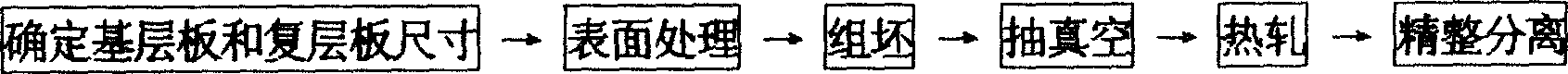

Process for producing brazing hot rolled metal composite plate adopting composite cog

A metal clad plate, metal plate technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of large equipment investment, low bonding strength, scarcity of resources, etc., and achieve huge economic and social benefits, The effect of excellent corrosion resistance and excellent reprocessing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Manufacture three composite blanks with a width of 1400mm×thickness 200mm×length 9000mm. The rolling mills are used to produce hot coiled plates with a thickness of 3mm, 4mm and 5mm and a width of 1500mm carbon steel and stainless steel. The thickness of the clad stainless steel is 0.5mm, 0.8mm, 0.8mm.

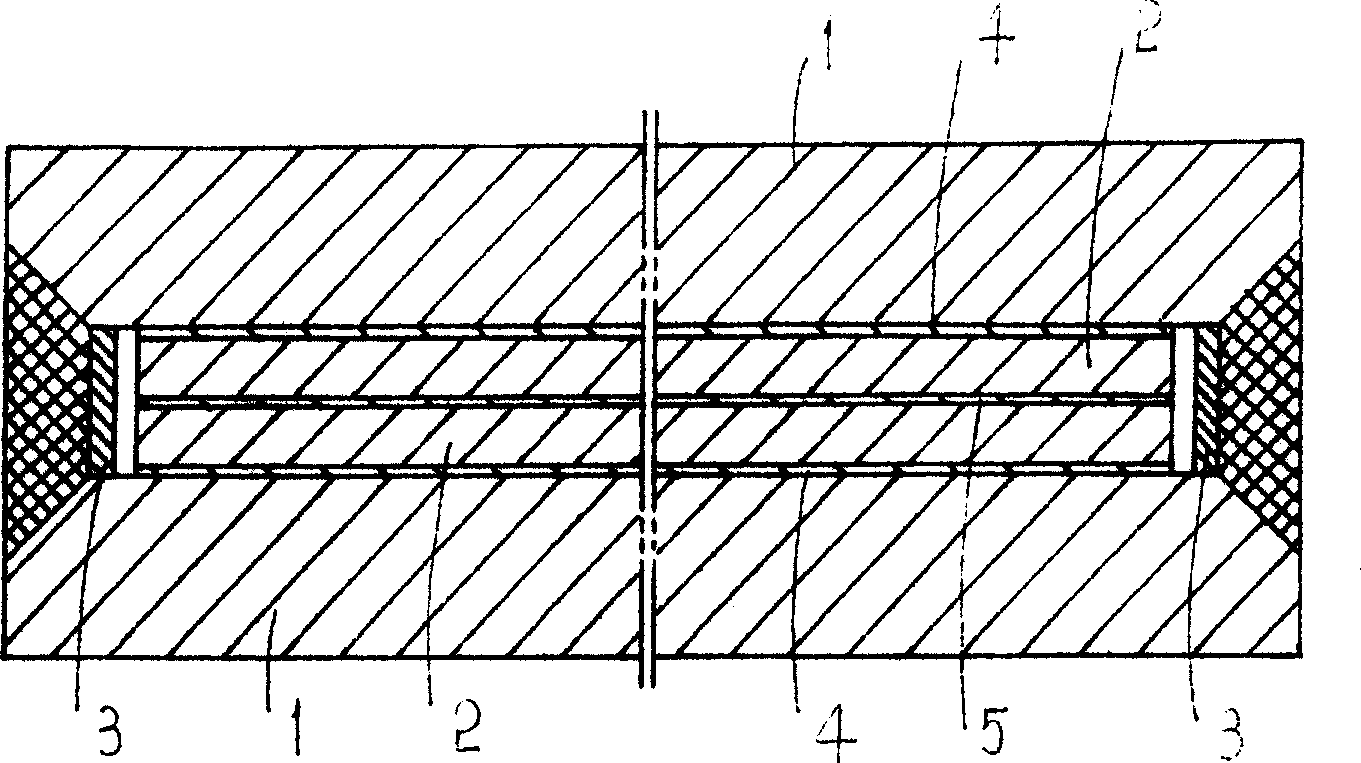

[0027] refer to figure 2 As shown in , first select six base Q235 carbon steel plates and six cladding 304 stainless steel plates to make three composite blanks, and the total thickness of each composite blank is 200mm. Since there are two base boards and two clad boards to form a set respectively, the thickness of each set of boards should be 200 / 2=100mm, where:

[0028] 1.3mm plate, the thickness of stainless steel is 0.5mm, the ratio is 0.5 / 3=1 / 6, the thickness of stainless steel: 100×1 / 6=16.7mm choose 17mm thick stainless steel plate, ordinary carbon steel 83mm.

[0029] 2.4mm plate, stainless steel thickness is 0.8mm, its ratio is 0.8 / 4=1 / 5, stainless steel thic...

Embodiment 2

[0034] Manufacture three composite billets with a width of 1050mm×thickness 150mm×length 2000mm. The medium plate rolling mill is used to produce carbon steel and stainless steel clad plates with a thickness of 6mm, 8mm and 20mm and a width of 2000mm respectively, and the thickness of the clad stainless steel is 1mm.

[0035] refer to figure 2 As shown in , first select six base Q235 carbon steel plates and six cladding 304 stainless steel plates to make three composite billets, each with a total thickness of 150mm. Since there are two base boards and two clad boards to form a set respectively, the thickness of each set of boards should be 150 / 2=75mm, where:

[0036] 1.6mm plate, the thickness of stainless steel is 1mm, its ratio is 1 / 6, the thickness of stainless steel: 75×1 / 6=12.5mm choose 13mm thick stainless steel plate, ordinary carbon steel 62mm.

[0037] 2.8mm plate, stainless steel thickness is 1mm, its ratio is 1 / 8, stainless steel thickness: 75×1 / 8=9.4mm choose 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com