Low-temperature pulse tube refrigerator with mixed structure

A technology of pulse tube refrigerator and hybrid structure, which is applied in refrigerators, gas cycle refrigerators, refrigeration components, etc., can solve the problems of inability to recover the hot end of refrigerators, large losses of regenerators, and limited phase modulation range, etc., and achieve Avoid the effects of high precision requirements, system efficiency improvement, reliability and life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

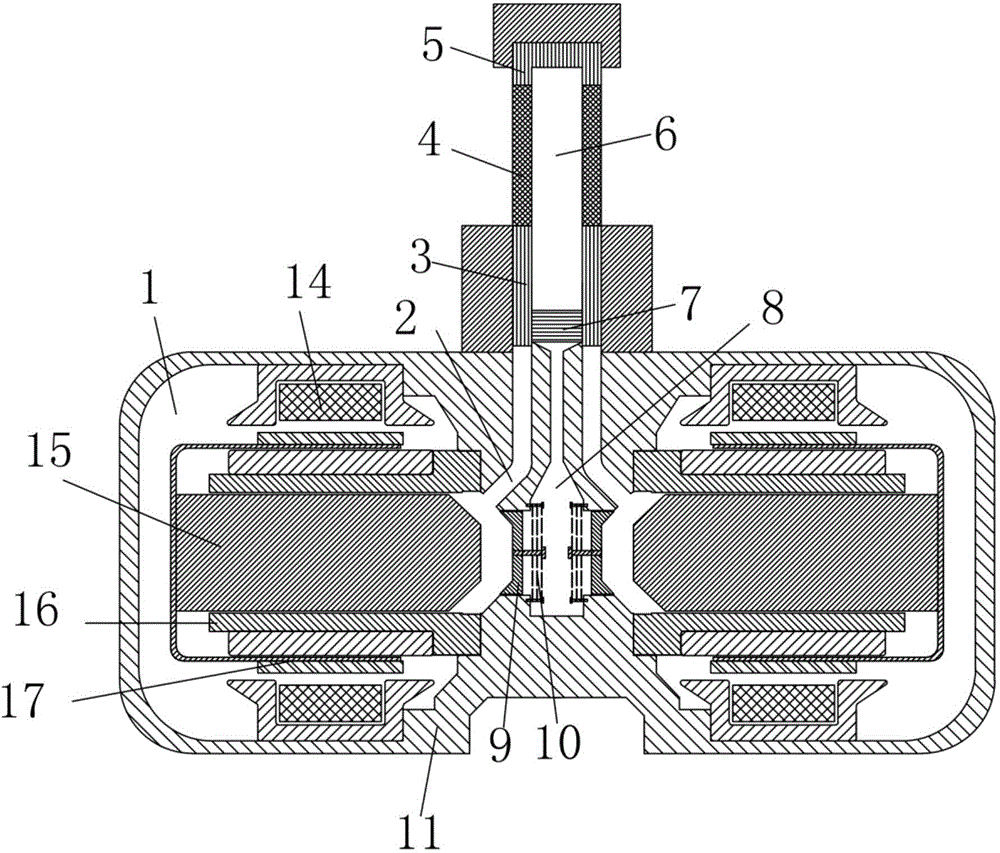

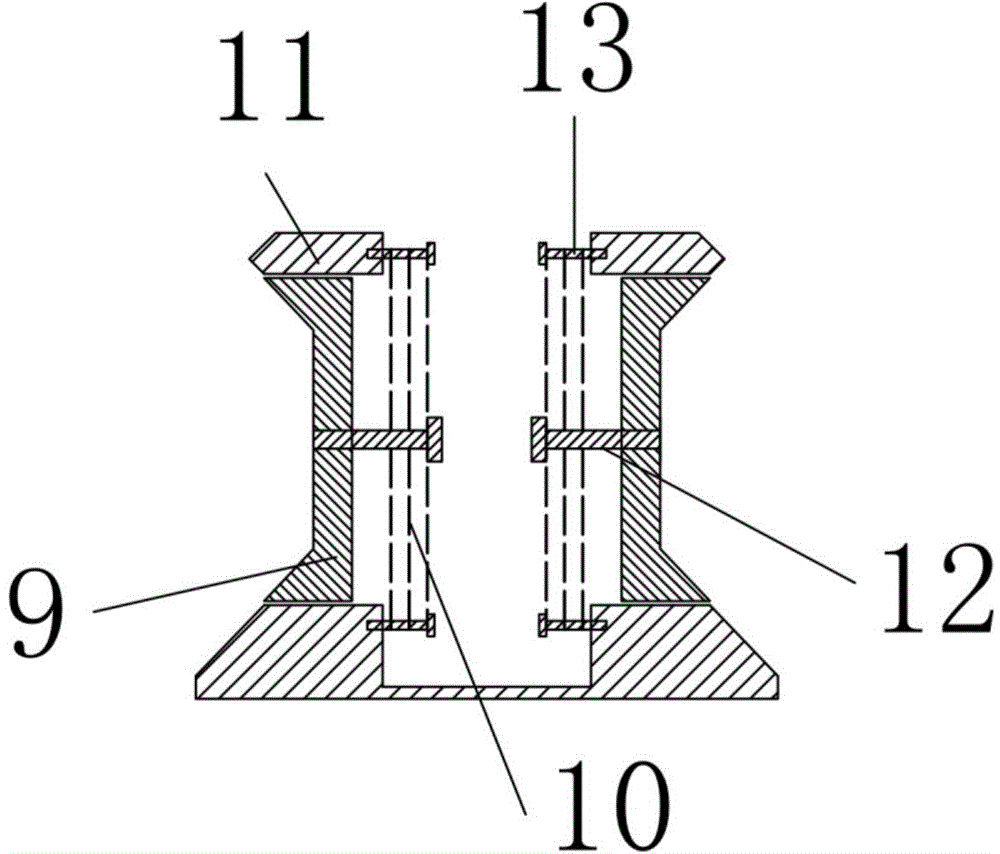

[0050] figure 1 It is the structural representation of the Stirling pulse tube refrigerator (embodiment 1) adopting the hybrid structure of the present invention; figure 1 As can be seen, the Stirling pulse tube refrigerator adopting hybrid structure of the present invention comprises:

[0051] A pair of oppositely placed linear compressor assemblies 1, the compressor pistons 15 of the pair of linear compressor assemblies 1 move in opposite directions and the vibrations generated are completely offset; the compressor cavities of the pair of linear compressor assemblies 1 communicate with each other to form a A total compression chamber 2;

[0052] The room temperature end heat exchanger 3, the regenerator 4 and the cold end heat exchanger 5 are sequentially fixedly installed at the center of the upper end face of the compressor housing of the pair of linear compressors;

[0053] The pulse tube hot end heat exchanger 7 and the pulse tube 6 are fixedly installed in the inner c...

Embodiment 2

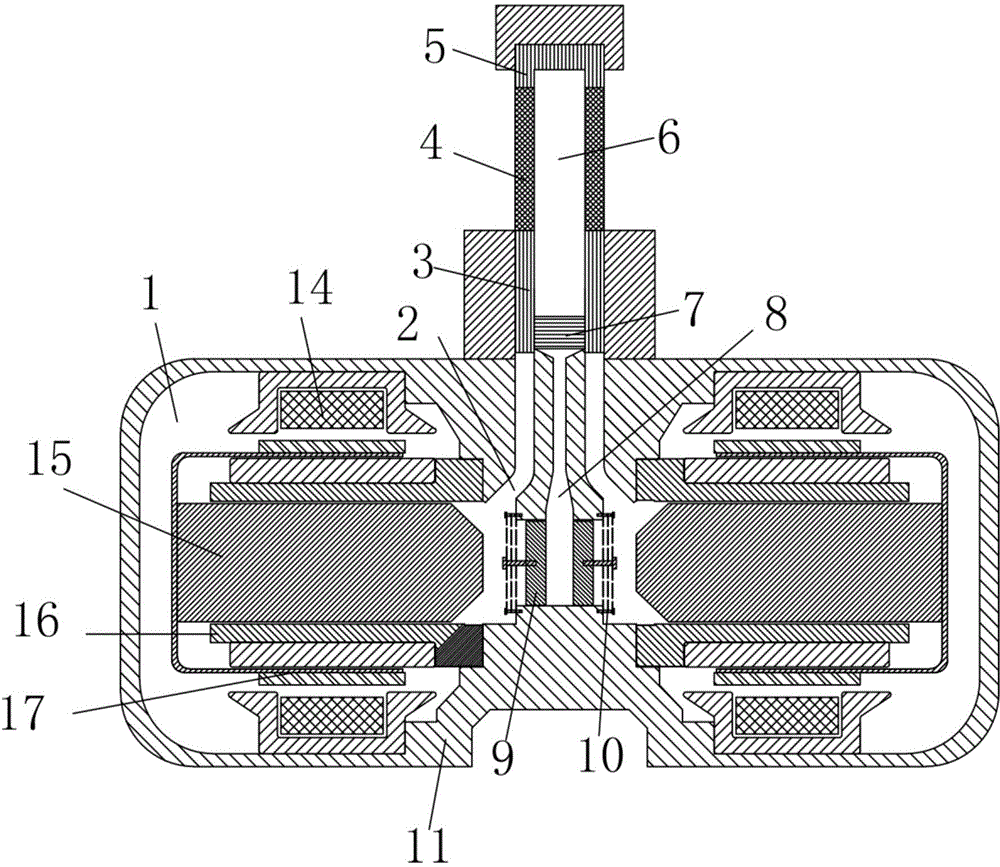

[0062] The basic structure of embodiment 2 is as image 3 Shown; The difference between this embodiment and Embodiment 1 is that two leaf springs 10 are respectively located in the left and right compression chambers 2 .

Embodiment 3

[0064] The basic structure of embodiment 3 is as Figure 4 Shown; The difference between this embodiment and Embodiment 1 is that: two leaf springs 10 are located inside the room temperature ejector piston 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com