Alcohol beverage dispensing apparatus

a technology for dispensing equipment and alcohol beverages, which is applied in the field of cooling systems, can solve problems such as preventing proper dispensing of beer, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

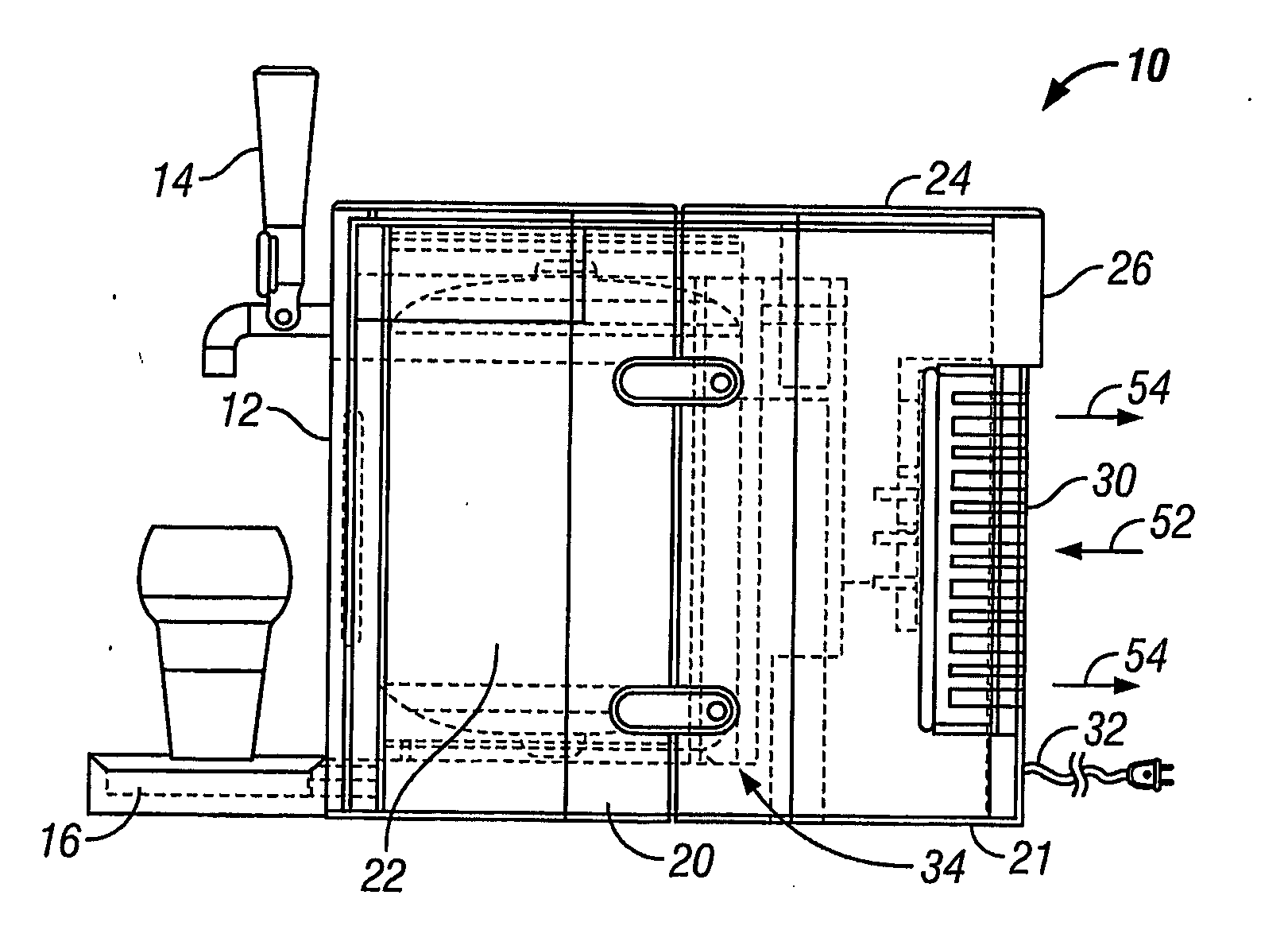

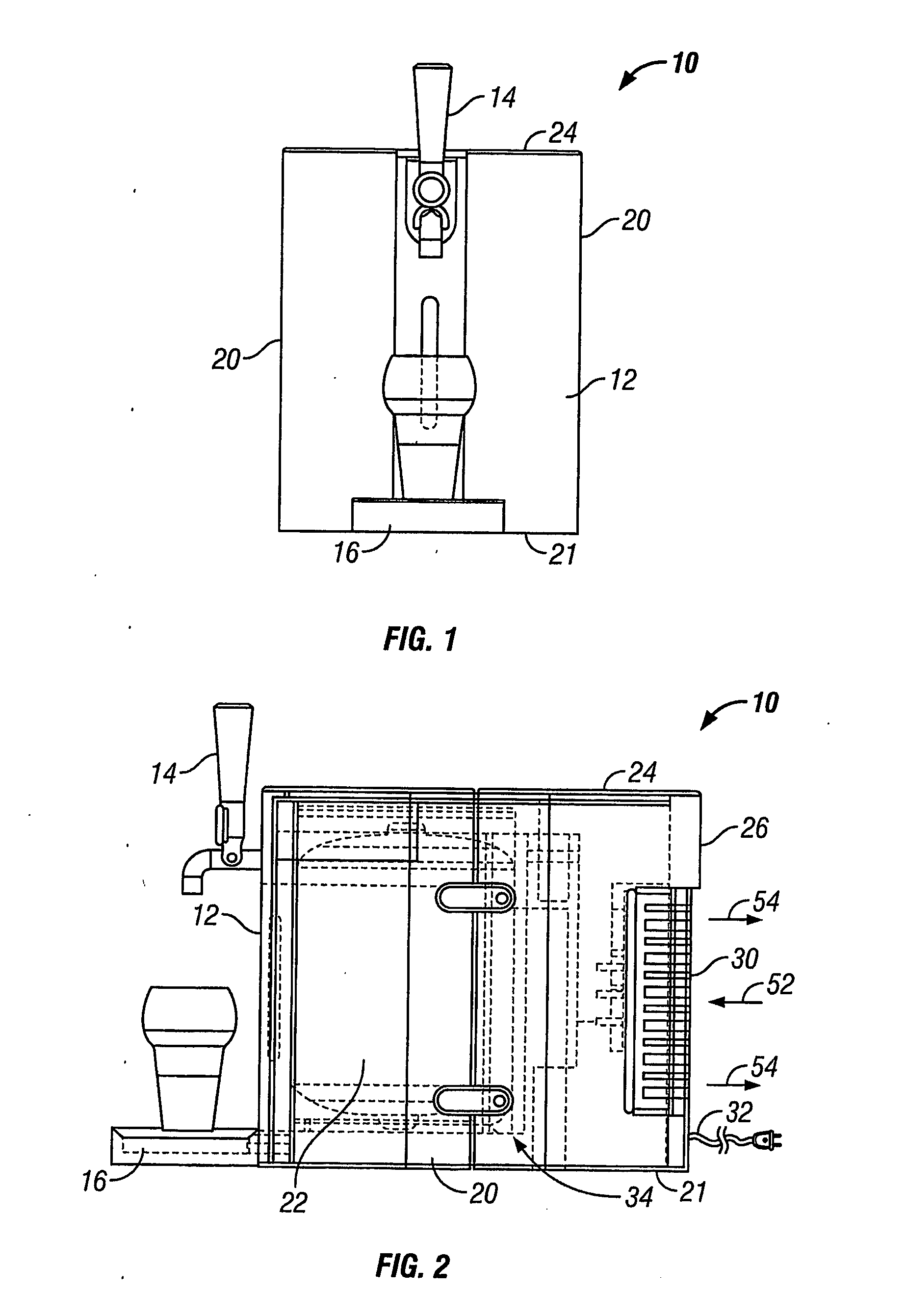

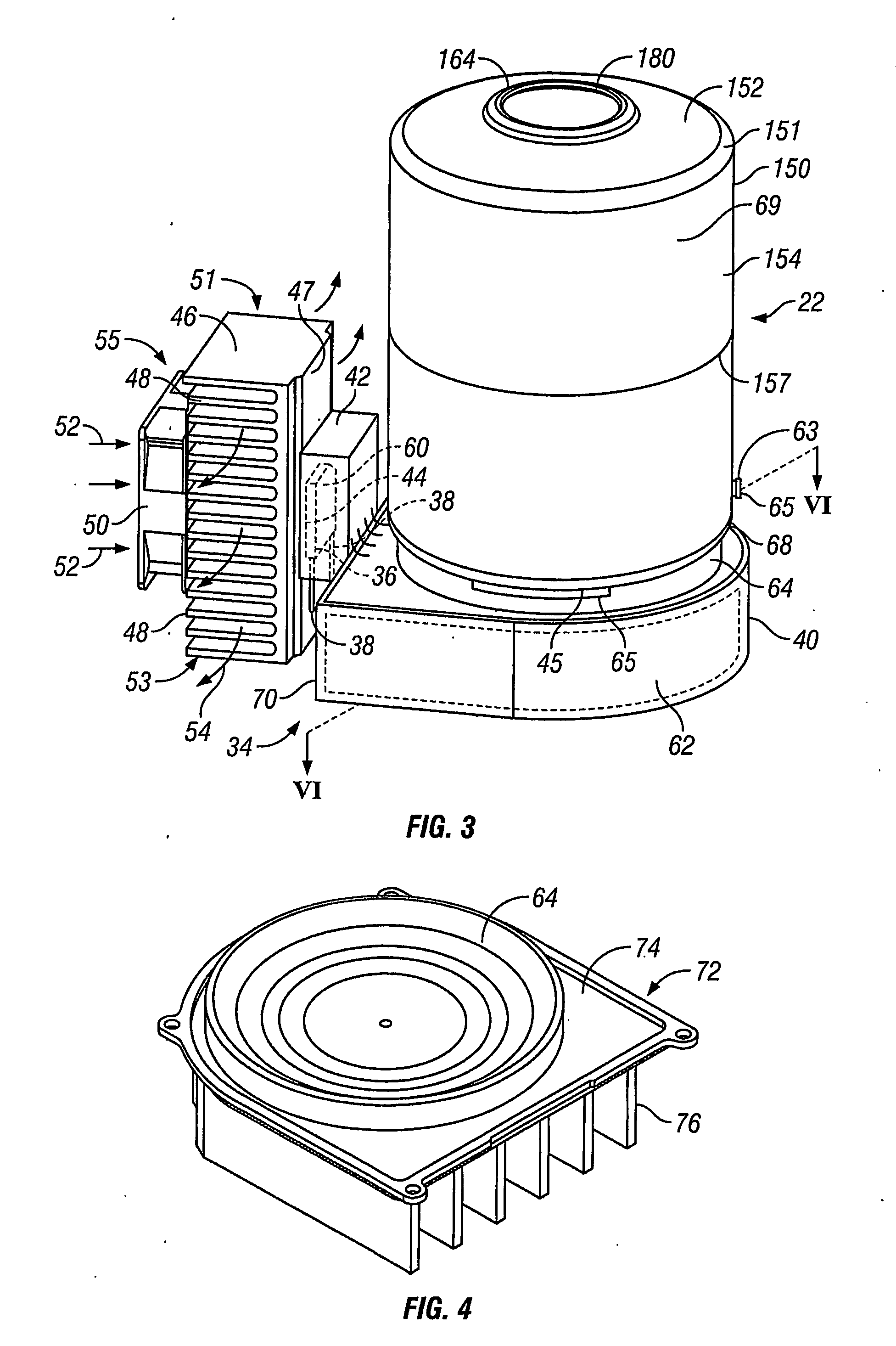

[0034] Referring to FIGS. 1 and 2 there is shown a home beer dispensing apparatus, appliance or unit 10. The dispensing apparatus 10 is primarily intended for use in domestic kitchens but may also be used in utility rooms, garages, domestic bars, caravans etc. While the preferred embodiment relates to dispensing beer, alternatively carbonated solutions or other alcohol beverages may be dispensed by apparatus 10.

[0035] The home beer dispensing apparatus 10 has a front wall 12 and a dispensing tap 14 protruding forward of the front wall 12. A drip tray 16 also protrudes forward of the front wall 12 and is adapted to support an open glass container 18 below the dispensing tap 14. The home beer dispensing apparatus 10 further has a base 21 adapted to rest on a counter top. The front wall 12 is an extension of two pivoting side walls 20 which may be moved between closed and open positions to allow the keg 22 (see FIG. 2 in broken lines) to be inserted into the housing of the home beer d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com