Multistage Stirling type pulse tube refrigerator

A pulse tube refrigerator and pulse tube technology, which are applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve the problems of not being able to take both

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

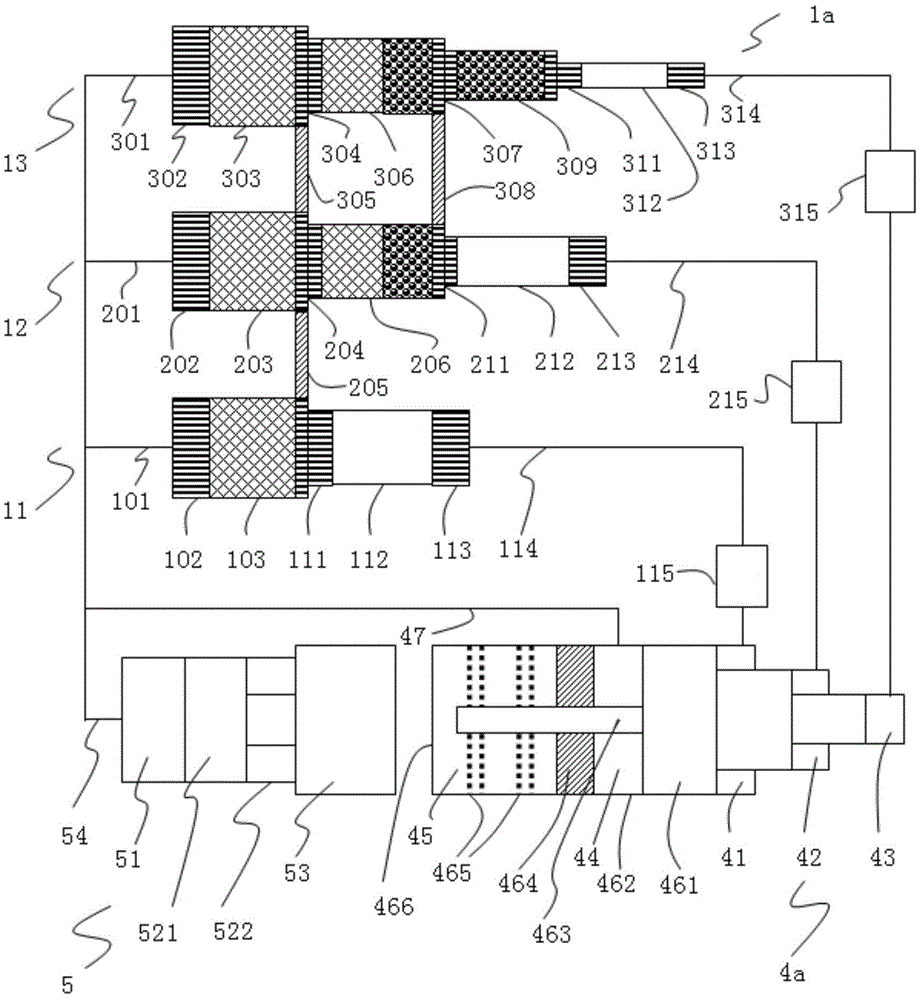

[0024] Three-stage piston pre-cooling pulse tube refrigerator, the structure is as follows figure 1 As shown, it includes a three-stage stepped piston system 4a, a compressor 5 and a three-stage pre-cooling cold head 1a.

[0025] The three-stage pre-cooling cold head 1 a includes a first-stage cold head 11 , a first-stage cold head 12 and a third-stage cold head 13 .

[0026] The first-stage cold head 11 is composed of a first-stage connecting pipe 101, a first-stage cooler 102, a first-stage regenerator 103, a first-stage cooling heat exchanger 111, a first-stage pulse pipe 112, a first-stage pulse The gas homogenizer 113 at the hot end of the tube and the first-stage vessel connecting pipe 114 are connected accordingly, and the first-stage vessel connecting pipe 114 has a first-stage adjustment chamber 115 on it. Gas can flow back and forth between the various components.

[0027] The second-stage cold head 12 is composed of a second-stage connecting pipe 201, a second-sta...

Embodiment 2

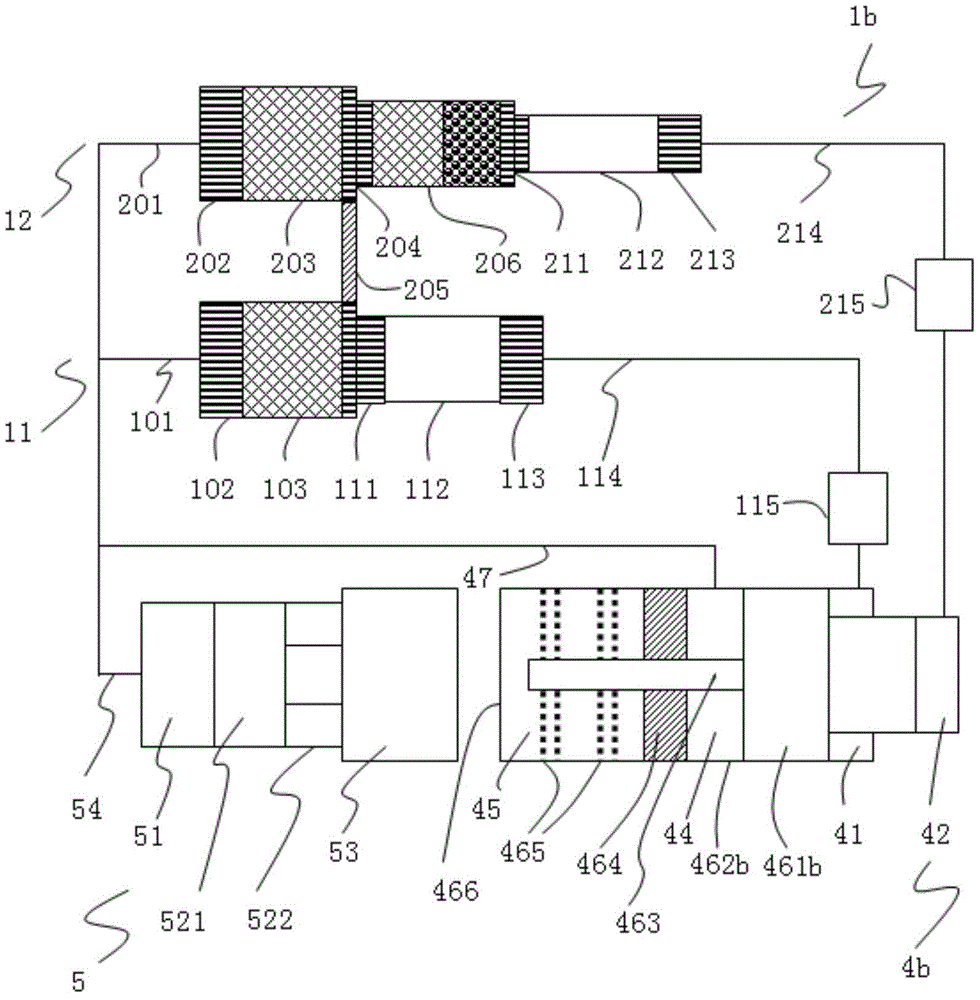

[0048] Two-stage stepped piston precooling pulse tube refrigerator, the structure is as follows figure 2 As shown, it includes a two-stage stepped piston system 4b, a compressor 5 and a two-stage pre-cooling cold head 1b.

[0049] The two-stage pre-cooling cold head 1 b includes a first-stage cold head 11 and a second-stage cold head 12 .

[0050] and figure 1 Compared with the second-stage pre-cooling cold head 1b, the third-stage cold head is missing, and the step-push piston and step cylinder of the two-stage step-push piston system 4b have become two-stage step push piston 461b and two-stage step cylinder 462b. The two-stage stepped push piston 461b and the two-stage stepped cylinder 462b form the first working chamber 41 of the pushing piston and the second working chamber 42 of the pushing piston.

[0051] Such as figure 2 As shown, there may be two adjustment chambers or only one adjustment chamber in the two-stage stepped piston pre-cooling pulse tube refrigerator...

Embodiment 3

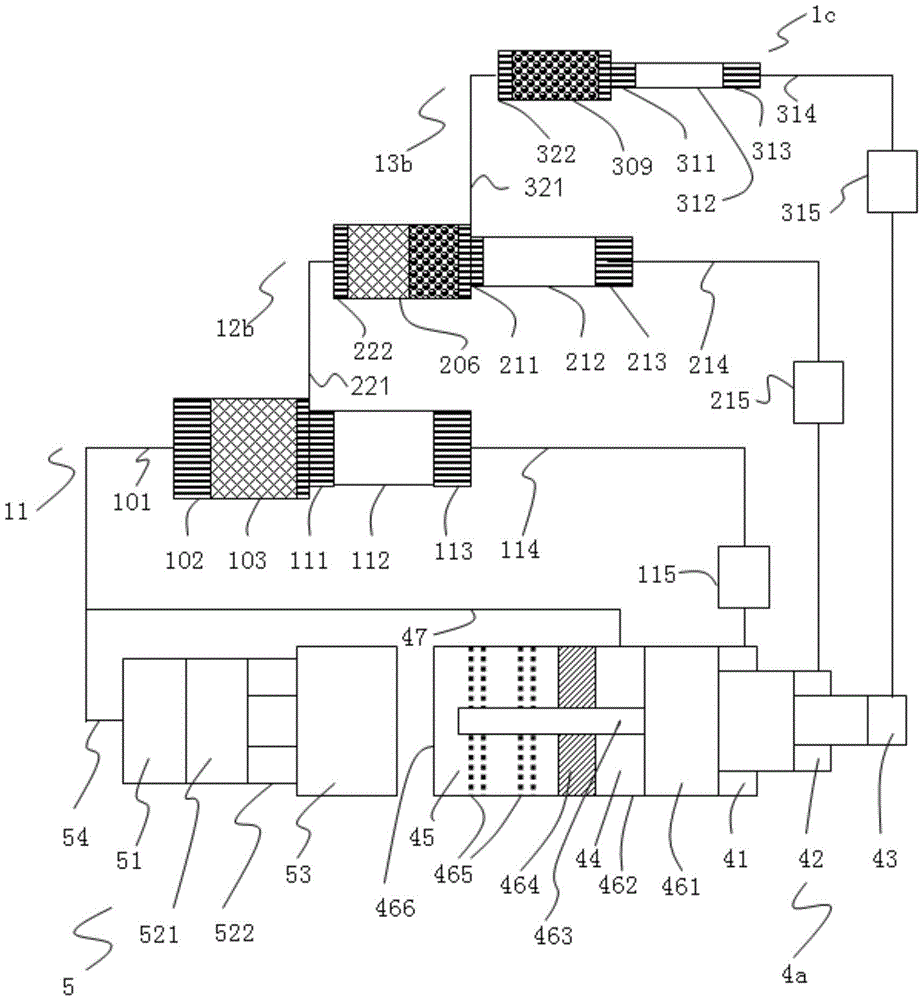

[0055] Three-stage stepped piston-coupled pulse tube refrigerator, such as image 3 As shown, it includes a three-stage stepped piston system 4a, a compressor 5 and a three-stage coupled cold head 1c.

[0056] The three-stage coupled cold head 1c includes a first-stage cold head 11, a second-stage coupled cold head 12b, and a third-stage coupled cold head 13b.

[0057] The second-stage coupling cold head 12b is composed of a second-stage cold connection pipe 221, a second-stage second regenerator gas homogenizer 222, a second-stage second regenerator 206, a second-stage cooling heat exchanger 211, and a second-stage second regenerator 206. The second-stage vessel 212 , the hot-end gas homogenizer 213 of the second-stage vessel and the second-stage vessel connection pipe 214 are sequentially connected, and the second-stage vessel connection pipe 214 is connected with a second-stage adjustment cavity 215 . Gas can flow back and forth between the various components.

[0058] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com