Prefabricated combined corrugated steel web T girder bridge

A corrugated steel web, combined technology, used in bridges, bridge parts, bridge materials, etc., can solve the cracking of the interface between the post-cast concrete and the precast part, the stress of the bridge structure during the use stage of the completed bridge, and the different shrinkage of concrete. Changes and other problems, to achieve the effect of good structural integrity, improved construction efficiency and service life, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

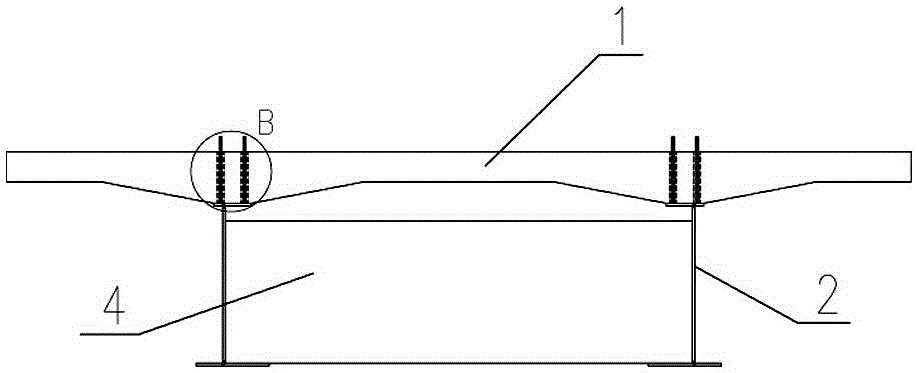

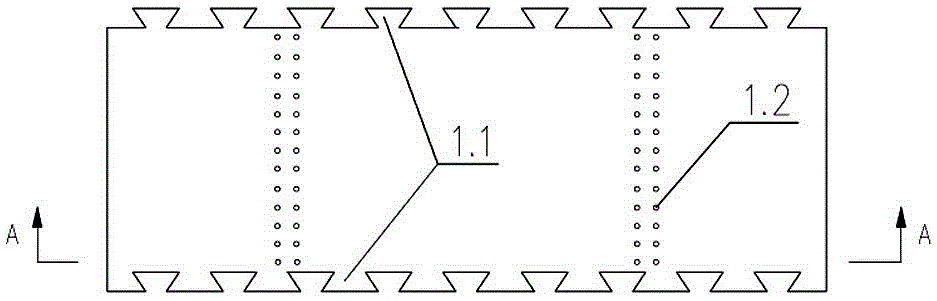

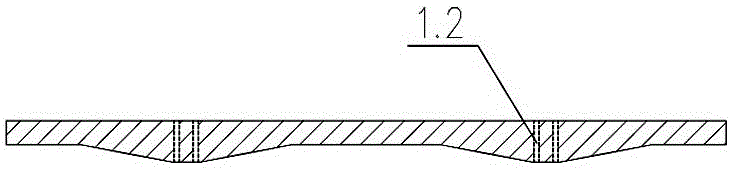

[0037] Such as figure 1 As shown, the prefabricated combined corrugated steel web T-girder bridge of the present invention includes a reinforced concrete roof 1 and a longitudinal beam 2 arranged below the reinforced concrete roof 1, and the reinforced concrete roof 1 is composed of multiple pieces with the same width as the bridge deck. The strip plates are spliced together, and the splicing surfaces of two adjacent strip plates are provided with mutually matching assembly grooves 1.1, and the strip plates are provided with insertion holes 1.2 corresponding to the positions of the longitudinal beams 2; the longitudinal beams 2 It is a group of corrugated steel webs 2.3 welded with a top edge steel plate 2.1 and a bottom edge steel plate 2.2. The top edge steel plate 2.1 is welded with a connecting nail 2.4, and the connecting nail 2.4 passes through the insertion hole 1.2 and passes through the pouring concrete 3 and the bar The shaped plates are fixed as a whole; the corru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com