A wear-resistant multi-principal alloy-diamond composite material and its preparation method and application

A multi-principal element alloy and composite material technology is applied in the field of multi-principal alloy-diamond composite materials and their preparation, which can solve the problems of affecting the structure and performance of the bonding phase, easy introduction of impurities, safety hazards, etc., and improve poor stability. , the effect of excellent wear and corrosion resistance, low friction coefficient and wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Material preparation.

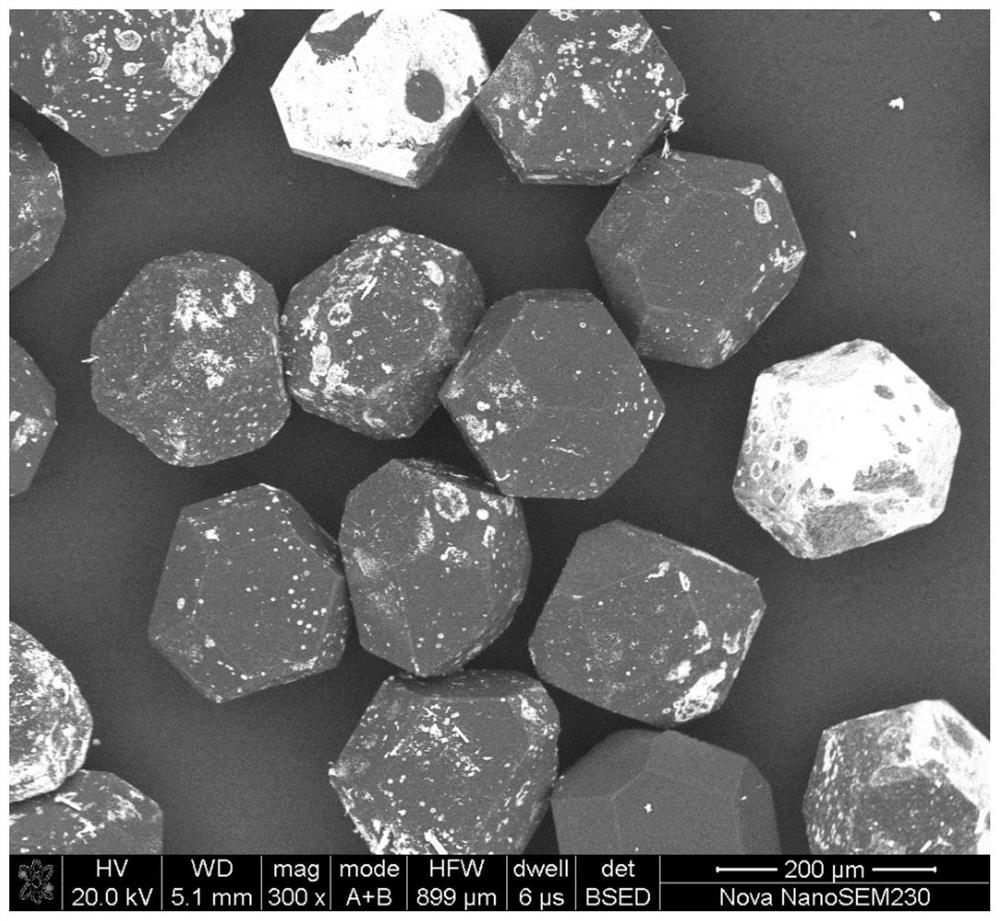

[0047] (1) Prepare CuNiCoCr alloy powder: select gas atomized CuNiCoCr alloy powder with a particle size of 45-100 μm, and its composition is Cu25Ni25Co25Cr25 (at.%).

[0048] (2) Prepare diamond powder: select D-grade diamond with a particle size of 150-180 μm.

[0049] (3) The above-mentioned CuNiCoCr alloy powder and diamond powder are fully mechanically mixed, and mixed powder is obtained after mixing. Among them, the volume percentage of diamond powder in the composite powder is 12.5 vol.%.

[0050] 2. Preparation of multi-principal alloy-diamond composites.

[0051] The mixed powder raw material was filled into a graphite mold, pre-pressed under a pressure of 20 MPa, and then spark plasma sintered at a sintering pressure of 30 MPa. Incubate for 5 min, increase the temperature from 400 °C to 850 °C at a heating rate of 50 °C / min, and hold for 10 min. A multi-principal alloy-diamond composite material was prepared.

[0052] 3. After g...

Embodiment 2

[0055] 1. Material preparation.

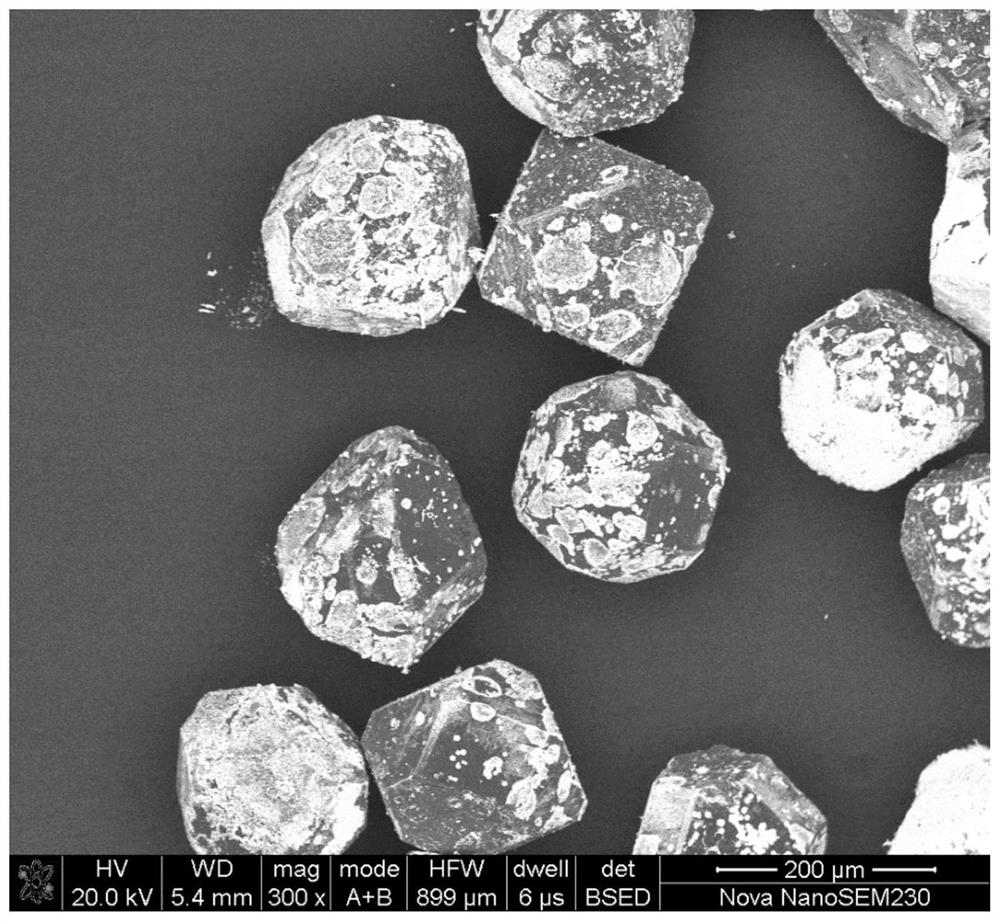

[0056] (1) Prepare CuNiCoCr alloy powder: select gas atomized CuNiCoCr alloy powder with a particle size of 45-100 μm, and its composition is Cu30Ni25Co25Cr20 (at.%).

[0057] (2) Prepare diamond powder: select D-grade diamond with a particle size of 150-180 μm.

[0058] (3) The above-mentioned CuNiCoCr alloy powder and diamond powder are fully mechanically mixed, and mixed powder is obtained after mixing. Among them, the volume percentage of the diamond powder in the composite powder is 15 vol.%.

[0059] 2. Preparation of multi-principal alloy-diamond composites.

[0060] The mixed powder raw material was filled into a graphite mold, pre-pressed under a pressure of 20 MPa, and then spark plasma sintered at a sintering pressure of 30 MPa. Incubate for 5 min, increase the temperature from 400 °C to 850 °C at a heating rate of 50 °C / min, and hold for 10 min. A multi-principal alloy-diamond composite material was prepared.

[0061] 3. After...

Embodiment 3

[0064] 1. Material preparation.

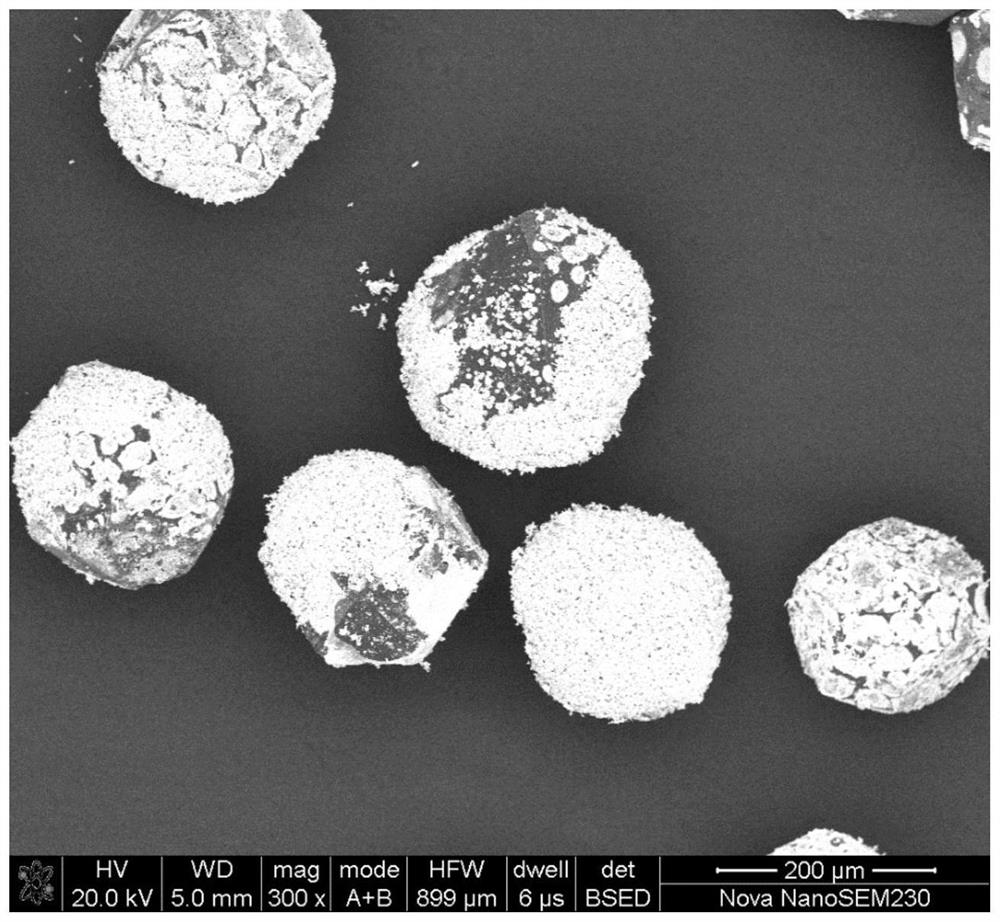

[0065] (1) Prepare CuNiCoCr alloy powder: select gas-atomized CuNiCoCr alloy powder with a particle size of 45-100 μm, and its composition is Cu35Ni25Co25Cr15 (at.%).

[0066] (2) Prepare diamond powder: select D-grade diamond with a particle size of 150-180 μm.

[0067] (3) The above-mentioned CuNiCoCr alloy powder and diamond powder are fully mechanically mixed, and mixed powder is obtained after mixing. Among them, the volume percentage of the diamond powder in the composite powder is 20 vol.%.

[0068] 2. Preparation of multi-principal alloy-diamond composites:

[0069] The mixed powder raw material was filled into a graphite mold, pre-pressed under a pressure of 20 MPa, and then spark plasma sintered at a sintering pressure of 30 MPa. Incubate for 5 min, increase the temperature from 400 °C to 850 °C at a heating rate of 50 °C / min, and hold for 10 min. A multi-principal alloy-diamond composite material was prepared.

[0070] 3. After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com