Acrylic acid-epoxy resin modified aqueous polyurethane preparation method

A technology of water-based polyurethane and epoxy resin, which is applied in the field of acrylic/epoxy resin modified water-based polyurethane, can solve the problems of limiting the promotion and application of water-based polyurethane, poor weather resistance, heat resistance, and low bonding strength, and achieves Effects of protecting physical and mental health, high weather resistance, and excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

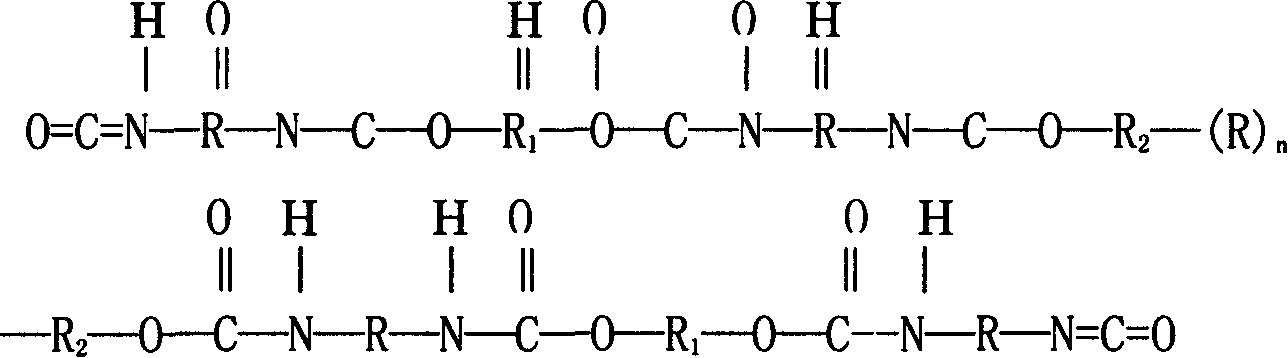

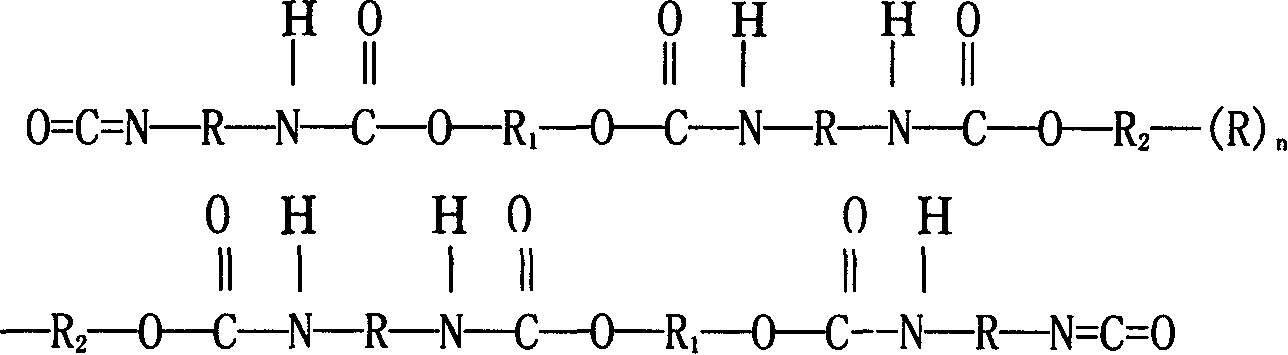

[0043] Example 1: 35 kilograms of polyether polyols were added to the reactor, heated to 60 ° C, under the condition of vacuum degree of 0.09 Mpa, dehydration treatment was performed for 0.6 hours, 23 kg of TDI was added, and the reaction was carried out at 90 ° C for 2-3 hours (NCO% was 10.6 %), add 3.5 kilograms of dimethylol propionic acid, cool to 85 ℃ and react for 1-2 hours (NCO% is 5.3%), add 3.8 kilograms of 1,4-butanediol, 8 kilograms of acrylic acid modified epoxy resins, 20 kilograms of butyl acrylate and 32 kilograms of acetone were mixed with a dispersion solution, and reacted for 2-4 hours (NCO% was 0.86%) at 65° C. to obtain a modified polyurethane resin, whose structural formula was I. Add the modified polyurethane resin to the mixing tank, control the speed at 900 rpm, add 4.1 kg of triethylamine, 200 kg of distilled water, 3 kg of isophorone diamine, and 2.9 kg of sodium persulfate at a room temperature of 3°C to initiate polymerization React for 0.5-1.5 hour...

Embodiment 2

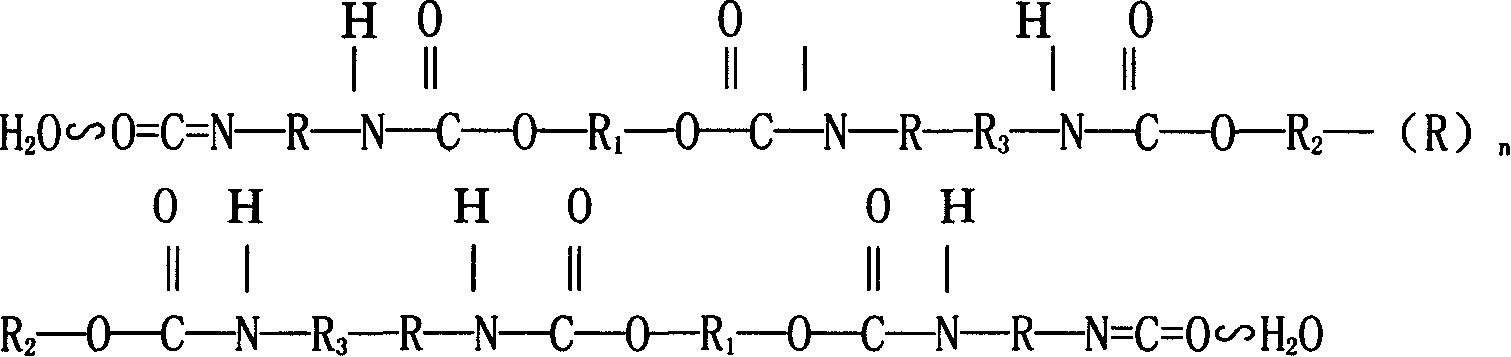

[0049] Example 2: Add 60 kg of polyester polyol to the reactor, heat up to 68°C, dehydrate for 1 hour under the condition of vacuum degree of 0.09Mpa, add 32 kg of TDI, and react for 2-3 hours at 85°C (NCO% is 9.8%) ), add 6.5 kg of dimethylol propionic acid, react for 1-2 hours (NCO% is 4.9%) at 75°C, add 8 kg of ethylene glycol, 15 kg of acrylic modified epoxy resin, and 35 kg of acrylic acid monomer , 42 kilograms of acetone mixed dispersion, reacted 2-4 hours (NCO% is 0.91%) under the condition of 65 ℃ to obtain the modified polyurethane resin, the modified polyurethane resin was added to the mixing tank, 900 rev / min of rotating speed, room temperature Stir and disperse at 15°C, add 9 kg of triethylamine, 289 kg of distilled water, add 2 kg of isophorone diamine, 1.5 kg of potassium persulfate, stir and disperse to initiate polymerization for 0.5-1.5 hours to obtain modified polyurethane Aqueous dispersion, the modified polyurethane aqueous dispersion is added to the preci...

Embodiment 3

[0051] Embodiment 3: 80 kilograms of polycaprolactone polyols are put into reactor, 75 ℃, after dehydration treatment under 0.09Mpa condition for 40 minutes, add MDI36 kilograms, react 2-3 hours under 78 ℃ of conditions (NCO% is 11.3%), Add 7.8 kg of dimethylol propionic acid and 6.4 kg of 1,4-butanediol, react for 1-2 hours at 82°C (NCO% is 4.65%), then add 16 kg of acrylic acid modified epoxy resin, butyl acrylate A dispersion of 30 kg of a blend of ester and acrylic acid and 50 kg of acetone is reacted at 76°C for 2-4 hours (NCO% is 0.68%) to obtain a modified polyurethane resin. Add the modified polyurethane resin into the mixing tank with a rotation speed of 1200 rpm and a room temperature of 20°C. Stir and disperse into 6.8 kg of triethylamine, 264 kg of distilled water, 1.6 kg of diethylenetriamine, and 1.5 kg of sodium persulfate, and continue Dispersion initiates polymerization for 0.5-1.5 hours to obtain a modified polyurethane aqueous dispersion. The modified polyu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com