Process for industrially producing carbon, gas, oil and electricity through biomass energy forming and destructive distillation

A technology for pyrolysis, dry distillation and biomass energy, applied in the field of biomass energy development, can solve the problems of short life of molding machine parts, waste of energy, accelerated wear speed, etc., so as to reduce the probability of cracking, reduce production costs, and ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

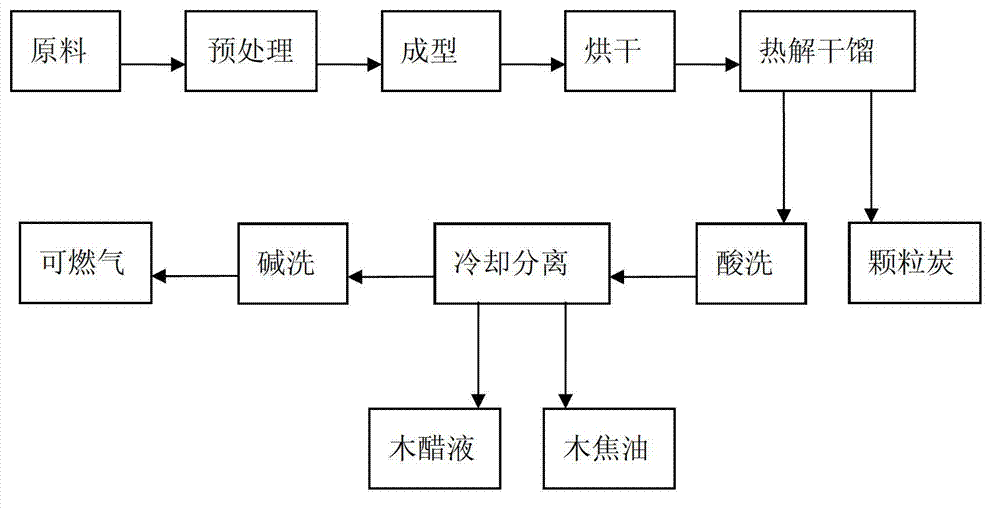

[0045] Such as figure 1 As shown, the method of the present invention is as follows: (1) raw material pretreatment-the raw material is pulverized;

[0046] (2) Forming - pressing the pretreated raw materials into shaped particles of a certain shape;

[0047] (3) Drying - control the moisture content in the shaped granules to the required range;

[0048] (4) Pyrolysis and dry distillation - under the condition of isolation or a small amount of air, the dried shaped particles are converted into granular carbon, gas and liquid through thermochemical conversion;

[0049] (5) Acid washing - acid washing of the gas generated by pyrolysis and dry distillation;

[0050] (6) Cooling and separation - cooling the gas after pickling, and separating the cooled liquid from wood tar and wood vinegar after the gas and liquid are separated;

[0051] (7) Alkaline washing - Alkaline washing is performed on the gas after cooling and separation.

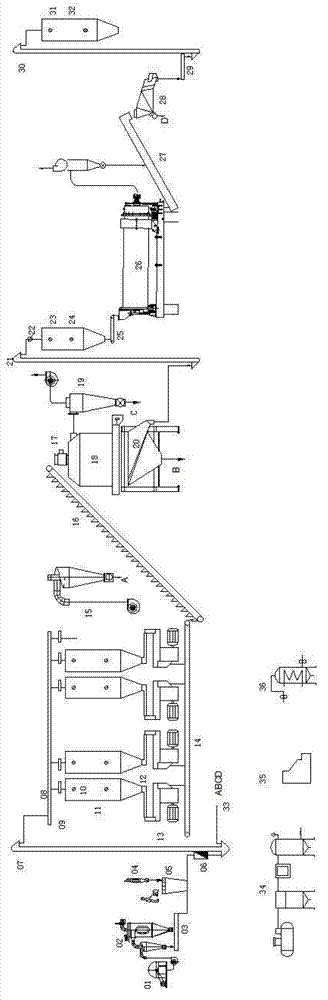

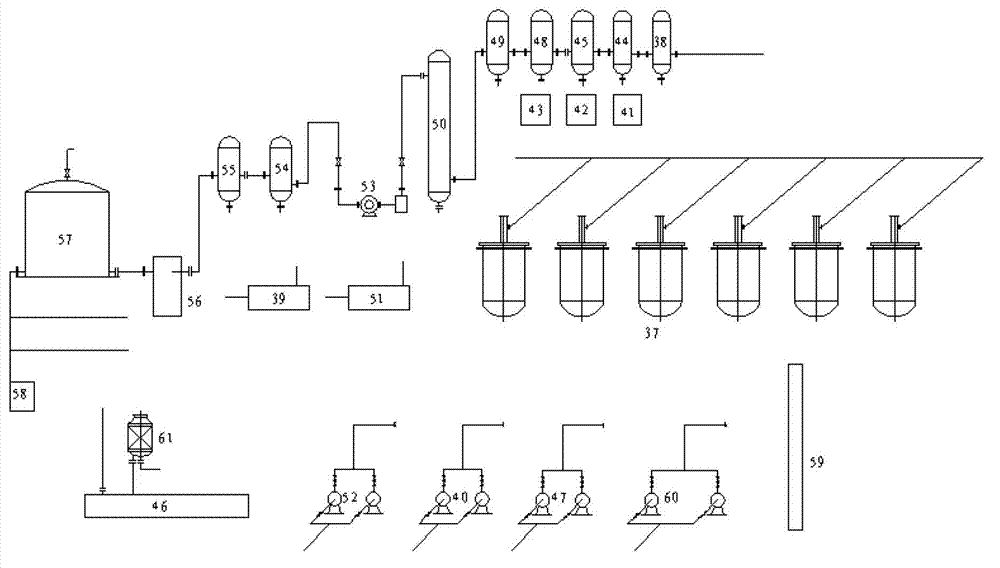

[0052] Biomass molding process flow of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com