Natural silane cross-linking LSOH (Low Smoke Zero Halogen) flame-retardant polyolefin cable material and preparation method thereof

A polyolefin cable material, natural cross-linking technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of non-cross-linking or pre-cross-linking, side reactions, high requirements for extrusion equipment and extrusion process, etc. Avoid side reactions, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

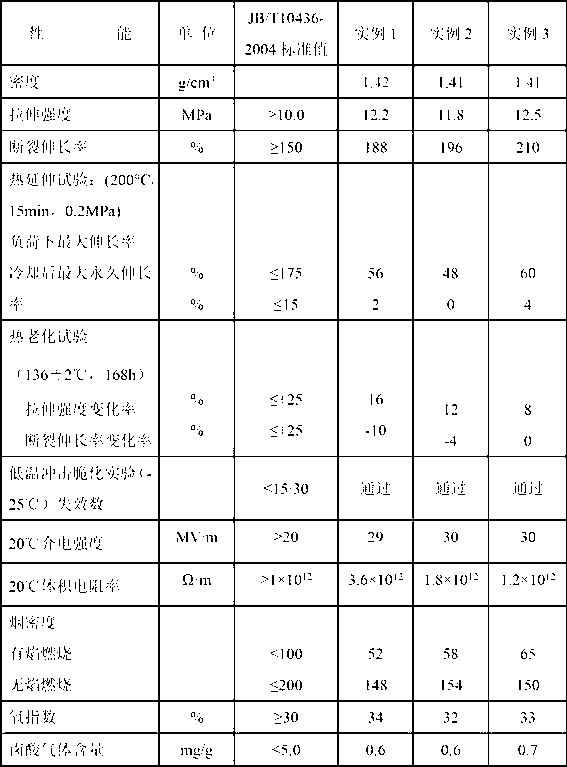

Examples

Embodiment 1

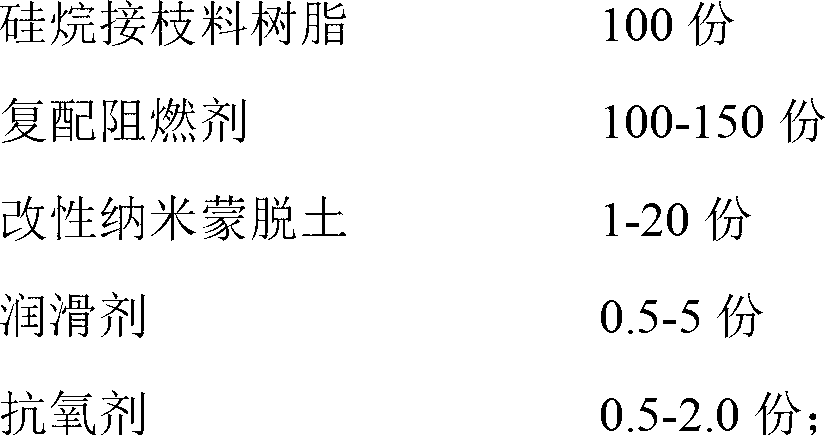

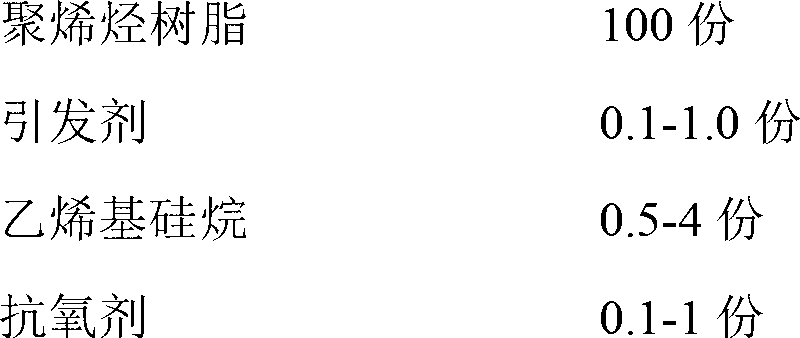

[0048] Silane graft resin:

[0049] 25 parts of polyethylene (Jinshan Petrochemical DJ210), 30 parts of ethylene-vinyl acetate copolymer (DuPont 265) with a vinyl acetate content of 28%, 45 parts of ethylene octene copolymer elastomer (Dow 8200), vinyl 2.5 parts of trimethoxysilane, 0.2 part of di-tert-butyl peroxide, 0.1 part of antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, through twin-screw The extruder reacts, extrudes and granulates, and after cooling, it is dried to obtain the silane graft resin;

[0050] The compound flame retardant consists of:

[0051] Aluminum hydroxide 100 parts

[0052] 30 parts of magnesium hydroxide

[0053] Zinc borate 20 parts

[0054] Silane graft material flame retardant blend material A: 100 parts of silane graft material resin prepared above, 140 parts of compound flame retardant, 5 parts of modified nano-montmorillonite (Cloisite15A), 3 parts of PE wax, silicon 2 parts of ketone masterb...

Embodiment 2

[0059] Silane grafting material resin: 35 parts of polyethylene (Exxon 3518CB), 35 parts of ethylene-vinyl acetate copolymer (Beijing organic 18-3) with a vinyl acetate content of 18%, polyolefin elastomer (Mitsui DF840 ) 30 parts, vinyltrimethoxysilane 2 parts, dicumyl peroxide 0.5 part, antioxidant tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester 0.3 parts, through twin-screw extruder reaction extrusion granulation, after cooling, carry out drying treatment to obtain silane graft material resin.

[0060] The compound flame retardant consists of:

[0061] Aluminum hydroxide 100 parts

[0062] Magnesium hydroxide 100 parts

[0063] Zinc borate 40 parts

[0064] Silane grafting material flame retardant blend material A: 100 parts of silane grafting material resin prepared above, 130 parts of compound flame retardant, 10 parts of modified nano-montmorillonite (Cloisite20A), 2 parts of zinc stearate , 3 parts of silicone masterbatch, 0.6 part o...

Embodiment 3

[0068] Silane graft resin: 30 parts of polyethylene (Jilin Petrochemical 7042), 40 parts of ethylene-ethyl acrylate copolymer with 16% ethyl acrylate content, 30 parts of ethylene octene copolymer elastomer (Exxon 8203) , 3 parts of vinyl triethoxysilane, 0.3 parts of di-tert-butyl peroxide, through twin-screw extruder reaction extrusion granulation, after cooling, carry out drying treatment to obtain silane graft material resin.

[0069] The compound flame retardant consists of:

[0070] Aluminum hydroxide 100 parts

[0071] Magnesium hydroxide 200 parts

[0072] Zinc borate 50 parts

[0073] Silane grafting material flame retardant blend material A: 100 parts of silane grafting material resin prepared above, 125 parts of compound flame retardant, 15 parts of modified nano-montmorillonite (Cloisite93A), 1.5 parts of stearic acid, 4 parts of silicone masterbatch, 0.8 part of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester of antioxidant,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com