Aerogel preparation method

An aerogel and gel technology, applied in the field of aerogel, can solve the problems of labor-consuming solvent replacement, high sublimation pressure, complicated equipment, etc., and achieve the effects of suitable promotion, large porosity and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

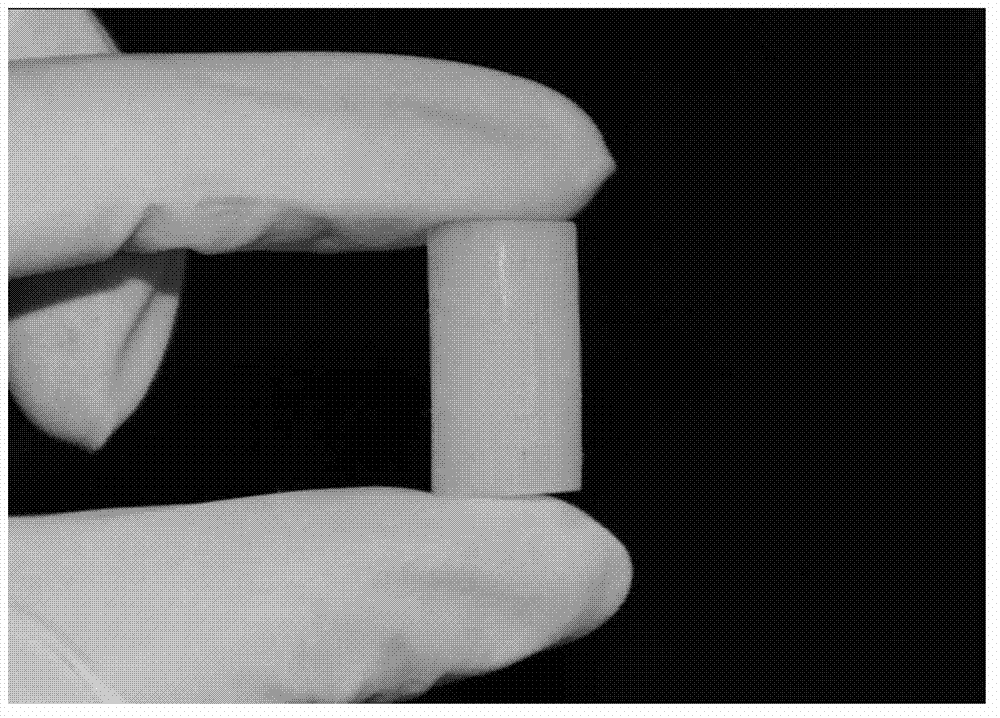

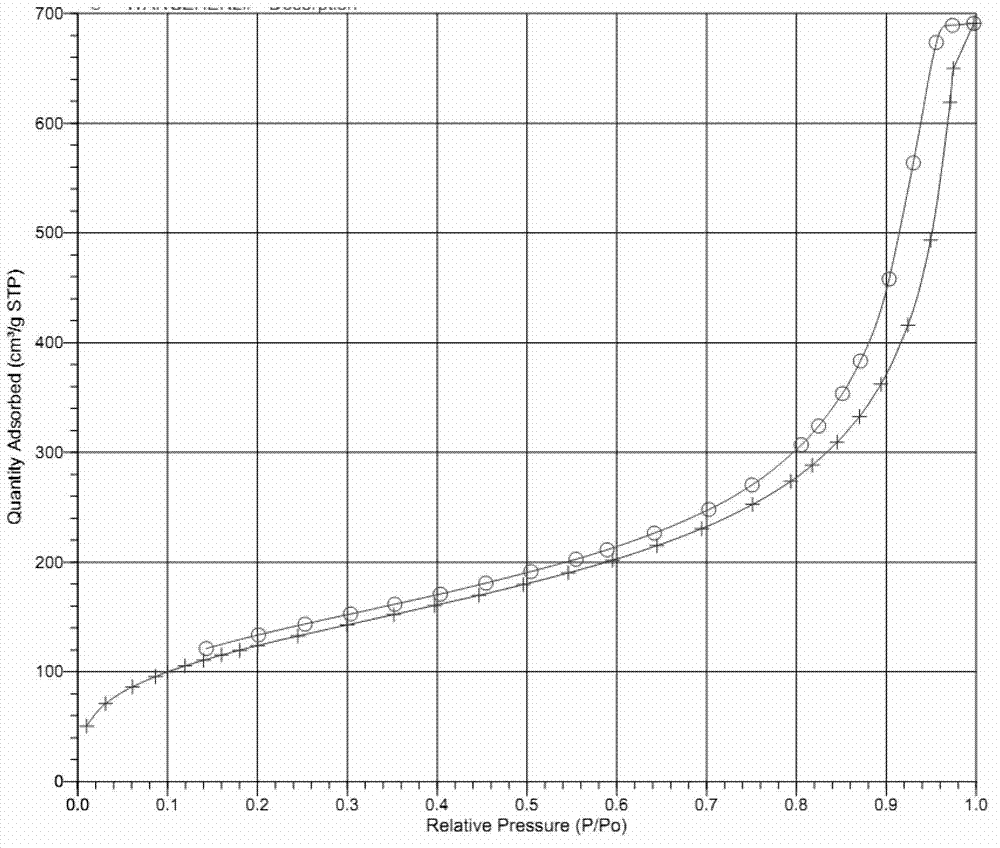

[0035] Embodiment 1, use vacuum drying method to prepare silica airgel

[0036] Dissolve 5.0g of tetraethyl orthosilicate in 30mL of ethanol, add 3mL of concentrated hydrochloric acid (mass fraction: 37%), mix well, then add dropwise 2mL of concentrated ammonia water (mass fraction: 28%), stir evenly and let it stand to obtain two silica gel. Replace the solvent of the gel with ethanol 10 times within 3 days to remove unreacted small molecules and impurities. At room temperature, immerse the silica gel in ethanol (it is advisable that the liquid level is just below the gel), and put it in In the vacuum tank, vacuumize the system to make the system pressure reach 10Pa. After the solvent is completely evaporated, the silica airgel can be obtained. its photo as figure 2 As shown, the density is 0.11g / cm 3 , with a porosity of 94%, tested by nitrogen adsorption (such as image 3 Shown) The obtained BET specific surface area is 469m 2 / g.

Embodiment 2

[0037] Example 2, Preparation of Bridged Silsesquioxane Airgel Using Vacuum Drying Method

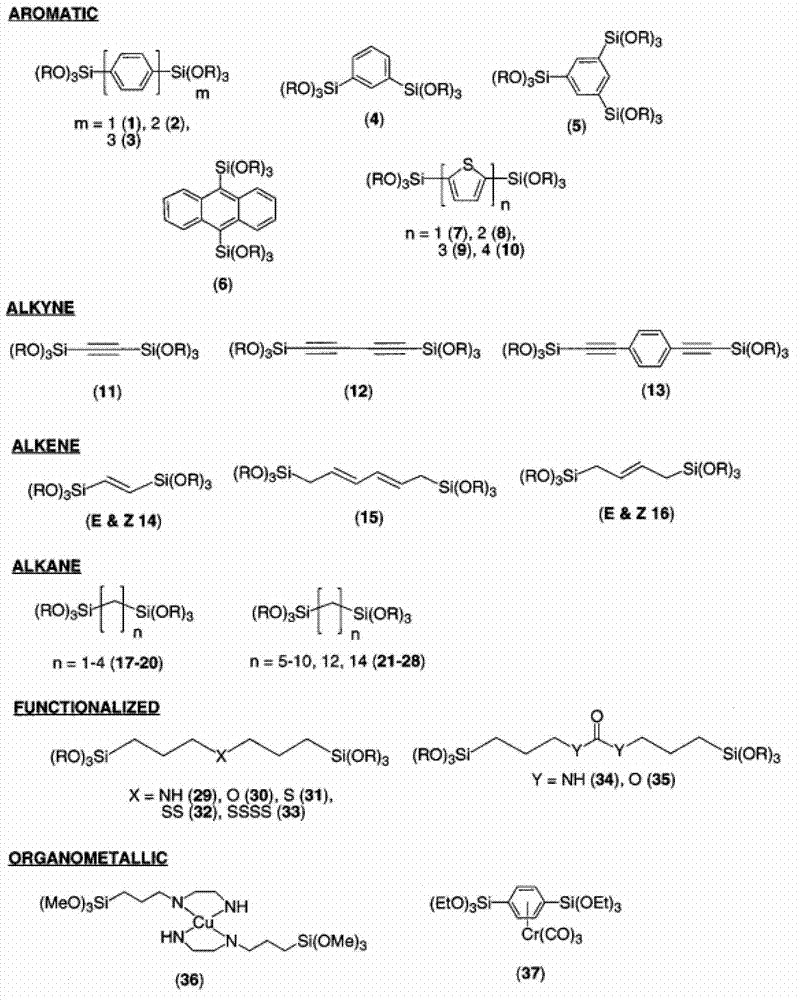

[0038] Get 3.1g of silsesquioxane monomers with thioether as the bridging segment, the structure is as follows figure 1 Equation 31 in

[0039]

[0040] Dissolve it in 30mL of ethanol, add 6mL of concentrated hydrochloric acid, mix well, put it in an oven at 60°C to make it gel. Replace the solvent of the gel with ethanol 10 times within 3 days to remove unreacted small molecules and impurities. At room temperature, immerse the gel in ethanol (it is better if the liquid level is just below the gel), and put it in a vacuum tank In the process, vacuumize the system pressure to 20Pa, and after the solvent is completely volatilized, bridged silsesquioxane airgel can be obtained. its photo as Figure 4 As shown, the density is 0.065g / cm 3 , with a porosity of 97%, tested by nitrogen adsorption (such as Figure 5 Shown) The obtained BET specific surface area is 584m 2 / g.

Embodiment 3

[0041] Embodiment 3, use vacuum drying method to prepare RF airgel

[0042] Take 1.9g of resorcinol (Resorcinol) and 1.0g of formaldehyde (Formaldehyde), dissolve it in 30mL of water, add 12mg of sodium carbonate, and gel at 85°C. Change the water in the gel 10 times within 3 days to remove unreacted small molecules and impurities. At room temperature, immerse the gel in water (it is advisable that the liquid level is just below the gel), put it in a vacuum tank, and pump it. Make the system pressure up to 1Pa under vacuum, and after the solvent is completely volatilized, RF airgel can be obtained. its photo as Figure 6 As shown, the density is 0.10g / cm 3 , with a porosity of 94%, tested by nitrogen adsorption (such as Figure 7 Shown) The obtained BET specific surface area is 536m2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com