Staggered complex micro-channel miniature heat exchanger

A technology of micro-channel and heat exchanger, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., to achieve the effects of improving uniformity, increasing heat exchange effect, and facilitating installation and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

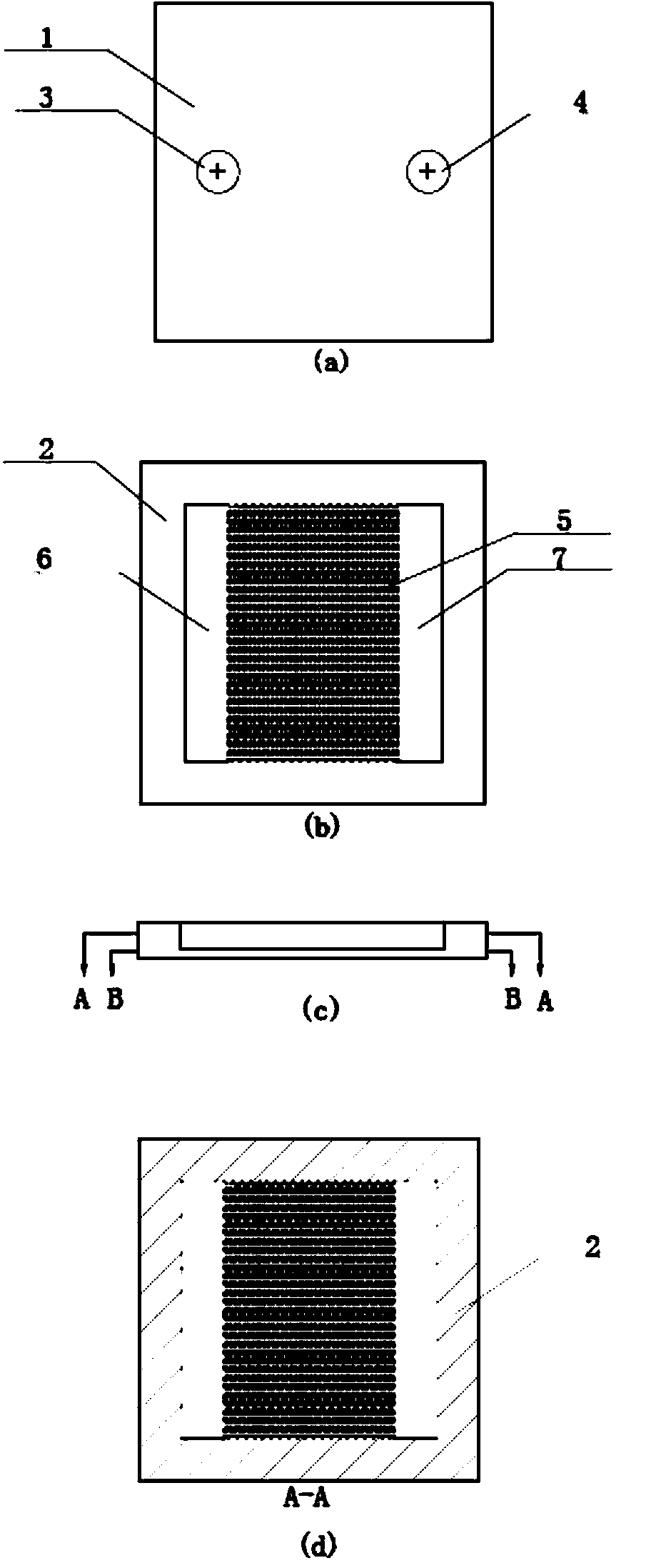

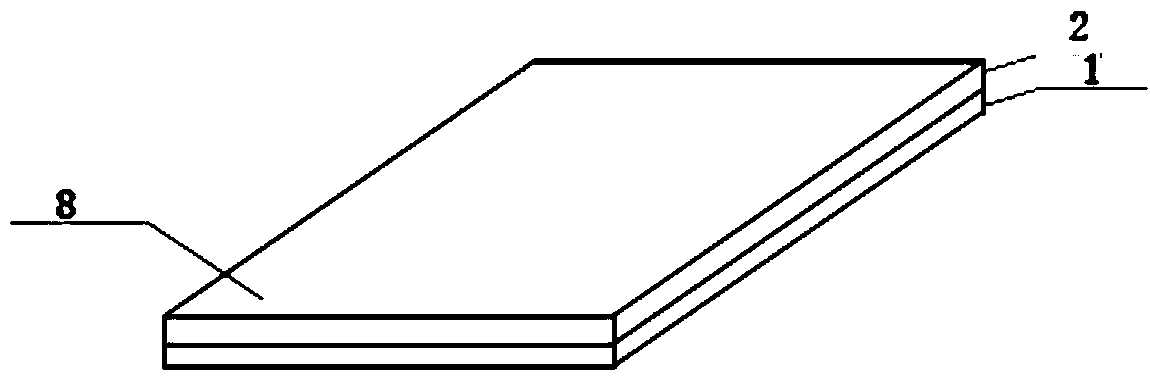

[0045] With the rapid development of information technology and electronic technology, the power of electronic chips has increased dramatically, and effective heat dissipation has become a crucial issue in the development of chips. The misplaced fan-shaped groove microchannel micro heat exchanger is composed of a substrate 2 and an encapsulation sheet 1 with complex channels, see figure 1 and figure 2 . The substrate is made of silicon, the package is made of glass, and the working medium is deionized water. Because the cost of high-power chips is very expensive, in this embodiment, a thin-film heat source is used instead of chips for new energy testing. The thin-film heat source adopts platinum metal heating film. After optimization of microelectronics circuit design, the platinum heating film can generate heat evenly to simulate the heat dissipation of electronic chips. The input voltage of platinum heating film is determined according to the heat production of the chip. ...

Embodiment 2

[0051] The present invention will be further described below in conjunction with the accompanying drawings and the application of the misplaced triangular groove microchannel micro heat exchanger in the heat dissipation of electronic chips:

[0052] With the rapid development of information technology and electronic technology, the power of electronic chips has increased dramatically, and effective heat dissipation has become a crucial issue in the development of chips. The misplaced triangular groove microchannel micro heat exchanger is composed of a substrate 2 and an encapsulation sheet 1 with complex channels. See figure 1 and figure 2 . The substrate is made of silicon, the package is made of glass, and the working medium is deionized water. Because the cost of high-power chips is very expensive, in this embodiment, a thin-film heat source is used instead of chips for new energy testing. The thin-film heat source adopts platinum metal heating film. After optimization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com