Acrylate pressure sensitive adhesive emulsion of PET substrate for battery packaging, preparation method and application thereof

A pressure-sensitive adhesive emulsion, acrylate technology, applied in pressure-sensitive films/sheets, adhesives, ester copolymer adhesives, etc., can solve problems such as affecting the health of operators, polluting the environment, warping and cracking of PET substrates, etc. , to reduce the probability of warping and cracking, good mechanical properties, and ensure the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

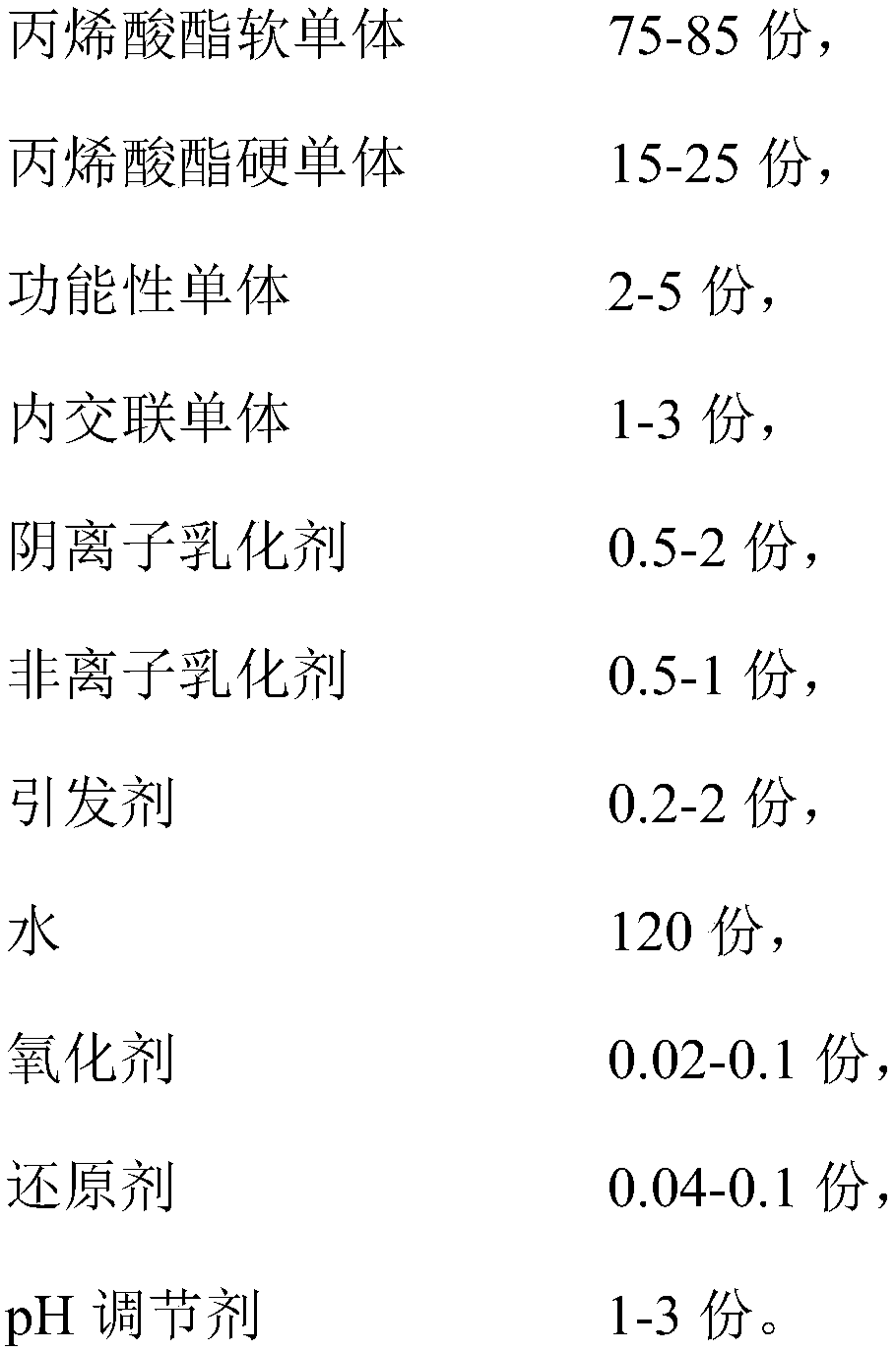

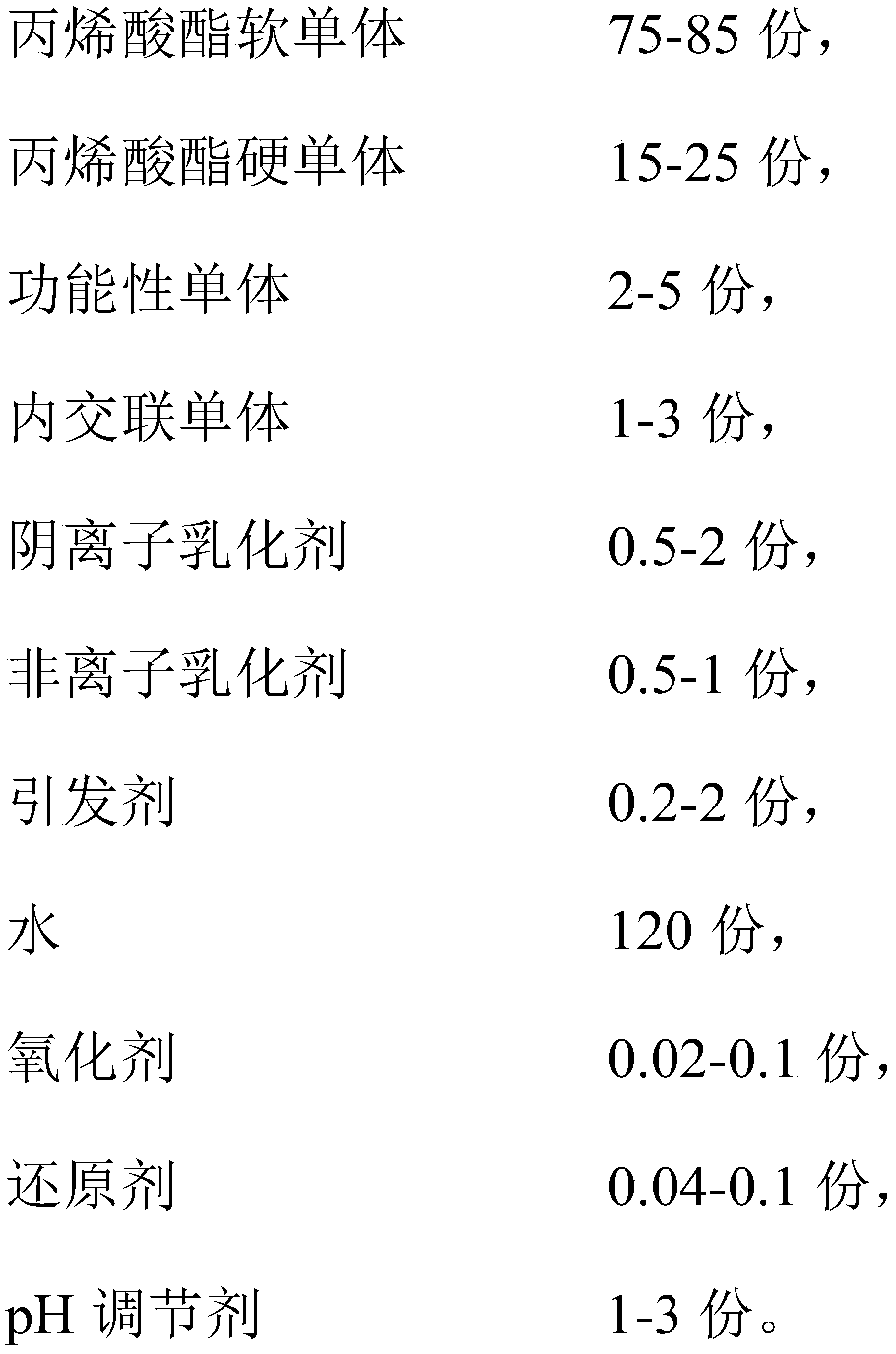

Method used

Image

Examples

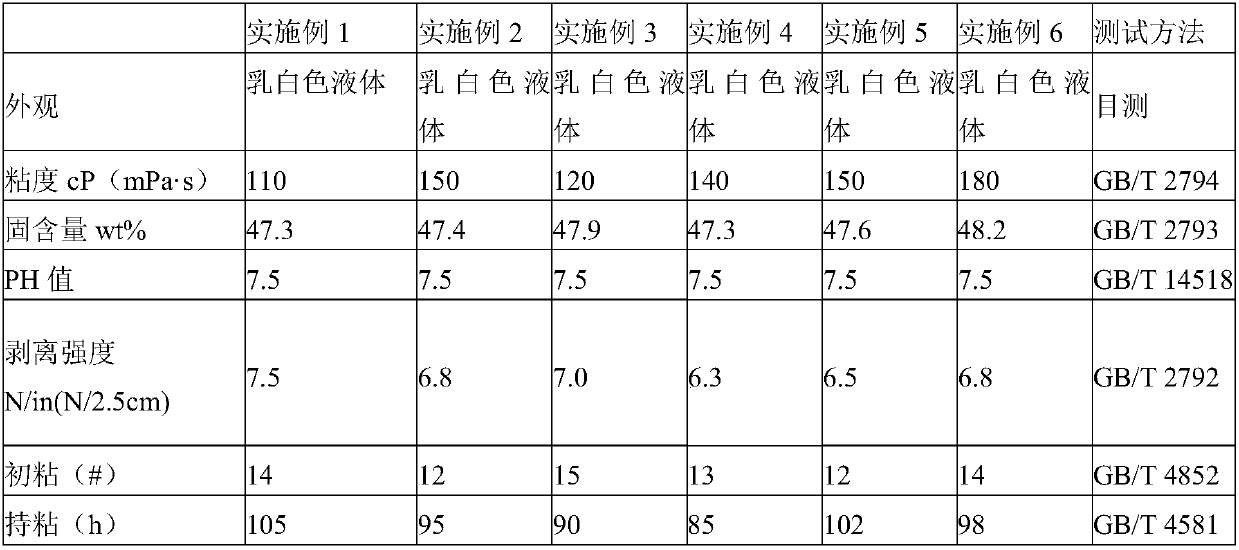

Embodiment 1

[0045] A PET substrate acrylic pressure-sensitive adhesive emulsion for battery packaging. Its preparation method includes the following steps:

[0046] (1) Weigh 0.75g anionic emulsifier sodium dodecyl benzene sulfonate, 0.6g nonionic emulsifier polyoxyethylene ether sorbitol hexastearate, 0.1g buffer ammonium bicarbonate, 40g deionized water, Stir at room temperature to obtain the emulsifier aqueous solution; slowly add a mixed monomer consisting of 75g butyl acrylate, 24g methyl acrylate, 3.0g hydroxyethyl acrylate, 2.0g acrylic acid, 2.0g N-methylolacrylamide, and stir for 30min at a stirring speed of 600r / min, the pre-emulsion is prepared.

[0047] (2) Weigh 0.42 g of ammonium persulfate and add 10 g of deionized water to dissolve to prepare an aqueous initiator solution.

[0048] (3) Heat 60 g of deionized water to 80° C., add 7.37 g of pre-emulsion and keep it for 2 minutes, then add 5.21 g of the initiator aqueous solution, and keep it for 20 minutes to prepare a seed emuls...

Embodiment 2

[0054] A PET substrate acrylic pressure-sensitive adhesive emulsion for battery packaging. Its preparation method includes the following steps:

[0055] (1) Weigh 0.9g anionic emulsifier sodium dodecylbenzene sulfonate, 0.5g nonionic emulsifier polyoxyethylene ether sorbitol hexastearate, 0.3g buffer ammonium bicarbonate, 40g deionized water, Stir at room temperature to obtain the emulsifier aqueous solution; slowly add a mixed monomer consisting of 80g butyl acrylate, 20g methyl acrylate, 2.0g hydroxyethyl acrylate, 2.0g acrylic acid, 2.0g N-methylolacrylamide, and stir for 30min at a stirring speed of 600r / min, the pre-emulsion is prepared.

[0056] (2) Weigh 0.2 g of ammonium persulfate and add 10 g of deionized water to dissolve to prepare an aqueous initiator solution.

[0057] (3) Heat 60 g of deionized water to 80° C., add 7.38 g of pre-emulsion and keep it for 2 minutes, and then see 5.1 g of the initiator aqueous solution and keep it for 20 minutes to prepare a seed emulsi...

Embodiment 3

[0063] A PET substrate acrylic pressure-sensitive adhesive emulsion for battery packaging. The preparation method thereof includes the following steps:

[0064] (1) Weigh 1.0g anionic emulsifier sodium dodecylbenzene sulfonate, 0.8g nonionic emulsifier polyoxyethylene ether sorbitol hexastearate, 0.15g buffer ammonium bicarbonate, 40g deionized water, Stir at room temperature to obtain an emulsifier aqueous solution; slowly add a mixed monomer consisting of 80g isooctyl acrylate, 25g methyl methacrylate, 1.0g hydroxyethyl methacrylate, 1.0g methacrylic acid, and 1.5g N-methylol acrylamide , Stir for 30min, stirring speed 600r / min, to prepare pre-emulsion.

[0065] (2) Weigh 0.8 g of ammonium persulfate and add 10 g of deionized water to dissolve to obtain an aqueous initiator solution.

[0066] (3) Heat 60 g of deionized water to 80° C., add 7.5 g of pre-emulsion and keep it for 2 min. Bye, for example, 5.4 g of the initiator aqueous solution, keep it for 20 min to prepare a seed em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com