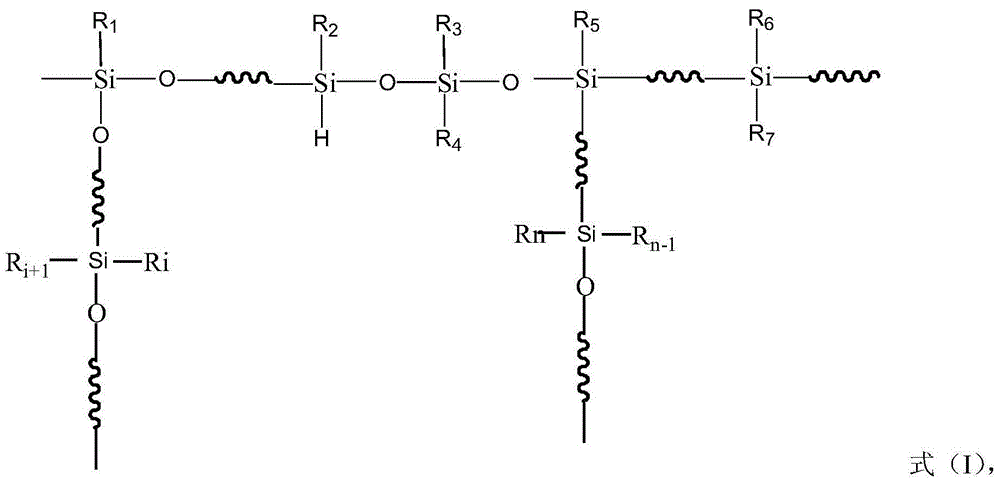

Organic silicon solventless impregnating resin and synthesizing method thereof

A technology of impregnating resin and synthesis method, which is applied in the field of silicone resin and its synthesis, which can solve the problems of large shrinkage, low mechanical strength, and easy cracking of cured products, and achieve reduced shrinkage, simple preparation method, and reduced cracking probability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

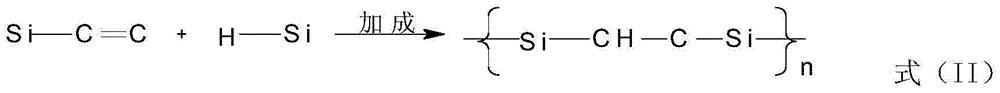

Method used

Image

Examples

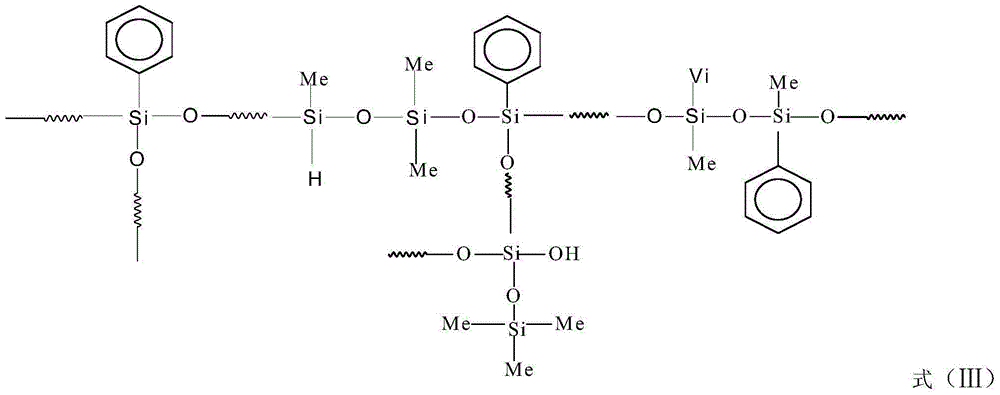

Embodiment 1

[0023] Take 0.6mol a phenyl trichlorosilane, 0.4mol methyl vinyl dichlorosilane, 0.2mol dimethyl dichlorosilane, 0.2mol methylphenyl dichlorosilane, 0.5mol methyl hydrogen dichlorosilane and 0.4mol Trimethylchlorosilane, slowly add the organosilicon monomer dropwise to a flask with rapid stirring at 15°C, drop the hydrolysis reaction for 4 hours, then concentrate, separate the resin layer, and reflux aging at 80°C React for 4 hours, then wash with water until neutral to obtain a hydrolyzed prepolymer, vacuumize the upper resin layer to remove solvent and remove low boilers, then add 0.06g isopropanol-coordinated platinum catalyst and 0.12g vinyl ring Hexyl alcohol, stirred evenly, promptly discharged to obtain the product, the schematic structural formula of the obtained product is as follows structure (Ⅲ).

[0024]

Embodiment 2

[0026] Take 0.5mol phenyltrimethoxysilane, 0.2mol methyltrichlorosilane, 0.2mol methylvinyldichlorosilane, 0.1mol dimethyldiethoxysilane, 0.2mol diphenyldimethoxysilane solid, 0.3mol methylhydrogendiethoxysilane, 0.5mol dimethylvinylmethoxysilane and 0.1mol trimethylchlorosilane, slowly add the organosilicon monomer dropwise at a temperature of 50°C with rapid stirring In the flask, add dropwise hydrolysis reaction for 3 hours, then concentrate, separate the resin layer, reflux aging reaction at 100°C for 4 hours, then wash with water until neutral to obtain a hydrolyzed prepolymer, and carry out the upper resin layer Vacuumize the solvent and remove the low boilers, then add 0.08g of platinum catalyst coordinated by vinyl double head and 0.22g of NN-dimethylacetamide, stir evenly, and then discharge the product to obtain the product. The schematic structural formula of the obtained product is as follows: (Ⅳ).

[0027]

Embodiment 3

[0029] Take 0.4mol phenyltrimethoxysilane, 0.4mol methylvinyldichlorosilane, 0.2mol dimethyldiethoxysilane, 0.1mol methylphenyldichlorosilane monomer, 0.6mol methylhydrogen dichlorosilane Chlorosilane and 0.3mol dimethylvinylmethoxysilane, slowly add the organosilicon monomer dropwise to a flask with rapid stirring at 20°C, drop the hydrolysis reaction for 5 hours, then concentrate, and the resin layer Separated, reflux aging reaction at 120°C for 4 hours, then washed with water until neutral to obtain a hydrolyzed prepolymer, vacuumed the upper resin layer to remove solvent and low boilers, and then added 0.03g of vinyl cyclotetrasilicon The oxane-coordinated platinum catalyst and 0.08 g of triphenylphosphine were stirred evenly, and the product was discharged to obtain the product. The schematic structural formula of the obtained product was as follows structure (Ⅴ).

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com