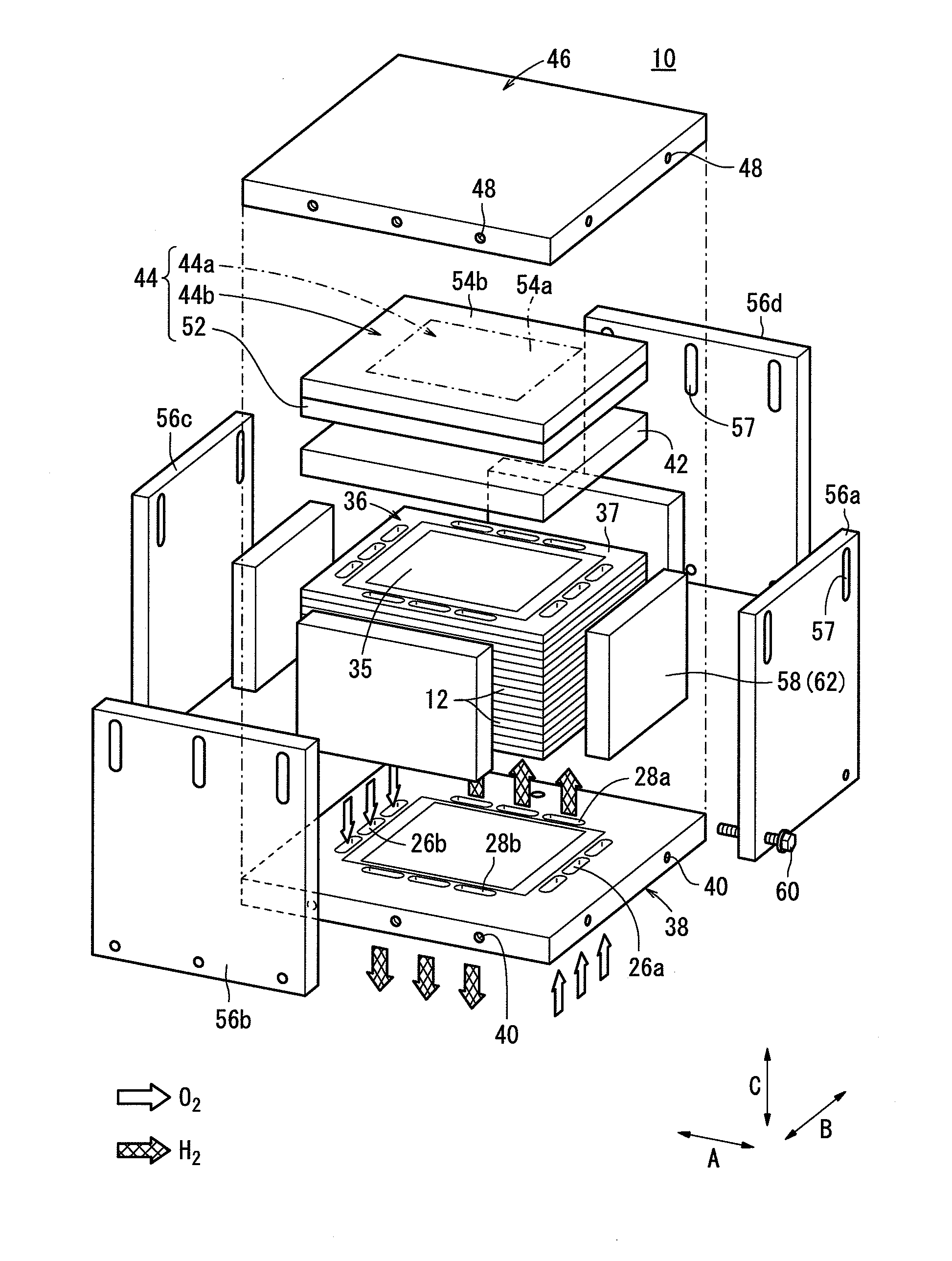

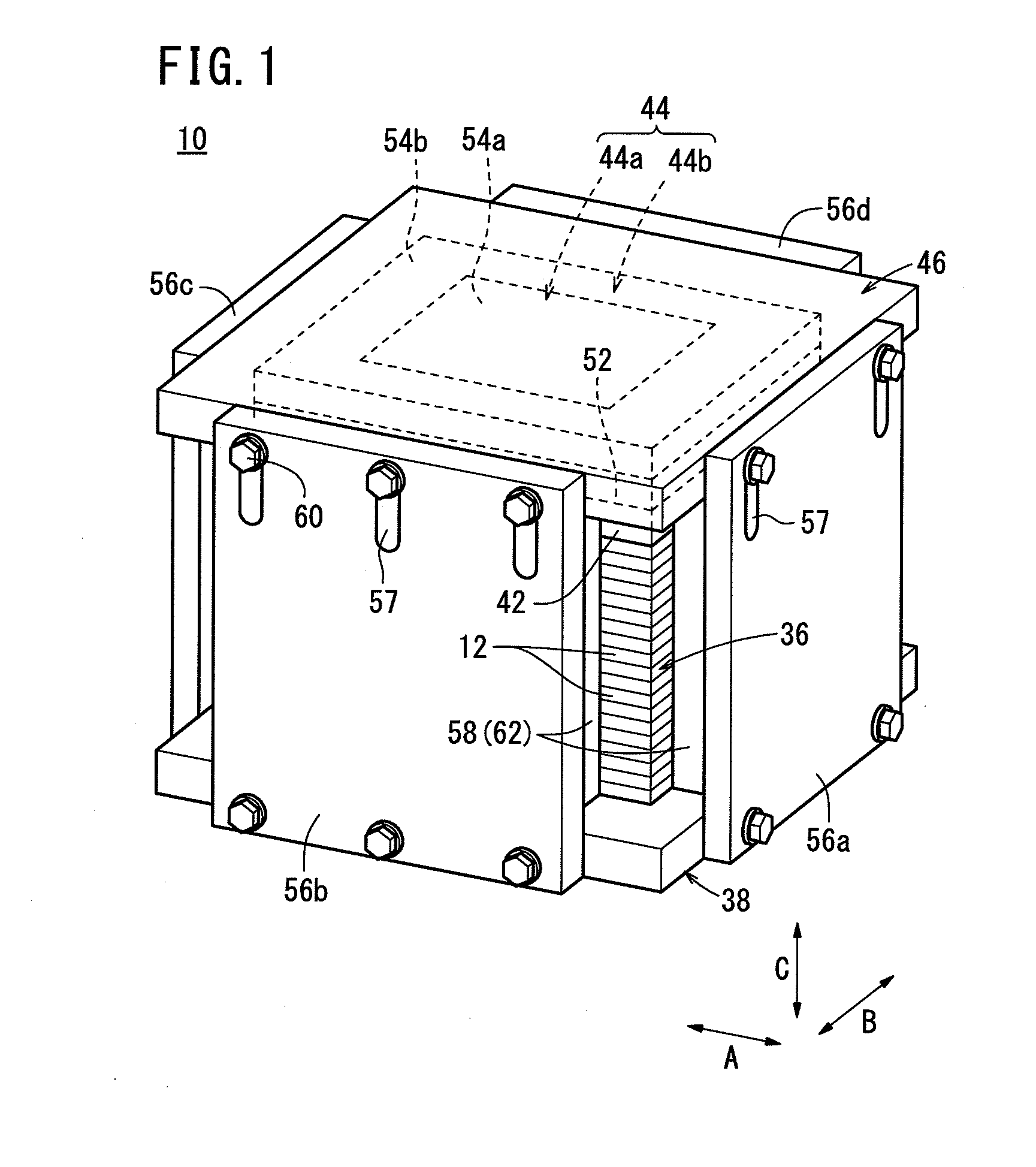

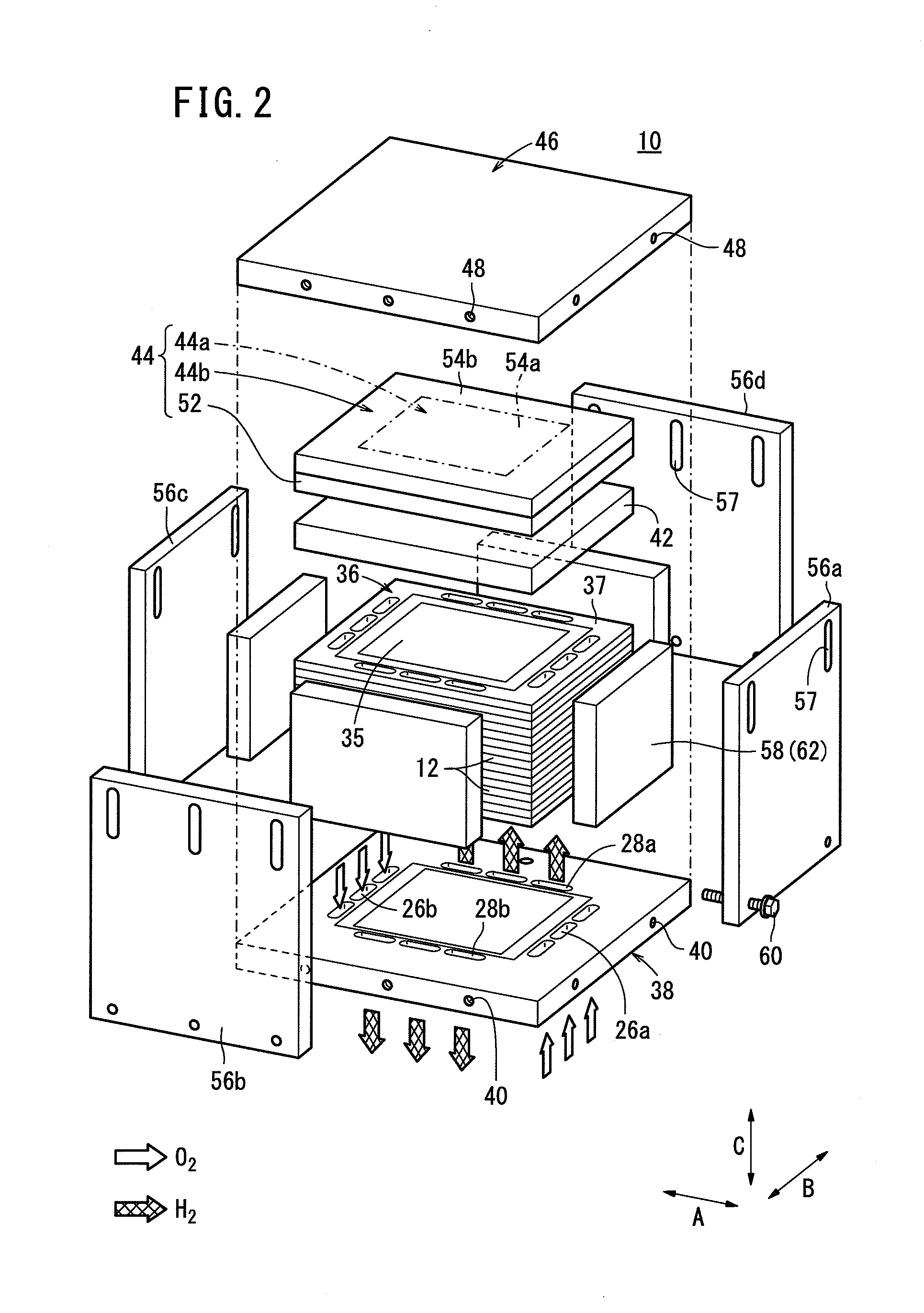

Sofc stack with temperature adapted compression force means

ActiveUS20140134515A1Increased durabilityGood heat insulationFuel cells groupingSolid electrolyte fuel cellsFiberFuel cells

A fuel cell stack includes a stack body formed by stacking a plurality of solid oxide fuel cells in a stacking direction. The fuel cell stack includes wall plate members and fuel cell support members. The wall plate members are provided in the stacking direction of the stack body around the sides of the stack body. Each of the fuel cell support members includes a composite layer made of composite material of alumina fiber and vermiculite. The fuel cell support members are interposed between the wall plate members and the sides of the stack body, and apply a load to the sides of the stack body in directions of a separator surface.

Owner:HONDA MOTOR CO LTD

Narrow-angle directional microphone

InactiveUS20130064409A1Easy to assemblePrevent static electricityPiezoelectric/electrostrictive microphonesMicrophone structural associationEngineeringNarrow angle

A narrow-angle directional microphone having an acoustic tube, accommodated in a cylindrical microphone case, in a circumferential wall of which an opening is formed to be covered with an acoustic resistor and to a rear end of which a microphone unit is attached, prevents abnormal noise from occurring. The narrow-angle directional microphone includes a first acoustic resisting material provided on an outer circumferential surface of the acoustic tube and covering the opening; and a second acoustic resisting material provided between the first acoustic resisting material and an inner circumferential surface of the microphone case, having a predetermined elastic force in a thickness direction. The second acoustic resisting material covers the first acoustic resisting material, and is fixed to the acoustic tube; and presses the outer circumferential surface of the acoustic tube and the inner circumferential surface of the microphone case by the elastic force.

Owner:AUDIO-TECHNICA

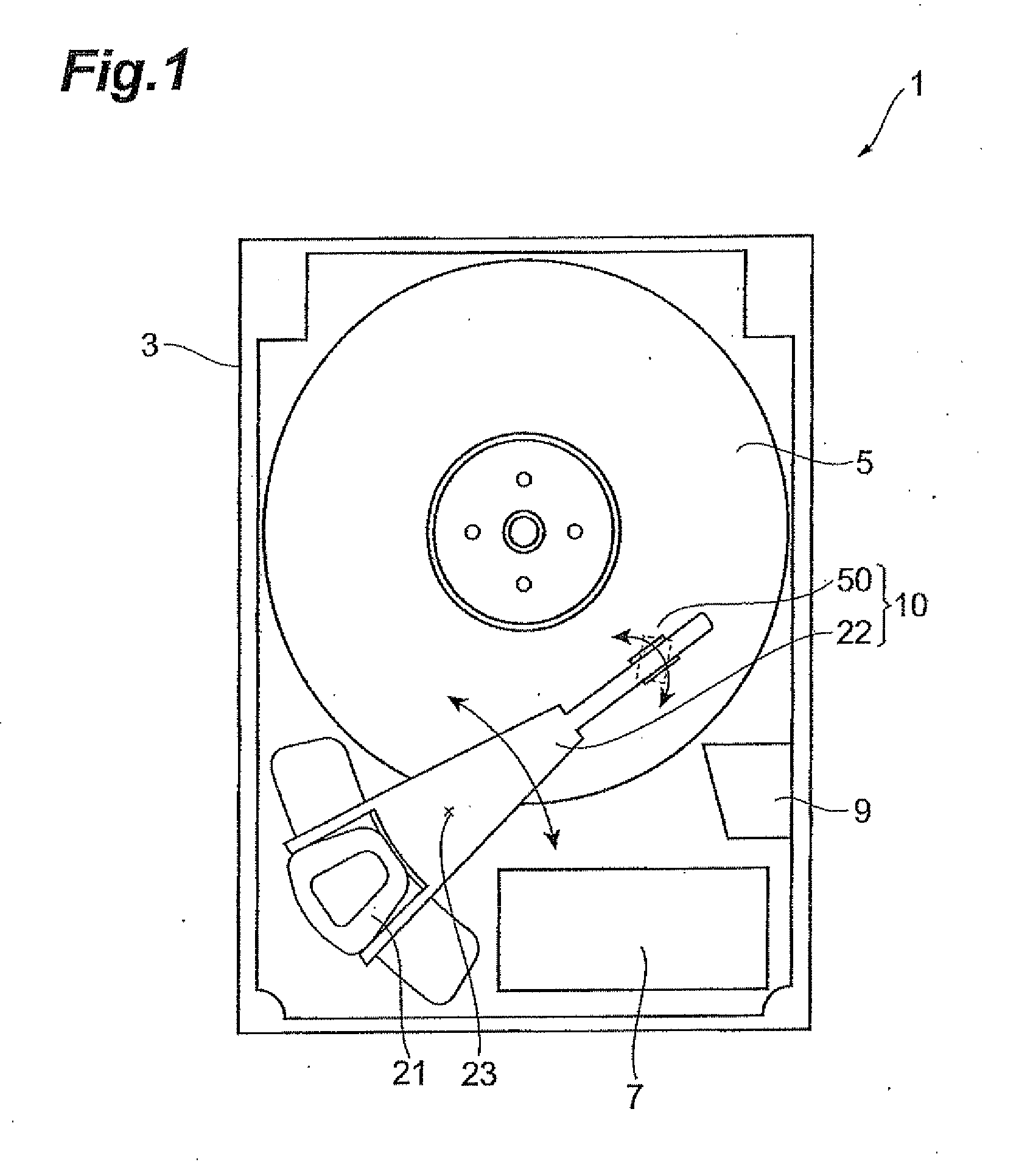

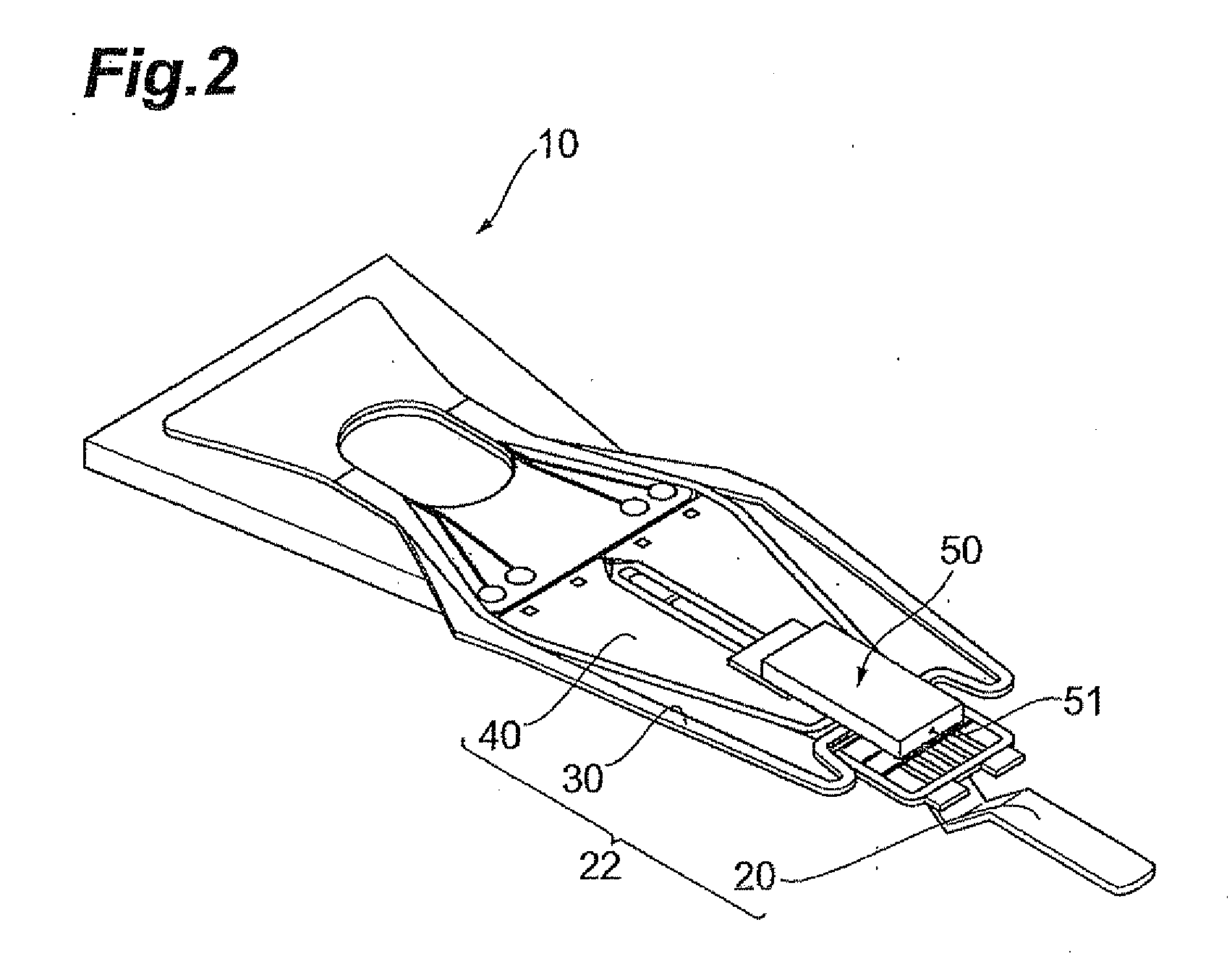

Thin-film piezoelectric device, production method thereof, head gimbals assembly using the thin-film piezoelectric device, and hard disk drive using the head gimbals assembly

ActiveUS20100097723A1Improve performanceLow costTrack finding/aligningPiezoelectric/electrostriction/magnetostriction machinesHard disc driveEngineering

A method includes a step of stacking a first electrode layer, a piezoelectric layer, and a second electrode layer on a first substrate to form a first laminate; a step of stacking a support layer on a second substrate to form a second laminate; a step of bonding the first and second laminates through an adhesive layer to form a third laminate; a step of removing the first substrate from the third laminate; a step of processing the third laminate in a desired shape; and a step of removing the second substrate. A Young's modulus of the adhesive layer is smaller than a Young's modulus of the piezoelectric layer. Respective Young's moduli of the second electrode layer and the support layer are larger than the Young's modulus of the adhesive layer. The third laminate has no other piezoelectric layer except for the aforementioned piezoelectric layer.

Owner:TDK CORPARATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com