Bidirectional tosh grinding ultra-fine crashing objects and its method

A technology of ultra-fine crushing and two-way rotation, which is applied in grain processing and other directions, and can solve problems such as unguaranteed safety issues, prone to combustion or explosion, and danger of heating the cylinder, so as to reduce energy consumption, shorten production time, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

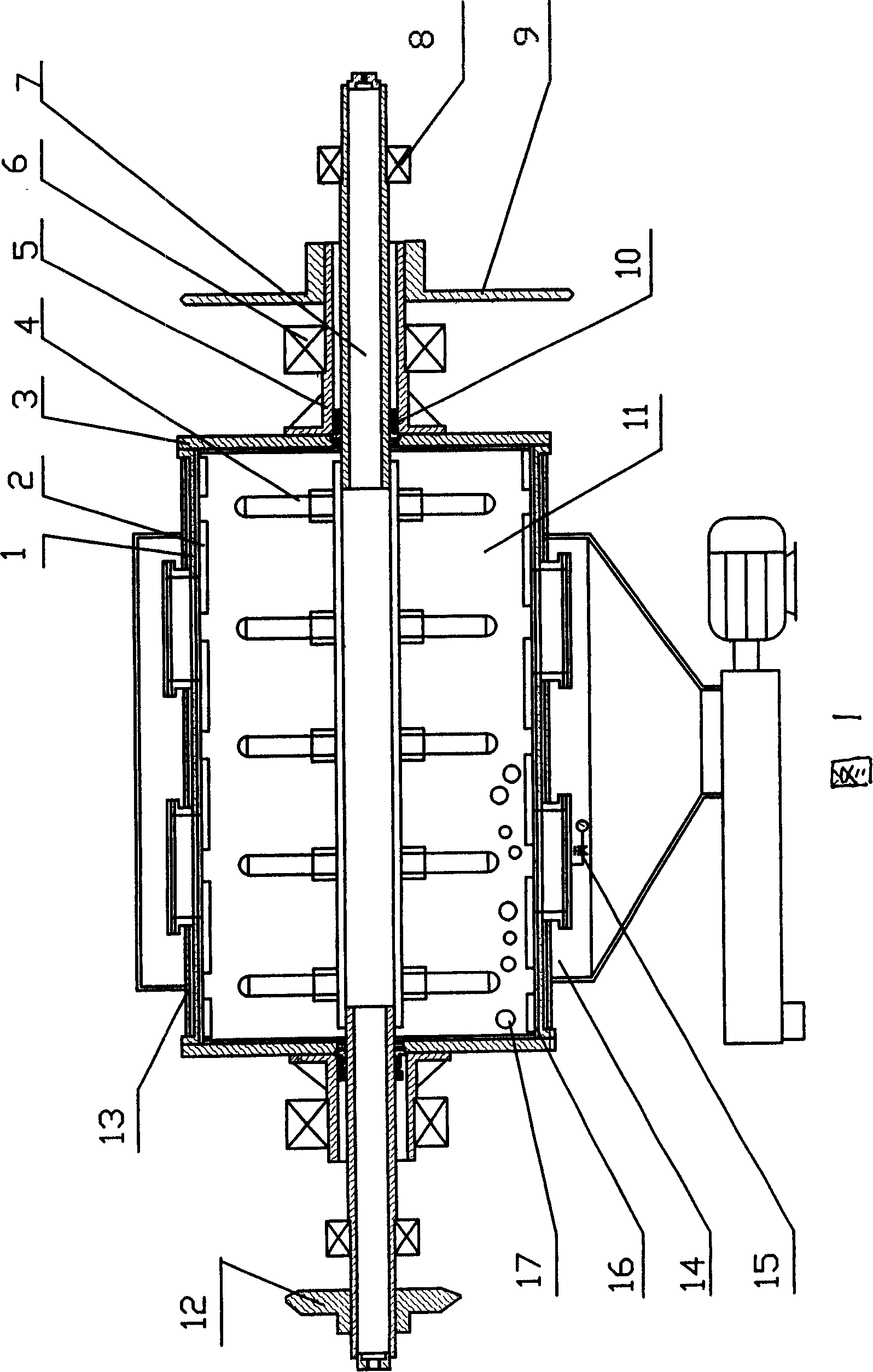

[0026] Embodiment 1: the production of superfine flaky aluminum powder: spherical spray aluminum powder (mean particle diameter d 50 = about 20 μm) into the two-way rotating ball mill ultra-fine grinding equipment with a volume of 800L in cylinder body 1, the feeding amount is 200kg, and adding stearic acid accounting for 5% of aluminum powder weight as surface coating agent, grinding ball 17 (stainless steel The amount of steel ball) is 1 ton, and the following gradation is selected, that is, Φ5~10mm: 45%, Φ10~20mm: 35%, Φ20~30: 20%, the rotation speed of cylinder 1 is 70 rpm, and the rotation speed of inner rotating shaft 7 The motor power is 40 rpm, the motor power is 30kW, and the cooling water is passed through the cylinder jacket 13 during the production process, and the spherical aluminum powder can be ultra-fine after 4 to 5 hours of crushing to an average particle size of d 50 <3 μm flake aluminum powder, then immediately put it into the airtight receiving bin 14, and...

Embodiment 2

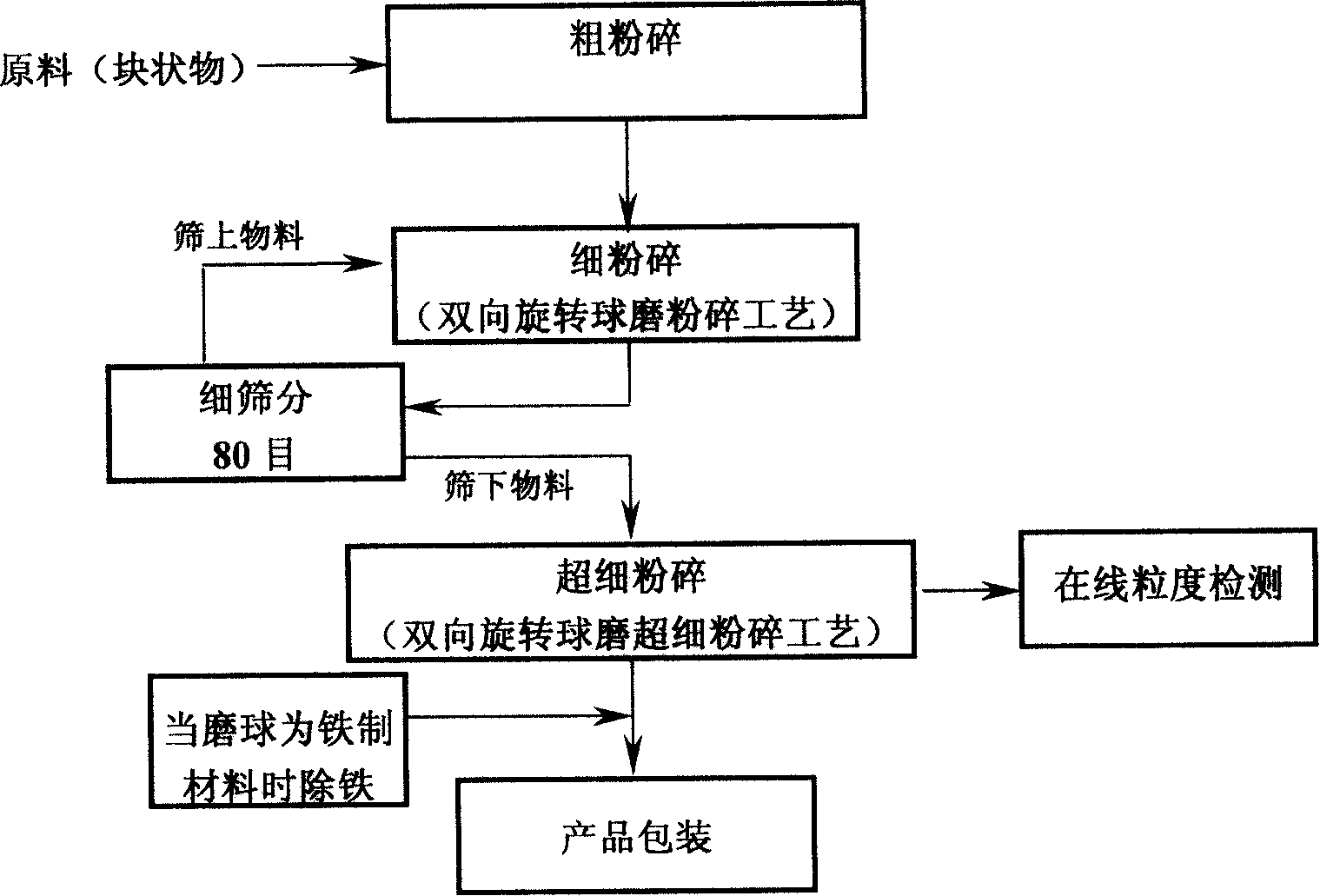

[0027]Embodiment 2: production of superfine oak wood charcoal powder: the oak wood charcoal stick (Φ=5cm) that length is 20cm is broken into the charcoal particle of about 10 orders by rough crushing process, for avoiding the mixing of a small amount of large particles (more than 5mm), coarse Coarse screening must be carried out after crushing to ensure that the particle size of coal particles entering the subsequent fine crushing process is basically uniform, so as to reduce fine crushing time, reduce energy consumption, and improve production efficiency and product uniformity. Coarsely pulverized charcoal particles are finely pulverized using the two-way rotating ball mill pulverization technology, and the corresponding equipment with cylinder body 1 of 800L is selected, the feeding amount is 350kg each time, and the consumption of grinding balls 17 (bearing steel balls) is 1.25 tons. The following grades are selected: Matching, that is, Φ20~30mm: 20%, Φ30~40mm: 30%, Φ40~50: ...

Embodiment 3

[0028] Example 3: Production of superfine rubber and plastic filler—coal-based composite functional powder: use impact crushing techniques such as jaw crushing to crush coal lumps (Φ=15cm) into coal particles with a diameter of 10 mesh, and pass through a 10 mesh drum Sieve and sieve, and the undersieve is added to the two-way rotating ball mill for fine crushing. The cylinder 1 has a volume of 2000L and is equipped with 4 tons of grinding balls 17 (bearing steel balls), and its gradation is: Φ20~30mm: 20%, Φ30~40mm: 30%, Φ40~50mm: 50%, the ball-to-material ratio is 10:1, ball milling at a speed of 60 rpm for cylinder 1 and 35 rpm for inner rotating shaft 7 After 1 hour, the powder can be unloaded and placed in the airtight receiving bin 14 at the lower end of the ball mill, sieved through an 80-mesh vibrating sieve, the undersize is stored, and a small amount of oversize is returned to the two-way rotary ball mill crushing equipment for further pulverization. The fine powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com