Water-based heat-resistant polyurethane resin and preparation method of same

A technology of polyurethane resin and water-soluble polyurethane, which is applied in the field of water-based heat-resistant polyurethane resin and its preparation, can solve the problems of loss of protection performance, poor heat resistance and water resistance of coating film, poor water resistance, etc., achieve excellent water dispersion performance, improve Excellent effect of heat resistance grade and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2)

[0028] The water-soluble polyurethane prepolymer of the present invention is composed of 5-20wt% hydrophilic hydroxyl-containing monomer, 20-40wt% polyisocyanate, 5-20wt% glycol and 30-60wt% hydrophilic solvent. 50 ~ 100 ℃, formed by polyaddition reaction, the sum of the weight percentages of the above components is 100%;

Embodiment 1

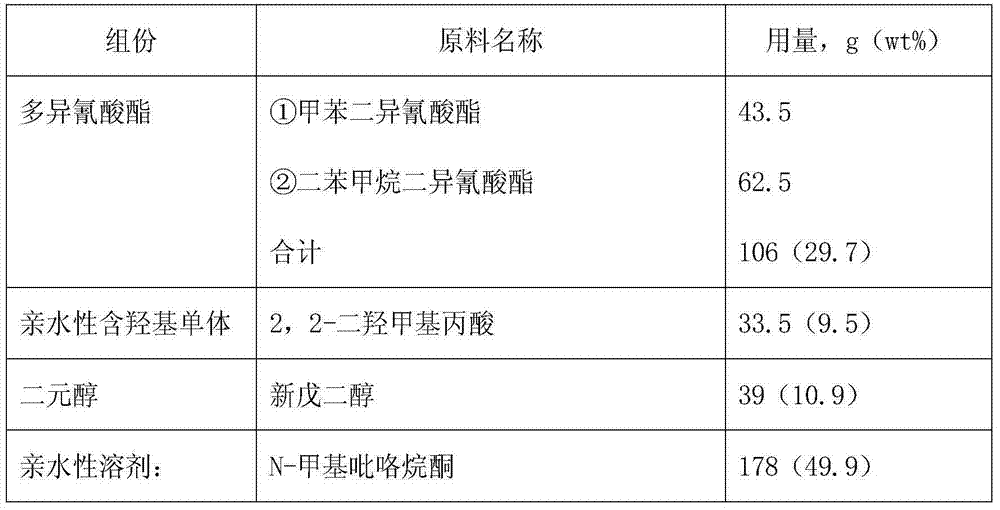

[0030] ① Prepare the raw materials according to the ratio in Table 1

[0031] Table 1

[0032]

[0033] ②Preparation process

[0034]Add the above-mentioned raw materials into the reaction container, stir and slowly raise the temperature to 90°C, keep the temperature for 3 hours, test the residual NCO content until the residual NCO content is ≤0.1wt%, and cool down to room temperature to obtain a water-soluble polyurethane prepolymer. The number-average molecular weight ranges from 1000 to 8000g / mol, and both ends of the linear molecular chain are hydroxyl groups, which are preserved for future use.

Embodiment 2

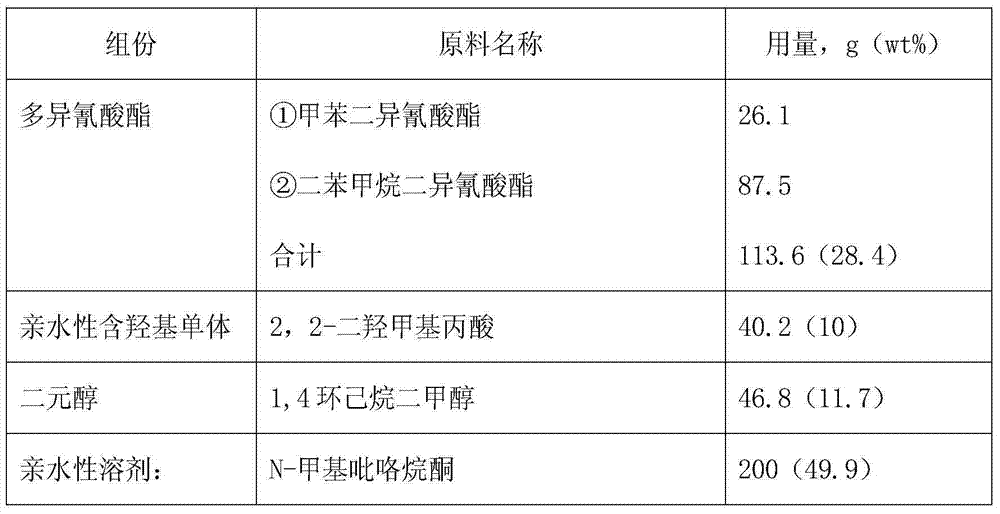

[0036] ① Prepare the raw materials according to the ratio in Table 2.

[0037] Table 2

[0038]

[0039] ②Preparation process

[0040] Add the above-mentioned raw materials into the reaction container, stir and slowly raise the temperature to 90°C, keep the temperature for 3 hours, test the residual NCO content until the residual NCO content is ≤0.1wt%, and cool down to room temperature to obtain a water-soluble polyurethane prepolymer. The number-average molecular weight ranges from 1000 to 8000g / mol, and both ends of the linear molecular chain are hydroxyl groups, which are preserved for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com