Synthetic process method of methyl acetate and apparatus thereof

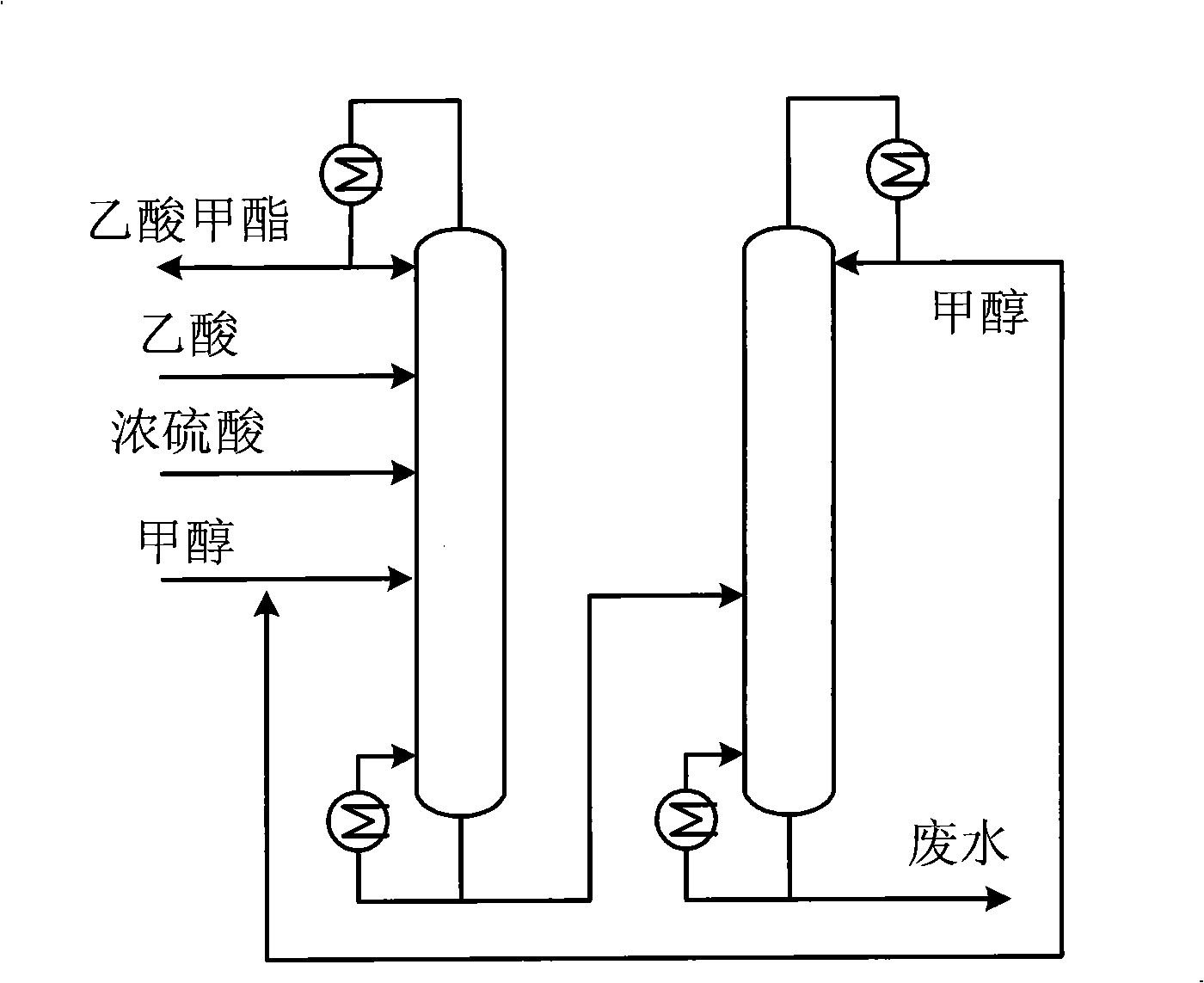

A technology of methyl acetate and synthesis device, which is applied in the preparation of carboxylate, chemical instruments and methods, chemical industry, etc., can solve problems such as unfavorable economic benefits, remixing, low thermodynamic efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

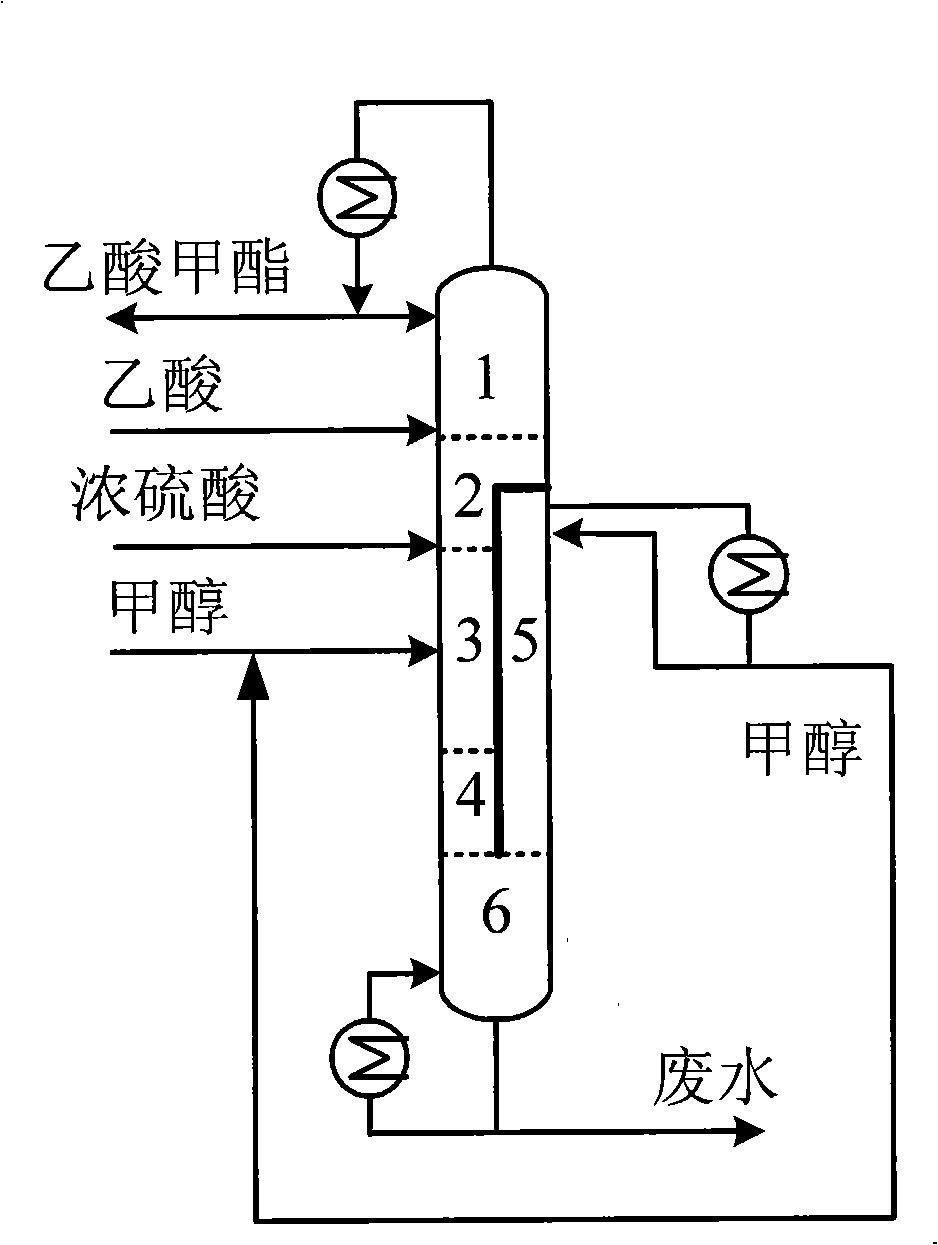

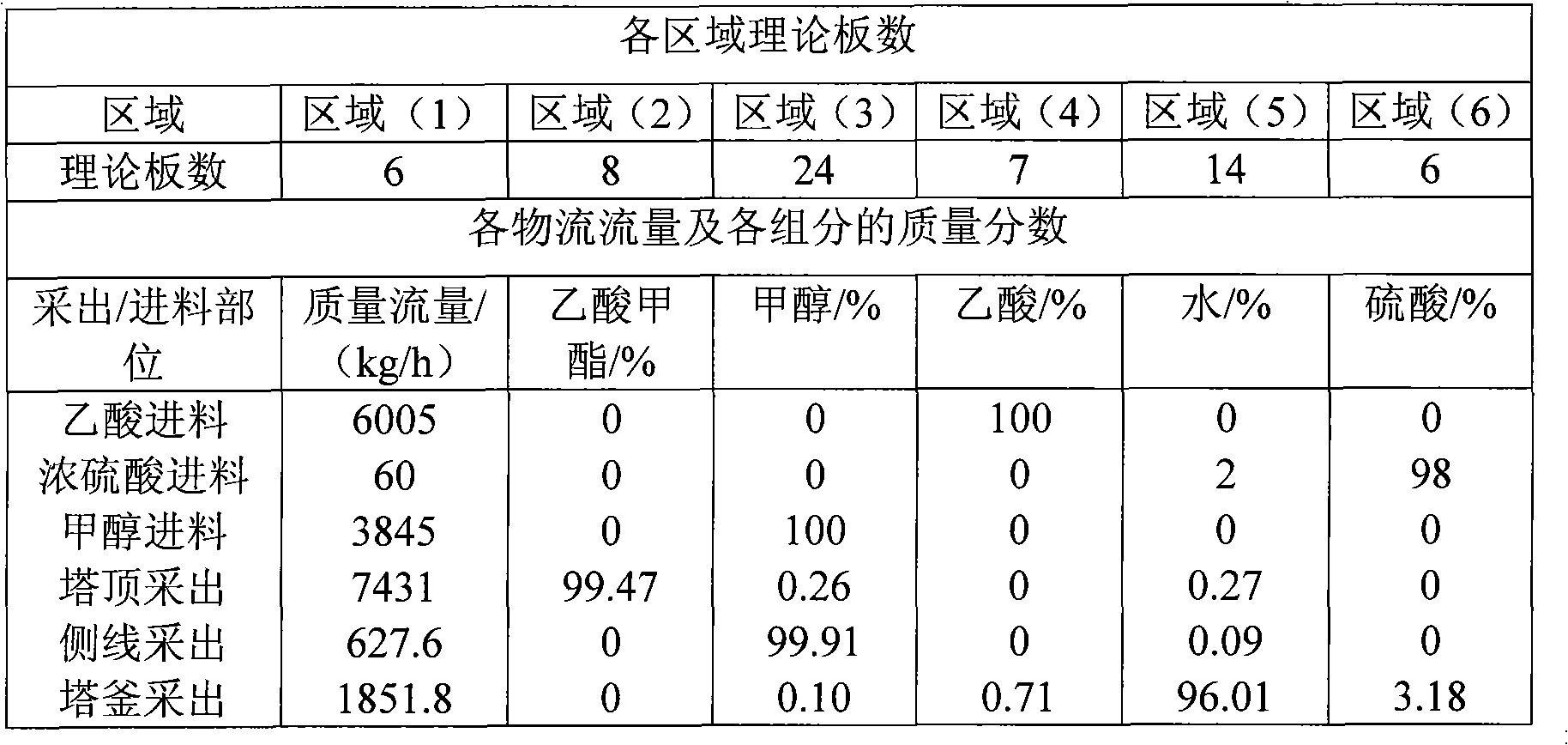

[0020] Example 1: if figure 2 process shown. The number of theoretical plates, feed flow and composition of each area are shown in Table 1. The cross-sectional area ratio of the stripping section (4) and the side rectification section (5) is 3.4:1, and the molar ratio of methanol feed to acetic acid feed is The feed mass ratio of concentrated sulfuric acid and acetic acid is 1:100, and the feed positions of acetic acid, concentrated sulfuric acid and methanol (counting from top to bottom) are the seventh theoretical board on the left and the fifteenth on the left The theoretical plate and the 36th theoretical plate on the left are both fed at 30°C. The reflux ratio at the top of the tower is 1.16, and the reflux ratio at the side line is 1.42. The flow rate and composition of each stream are shown in Table 1. The resulting acetic acid conversion was 99.78%. The number of theoretical plates in the rectification section (1) and the side line rectification section (5) includes...

example 2

[0023] Example 2: if figure 2process shown. Feed composition, feed heat state, feed position and the number of theoretical plates in each area are the same as example 1, but methanol feed and acetic acid feed molar ratio become 1.4: 1, stripping section (4) and side line rectifying section ( 5) The cross-sectional area ratio is 2.1:1. The top reflux ratio is 1.19, and the side reflux ratio is 1.67. The flow rate and composition of each stream are shown in Table 2. The resulting acetic acid conversion was 99.75%.

[0024] Table 2 Example 2 Each logistics mass flow rate and each component mass fraction

[0025] Extraction / feeding department

example 3

[0026] Example 3: if figure 2 process shown. Except that the methanol feed is a mixture containing a small amount of impurity water with a methanol mass fraction of 98%, the composition of the feed, the thermal state of the feed, the position of the feed and the number of theoretical plates in each area are the same as in Example 1, and the stripping section (4) and the side line The cross-sectional area ratio of the rectifying section (5) is 3.6:1. The top reflux ratio is 1.14, and the side reflux ratio is 1.52. The flow rate and composition of each stream are shown in Table 3. The resulting acetic acid conversion was 99.78%.

[0027] Table 3 Example 3 Each logistics mass flow rate and each component mass fraction

[0028] Extraction / feeding department

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com