Method for producing composite diamond saw blade substrate

A technology of diamond saw blade and manufacturing method, which is applied in the direction of cutting tool manufacturing, manufacturing tools, metal sawing equipment, etc. of sawing machine devices, and can solve the problem of uneven hardness, inconsistent microstructure and grain size in spot welding areas, and affecting saw blades. Problems such as working status and life expectancy, to achieve the effect of reducing the probability of cracks, uniform internal stress, and improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

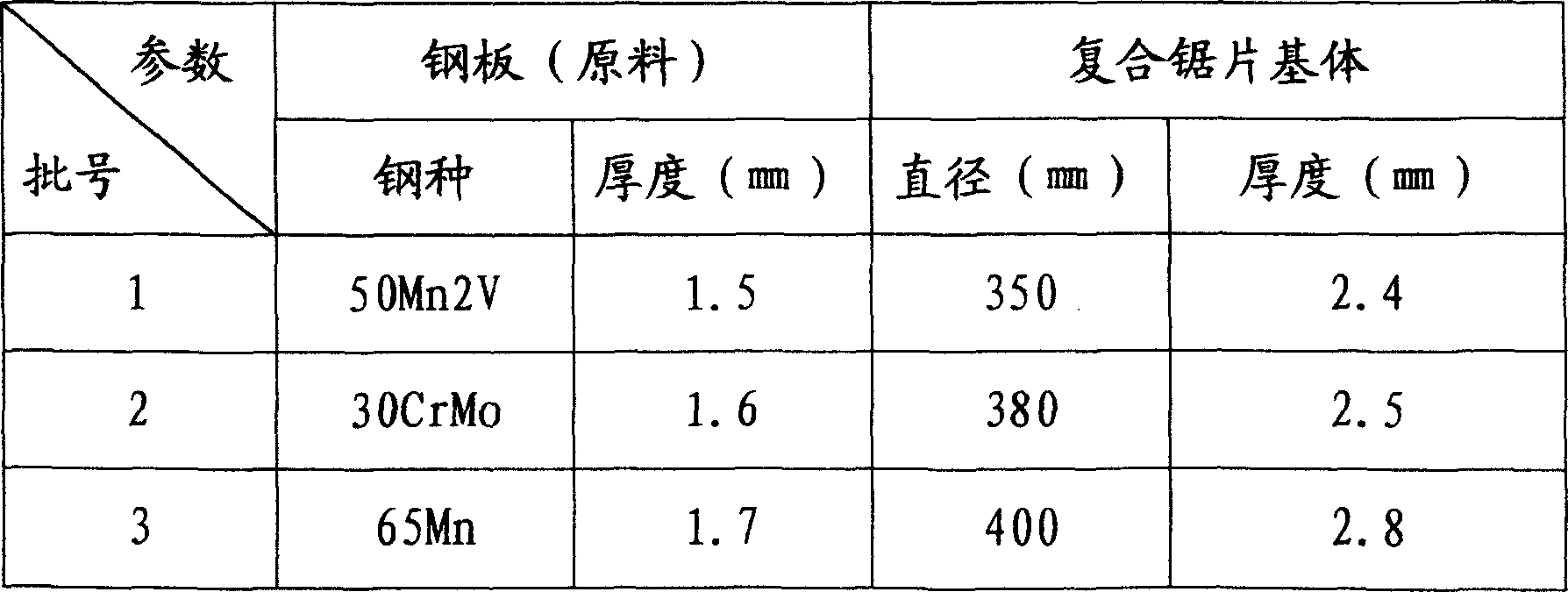

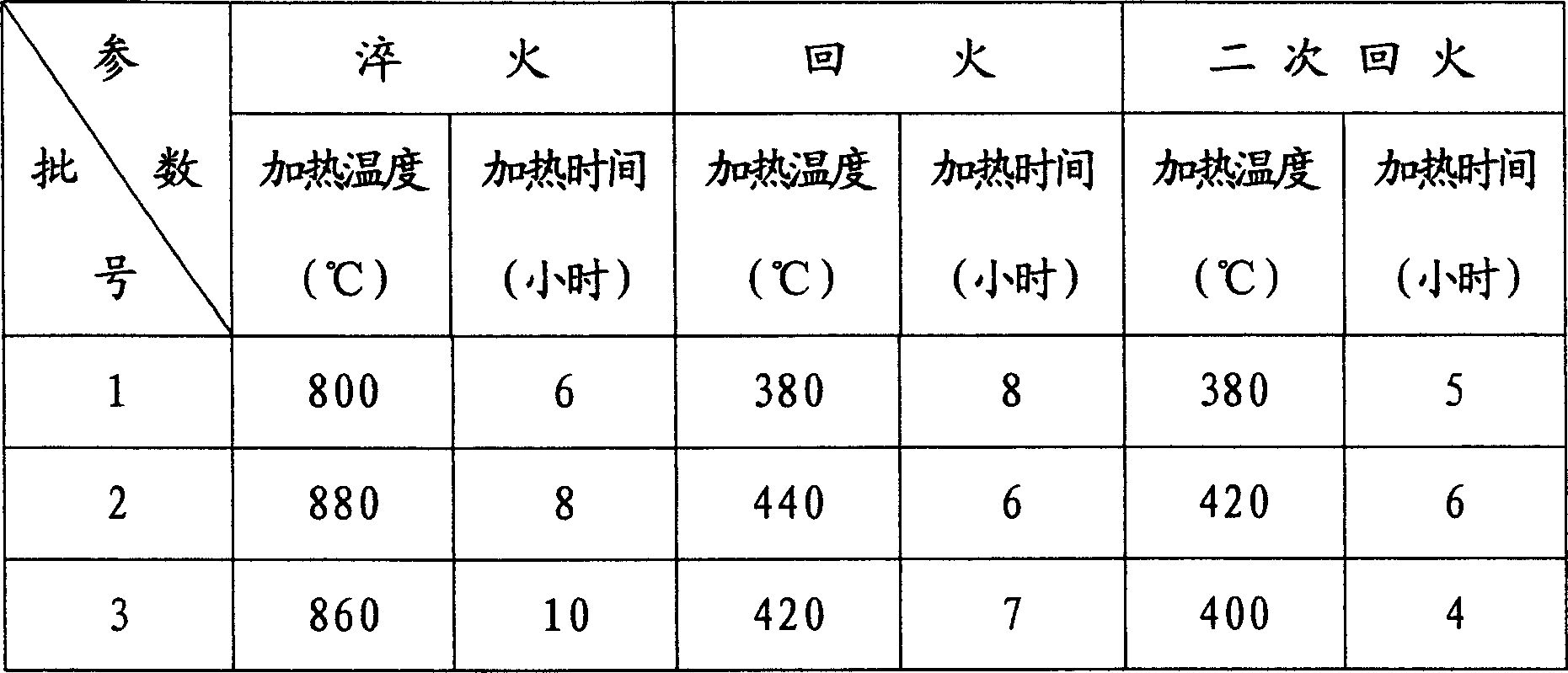

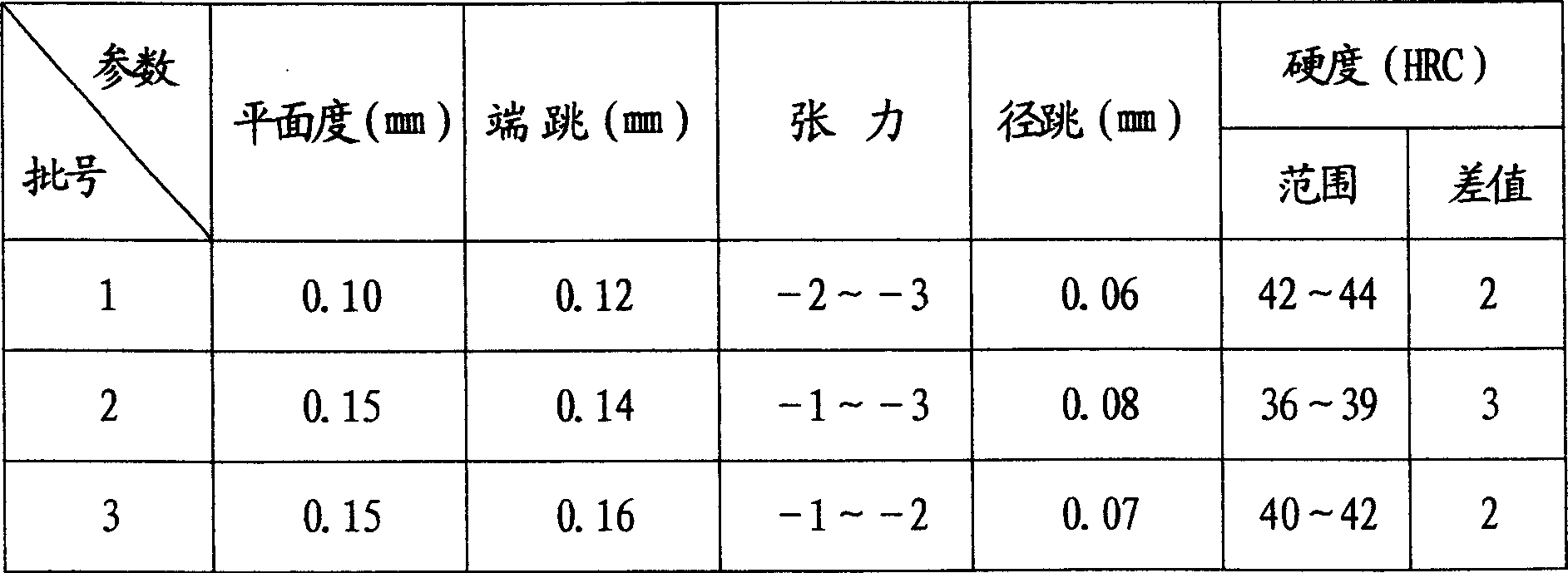

[0036] According to the manufacturing method described in the present invention, 3 batches of composite diamond saw blade substrates were trial-produced. The grades and specifications of the steel plates used in the substrate, and the size requirements of the substrate are shown in Table 1. Then carry out the configuration of the single saw blade base, according to the size specifications of the three batches of saw blade bases, blanking, punching, rounding and punching are carried out, and the two sides are coarsely ground, and then the saw blade base is combined. The damping material is clamped between the grinding surfaces of the equipped saw blade base. After clamping, the combined saw blade base is spot-welded for two circles along the circumferential direction, with several welding points per circle, and it becomes a composite diamond saw blade base. billet. Afterwards, quenching and tempering treatment is carried out. The quenching and tempering parameters are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com