Heat preservation composite wall provided with meshed plaster on two sides

A thermal insulation composite and wall technology, applied in thermal insulation, building thermal insulation materials, walls, etc., can solve the problems of inconvenient installation of anti-theft fences and heavy decorations, affecting the energy saving and thermal insulation effect of composite walls, and difficulty in achieving low heat transfer coefficients. It can achieve the effect of energy saving and heat preservation, good fire prevention and anti-seismic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

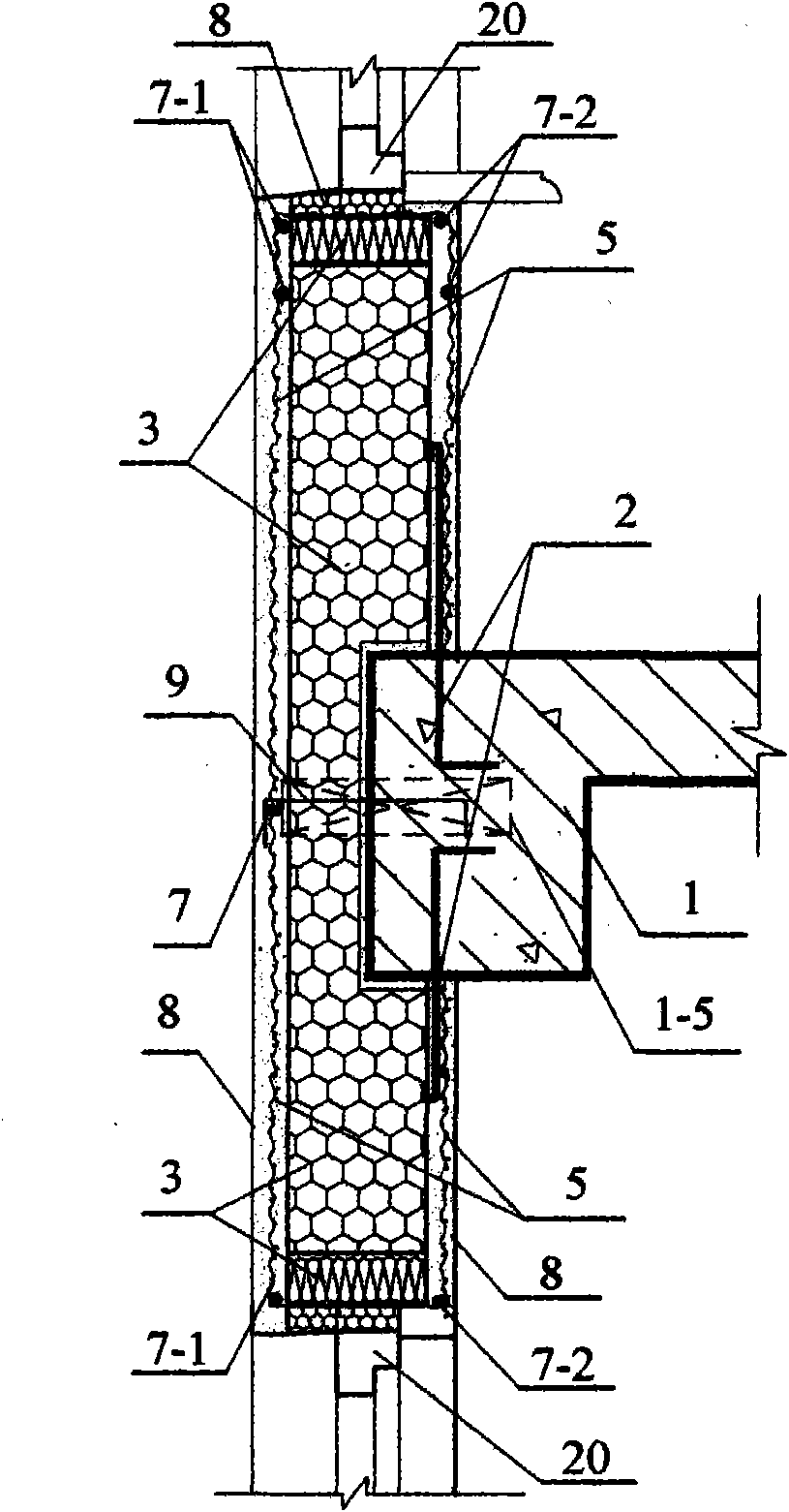

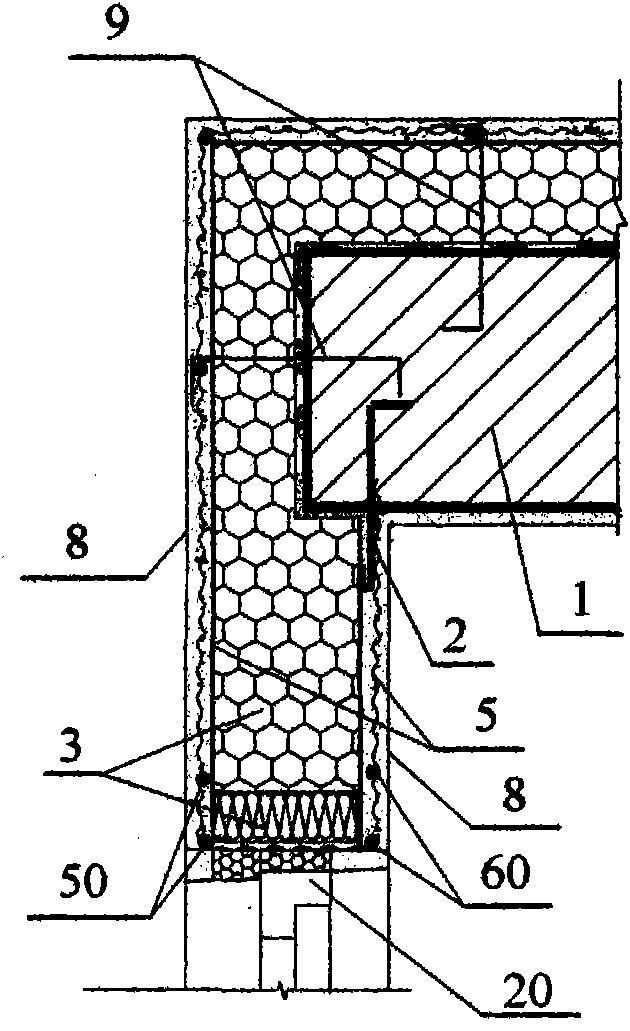

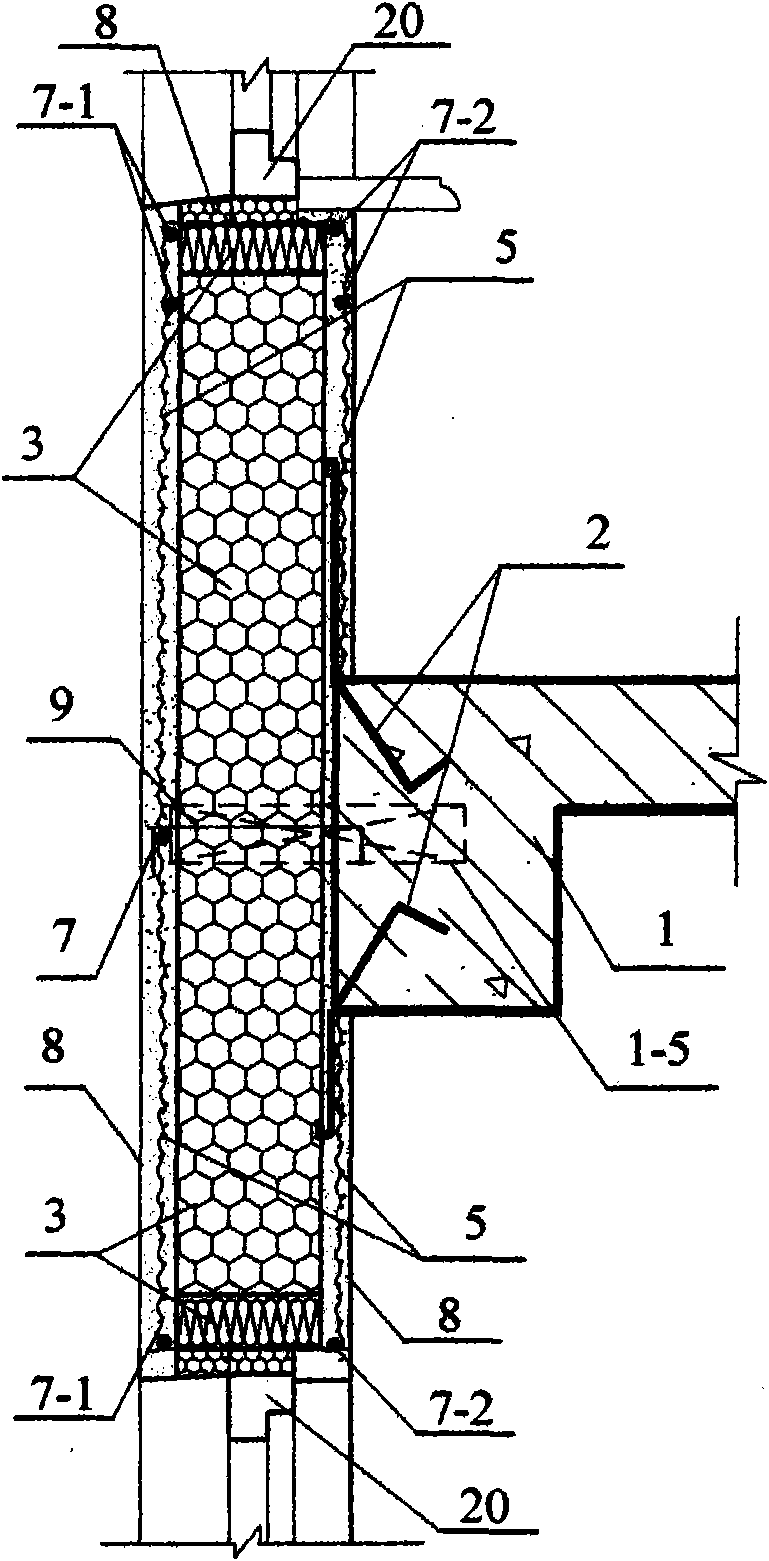

[0057] Specific implementation mode one: see Figure 1 to Figure 12 , Figure 14 , a thermal insulation composite wall with net plastering on both sides of this embodiment is composed of a load-bearing member 1 of the main building structure, a short anchoring steel bar 2, a core layer 3, a mesh tensile material 5, doors and windows 20, and outdoor vertical steel bars 50. Indoor vertical steel bars 60, outdoor horizontal additional steel bars 7-1, indoor horizontal steel bars 7-2, protective layer 8, and supporting cantilever beams 1-5; the load-bearing member 1 of the main structure of the building is a beam (including the foundation Beam), board (including base plate), column, load-bearing wall; the core layer 3 is polymer insulation material, or mineral wool or plant straw or paper honeycomb board or insulation mortar; the mesh tensile material 5 is Alkali-resistant mesh cloth 5-1 or metal mesh 5-2 or bamboo reinforcement mesh 5-3; the protective layer 8 is cement mortar o...

specific Embodiment approach 2

[0067] Specific implementation mode two: see Figure 5 ~ Figure 7 The difference between this embodiment and the specific embodiment one is: this embodiment increases the waterproof and moisture-proof layer 15; the waterproof and moisture-proof layer 15 has the following three installation methods: 1), the waterproof and moisture-proof layer 15 is directly pasted on the core layer of the hole 3, or the waterproof and moisture-proof layer 15 wraps the core layer 3 of the hole, and the doors and windows 20 are installed on the waterproof and moisture-proof layer 15; 2), alkali-resistant mesh cloth 5-1 is pasted on the surface of the hole core layer 3, and the waterproof and moisture-proof layer 15 is pasted Above the alkali-resistant mesh cloth 5-1, the doors and windows 20 are installed on the waterproof and moisture-proof layer 15; 3), the waterproof and moisture-proof layer 15 is pasted on the core layer 3, or the waterproof and moisture-proof layer 15 wraps the core layer 3 o...

specific Embodiment approach 3

[0070] Specific implementation mode three: see Figure 1 ~ Figure 4 , Figure 9~ Figure 12 The difference between this embodiment and the specific embodiment one or two is: this embodiment increases the internal and external tension connection steel wire 9; the inner end of the internal and external tension connection steel wire 9 is anchored in the load-bearing member 1 of the main structure of the building, and the outer end is connected to the outdoor Vertical reinforcement 50 is connected, or the outer end is connected with the outdoor horizontal additional reinforcement 7-1, or the outer end is connected with the outdoor mesh tensile material 5; -1 or the outdoor mesh tensile material 5 is connected to the indoor vertical steel bar 60, the indoor horizontal steel bar 7-2 or the indoor mesh tensile material 5.

[0071] The inner and outer drawing connecting steel wires 9 can be Φ2.5 or Φ3 stainless steel drawing connecting steel wires, the stainless steel wires are soft, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com