Phase-change temperature control device integrating heat pipe and foam metal core body

A metal foam and integrated heat pipe technology, applied in the direction of electric solid devices, semiconductor devices, indirect heat exchangers, etc., can solve the temperature gradient and concentrated thermal stress affecting the structural reliability of the phase change temperature control device, and increase the phase change temperature control device Quality and volume, weakening the thermal conductivity of the phase change temperature control device and other issues, to achieve the effect of improving the effective utilization rate, high effective utilization rate, and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation of the phase-change temperature control device of the integrated heat pipe and metal foam core according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. The method is described in detail as follows, but the examples are only for reference and illustration, and are not intended to limit the scope of application of the present invention.

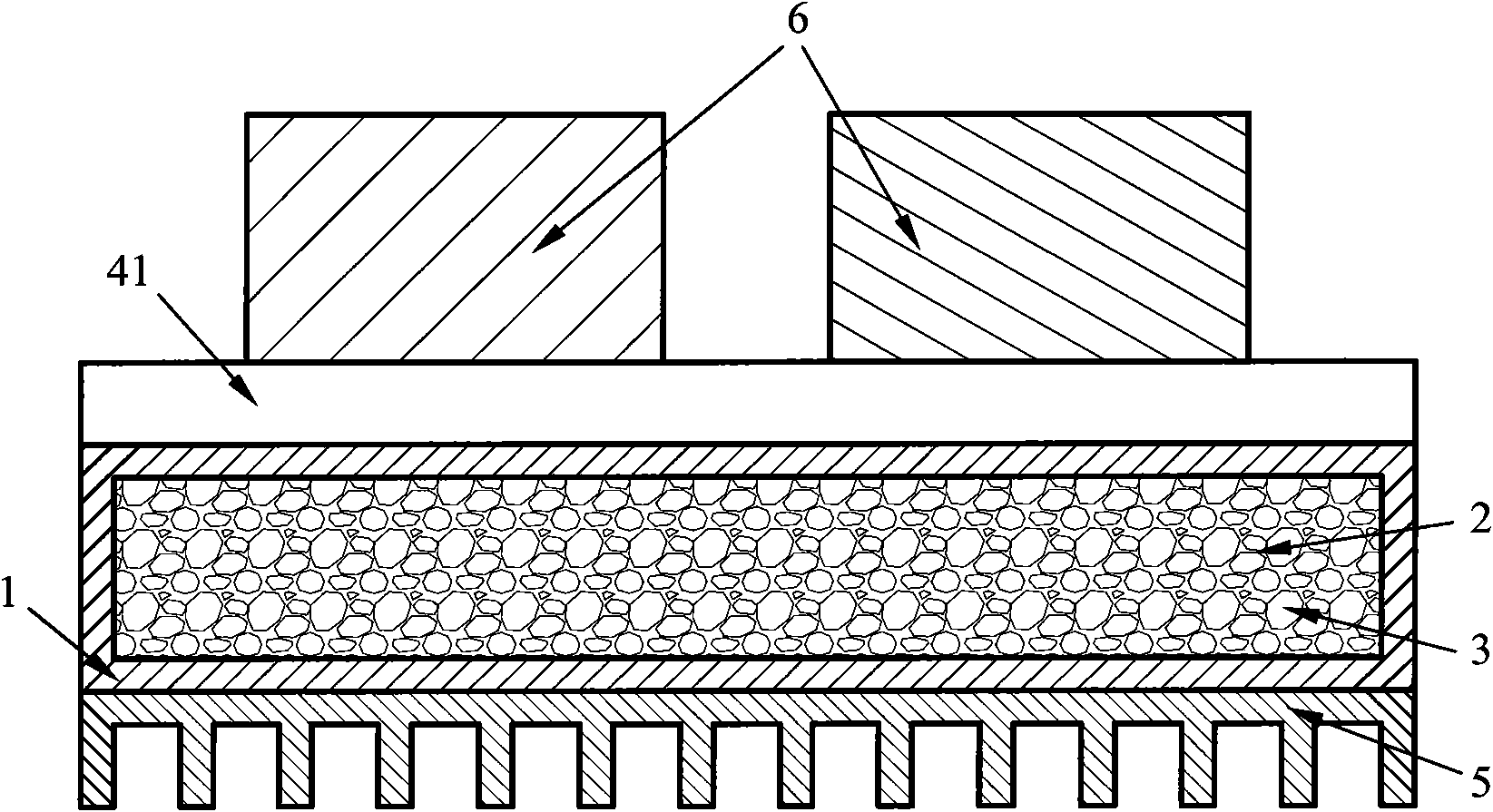

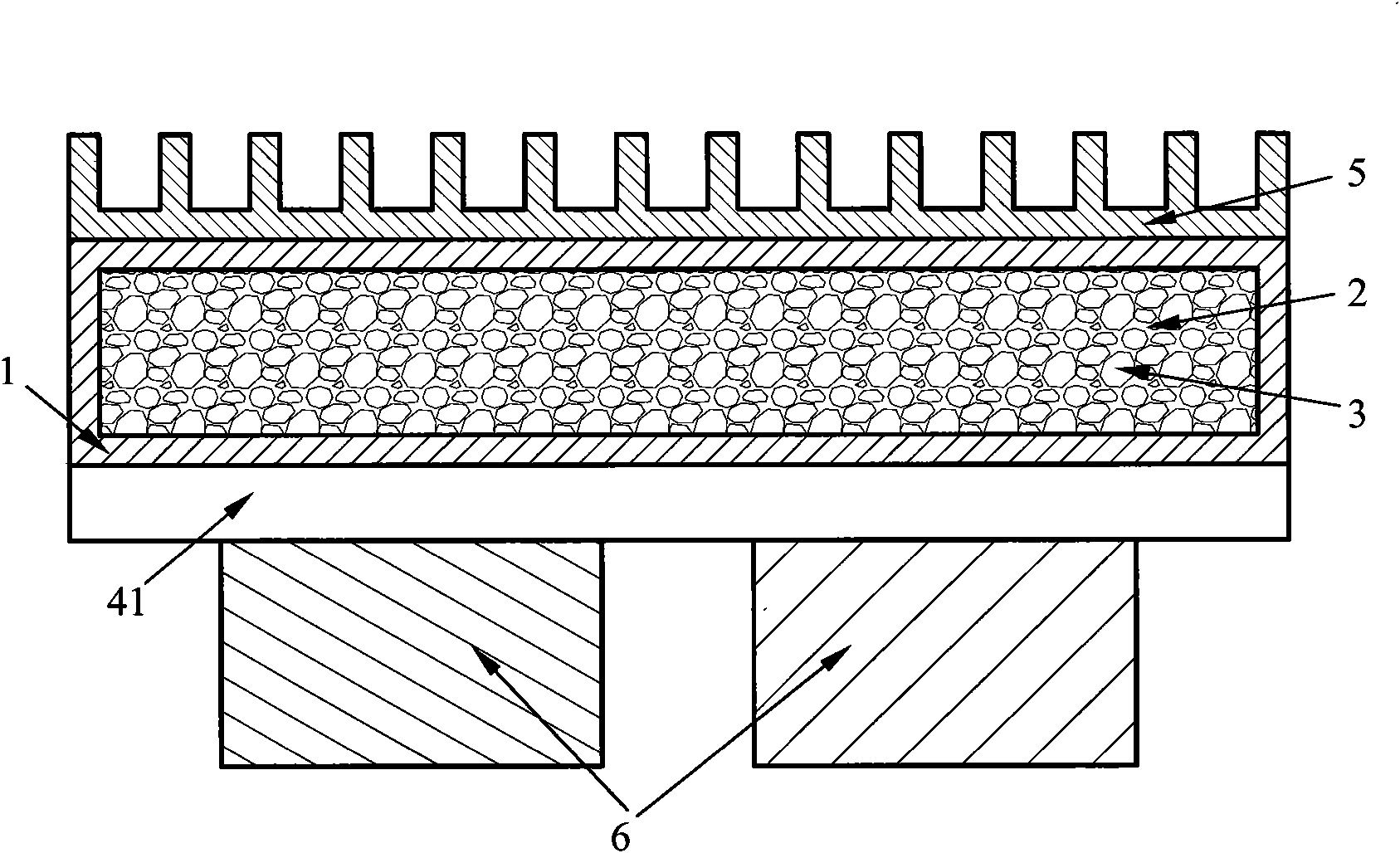

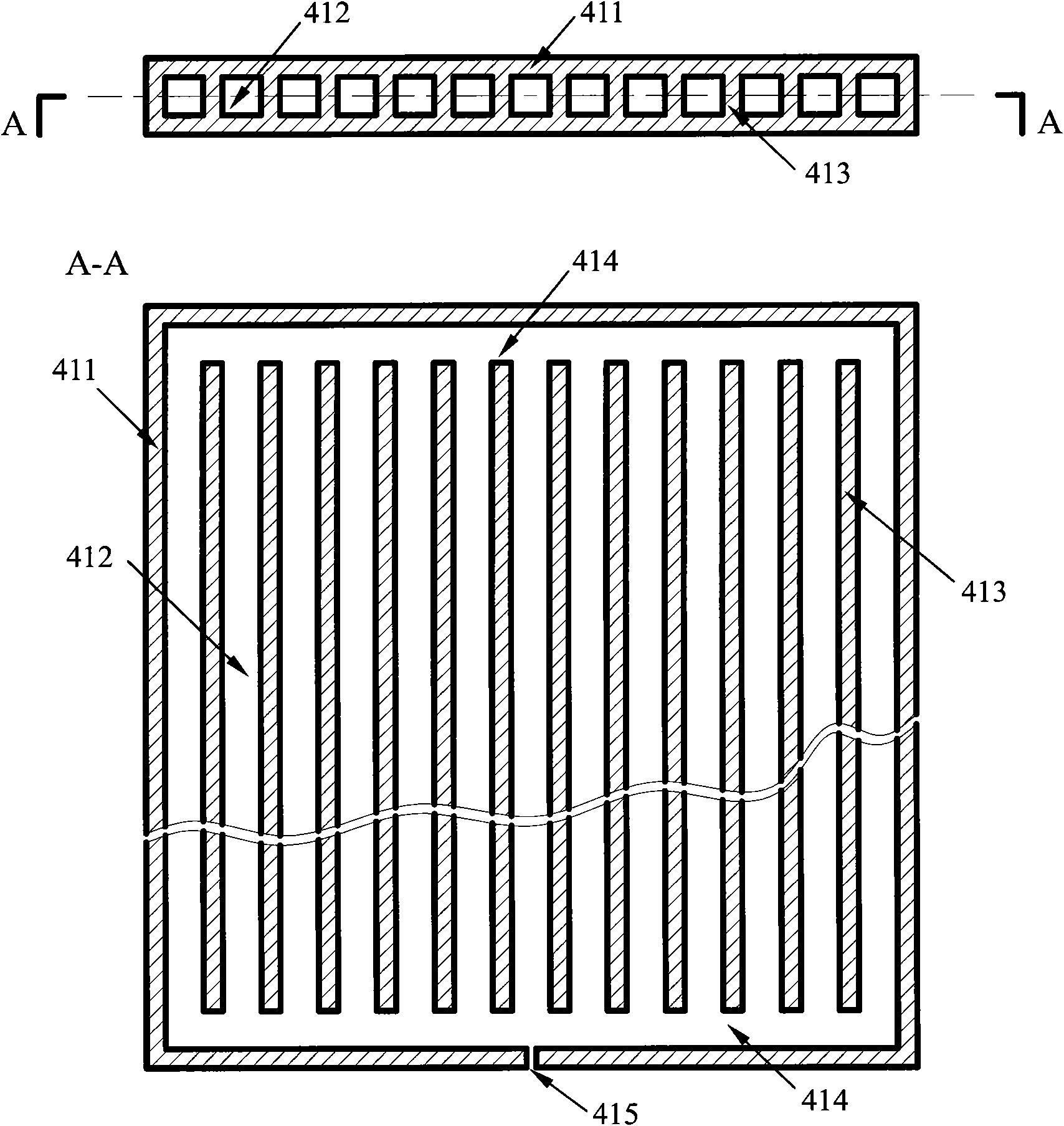

[0028] Figure 1 is a cross-sectional view of a phase-change temperature control device integrating a flat heat pipe and a metal foam core. There are two types of relative positions between the phase-change temperature control device and electronic equipment, Figure 1a It shows that the electronic equipment is placed on the phase-change temperature control device (hereinafter referred to as positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com