Cement based polymer heat preserving dry powder mortar and using method thereof

A technology of dry powder mortar and thermal insulation mortar is applied in the field of building materials, which can solve the problems of complex construction process, high cost and poor economy, and achieve the effects of simplifying procurement, saving material consumption, and reducing structural loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to further understand the features and technical contents of the patent of the present invention, the patent is now described with reference to the following examples and implementation methods. These factual modes and embodiments are only used to explain the patent of the present invention, rather than limit the present invention The scope of patent protection.

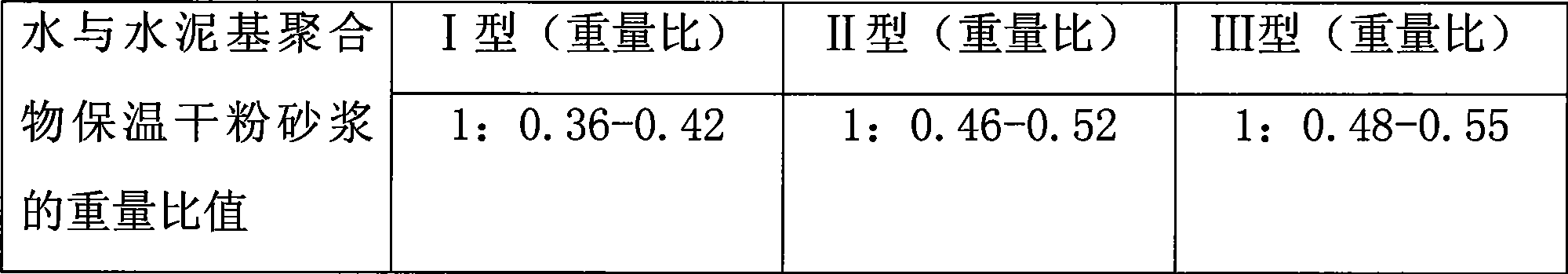

[0021] The patent of the present invention can have multiple embodiments. A cement-based polymer thermal insulation dry powder mortar contains cement, light aggregate, fly ash, and quartz sand. The proportioning of the components by weight is as follows: cement, 30-40 parts The total amount of light aggregate is 40-50 parts; fly ash, 8-10 parts; quartz sand, 10-20 parts, dispersible latex powder and water-retaining agent, water-repellent agent, polypropylene fiber, wood fiber, mortar plastic One or more components in the chemical agent, the total amount of which is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com