Method for hydrophilic modification of ultrahigh molecular weight polyethylene microporous membrane surface

A technology of ultra-high molecular weight and microporous membranes, which is applied in the field of preparation of ozone-grafted ultra-high molecular weight polyethylene microporous membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

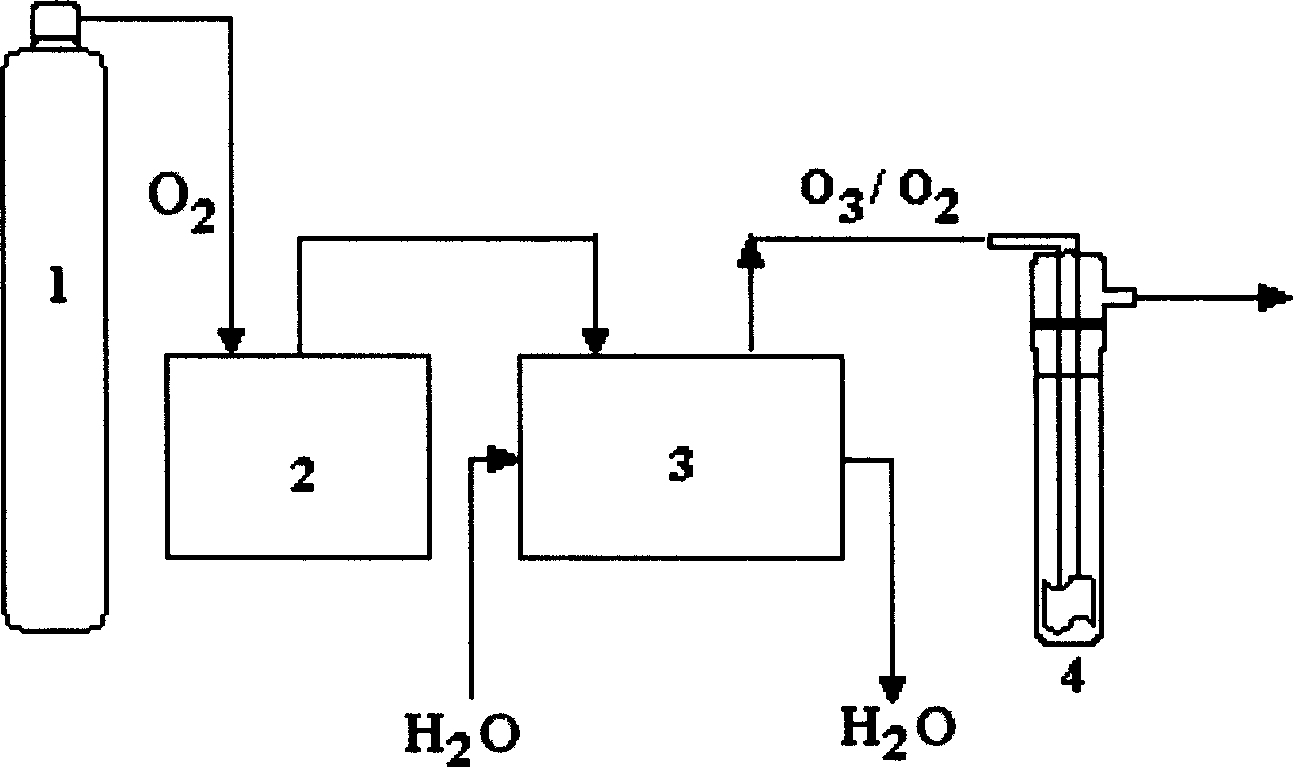

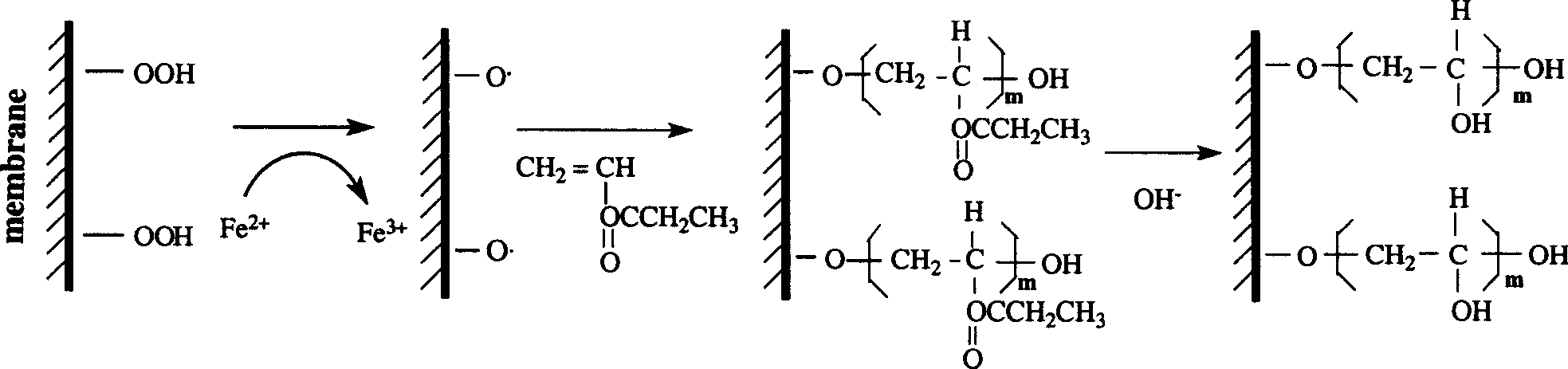

Method used

Image

Examples

Embodiment 1

[0038]Example 1: Treat the pretreated UHMWPE microporous membrane with a size of 5 × 10cm at a voltage of 180V, a discharge current of 0.8A and an oxygen flow rate of 1.0L / min for 15min with an ozone concentration of 40mg / L, and then place it in a polymerization tube In, add 10.0% purified vinyl acetate (VAc) ethanol solution, and add 1.0×10 -6 mol / L ferrous chloride catalyst aqueous solution, seal the polymerization tube, place it in a constant temperature oscillator, react at 20°C for 10h, take it out, clean the membrane, and put it in 0.5mol / L NaOH methanol solution at 25°C After saponification and hydrolysis for 10 hours, wash the membrane to neutrality, and the prepared hydrophilic microporous membrane has a water flux of 246L / m at 0.5MPa 2 h.

Embodiment 2

[0039] Example 2: Treat the pre-treated UHMWPE microporous membrane with a size of 5 × 5cm at a voltage of 220V, a discharge current of 0.2A and an oxygen flow rate of 0.2L / min for 90min with an ozone concentration of 10mg / L, and then place it in a polymerization tube In, add 20% purified vinyl acetate (VAc) in acetone solution, and add 5.0×10 -3 mol / L ferrous ammonium sulfate catalyst aqueous solution, seal the polymerization tube, place it in a constant temperature oscillator, react at 40°C for 5h, take it out, clean the membrane, and put it in 1.0mol / L KOH ethanol solution at 10°C After saponification and hydrolysis for 8 hours, wash the membrane to neutrality, and the prepared hydrophilic microporous membrane has a water flux of 156L / m under 0.5MPa 2 h.

Embodiment 3

[0040] Example 3: Treat the pretreated UHMWPE microporous membrane with a size of 5×10cm at a voltage of 200V, a discharge current of 0.4A and an oxygen flow rate of 0.4L / min for 30min with an ozone concentration of 30mg / L, and then place it in a polymerization tube In, add 3% ethyl acetate solution of purified vinyl acetate (VAc), and add 2.6×10 -4 mol / L ferrous ammonium sulfate catalyst aqueous solution, seal the polymerization tube, place it in a constant temperature oscillator, react at 40°C for 3 hours, take it out, clean the membrane, put it in 0.8mol / L NaOH isopropanol solution, After saponification and hydrolysis at 50°C for 2 hours, the membrane was washed to neutrality. The prepared hydrophilic microporous membrane had a water flux of 201L / m at 0.5MPa 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com