High finned heat-exchange tube and processing method thereof

A technology for heat exchange tubes and processing methods, which is applied in the field of processing high-fin heat exchange tubes and high-fin heat exchange tubes. Thermal performance and other issues, to achieve the effect of eliminating contact thermal resistance, simple method, and improved heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention will be further described below in conjunction with the given drawings and specific embodiments to facilitate understanding of the present invention, but does not constitute a limitation to the present invention.

[0038] A) Select a heat-treated pipe body 1 with a grade of TP2, a tensile strength of 230-240MPa, an elongation ≥ 40%, a HV value between 40-50, and a grain size ≥ 0.02mm. The outer surface of the pipe body 1 The diameter is 19mm and the inner diameter is 16.8mm;

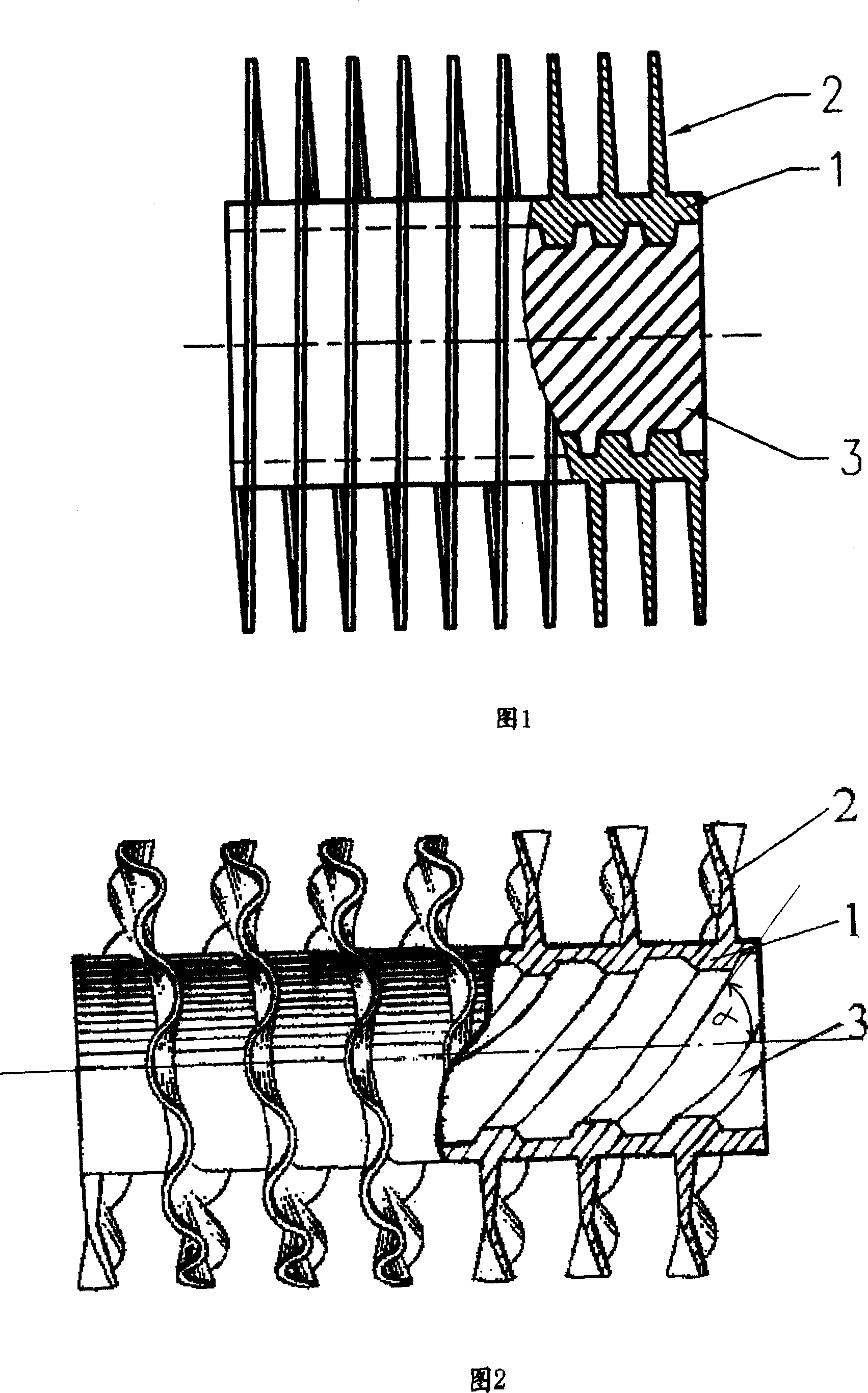

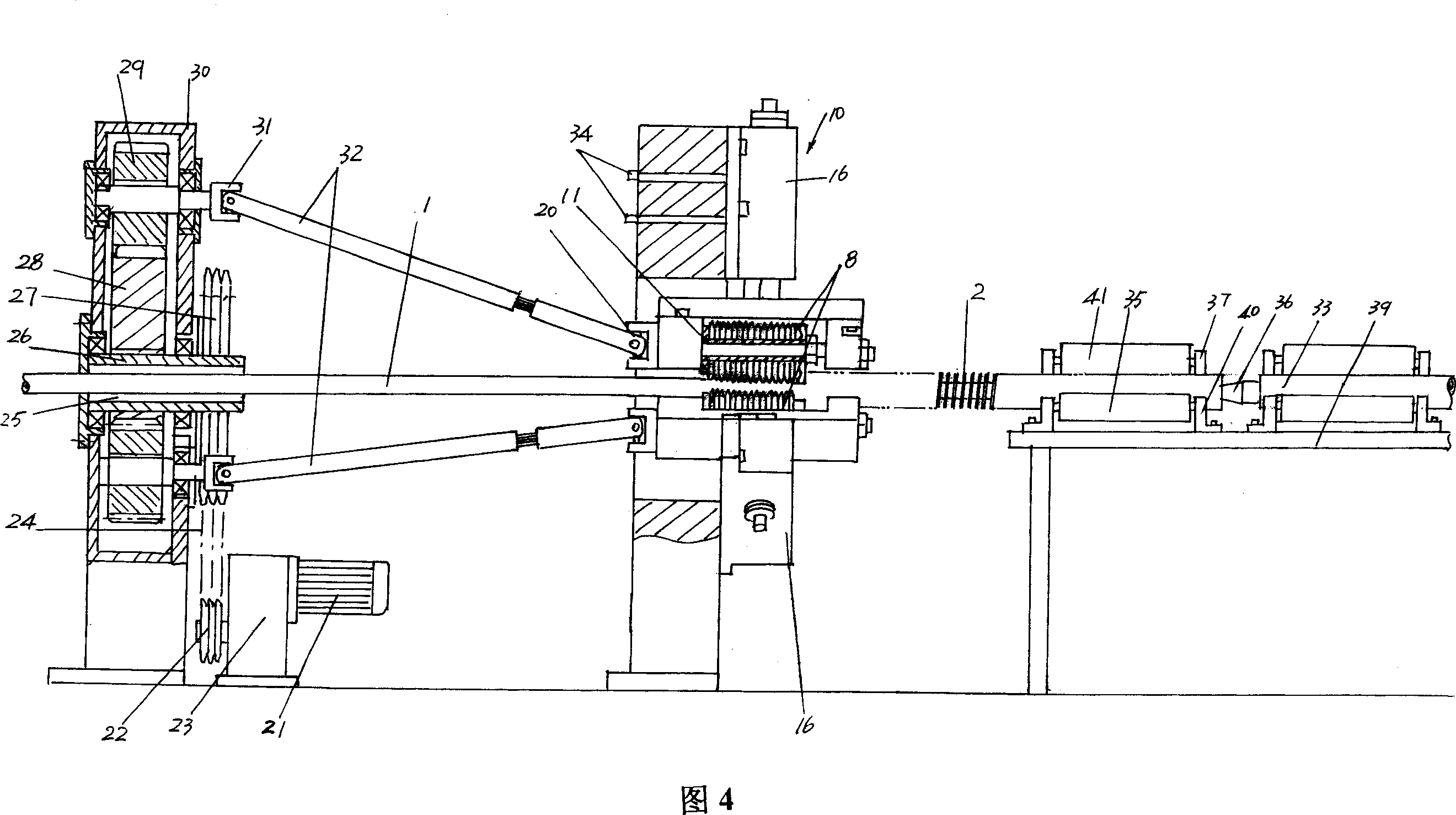

[0039] B) Equipped with three sets of combined molds 8 shown in Figure 5, which are composed of the slotting die 5 shown in Figure 7, the straight fin forming die 6 and the corrugated fin forming die 7, the slotting die 5 is like a common cutting Sheets or cutting blades are used to cut grooves on the outer wall of the pipe body 1. Usually, each group of slotting dies 5 has multiple or multiple handles. In this embodiment, 26 dies are selected. Each group of straight fin form...

Embodiment 2

[0044] When the pipe body 1 described in step C) is placed on the three-roll rolling mill, an inner mold is set in the pipe body 1, the inner mold is a smooth cylindrical section, and the grooved mold 5 and the straight fin forming mold 6 are external Under the action of pulling the fins 2 outward, the inner wall of the tube body 1 forms a relatively shallow wavy shape extending toward the axis of the tube body 1 at a position corresponding to the outer fins 2 , as shown in FIG. 7 . The groove 4, the pipe body 1 with the groove 4, is more suitable for the fluid in the pipe that is relatively dirty and easily fouled or the flow resistance loss of the fluid in the pipe is not allowed to be too large. All the other are the same as the description of embodiment 1.

Embodiment 3

[0046] The height of the processed outer tooth sheet 2 is 5mm, the wing pitch is 2mm, the number of waves on the circumference is 3, the helix angle α formed by the inner fin 3 and the center line of the pipe body is 20°, and the inner fin 3 Take a high-finned heat exchange tube with a height of 0.2 mm as an example.

[0047] Only take the pipe body 1 of step A) as having an outer diameter of 19 mm and a wall thickness of 1.1 mm;

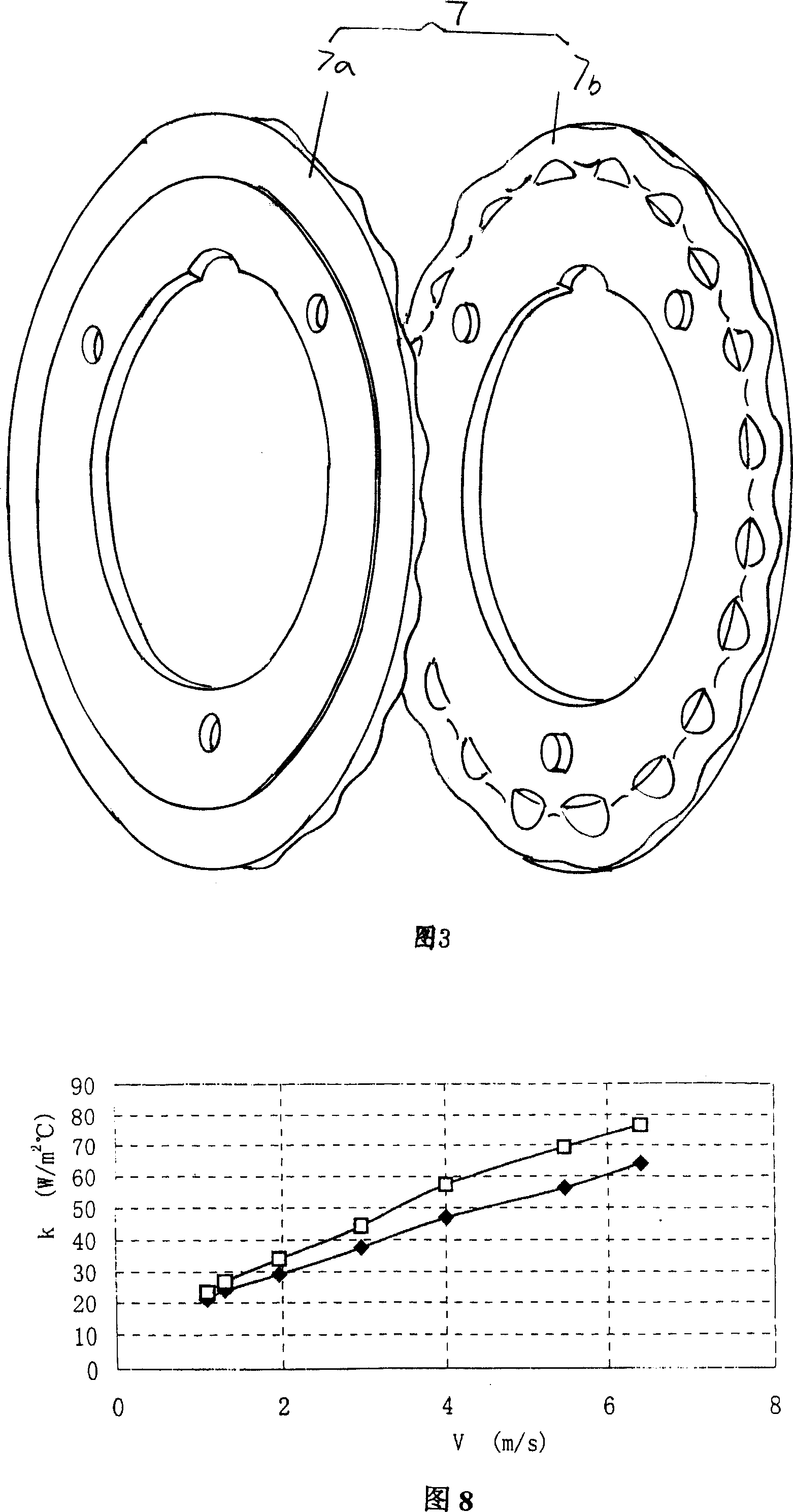

[0048] Only the thickness of the slotting die 5 in step B) is taken as 1.5 mm, and the size of the knife tip is gradually increased by 0.1 mm from 0.2 mm. There are 14 slotting dies 5 in each group, and the number of straight fin forming dies 6 in each group The thickness of each pair of straight fin forming dies 6 is 1.6mm, and each set of corrugated fin forming dies 7 is one, and the paired concave and flanges on the first and second die halves 7a, 7b The quantity is 6 pairs;

[0049] Adjust the feed distance of the three-roll rolling mill in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com