Construction process for self-heat-insulation system of autoclaved aerated concrete block wall

A technology of concrete blocks and autoclaved air filling, which is applied in thermal insulation, climate change adaptation, and climate sustainability, and can solve problems such as cracking, leakage, thermal insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

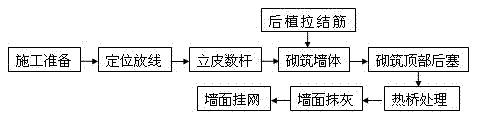

[0019] Such as figure 1 As shown, the autoclaved aerated concrete block wall self-insulation system construction technology of the present invention has included the following steps:

[0020] The first step: construction preparation

[0021] 1. Sprinkle water on the block masonry surface 1-2 times 2 days before masonry. The moisture content of the upper wall of the block should be 10%-15%, and the surface immersion depth should be 8-10mm.

[0022] 2. Special tools should be used for sawing blocks. Axes or tile knives are not allowed to chop at will. In order to reduce the workload of on-site sawing during construction, avoid waste, and facilitate material preparation, the arrangement of blocks should be designed before masonry.

[0023] 3. Air-entrained concrete of different densities and strength levels should not be mixed, and blocks from different manufacturers should not be mixed. Air-entrained concrete blocks should not be mixed with other bricks and blocks. Partial use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com