Preparation process for preventing surface impure crystal and recrystallization from formation of mono-crystal hollow turbine blade

A turbine blade and preparation technology, which is applied in the field of superalloys, can solve the problems of recrystallization of blades, nucleation and growth of miscellaneous crystals on the surface of castings, and easy supercooling, etc., to suppress miscellaneous crystals, avoid recrystallization, and avoid residual stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] detailed description: Below in conjunction with accompanying drawing, the present invention will be further described:

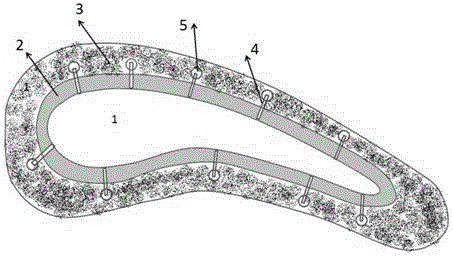

[0025] The invention relates to a preparation process for preventing the formation of surface miscellaneous crystals and recrystallization of a single crystal hollow turbine blade. The steps of the process are as follows:

[0026] (a) Prepare the blade wax mold containing the core; place the ceramic core in the wax mold, and form a wax mold on the surface of the core (2), the wax mold is formed by injection molding, and the injection temperature is 63°C-68 ℃, the pressure is 0.3-0.5MPa, the injection time is 10-30 seconds, and the holding time is 10-30 seconds;

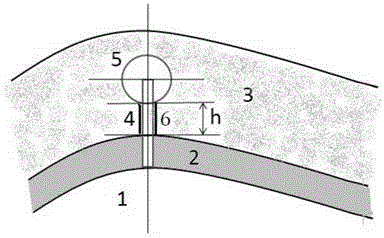

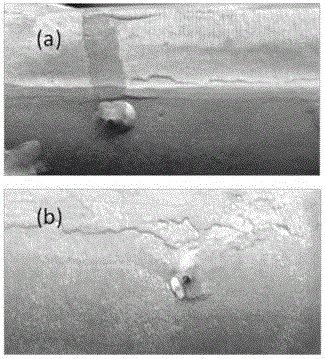

[0027] (b) Insert a platinum wire on the surface of the wax pattern to position the core; take the wax pattern, insert the platinum wire into the wax pattern perpendicular to the surface of the wax pattern, the insertion depth is equal to the thickness of the wax pattern, so that the insert...

Embodiment 1

[0034]Place the ceramic core in the wax mold. The wax mold is formed by injection molding. The injection temperature is 63°C, the pressure is 0.5MPa, the injection time is 10 seconds, and the pressure holding time is 10 seconds; take out the wax mold and place it perpendicular to the wax Insert the platinum wire into the wax mold in the direction of the mold surface, the insertion depth is equal to the thickness of the wax mold, and the insertion end of the platinum wire is in full surface contact with the ceramic core; the diameter of the platinum wire is 0.3mm, and the length of the platinum wire exposed to the surface of the wax mold is 5mm; wax balls are prepared by the liquid drop method at the exposed end of the platinum wire. The shortest distance h between the spherical surface of the wax ball and the surface of the wax model should not be less than 2mm. If it is larger than 1mm, the diameter of the wax ball is 1mm; the other part of the platinum wire exposed to the sur...

Embodiment 2

[0036] Place the ceramic core in the wax mold. The wax mold is formed by injection molding. The injection temperature is 65°C, the pressure is 0.5MPa, the injection time is 30 seconds, and the pressure holding time is 30 seconds; take out the wax mold and place it perpendicular to the wax Insert the platinum wire into the wax mold in the direction of the surface of the mold, the insertion depth is equal to the thickness of the wax mold, the insertion end of the platinum wire is in full surface contact with the ceramic core; the diameter of the platinum wire is 0.6mm, and the length of the platinum wire exposed to the surface of the wax mold is 8mm; the wax ball is prepared by droplet method at the exposed end of the platinum wire. The shortest distance h between the spherical surface of the wax ball and the surface of the wax model should not be less than 2mm. If it is larger than 1mm, the diameter of the wax ball is 3mm; the side part of the platinum wire exposed to the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com